Choosing SourcifyChina Factory for purchasing a laser machine for rust removal ensures reliability and quality. Their state-of-the-art technology guarantees effective rust eradication, enhancing machine longevity and performance.

SourcifyChina Factory boasts a robust supply chain, ensuring the timely delivery of products. With meticulous quality checks, buyers receive high-standard laser machines, minimizing downtime and operational disruptions.

Exceptional customer service is a hallmark of SourcifyChina Factory. From pre-sale consultations to after-sale support, the team provides comprehensive assistance, ensuring seamless transactions and satisfying purchasing experiences.

Additionally, SourcifyChina Factory offers competitive pricing without compromising on quality. Bulk purchasing options further reduce costs, making it an economical choice for buyers seeking high-value returns.

Choosing SourcifyChina Factory for purchasing laser machines for rust removal from China is a sound decision for those prioritizing technology, service, and cost-efficiency. Their commitment to excellence ensures buyers receive top-tier products and support.

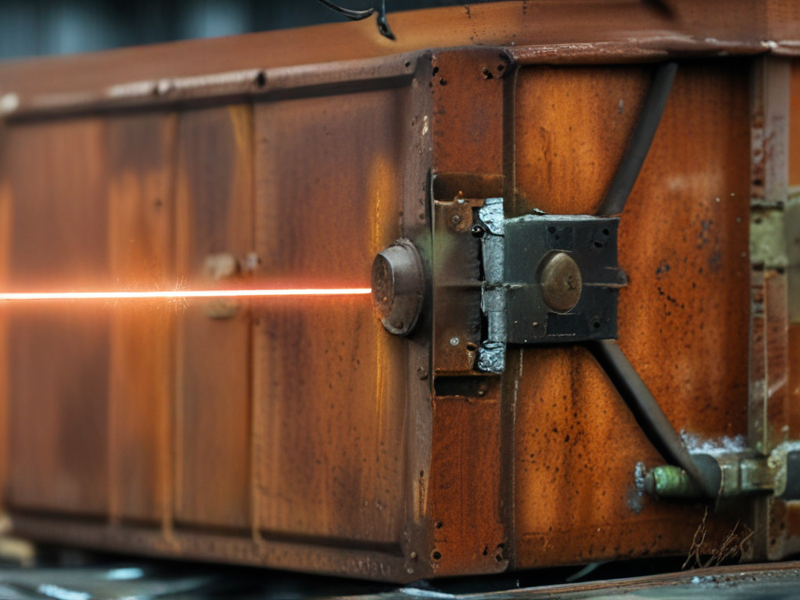

Laser machine rust removal is a modern and efficient method to clean rust from various surfaces, employing high-energy laser beams to precisely eliminate corrosion without damaging the underlying material.

– Portable Handheld Laser Cleaners: Ideal for small-scale, on-site rust removal, offering flexibility and convenience.

– Automated Laser Rust Removal Systems: Integrated into production lines for continuous and large-scale rust removal, enhancing efficiency and consistency.

– Pulsed Laser Systems: Use short, high-intensity bursts to remove rust with minimal heat generation, suitable for delicate materials.

– Continuous Wave (CW) Laser Systems: Provide a constant laser beam, effective for rapid rust removal on robust surfaces.

– Fiber Laser Cleaners: Known for their compact design, high power output, and low maintenance, making them suitable for a wide range of applications.

– CO2 Laser Cleaners: Utilize CO2 gas to produce laser beams, often used for non-metallic surfaces needing rust removal.

– YAG (Yttrium Aluminum Garnet) Lasers: Feature high precision and are used for detailed work on more intricate or sensitive parts.

– Hybrid Laser Systems: Combine different laser technologies to optimize rust removal efficiency and versatility.

Laser rust removal offers eco-friendly and non-abrasive benefits over traditional methods, leaving surfaces clean and ready for further treatment or coating.

Laser machine rust removal offers a highly efficient, non-contact solution for removing rust and other contaminants from metal surfaces. This technology is increasingly utilized across various industries for its precision and speed.

– Automotive Restoration: Quickly cleans rust from automotive parts, aiding in restoration and repair processes.

– Industrial Equipment Maintenance: Extends the lifespan of machinery by removing corrosive elements without damaging the equipment.

– Aerospace Applications: Ensures the integrity of aerospace components by eliminating rust without compromising material structure.

– Marine Industry: Effectively removes rust from ships and marine equipment, improving safety and reducing maintenance costs.

– Manufacturing: Prepares metal surfaces for welding, coating, or other processes by thoroughly cleaning rust and debris.

– Cultural Heritage Conservation: Safely restores historical artifacts and delicate objects without causing further deterioration.

– Oil and Gas Sector: Keeps pipelines and industrial structures rust-free, reducing the risk of leaks and improving safety.

– Construction: Cleans structural steel components, maintaining their strength and extending their usefulness.

– Electronics Industry: Prepares surfaces for precision manufacturing processes by removing micro-contaminants.

– Military Applications: Maintains the readiness and reliability of military vehicles and equipment by efficiently removing rust.

By using laser technology, industries can achieve rust removal that is environmentally friendly and cost-effective, eliminating the need for harsh chemicals and lengthy manual labor.

The SourcifyChina laser machine for rust removal represents a significant advancement in material handling technology. Utilizing high-intensity laser beams, the device effectively vaporizes rust without damaging the underlying metal. This non-contact method ensures precision and preserves the integrity of the material.

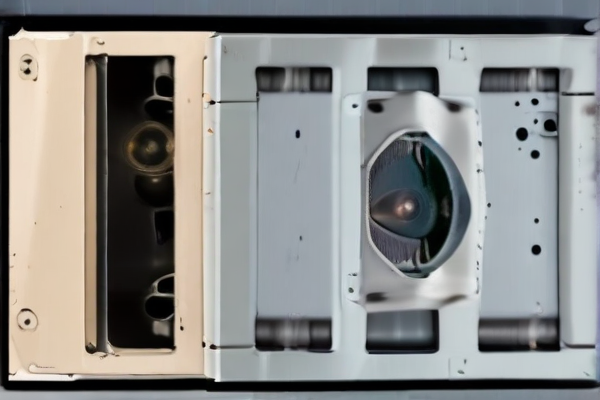

Constructed with industrial-grade components, the machine boasts a durable housing made from aluminum and corrosion-resistant steel. Its compact design allows for easy integration into various work environments, including automotive workshops and manufacturing plants.

Efficient and environmentally friendly, it eliminates the need for harmful chemicals and abrasive materials. This contributes to a safer workplace and reduces long-term operational costs while maintaining a high standard of rust removal.

User-friendly features include an intuitive control panel and automated settings for different levels of rust. These make it accessible for both skilled technicians and novices. The device also supports adjustable laser power, providing flexibility in tackling varying degrees of rust.

SourcifyChina ensures high-quality laser machine rust removal through meticulous quality control processes. Advanced laser technologies are employed to achieve precise and efficient rust removal, setting industry standards.

Raw materials undergo rigorous inspection to guarantee excellent performance. Suppliers are vetted thoroughly, ensuring defect-free components contribute to a reliable final product.

During assembly, each machine part is carefully installed with precision. Automated systems and skilled technicians collaborate to maintain consistency and accuracy throughout the production process.

Regular in-line testing identifies potential issues early. Non-conforming parts are promptly remediated to prevent defects in finished products, ensuring top-notch quality.

Final product testing includes rigorous functional assessments. Each laser machine is subjected to performance tests, simulating various operational conditions to verify reliability and effectiveness.

Comprehensive quality audits are conducted regularly, adhering to stringent industry standards. Continuous improvement initiatives are implemented based on feedback, fostering innovation and excellence.

Packaging procedures follow strict guidelines to prevent damage during transit. Robust packaging solutions protect the machines, ensuring they reach customers in optimal condition.

Customer feedback is solicited and highly valued. Insights gathered contribute to ongoing enhancements, aligning SourcifyChina’s products with evolving market needs and quality expectations.

SourcifyChina’s dedication to quality control ensures their laser machines deliver superior rust removal capabilities. Stringent checks and balances throughout manufacturing guarantee customers receive robust and efficient solutions.

SourcifyChina’s laser machine for rust removal offers advanced technology to clean and refurbish metal surfaces efficiently. Utilizing high-powered laser beams, it targets rust precisely, ensuring minimal damage to underlying material. This makes it ideal for industrial applications where surface integrity is paramount.

The machine’s portability and user-friendly interface distinguish it from traditional rust removal methods, enabling operators to work on-site with ease. Whether dealing with small areas or large structures, the device ensures consistent and reliable results, minimizing downtime. Its eco-friendly operation means no harmful chemicals or secondary waste, promoting a safer work environment.

The versatility of this laser rust remover extends to various metals, including steel, iron, and alloys, making it a one-stop solution for industries like automotive, aerospace, and construction. Adjustable laser settings allow tailored treatments for different levels of corrosion, enhancing its adaptability and efficacy. Its precision reduces the need for follow-up processes, cutting overall project costs and time.

Furthermore, SourcifyChina’s commitment to innovation is evident in the machine’s advanced safety features, which protect operators from potential hazards. Automated systems and real-time monitoring ensure efficient operation and swift issue resolution. After-sales support and training services further ensure clients get the best performance from their investment.

In summary, SourcifyChina’s laser rust removal machine combines efficiency, safety, and adaptability, offering an unparalleled solution for industrial rust management. Its advanced capabilities and user-focused design make it a valuable asset in maintaining and refurbishing metal structures efficiently and safely.

Laser machine rust removal offers an efficient and eco-friendly solution for eliminating rust from metal surfaces, resulting in reduced labor costs and minimal environmental impact.

Benefits of Laser Machine Rust Removal:

– Precision and Accuracy: Laser rust removal machines offer high precision, enabling you to target specific areas without damaging the surrounding material.

– Non-Contact Process: The non-contact nature ensures no mechanical stress or wear on the parts being cleaned, extending their lifespan.

– Eco-Friendly: Laser cleaning is an environmentally friendly method, eliminating the need for chemical treatments and reducing hazardous waste.

– Safety: The process is safer for operators, as there is no risk of chemical exposure and minimal need for protective gear.

– Cost-Effective: Reduced labor costs and less downtime make laser rust removal a cost-effective solution for large-scale operations.

– Versatility: Suitable for a variety of metals and surfaces, laser machines can handle diverse applications in different industries.

– Minimal Surface Damage: The controlled process ensures that the base material experiences minimal damage or alteration.

– Automated and Efficient: Laser machines can be easily integrated into automated systems, increasing efficiency and consistency in industrial cleaning processes.

– Quick Setup and Cleanup: Minimal setup time and easy cleanup process save time and reduce overall project timelines.

– Lower Maintenance: Laser rust removal systems require less maintenance compared to traditional rust removal methods, adding to their long-term cost savings.

Incorporating laser rust removal into your maintenance practices offers a suite of benefits that can improve productivity, reduce costs, and support sustainable practices across various industries.

Laser machine rust removal is an advanced and efficient method for eliminating rust and other contaminants from surfaces. It offers various features that make it preferable over traditional methods.

– Precision: Laser machines deliver pinpoint accuracy, ensuring that only the rust is targeted without damaging the underlying material.

– Efficiency: The high speed of laser beams enables quick rust removal, significantly reducing labor time.

– Non-contact Process: Since it is a non-abrasive and non-contact method, it minimizes wear and tear on the base material.

– Eco-friendly: Laser rust removal does not require chemicals, making it an environmentally friendly option.

– Minimal Waste: The process produces minimal waste, as rust is vaporized and can be collected easily.

– Versatility: Suitable for various materials including metals, plastics, and composites.

– Safety: Modern laser systems incorporate safety features such as automatic shutoff and protective shields.

– Ease of Use: User-friendly interfaces and automated settings simplify operation.

– Cost-effective: While the initial investment might be high, the long-term savings on maintenance, consumables, and environmental compliance make it cost-effective.

– Portability: Several models are designed to be portable, allowing for on-site rust removal tasks.

– Consistency: Delivers uniform results irrespective of the complexity of the surface geometry.

Utilizing these advanced features, laser machines offer an unparalleled solution for rust removal, making them a valuable asset in industries ranging from automotive to aerospace.

SourcifyChina offers advanced laser machines designed for efficient rust removal from a variety of surfaces. These machines use high-powered lasers to clean metals without damaging the underlying material, ensuring longevity.

Custom products tailored to specific industry needs are available. Whether you’re in automotive, shipbuilding, or agriculture, SourcifyChina can provide systems optimized for your requirements. Detailed consultations help in crafting the perfect equipment.

Projects undertaken by SourcifyChina demonstrate their expertise and commitment to quality. From refurbishing industrial machinery to revamping antique items, the team’s proficiency guarantees successful outcomes and satisfied clients.

Their innovative technology not only removes rust but also enhances the overall appearance and performance of metal objects. With SourcifyChina, clients can expect excellent results, elevating their operations with cutting-edge solutions.

In summary, SourcifyChina’s laser rust removal machines are versatile, customizable, and effective, making them an ideal choice for diverse industries. Their commitment to quality ensures durability and top-notch performance in every project.

SourcifyChina Laser Machine Rust Removal has solidified its reputation as a premier provider of cutting-edge laser cleaning solutions, particularly focusing on the intricate and demanding task of rust removal. Specializing in high-performance laser machines, the company leverages state-of-the-art technology to offer an eco-friendly and highly efficient alternative to traditional rust removal methods. Their advanced laser systems are designed to deliver precision and speed, ensuring that industrial surfaces and delicate components are meticulously cleaned without abrasive damage or hazardous chemicals. Catering to a wide range of industries, from automotive to heavy machinery, SourcifyChina provides tailored solutions that not only extend the lifespan of valuable equipment but also enhance overall operational efficiency. With a commitment to innovation and customer satisfaction, the company stands out for its responsive service and technical expertise, making it a trusted partner for businesses aiming to maintain the highest standards of cleanliness and functionality in their operations.

Laser machine rust removal technology has found significant applications in the aerospace, defense, and marine industries, where maintaining the integrity and performance of critical components is paramount. In the aerospace industry, aircraft structures and components are subject to harsh environmental conditions that can lead to corrosion and rust. Laser rust removal offers a precise and non-abrasive method to clean and prepare surfaces for inspection, repair, or coating. This technology ensures that delicate materials are not damaged, preserving the original integrity and extending the lifespan of expensive aerospace components. The precision of laser rust removal also enhances the safety and reliability of aircraft, reducing the risk of failure due to rust and corrosion.

In the defense sector, equipment and vehicles are often exposed to rugged and corrosive environments, making rust removal a critical maintenance task. Laser rust removal provides a fast, efficient, and eco-friendly solution to maintain the operational readiness of military hardware such as tanks, ships, and weapons systems. The marine industry similarly benefits from laser rust removal technology, particularly in maintaining the structural integrity of ships and submarines. Marine vessels face constant exposure to saltwater, leading to aggressive corrosion. Traditional rust removal methods can be time-consuming and environmentally harmful, whereas laser rust removal is quicker, more accurate, and significantly reduces environmental impact by eliminating the need for chemical solvents. Ultimately, the adoption of laser machine rust removal in these sectors not only enhances the durability and functionality of critical assets but also supports sustainable and cost-effective maintenance practices.

Automotive and electronics industries are increasingly leveraging laser machine rust removal technology to enhance the lifespan and efficiency of parts and components. In the automotive sector, rust and corrosion are persistent issues that affect everything from car bodies to engine components, compromising both safety and performance. Traditional rust removal methods like sandblasting or chemical treatments can be messy, time-consuming, and often less precise. Laser rust removal, however, offers a clean and precise solution. Using high-energy laser pulses, the rust is vaporized without affecting the underlying metal. This non-contact method not only ensures a higher level of precision but also reduces the wear and tear on parts, extending their longevity. Furthermore, this technique is environmentally friendly, generating minimal waste and eliminating the need for chemical agents that can be harmful to both the user and the environment.

In the electronics industry, where precision and cleanliness are paramount, laser machine rust removal finds significant applications. Electronic components, especially those made of conductive metals like copper and aluminum, can suffer from oxidation, which diminishes their performance. Laser cleaning can meticulously remove this oxidation without damaging the delicate components or leaving residues that could impair functionality. The focus on precision is crucial, as even a tiny amount of residual rust or oxidation can lead to electrical short circuits or malfunctioning devices. Additionally, as electronic devices continue to miniaturize, the demand for precision cleaning technologies like laser rust removal grows. The process is highly controllable, allowing for the cleaning of extremely small and intricate components, which is essential for maintaining the reliability and performance of modern electronic gadgets.

In the construction industry, laser machine rust removal has revolutionized the way builders and maintenance teams handle rust on metal structures. Traditionally, rust removal methods such as sandblasting or chemical treatments were labor-intensive, time-consuming, and posed significant safety and environmental risks. Laser rust removal, on the other hand, offers a cleaner and more efficient alternative. By emitting high-energy laser beams that precisely target rusted areas without affecting the underlying metal, these machines ensure thorough and rapid rust removal. This technology is particularly beneficial for maintaining construction equipment, scaffolding, and steel frameworks, leading to prolonged structural integrity and reduced maintenance costs. Its precision also means less wastage and the ability to perform rust removal in situ, without dismantling large structures, thus saving considerable time and resources.

In the energy sector, the application of laser machine rust removal extends to the maintenance and repair of critical infrastructure such as pipelines, storage tanks, and offshore platforms. Rust can severely compromise the safety and functionality of these installations, increasing the risk of leaks or structural failures. The precision and efficiency offered by laser rust removal are invaluable in such scenarios, ensuring that metal surfaces are thoroughly cleaned without causing any damage to the material integrity. Additionally, since energy infrastructure often operates in remote or harsh environments, the portability of laser rust removal machines makes them an ideal solution. They provide a low-footprint and eco-friendly method of maintenance that aligns well with the industry’s move towards more sustainable practices. By embracing this technology, the energy sector can enhance its operational reliability, extend the lifespan of its assets, and maintain compliance with stringent safety and environmental regulations.

The industrial equipment sector has embraced laser machine technology for rust removal due to its precision, efficiency, and eco-friendly nature. Traditionally, rust removal has been a labor-intensive process involving chemical treatments or abrasive blasting, both of which pose environmental hazards and health risks to workers. Laser machines, on the other hand, utilize high-powered, focused laser beams to vaporize rust without damaging the underlying metal, thereby extending the lifespan of industrial equipment. This technology ensures that machinery and components retain their structural integrity and performance capabilities, making it an indispensable tool for companies striving to maintain high operational standards.

Furthermore, laser rust removal promotes sustainability and cost-effectiveness in the industrial equipment industry. Since it eliminates the need for hazardous chemicals and reduces waste, companies can significantly lower their environmental footprint. Additionally, the precision of laser machines minimizes material loss and reduces the frequency of equipment replacement, leading to substantial cost savings over time. The non-contact nature of laser cleaning also allows for automation and integration into complex manufacturing processes, enhancing overall productivity. As industries continually seek ways to optimize efficiency and meet stringent environmental regulations, the adoption of laser rust removal technology represents a forward-thinking approach that balances performance, safety, and sustainability.

Laser machines for rust removal are steadily becoming invaluable in the medical device manufacturing sector due to their precision, efficiency, and preservation qualities. Unlike traditional, abrasive cleaning methods, laser technology employs a high-energy beam to vaporize rust and other contaminants without compromising the structural integrity of the underlying metal. This is particularly crucial for medical devices which demand exceptional cleanliness and precision to ensure patient safety and compliance with stringent regulatory standards. By utilizing laser machines, manufacturers can achieve a higher level of cleanliness that is essential for devices that, for example, are used in direct contact with human tissue or blood, thereby minimizing risks of infections or other complications. Additionally, the laser removal process is contactless, which virtually eliminates the risk of mechanical fatigue or surface damage.

Another significant advantage of laser rust removal in the medical device industry is its eco-friendliness and operational efficiency. Traditional rust removal methods often involve chemicals or mechanical abrasion, both of which can produce hazardous waste and require extensive post-cleaning disposal procedures. The laser cleaning process is environmentally benign, generating minimal waste, mostly in the form of particulate matter that can be easily contained and disposed of. Moreover, the automation capabilities inherent in laser systems enable higher throughput and consistent results, thereby significantly reducing downtime and labor costs. These efficiencies are critical in a field where time-to-market can affect the viability of healthcare solutions. Thus, laser rust removal not only maintains the high standards necessary for medical devices but also contributes to more sustainable manufacturing practices.

Laser machine rust removal is revolutionizing the machining and manufacturing industries with its precision, efficiency, and eco-friendliness. The technology employs high-intensity laser beams to vaporize rust, oxidation, and other contaminants from metal surfaces, ensuring a clean and smooth finish without the need for abrasive materials or chemicals. This process significantly reduces preparation times and production downtimes, enhancing overall productivity. In addition, the non-contact nature of laser cleaning minimizes the risk of damaging the underlying material, which is particularly beneficial in maintaining the integrity of sensitive components used in aerospace, automotive, and electronic sectors.

Furthermore, the adoption of laser rust removal in manufacturing echoes the industry’s commitment to sustainability. Traditional rust removal methods often involve the use of hazardous chemicals and materials that can pose environmental and health risks. In contrast, laser cleaning produces no secondary waste, lowers energy consumption, and reduces the need for disposal of harmful residues, aligning with stricter regulatory standards and green manufacturing practices. Beyond rust removal, lasers can also be fine-tuned to prepare surfaces for subsequent processes like welding or coating, further integrating seamlessly into automated production lines and advancing smart manufacturing initiatives. This combination of precision, speed, and sustainability is setting new benchmarks for quality and efficiency in modern machining and manufacturing environments.

Sure! Here is a list of frequently asked questions (FAQ) along with answers for manufacturing “laser machine rust removal quality work from SourcifyChina factory”:

1. What is the primary use of the laser machine for rust removal?

The primary use of the laser machine is to remove rust, paint, and other surface contaminants from metal surfaces with precision and efficiency.

2. How effective is the laser rust removal process?

The laser rust removal process is highly effective, offering a clean, residue-free surface with minimal effort and without damaging the underlying material.

3. What types of metals can the laser rust removal machine handle?

The machine can handle a variety of metals, including steel, iron, aluminum, copper, and more.

4. How does laser rust removal compare to traditional methods?

Laser rust removal is faster, more precise, eco-friendly, and leaves no chemical residue, compared to traditional methods like sandblasting and chemical treatments.

5. Is training required to operate the laser machine?

Yes, basic training is required to ensure safe and effective operation. SourcifyChina provides training and user manuals with every machine.

6. What safety measures should be taken while using the laser machine?

Operators should wear protective eyewear and follow standard safety protocols, as outlined in the machine manual.

7. How long does the laser machine last?

With proper maintenance, the laser machine from SourcifyChina can last for upwards of 100,000 operating hours.

8. Can the laser machine be used for applications other than rust removal?

Yes, the machine can also be used for cleaning, surface preparation, and even some marking applications.

9. What kind of maintenance does the laser machine require?

Regular cleaning of optics, timely replacement of consumables, and periodic software updates are necessary to keep the machine in optimal working condition.

10. How can I place an order or request more information?

You can place an order or request more information by visiting SourcifyChina’s official website or contacting their sales department directly.

This concise FAQ should help in addressing common customer queries regarding laser rust removal machines manufactured by SourcifyChina factory.

Choosing a laser machine for rust removal from a reputable manufacturer such as SourcifyChina can greatly enhance your production efficiency and product quality. Here are some tips to consider:

1. Evaluate Specifications: Ensure the laser machine’s power (measured in watts) meets your rust removal needs. A higher wattage generally means faster and more thorough cleaning, but it might also be more expensive.

2. Check Quality and Reliability: SourcifyChina is known for high-quality manufacturing. Verify the machine’s build quality, including the reliability of critical components like the laser source, cooling system, and scanning head.

3. Customer Support: Good after-sales service is crucial. SourcifyChina typically offers customer support; ensure you have access to technical assistance and spare parts.

4. Sample Testing: If possible, request sample testing on your specific material. This will help you understand the machine’s effectiveness for your particular rust removal applications.

5. Training and Setup: Ask if SourcifyChina provides training for your team and assistance with machine setup. Proper training ensures optimal machine operation and longevity.

6. Ease of Use: Look for machines with user-friendly interfaces. This minimizes the learning curve and reduces chances of operational errors.

7. Energy Efficiency: Consider machines that are energy-efficient, which can significantly cut down operational costs over time.

8. Compliance and Safety: Ensure the machine meets international safety standards and has appropriate certifications. This is crucial for operator safety and reducing liability.

9. Cost & Warranty: Compare the costs, but also factor in the warranty. SourcifyChina often offers competitive pricing and solid warranty terms, which can be beneficial in the long run.

10. Feedback and Reviews: Look for customer reviews or case studies. Positive feedback from other buyers can provide additional confidence in your purchase decision.

By considering these factors, you can make a more informed decision when sourcing a rust removal laser machine from SourcifyChina.

Q: What types of laser machines for rust removal does SourcifyChina factory offer?

A: SourcifyChina provides a range of laser rust removal machines including portable handheld models, automated systems, and high-power industrial machines designed to cater to different scales and types of rust removal tasks.

Q: What are the main benefits of using laser rust removal from SourcifyChina?

A: The primary benefits include precision, efficiency, eco-friendliness (no chemical use), minimal substrate damage, and reduced operation costs over traditional methods.

Q: What is the lead time for ordering a laser rust removal machine from SourcifyChina?

A: The lead time typically ranges from 2 to 4 weeks, depending on the specific model and any customization requirements.

Q: Can the laser rust removal machines from SourcifyChina be customized?

A: Yes, SourcifyChina offers customization options to tailor the machines according to specific client needs, including power settings, size, and additional features.

Q: How do I place an order or inquire about pricing for a laser rust removal machine from SourcifyChina?

A: You can contact SourcifyChina directly through their official website or customer service email for orders and pricing information. They typically respond within 24-48 hours.

Q: What kind of after-sales service does SourcifyChina provide?

A: SourcifyChina offers comprehensive after-sales support including installation assistance, user training, maintenance services, and a warranty period for their products.

Q: Are the laser rust removal machines from SourcifyChina safe to use?

A: Yes, the machines are designed with safety in mind, incorporating features such as protective casings, emergency stop functions, and compliance with international safety standards.

Q: Is technical support available for the laser rust removal machines?

A: SourcifyChina provides technical support through online consultations, manuals, video guides, and on-site assistance if necessary.

Q: What is the power consumption of these machines?

A: Power consumption varies by model, but SourcifyChina provides detailed specifications for each machine, ensuring customers can select a model that fits their power efficiency requirements.

Q: Can the laser rust removal machines be used on all types of metals?

A: These machines are typically effective on a wide range of metals, including steel, aluminum, and iron. Specific guidelines and testing may be required for certain alloys.

Sourcing a laser machine for rust removal from SourcifyChina can be an efficient way to obtain high-quality industrial equipment at competitive prices. Here are some tips to streamline the process:

1. Define Specifications: Clearly outline the technical specifications and requirements for the laser rust removal machine. This includes power, size, efficiency, and additional features.

2. Research and Verify:

– Website and Catalog: Visit SourcifyChina’s official website to browse their catalog and products.

– Certifications: Ensure the factory holds necessary certifications like ISO9001, CE, or other relevant quality assurances.

3. Compare Options: Investigate different models offered and compare features, prices, warranty terms, and customer reviews.

4. Request Quotes: Contact SourcifyChina directly to request detailed quotations. Include specifications to get accurate pricing.

5. Check Testimonials and References: Look for customer testimonials on the website or ask the factory to provide references. Speaking directly to other customers can offer insights into product performance and company reliability.

6. Sample Testing: If possible, request a sample or a demo video to evaluate the laser machine’s effectiveness in rust removal.

7. Understand Import Regulations: Be aware of import duties, taxes, and compliance regulations in your country. Verify that the supplier can compile with the documentation necessary for a smooth customs process.

8. Payment Terms: Negotiate clear payment terms. Consider starting with a small order to mitigate risks.

9. Inspect Before Shipment: Arrange for a third-party inspection to verify the quality and functionality of the machines before shipping.

10. After-Sale Support: Confirm the availability of after-sale support, including training, maintenance, and spare parts supply.

By following these steps, you can effectively source a reliable laser machine for rust removal from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.