SourcifyChina Factory offers unparalleled expertise in manufacturing laser metal cleaning systems. Their advanced technology ensures precision and efficiency, meeting international standards. Buyers benefit from superior quality products tested rigorously for reliability.

The factory’s commitment to innovation guarantees cutting-edge solutions for various industrial applications. Their experienced team consistently delivers on promises, providing excellent after-sales support and customer service.

Competitive pricing is another compelling reason to choose SourcifyChina Factory. By producing cost-effective solutions without compromising on quality, they offer the best value for your investment, making them a trustworthy partner.

Strategically located in China, SourcifyChina Factory has excellent logistics capabilities that expedite shipping processes. This enables timely and efficient delivery, reducing downtime and ensuring smooth operations for buyers globally.

In conclusion, partnering with SourcifyChina Factory gives buyers access to high-quality, competitively priced laser metal cleaning systems, backed by a commitment to innovation and exceptional customer service. Their strategic location further enhances their reliability, making them an ideal choice for international business.

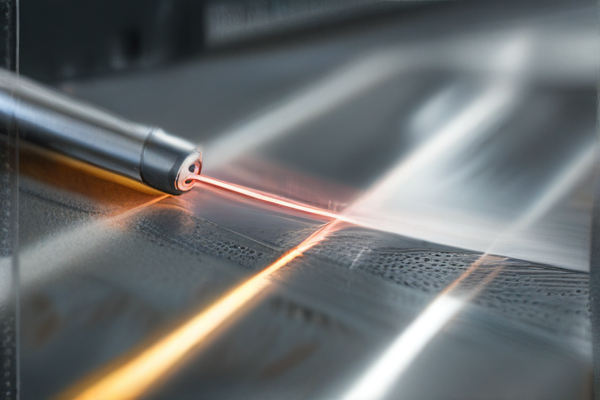

Laser metal cleaning is a non-contact process that uses laser light to remove contaminants, rust, paint, and other coatings from metal surfaces. It’s effective, eco-friendly, and suitable for various industries.

Types and options for laser metal cleaning include:

– Pulsed Lasers: Ideal for delicate surfaces, providing controlled energy bursts.

– Continuous Wave Lasers: Suitable for more robust cleaning, offering constant power.

– Portable Laser Cleaners: Handy for on-site applications, easy to transport.

– Fixed Laser Systems: Used in industrial settings, integrated into production lines.

– Fiber Lasers: Efficient and reliable, with minimal maintenance.

– CO2 Lasers: Effective for specific materials, such as non-metallic inclusions on metal surfaces.

– Handheld Lasers: User-friendly, versatile for various cleaning tasks.

– Automated Laser Cleaning Systems: For high-volume applications, ensuring consistent results.

– Laser Ablation: Removes coatings by vaporizing the surface layer, suitable for precise applications.

– Laser Cleaning Robots: Used in complex or hazardous environments, enhancing safety and efficiency.

– UV Lasers: Specialized for fine cleaning tasks, such as electronics or small parts.

Overall, laser metal cleaning offers diverse options to meet specific needs, balancing efficiency, cost, and environmental impact.

Laser metal cleaning is a highly efficient process used for industrial and commercial applications to remove contaminants, oxides, and coatings from metal surfaces without causing damage.

– Aerospace Industry: Precisely clean aircraft parts and equipment to maintain performance and longevity.

– Automotive Manufacturing: Remove rust, paint, and coatings from car components, ensuring optimal function and appearance.

– Restoration Projects: Clean historic metal artifacts and structures without abrasives or chemicals, preserving original surfaces.

– Electronics Manufacturing: Clean delicate components without causing thermal stress or material degradation.

– Shipbuilding: Prepare metal surfaces for welding and painting, improving adhesion and reducing maintenance.

– Nuclear Industry: Safely decontaminate and clean metal surfaces in radioactive environments without generating hazardous waste.

– Pipeline Maintenance: Remove rust and buildup from pipelines, ensuring smooth operation and reducing corrosion risks.

– Medical Equipment: Sterilize and decontaminate surgical tools and instruments, ensuring safety and precision.

– Tool and Die Cleaning: Maintain molds and dies by removing residue and contaminants that affect production quality.

– Food Processing: Clean metal surfaces in machinery, ensuring hygiene without chemical residues.

– Railway Maintenance: Clean and prepare metal parts of trains and tracks, enhancing durability and performance.

– Military Applications: Maintain equipment and vehicles by removing oxidation and contaminants, ensuring reliability.

– Building Maintenance: Clean building facades and architectural metal features, improving aesthetics and lifespan.

– Power Generation: Clean turbines and other metal components in power plants, enhancing efficiency and operation.

– Art Conservation: Restore metal sculptures and artworks by removing corrosion and contaminants without physical damage.

– Mining Equipment: Ensure machinery operates efficiently by removing debris and buildup from metal surfaces.

– Tool Reconditioning: Extend the life of tools and equipment by removing wear marks and buildup.

Laser metal cleaning offers numerous advantages, including environmental safety, precision, and minimal material removal, making it an ideal solution for various industries.

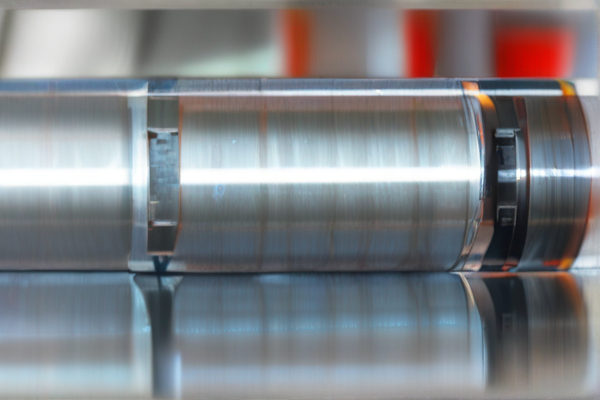

“SourcifyChina laser metal cleaning” utilizes advanced laser technology to remove contaminants from metal surfaces. This method offers precision, ensuring that only undesired layers are eradicated, while leaving the base metal intact.

The equipment employed by SourcifyChina can clean various metals including steel, aluminum, and copper. It’s versatile, catering to multiple industries such as automotive, aerospace, and manufacturing, with adjustable laser settings to suit different cleaning requirements.

Laser cleaning is eco-friendly, generating minimal waste compared to conventional methods. There are no hazardous chemicals involved, making it safe for both operators and the environment. This leads to cleaner workplaces and reduced disposal costs.

The efficiency of SourcifyChina’s laser cleaning technology also translates to time and cost savings. It’s a non-contact process, which minimizes wear and tear on the machines and the metal surfaces being cleaned. This makes it a highly durable and reliable solution for long-term operations.

In summary, SourcifyChina’s laser metal cleaning offers a precise, versatile, and eco-friendly method to maintain metal surfaces. By employing advanced laser technology, they ensure high efficiency and cost-effectiveness, making it an ideal solution across various industries.

SourcifyChina’s laser metal cleaning quality control process is integral to ensuring superior product performance and client satisfaction. At each stage, thorough inspections are conducted to maintain the highest standards.

Initial quality checks commence with raw material verification, ensuring only premium metals are selected. Precision measurements are taken to confirm material integrity before processing.

During laser cleaning, real-time monitoring systems continuously assess performance. State-of-the-art sensors and cameras detect any deviations or defects, allowing for immediate corrections.

Post-cleaning, all treated metals undergo rigorous testing for cleanliness, accuracy, and surface finish. Automated and manual inspections guarantee optimal results consistent with client requirements.

Continuous improvement initiatives form the backbone of SourcifyChina’s quality control. Feedback loops from inspection data drive process enhancements, ensuring the company remains at the forefront of laser metal cleaning technology.

SourcifyChina’s laser metal cleaning revolutionizes surface preparation, offering precision cleaning for industries such as aerospace, automotive, and manufacturing. Utilizing advanced laser technology, it effectively removes rust, oxides, oil, and other contaminants from metal surfaces.

This eco-friendly process produces minimal waste, eliminating the need for harsh chemicals, water, or abrasive mediums, thereby reducing environmental impact and complying with stringent regulations. The non-contact method prevents damage to the substrate, ensuring the integrity of delicate components.

High-efficiency laser cleaning enhances production timelines by minimizing downtime, offering rapid and thorough cleaning in a fraction of the time compared to traditional methods. Customizable settings cater to various cleaning needs, from fine-tuning energy levels to adjusting laser pulse duration.

The user-friendly interface simplifies operation, empowering technicians with minimal training to achieve optimal results. Integrated safety features ensure worry-free use, protecting operators from potential hazards associated with laser technology.

SourcifyChina’s robust laser cleaning systems are engineered for durability and reliability, capable of withstanding harsh industrial environments. Their compact design enables easy integration into existing workflows, enhancing overall productivity.

Cost-effectiveness is another key advantage, as the reduction in consumable materials and maintenance leads to significant long-term savings. Clients benefit from an impressive return on investment, recouping costs quickly through improved efficiency and reduced waste.

Furthermore, SourcifyChina offers comprehensive support, from initial consultation to after-sales service, ensuring clients receive tailored solutions that meet their specific needs. Their commitment to quality and customer satisfaction is evident in their ongoing innovation and dedication to excellence in laser metal cleaning technology.

Laser metal cleaning offers a modern, efficient solution for removing contaminants from metal surfaces. This technology provides numerous benefits over traditional cleaning methods.

– Precision: Laser cleaning targets specific areas without affecting surrounding material, ensuring minimal damage to the metal surface.

– Environmental Friendliness: It eliminates the need for chemical solvents, reducing environmental impact and worker exposure to harmful substances.

– Cost-Effectiveness: Reduces long-term costs by minimizing waste and maintenance requirements.

– Versatility: Effective on various contaminants like rust, paint, and oil, applicable to different metals.

– Non-Contact Process: Prevents wear and tear on the material, enhancing longevity.

– Automation Compatibility: Easily integrates with automated systems, improving efficiency and consistency.

– Surface Preparation: Prepares metal surfaces for further processing, such as coating or welding, by ensuring cleanliness.

Laser metal cleaning is a modern, efficient method of removing contaminants like rust, paint, and oxides from metallic surfaces. This technique offers various features that make it highly advantageous for industrial applications.

– Precision: Provides highly accurate cleaning without damaging the underlying material.

– Non-contact: Unlike traditional methods, laser cleaning is entirely non-contact, reducing wear and tear.

– Environmentally Friendly: No need for chemicals or abrasive materials, resulting in less waste and pollution.

– Low Maintenance: Equipment requires minimal upkeep compared to conventional methods.

– Versatility: Effective on a wide range of metals including steel, aluminum, and copper.

– Reduced Downtime: Faster setup and cleaning times enhance productivity.

– Safety: Lower risk of exposure to hazardous substances compared to chemical cleaning.

– Energy Efficiency: Consumes less energy and reduces operational costs.

– Remote Operation: Can be automated and controlled remotely, enhancing operator safety.

– Surface Preparation: Ideal for preparing surfaces for welding, coating, or bonding.

Laser metal cleaning thus stands out as a superior choice for industries looking to improve operational efficiency while being environmentally responsible.

SourcifyChina offers state-of-the-art laser metal cleaning solutions tailored to the unique needs of each project. Leveraging cutting-edge technology, they ensure precision and efficiency in every custom product.

Their laser metal cleaning services are perfect for industries requiring meticulous surface preparation, such as aerospace, automotive, and manufacturing. The method is non-contact and eco-friendly, producing minimal waste.

Customers are guaranteed a significant increase in productivity and cost savings owing to the reduced downtime and labor involved. SourcifyChina’s team of experts collaborates closely with clients to deliver optimal results that adhere to stringent quality standards.

In addition to cleaning, they provide engraving, cutting, and welding services. These versatile capabilities make SourcifyChina a one-stop solution for all your metalworking needs.

Client feedback highlights the superior quality and durability of products processed through SourcifyChina’s laser technology. Every project benefits from a meticulous approach and reliable customer support, ensuring long-term satisfaction.

Whether it’s refurbishing antique machinery parts or preparing metal surfaces for painting, SourcifyChina’s laser metal cleaning solutions offer unmatched precision and reliability. Their commitment to innovation and customer satisfaction sets them apart in the industry.

SourcifyChina Laser Metal Cleaning is a pioneering company specializing in advanced laser cleaning solutions for a variety of industrial applications. Utilizing cutting-edge laser technology, SourcifyChina offers an environmentally-friendly and efficient method to clean, remove rust, and prepare metal surfaces for further processing. The company’s laser systems are designed to replace traditional, labor-intensive cleaning techniques that often involve hazardous chemicals and produce large amounts of industrial waste. Known for its innovation and reliability, SourcifyChina caters to a diverse client base, ranging from automotive manufacturers to aerospace engineers. Their state-of-the-art laser equipment ensures precision, reduces downtime, and enhances production quality, making them a preferred choice in the industry. With a firm commitment to customer satisfaction and sustainability, SourcifyChina continues to drive the market forward, providing tailored solutions that meet the evolving needs of their clients.

Laser metal cleaning has emerged as a transformative technology in the aerospace sector, where precision, efficiency, and surface integrity are paramount. This non-contact method employs high-intensity laser pulses to ablate contaminants, such as oils, rust, and old paint layers, from metal surfaces without damaging the substrate. In aerospace manufacturing and maintenance, laser metal cleaning is ideal for preparing surfaces for welding or bonding, as it ensures optimal adhesion by completely removing residues that traditional mechanical or chemical methods might leave behind. Moreover, the increased demand for lightweight and durable materials in aerospace applications aligns perfectly with laser cleaning’s ability to handle delicate surfaces like aluminum and titanium, which are commonly used in aircraft structures and components.

In the defense and marine industries, the robustness and versatility of laser metal cleaning offer significant operational advantages. Military equipment and naval vessels often operate in harsh environments that accelerate corrosion and buildup of contaminants. Laser cleaning not only enhances the lifespan of critical components by effectively removing corrosive agents and marine growths, but also reduces the downtime associated with maintenance. Traditional methods like sandblasting or chemical treatments can be labor-intensive, hazardous, and environmentally detrimental. Laser cleaning, however, minimizes waste and operates in a safer, eco-friendly manner, aligning with increasing regulations and sustainability goals. Its portability further allows for on-site applications, making it a vital tool for maintaining the readiness and reliability of defense and marine assets.

Laser metal cleaning is making significant strides in the automotive industry, revolutionizing processes such as paint removal, rust removal, and surface preparation. Traditional methods like sandblasting or chemical treatments often pose risks to both worker safety and the environment, not to mention reducing the lifespan of metal parts. Laser cleaning, however, offers a non-invasive and highly precise alternative. Lasers can selectively remove contaminants from metal surfaces without damaging the substrate, enhancing the durability and aesthetic quality of automotive components. This method not only improves process efficiency but also reduces operational costs by eliminating the need for consumables and extensive post-cleaning treatments, making it an attractive option for automotive manufacturers striving for sustainability and precision.

In the electronics sector, laser metal cleaning is equally transformative, particularly in the preparation of surfaces where precision is paramount. Delicate components such as circuit boards and microchips often require ultra-clean surfaces for optimal performance and reliability. Traditional cleaning methods can introduce residues or cause physical damage, potentially compromising the functionality of these high-value electronics. Laser cleaning offers an unparalleled level of control, removing oxides, solder residues, and other contaminants with micron-level precision. Additionally, the process is contactless and free of abrasive forces, which is crucial for maintaining the integrity of delicate electronic components. This technology not only enhances the quality and longevity of electronic devices but also aligns well with the industry’s push towards greener manufacturing processes by minimizing chemical waste and energy consumption.

Laser metal cleaning is revolutionizing the construction industry by delivering precise, efficient, and environmentally friendly solutions for surface preparation. Traditional methods like sandblasting and chemical treatments often fall short when it comes to adequately preparing substrates for subsequent coatings or bonding procedures. Laser cleaning, however, uses concentrated light pulses to remove contaminants, rust, and old paint without damaging the underlying metal. This level of precision ensures that structural components maintain their integrity, which is crucial for construction projects that demand high safety standards. Moreover, the process produces minimal waste and requires no harsh chemicals, significantly reducing the environmental footprint associated with construction activities.

In the energy sector, laser metal cleaning is paving the way for enhanced maintenance and prolonged lifespan of critical infrastructure. Power plants, refineries, and renewable energy installations often operate in harsh environments that lead to significant wear and tear on metal components. Laser cleaning offers a non-contact, reliable method to remove oxidation, scale, and other contaminants from metal surfaces, thereby improving thermal and electrical conductivity. For example, steam turbine blades or photovoltaic panels benefit from laser cleaning, which can enhance efficiency and operational longevity. The ability to perform precise cleaning even in hard-to-reach areas makes laser technology an indispensable tool for maintaining the high efficiency and reliability required in the energy industry, ultimately contributing to more sustainable and cost-effective energy production and distribution.

The industrial equipment industry is increasingly leveraging laser metal cleaning technology to enhance production efficiency and product quality. Laser metal cleaning involves the use of high-intensity laser beams to remove contaminants, rust, oxide layers, and other impurities from metal surfaces. This non-contact method offers several advantages over traditional abrasive or chemical cleaning processes. It provides precise control, reducing the risk of damaging the workpiece and ensuring a smoother and cleaner surface. Moreover, the technology is environmentally friendly as it eliminates the need for hazardous chemicals and significantly reduces waste production. Consequently, industries such as automotive, aerospace, and heavy machinery are adopting laser metal cleaning to prepare metal surfaces for welding, coating, or painting, thereby enhancing the durability and aesthetic appeal of their products.

In addition to its cleaning capabilities, laser metal cleaning also contributes to the maintenance and longevity of industrial equipment. Regular application of this technology can prevent corrosion and material degradation, which are common issues in environments exposed to harsh conditions. For instance, in the oil and gas industry, equipment such as pipelines and storage tanks benefit greatly from laser metal cleaning as it ensures their structural integrity and operational safety. The precision and speed of laser technology also mean that maintenance can be performed with minimal downtime, thereby increasing productivity. As industries continue to seek sustainable and efficient solutions, the adoption of laser metal cleaning is expected to grow, paving the way for advancements in industrial manufacturing and maintenance practices.

Laser metal cleaning technology has revolutionized the maintenance and manufacturing processes within the medical device industry. Its precision and efficacy in cleaning metallic surfaces are unparalleled, providing significant advantages over traditional methods such as chemical cleaning and abrasive blasting. The laser technique involves directing a focused beam of laser light onto the metal surface, which effectively removes contaminants like rust, oxides, and biofilms without causing any damage to the underlying material. This level of precision is paramount for medical devices, which require the highest standards of hygiene and integrity to ensure patient safety and compliance with stringent regulatory requirements. By eliminating residues and ensuring a pristine surface, laser cleaning paves the way for enhanced device performance and longevity.

Another critical advantage of laser metal cleaning in the medical device sector is its eco-friendly and efficient nature. Traditional cleaning methods often involve the use of hazardous chemicals and generate harmful waste, posing environmental and occupational health risks. In contrast, laser cleaning is a dry, contactless process that does not require consumables, thereby minimizing waste and environmental footprint. Furthermore, the automation potential of laser cleaning systems enhances productivity, offering rapid and consistent cleaning results with minimal human intervention. This efficiency not only reduces downtime but also leads to significant cost savings in the long run. Consequently, medical device manufacturers can maintain high production standards while championing sustainable practices, ultimately fostering a safer and cleaner manufacturing environment.

Laser metal cleaning has revolutionized the machining and manufacturing sectors by offering a non-contact, highly precise, and environmentally friendly method for removing contaminants, oxides, and other impurities from metal surfaces. Traditional cleaning methods, such as abrasive blasting, chemical treatments, and manual scrubbing, often involve significant manual labor, hazardous chemicals, and potential damage to the metal substrate. In contrast, laser metal cleaning utilizes focused laser beams to vaporize contaminants without affecting the underlying material. The precision of laser technology allows for targeted cleaning, ensuring that only the unwanted layers are removed, thereby preserving the integrity of the original metal. This is particularly beneficial in preparing surfaces for subsequent machining processes, such as welding, coating, or bonding, where surface cleanliness is critical for achieving high-quality results.

In the manufacturing industry, laser metal cleaning enhances productivity and cost-efficiency. Automated laser cleaning systems can be integrated into production lines, significantly reducing downtime and labor costs. These systems are capable of handling a wide variety of metal substrates and geometries, from intricate components to large structures, making them versatile across numerous applications, including aerospace, automotive, and electronics manufacturing. Additionally, the absence of abrasives or chemicals translates to a cleaner workplace environment, reduced waste management issues, and compliance with increasingly stringent environmental regulations. The precision and control offered by laser cleaning technology ensure consistent quality and repeatability, essential for high-volume manufacturing. Ultimately, the adoption of laser metal cleaning in machining and manufacturing not only improves process efficiency and product quality but also aligns with sustainable manufacturing practices.

FAQs for Laser Metal Cleaning Quality Work from SourcifyChina Factory

What is laser metal cleaning?

Laser metal cleaning is a process that uses laser technology to remove contaminants, rust, paint, and other unwanted materials from metal surfaces. It is a precise and environmentally friendly method that does not require chemicals or abrasive materials.

Why choose SourcifyChina for laser metal cleaning?

SourcifyChina is renowned for its high-quality laser cleaning services, using state-of-the-art equipment and experienced technicians. Our focus on precision and customer satisfaction ensures top-notch results for various applications.

What types of metals can be cleaned using laser technology?

Laser cleaning is suitable for a wide range of metals, including steel, aluminum, copper, and titanium. It is effective for both ferrous and non-ferrous metals.

What are the benefits of laser metal cleaning over traditional methods?

Laser metal cleaning offers several advantages, such as high precision, non-contact processing, minimal material loss, and the absence of chemical waste. It is also faster and safer compared to traditional methods like sandblasting and chemical cleaning.

Is laser metal cleaning safe for all applications?

Yes, laser metal cleaning is safe for various applications, including industrial maintenance, restoration, and surface preparation. However, it is essential to ensure proper safety measures and use appropriate equipment for specific applications.

How does laser metal cleaning affect the surface quality of the metal?

Laser cleaning can enhance surface quality by precisely removing contaminants without damaging the underlying material. It also prepares surfaces for subsequent processes like painting or coating, ensuring better adhesion and durability.

What industries benefit from laser metal cleaning?

Industries such as aerospace, automotive, manufacturing, and electronics benefit significantly from laser metal cleaning due to its precision, efficiency, and environmental friendliness.

How can I get a quote for laser metal cleaning services from SourcifyChina?

To get a quote, visit our website and fill out the inquiry form with details about your project. Our team will review your requirements and provide a tailored quote based on the specifics of your job.

What is the turnaround time for laser metal cleaning projects?

Turnaround time depends on the project size and complexity. SourcifyChina strives to deliver prompt and efficient service, typically completing most projects within a few days to a week.

Can laser cleaning remove all types of contaminants?

Laser cleaning is highly effective for removing a wide range of contaminants, including rust, paint, oil, and oxidation layers. However, its effectiveness may vary depending on the contaminant type and thickness.

When considering laser metal cleaning manufacturing from a factory like SourcifyChina, it’s crucial to optimize both the product quality and the efficiency of the process. Here are some key tips to ensure success:

1. Understand Your Needs: Clearly define the types of metals and the scale of your operations. Different metals may require varying laser power and settings.

2. Choose the Right Equipment: Invest in high-quality laser cleaning machines that are capable of handling your specific metals. Fiber lasers are particularly effective for metal cleaning due to their precision and efficiency.

3. Quality Assurance: Confirm that the SourcifyChina factory follows stringent quality control measures. Inspect sample products and request detailed information about their QA processes.

4. Technology Integration: Ensure the factory uses advanced technology such as AI and automation to enhance the accuracy and speed of the cleaning process.

5. Material Compatibility: Verify that the laser cleaning techniques employed are compatible with the types of metal and contaminants you’re dealing with. This will prevent potential damage and ensure optimal cleanliness.

6. Efficiency and Speed: Ask about the speed and efficiency of their laser cleaning systems. High-speed systems can significantly reduce production time and costs.

7. Energy Consumption: Evaluate the energy efficiency of the laser cleaning machines. Lower energy consumption reduces operational costs and environmental impact.

8. Support and Training: Ensure that the factory provides adequate support and training for the use of their laser cleaning equipment. Proper training minimizes errors and maximizes productivity.

9. Customization Options: Check if the factory offers customization options for their machinery to better suit your specific requirements.

10. Cost Analysis: Conduct a thorough cost-benefit analysis to ensure that the investment in laser cleaning equipment aligns with your budget while offering a good return on investment.

Following these tips will help you leverage SourcifyChina’s capabilities to achieve high-quality and efficient laser metal cleaning.

1. What types of laser metal cleaning machines do you offer at SourcifyChina Factory?

We offer a variety of laser metal cleaning machines including portable laser cleaners, handheld laser cleaning systems, and automated laser cleaning stations. Each machine is designed to meet specific cleaning requirements, ensuring high efficiency and precision.

2. What materials can be cleaned using your laser metal cleaning machines?

Our laser cleaning machines are capable of cleaning a wide range of materials, including but not limited to stainless steel, aluminum, brass, copper, and various alloys. They effectively remove rust, paint, oxides, and other contaminants without damaging the base material.

3. How do I place an order for a laser metal cleaning machine with SourcifyChina Factory?

To place an order, you can contact us directly through our website or email. Provide your specific requirements and we will guide you through the process, from selecting the right machine to payment and delivery options.

4. What is the lead time for delivery after placing an order?

The standard lead time for delivery is typically 3-4 weeks, depending on the order size and customization requirements. We strive to meet our clients’ timelines and will provide an exact delivery schedule upon order confirmation.

5. Do you offer technical support and training for using the laser metal cleaning machines?

Yes, we offer comprehensive technical support and training. Our experienced engineers can provide in-house training or virtual assistance to ensure you fully understand the operation and maintenance of the machines.

6. What is the warranty period for your laser metal cleaning machines?

Our laser metal cleaning machines come with a standard one-year warranty. This covers any manufacturing defects and technical issues. Extended warranties are available upon request.

7. Can I request a demonstration or sample cleaning before purchasing?

Yes, we offer demonstration sessions and can provide sample cleaning for your materials. This helps you evaluate the performance and suitability of our products for your specific applications.

8. How do I get in touch with SourcifyChina Factory for more inquiries?

You can reach us via our website contact form, email, or phone. Our customer service team is available to answer any additional questions and provide detailed information about our products and services.

Sourcing laser metal cleaning services from SourcifyChina factory can be efficient and straightforward if you follow these key steps:

1. Research and Validation:

– Check Credentials: Verify SourcifyChina’s certification, quality standards (ISO, CE), and industry reputation.

– Read Reviews: Look for customer feedback and case studies to gauge reliability.

2. Define Requirements:

– Material and Type: Specify the type of metal and contaminants to be cleaned.

– Precision and Scale: Detail the precision required and volume of work.

3. Contacting the Factory:

– Initial Inquiry: Use SourcifyChina’s official contact details for inquiries. Clearly state your needs.

– RFQ (Request for Quote): Send a detailed RFQ outlining specifications, quantities, deadlines, and any other pertinent details.

4. Sample Request:

– Ask for sample cleaning on your metal to assess quality and suitability.

5. Evaluate Technology:

– Ensure they use advanced laser cleaning technology (e.g., fiber laser) for efficiency and environmental safety.

6. Pricing and Terms:

– Compare Quotes: Request detailed quotes and compare costs, including per piece, bulk, or contract pricing.

– Payment Terms: Clarify payment terms, including deposits, milestones, and final payments.

– Shipping and Logistics: Confirm logistics support for international shipping, including Incoterms.

7. Quality Control:

– Implement a quality control agreement or inspections to ensure consistency and adherence to standards.

8. Communication:

– Use clear and continuous communication during the process. Ensure there’s a dedicated point of contact.

By following these tips, you can effectively source laser metal cleaning services from SourcifyChina factory that meet your quality and operational needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)