Certainly! Here’s a fitting title within your constraints:

“SourcifyChina: Your Reliable Source for High-Quality Factory Laser Metal Cutters”

Choosing SourcifyChina for purchasing laser metal cutters ensures access to high-quality, reliable machinery directly from trusted Chinese manufacturers. Their deep industry connections enable competitive pricing without sacrificing product excellence.

SourcifyChina offers comprehensive support, from initial consultation to post-purchase services, ensuring seamless transactions and addressing any concerns promptly. This dedication fosters long-term client relationships.

Leveraging their extensive network, SourcifyChina provides customized solutions tailored to buyers’ specific needs, ensuring each laser cutter meets precise requirements. They prioritize customer satisfaction above all else.

Additionally, SourcifyChina’s stringent quality control measures guarantee that every laser metal cutter undergoes rigorous testing. Buyers can trust the durability and efficiency of their purchases.

Complete transparency in their operations, from pricing to delivery schedules, builds trust and enables buyers to make informed decisions. SourcifyChina’s integrity is central to their business model.

In summary, choosing SourcifyChina combines the advantages of competitive pricing, personalized service, and stringent quality control, making it the ideal partner for purchasing laser metal cutters from China.

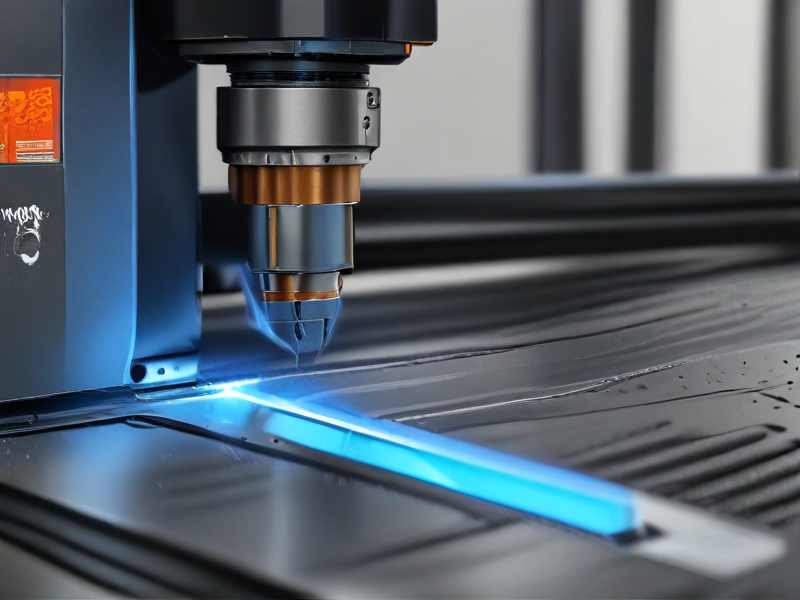

Laser metal cutters are precision tools used in various industries for cutting metal with high accuracy and efficiency. Different types of laser metal cutters offer various options catering to unique needs and applications.

– CO2 Laser Cutters: Ideal for cutting, engraving, and hollowing thin metals.

– Fiber Laser Cutters: Provide high-speed and versatile cutting for thicker and various metals.

– Nd:YAG Laser Cutters: Suitable for precision cutting on metals requiring intricate detailing.

– Disk Laser Cutters: Known for high power efficiency and suitability for hard metals.

– 3D Laser Cutters: Capable of cutting complex 3D shapes and structures.

– Hybrid Laser Cutters: Combine features of various laser technologies for enhanced functionality.

– Portable Laser Cutters: Designed for on-site cutting and flexibility in diverse locations.

– Gantry Laser Cutters: Utilize a gantry system for stable and precise large-scale cutting.

Overall, the selection of a laser metal cutter depends on factors like material type, thickness, precision requirements, and specific industrial applications.

A laser metal cutter is essential in various industries due to its precision and efficiency in cutting through metal materials with minimal wastage and high accuracy.

– Manufacturing: Utilized for fabricating machine parts, automotive components, and electronics.

– Construction: Helps in designing and shaping metal structures and frameworks.

– Aerospace: Precision cutting for complex parts and lightweight structures.

– Jewelry Making: Crafting intricate designs from precious metals.

– Art and Sculptures: Producing detailed and creative metal artworks.

– Medical Devices: Creating precise components for medical instruments.

– Prototype Development: Rapid development and testing of metal prototypes.

– Automotive Industry: Used for cutting and shaping car body panels and parts.

– Signage: Crafting metal signs with detailed and legible designs.

– Agriculture: Manufacturing of heavy-duty farming equipment.

– Defense: Precision manufacturing of parts for military equipment and vehicles.

– Electronics: Creating parts for devices such as phones and computers.

– Shipbuilding: Producing intricate components for ships and submarines.

– Tool Making: Fabricating specialized tools and dies for various applications.

– Furniture Design: Creating metal components for modern and durable furniture.

The versatility and accuracy of laser metal cutters make them indispensable across many sectors, ensuring high-quality production and innovation.

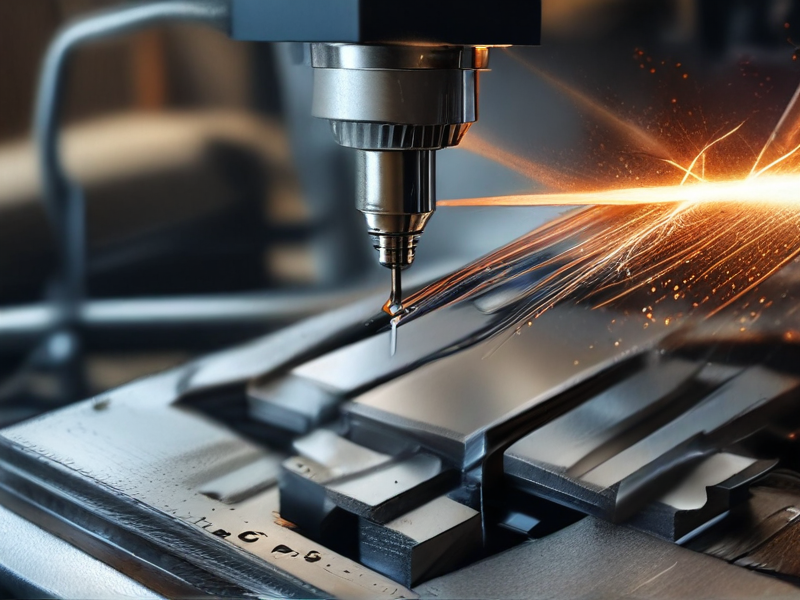

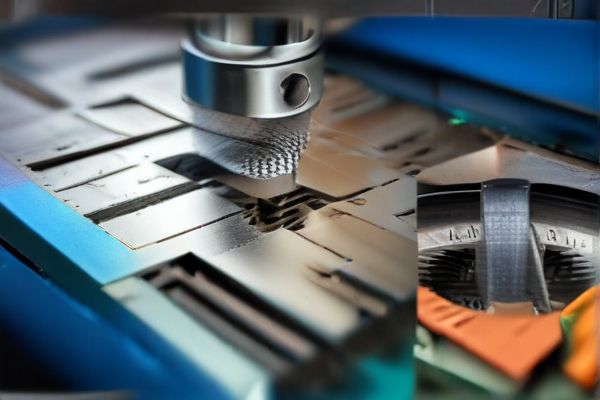

The “SourcifyChina Laser Metal Cutter” utilizes top-quality components to ensure durability and precision. The frame is made from high-strength steel, providing stability during operation and minimizing vibrations that could affect cutting accuracy.

The cutting head features industrial-grade sensors and optics, often composed of zinc selenide or fused silica, which ensure laser beam precision. These materials are chosen for their thermal and mechanical robustness, making the cutter effective for various metal types like steel, aluminum, and titanium.

Electrical components, including servomotors and power supplies, are selected for their efficiency and reliability. This focus on quality components ensures consistent performance in both small-scale and industrial applications.

Lastly, the machine’s software interface integrates seamlessly with CAD/CAM programs, bolstering its usability. The combination of premium materials and advanced software makes the “SourcifyChina Laser Metal Cutter” a versatile tool for precise metal fabrication.

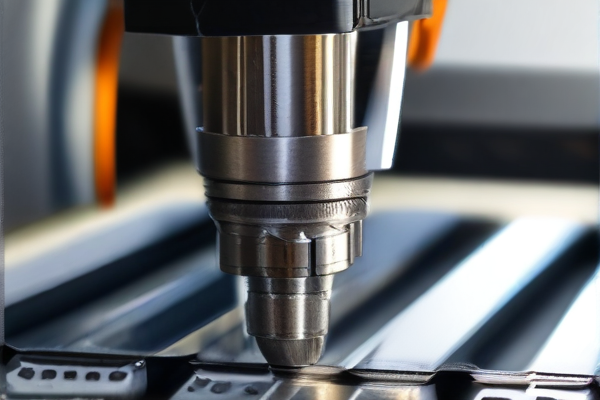

The SourcifyChina laser metal cutter stands as a hallmark of precision, efficiency, and quality. Its manufacturing process begins with sourcing premium raw materials to ensure robustness and durability in the final product.

Each component undergoes rigorous inspections, utilizing advanced technologies such as ultrasonic testing and X-ray analysis to detect any imperfections. Stringent quality parameters are established to maintain consistency across the board.

Throughout the machining and assembly phases, real-time monitoring systems are employed. These systems facilitate immediate detection and correction of any discrepancies, ensuring the utmost accuracy and reliability.

Post-assembly, each unit is subjected to exhaustive testing under varying operational conditions. This ensures the cutter’s performance meets the highest industry standards. The tests measure parameters like cutting speed, accuracy, and longevity.

Moreover, a final quality audit is conducted by specialized personnel. This involves a comprehensive review of the equipment, ensuring it meets the rigorous quality benchmarks set forth by SourcifyChina.

The culmination of dedicated processes and stringent checks ensures that each laser metal cutter delivered by SourcifyChina is a paragon of engineering excellence. Ensuring top-notch quality control, these cutters are reliable and built to last, fulfilling the demands of various industrial applications.

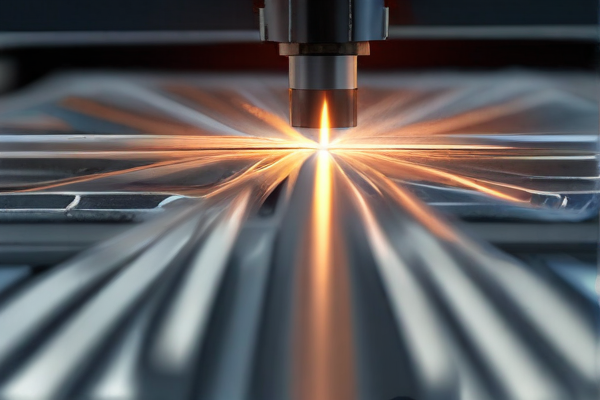

The SourcifyChina laser metal cutter is a cutting-edge tool known for its precision and efficiency. Using advanced laser technology, it delivers clean, accurate cuts on various metals. It is particularly effective for intricate designs, making it ideal for both industrial and artistic applications.

One of its standout capabilities is its speed. The laser cutter can process metal sheets swiftly, reducing production times and increasing throughput. This speed does not compromise on quality, ensuring each cut is as precise as the last. The machine’s high-speed functionality makes it an invaluable asset for businesses seeking fast, reliable performance.

Another crucial feature is its versatility. The SourcifyChina laser metal cutter accommodates various metals, including stainless steel, aluminum, brass, and copper. This adaptability means it can be employed in multiple industries, from automotive manufacturing to custom metalwork. Such versatility helps businesses diversify their offerings without needing multiple, specialized tools.

Durability and low maintenance are other significant advantages of this laser cutter. Built from robust materials and components, it is designed to withstand heavy-duty usage. The machine requires minimal upkeep, and any necessary maintenance is straightforward, allowing for more operational uptime and reduced costs related to machine care.

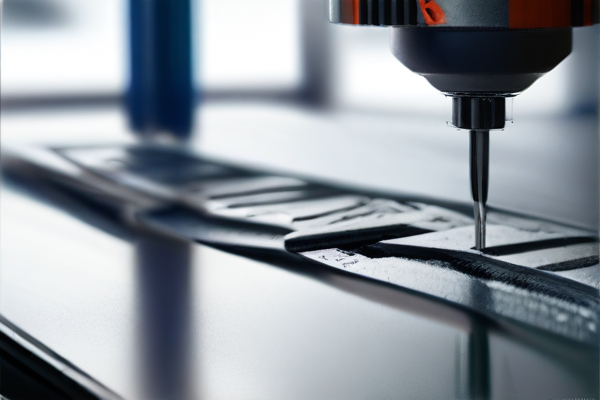

The user-friendly interface of the SourcifyChina laser metal cutter simplifies operation, making it accessible even to those with minimal technical expertise. Intuitive controls and clear displays guide users through each step, from setting parameters to executing cuts. This ease of use enhances productivity, as operators can focus on their primary tasks without grappling with complicated machinery.

In summary, the SourcifyChina laser metal cutter combines precision, speed, and versatility with durability and ease of use. Its capabilities make it an excellent choice for diverse applications, helping businesses improve productivity and achieve high-quality results consistently. Whether for large-scale industrial projects or intricate artistic endeavors, this laser cutter stands out as a reliable, efficient tool.

Laser metal cutters offer precision, speed, and versatility, making them indispensable in modern manufacturing processes. These advanced tools provide numerous benefits, enhancing productivity and product quality.

– Precision Cutting: Laser cutters deliver high-precision cuts with minimal material waste.

– Speed and Efficiency: They significantly reduce cutting times, boosting overall efficiency.

– Versatility: Capable of cutting a wide range of metals, including steel, aluminum, and titanium.

– Automation: Integrates well with automated systems, reducing manual labor requirements.

– Quality Finish: Results in smooth edges and reduces the need for secondary finishing processes.

– Cost-Effective: Minimizes material waste and decreases labor costs, improving overall profitability.

– Complex Shapes: Easily handles intricate and complex designs, expanding design possibilities.

– Reduced Heat-Affected Zones: Minimizes thermal distortion and maintains material integrity.

– Environmentally Friendly: Produces less waste and can use recycled materials, supporting sustainability efforts.

– Safety: Modern laser cutters come with advanced safety features, protecting operators from potential hazards.

– Low Maintenance: Requires less frequent maintenance compared to traditional cutting tools, reducing downtime.

– Scalability: Easily scalable for both small and large production runs.

– Non-Contact Process: Reduces the risk of material distortion or damage as there is no physical contact.

– Customization: Allows for easy customization and rapid prototyping, enhancing flexibility in production.

– Energy Efficiency: Consumes less energy compared to other cutting methods, contributing to lower operational costs.

In summary, the benefits of using laser metal cutters in manufacturing are substantial, from improving precision and efficiency to reducing costs and supporting sustainability efforts. These advantages make laser cutters a valuable asset in various industrial applications.

Laser metal cutters are advanced tools that use intense laser beams to cut various types of metals with high precision and speed. These devices offer a range of features that make them indispensable in industrial and manufacturing processes.

Key features include:

– Precision Cutting: Ability to cut intricate designs with minimal thermal distortion.

– Speed: Faster cutting compared to traditional methods, increasing productivity.

– Versatility: Can cut a wide range of metals including steel, aluminum, and titanium.

– Automation: Often equipped with CNC controls for automated and repetitive tasks.

– Energy Efficiency: Modern lasers are designed to consume less power, making operations cost-effective.

– Clean Cuts: Minimal burrs and a high-quality finish reduce the need for secondary processing.

– Safety Features: Includes protective enclosures and automated shut-off systems to enhance operator safety.

– Non-Contact Process: Reduces wear and tear on the machinery, extending the life of the equipment.

– Minimal Material Waste: High precision cutting results in less wastage of material.

Incorporating these features, laser metal cutters serve as efficient, reliable, and versatile tools in diverse industrial applications, from automotive to aerospace and beyond.

SourcifyChina specializes in custom laser metal cutting products, offering precision and quality for various industrial applications. Their advanced laser technology ensures each piece is crafted with meticulous detail and accuracy.

From intricate designs to robust industrial components, SourcifyChina excels in delivering products tailored to client specifications. Their high-speed laser cutters handle complex jobs efficiently, reducing turnaround times without compromising quality.

Clients benefit from SourcifyChina’s commitment to using premium materials to ensure durability and longevity. Whether it’s prototype development or full-scale production, their expertise guarantees top-notch results, meeting international standards.

SourcifyChina’s portfolio includes custom brackets, enclosures, and decorative pieces, each project reflecting a unique blend of craftsmanship and technology. Their bespoke solutions cater to various industries, including automotive, aerospace, and consumer electronics.

In conclusion, SourcifyChina’s laser metal cutting services stand out due to their precision, customizability, and commitment to quality. Their innovative approach ensures that each project, no matter the complexity, is executed flawlessly, making them a preferred choice for many businesses.

SourcifyChina, a renowned company in the manufacturing sector, has established itself as a leader in the production and distribution of high-precision laser metal cutters. Leveraging advanced technology and a commitment to quality, SourcifyChina offers an extensive range of laser cutting solutions that cater to various industries, including automotive, aerospace, and construction. Their state-of-the-art laser metal cutters are known for their exceptional accuracy, efficiency, and versatility, enabling businesses to achieve superior cutting performance and optimize production processes. With a strong emphasis on innovation, SourcifyChina continuously invests in research and development to ensure their products meet the evolving demands of the global market. Additionally, the company prides itself on providing comprehensive customer support and maintenance services, ensuring optimal machine performance and longevity. Through its dedication to excellence and customer satisfaction, SourcifyChina has earned a solid reputation as a trusted provider of cutting-edge laser cutting technology.

Laser metal cutters have significantly revolutionized the Aerospace, Defense, and Marine sectors by providing unparalleled precision and efficiency in fabricating complex components. In aerospace, the stringent standards for part tolerance and material integrity are met with ease through the use of advanced laser cutters. These machines are crucial for manufacturing critical components such as turbine blades, structural brackets, and intricate airframe parts. The precision of laser cutting ensures minimal material waste and reduces the need for supplementary machining processes, thus lowering production costs and lead times. Similarly, in the defense industry, the production of weaponry, armored vehicles, and other strategic machinery benefits from the high level of accuracy and repeatability offered by laser metal cutters. The ability to cut a variety of materials, including hardened alloys and composite metals, ensures robust and reliable equipment essential for defense applications.

The marine industry also leverages the capabilities of laser metal cutters to enhance the efficiency and durability of various components. Shipbuilding and submarine manufacturing demand precise and robust metal-cutting solutions to produce hull sections, bulkheads, and other critical structural elements. Laser cutters enable the swift fabrication of these large parts with precise seams and edges critical for the water-tight integrity and structural strength of marine vessels. Additionally, maintenance and repair operations in the marine industry benefit from laser cutting technology, enabling the rapid production of spare parts and custom components directly on-site or in dedicated facilities. Overall, laser metal cutters deliver the high precision, reduced material waste, and operational efficiency necessary to meet the stringent demands of Aerospace, Defense, and Marine applications.

Laser metal cutters have revolutionized the automotive industry with their unparalleled precision and efficiency. In manufacturing, these cutters are used to produce complex and intricate parts with exceptional accuracy, ensuring tight tolerances that are crucial for automotive components. From chassis and engine parts to intricate interior elements, laser cutters enable the production of lightweight and durable components that meet the rigorous safety and performance standards of the automotive world. The ability to quickly switch between different cutting programs also means faster production cycles and reduced downtime, allowing manufacturers to meet the growing demand for customized and high-quality vehicles. Moreover, the non-contact nature of laser cutting minimizes material waste and reduces the risk of deformities, further enhancing the efficiency and sustainability of automotive manufacturing processes.

In the electronics industry, laser metal cutters play a pivotal role in the fabrication of components for a wide array of devices, from consumer electronics to complex industrial systems. Precision is paramount in this sector, and laser cutters offer the exacting standards required for cutting delicate and intricate parts, including circuit boards, enclosures, and connectors. Their ability to cut through thin metals without causing thermal distortion ensures the integrity of the electronic components, which is critical for maintaining functionality and reliability. Additionally, laser cutters are instrumental in the rapid prototyping phase, where speed and flexibility are essential for developing innovative electronic products. Manufacturers can swiftly iterate designs and bring new products to market faster, keeping pace with the accelerated lifecycle of technological advancements. Furthermore, the automation capabilities of modern laser cutters streamline production processes, reducing labor costs and enhancing overall productivity in the electronics manufacturing sector.

Laser metal cutters have revolutionized the construction industry by offering unparalleled precision and efficiency in cutting metal components. Traditional methods like mechanical cutting or welding often result in rough edges and require additional finishing processes. In contrast, laser cutters utilize concentrated beams of light to achieve smooth, accurate cuts in a fraction of the time. This precision is crucial in construction, where exact measurements and fitting are essential for structural integrity. Laser metal cutters can effortlessly slice through various metals, including steel, aluminum, and titanium, thereby facilitating the creation of intricate architectural designs and robust frameworks. Moreover, their automation capabilities allow for mass production of identical components, thereby reducing human error and speeding up the construction timeline.

In the energy sector, laser metal cutters play a critical role in the manufacturing and maintenance of equipment and infrastructure. The precision of laser cutting is indispensable in the production of components for wind turbines, solar panels, and nuclear reactors. Laser metal cutters enable the fabrication of intricate parts that require tight tolerances, which is essential for the efficient functioning of these energy systems. Furthermore, laser cutting technology reduces material wastage, leading to cost savings and more sustainable production processes. In the realm of maintenance, laser metal cutters can be deployed for rapid, on-site repairs of energy infrastructure, minimizing downtime and operational disruptions. As the energy sector continues to evolve towards more sophisticated and sustainable solutions, laser metal cutting remains a vital tool for innovation and efficiency.

The industrial equipment industry has witnessed significant advancements with the incorporation of laser metal cutter technology. This cutting-edge equipment utilizes concentrated laser beams to slice through metal with remarkable precision and speed. Unlike traditional mechanical cutting methods, laser metal cutters provide a non-contact process, minimizing the risk of metal deformation and ensuring intricate, highly accurate cuts. Industries such as automotive manufacturing, aerospace, shipbuilding, and heavy machinery heavily rely on laser cutters to produce complex components with tight tolerances. The ability to efficiently cut through various metals including steel, aluminum, and titanium, while maintaining high levels of accuracy, enhances product quality and reduces production time and costs.

Moreover, the application of laser metal cutters extends beyond mere precision cutting. The integration of computer numerical control (CNC) systems allows for automated and programmable cutting processes, increasing productivity and enabling mass customization. This versatility supports a wide range of industrial applications, from crafting prototypes and small batches to large-scale production runs. Additionally, laser metal cutters are eco-friendly; they generate less waste material and lower energy consumption compared to traditional cutting tools. As industries continue to pursue sustainable and efficient manufacturing practices, the adoption of laser metal cutters is expected to grow, driving innovation and operational excellence within the industrial equipment sector.

Laser metal cutters have revolutionized the field of medical device manufacturing by offering unmatched precision and efficiency. In an industry where accuracy and hygiene are paramount, these cutters enable the production of intricate components with minimal material waste. Surgeons and patients alike benefit from the precision of devices such as surgical instruments, implants, and diagnostic equipment. The laser cutter’s fine focus allows for the creation of small, complex parts that would be difficult or impossible to fabricate with conventional methods. Moreover, the clean edges produced by laser cutting reduce the need for further processing, thereby maintaining the sterilization integrity of medical tools.

In addition to precision, laser metal cutters offer significant improvements in production speed, a critical factor in meeting the stringent demands of the healthcare sector. The technology supports rapid prototyping, enabling the swift transition from concept to functional devices. This is particularly valuable in customized medical solutions, such as patient-specific implants and orthopedic devices, where time-sensitive production is essential. Laser metal cutting also supports a wide range of biocompatible materials, from stainless steel to titanium, ensuring that the products meet medical standards for safety and durability. Overall, laser metal cutters have not only enhanced the quality and reliability of medical devices but have also accelerated their development and deployment, contributing to better patient outcomes.

Laser metal cutting is a highly advanced method employed in machining and manufacturing that utilizes a high-powered laser beam to precisely cut through metal materials. This technology, beloved for its accuracy and efficiency, is capable of producing intricate and highly detailed cuts, making it ideal for applications that demand precision. The laser beam, often comprising CO2, fiber, or neodymium lasers, is directed by computer numerical control (CNC) systems which ensure exact replication of digital designs. This method minimizes wastage and maximizes material utilization, which is particularly advantageous in industries such as aerospace, automotive, and electronics where precision components are critical.

In manufacturing, laser metal cutters excel not only in cutting but also in drilling, engraving, and marking metallic surfaces. Their ability to maintain consistent quality and high production rates makes them indispensable on production lines. Automated laser cutters can handle a variety of metals, including steel, aluminum, and titanium, thereby offering extensive versatility. Additionally, the non-contact nature of laser cutting reduces the risk of damaging delicate materials and increases the lifespan of the cutting tools. With the capacity to integrate into automated systems, laser metal cutters contribute significantly to streamlining manufacturing operations, improving throughput, and reducing labor costs. Overall, the capabilities of laser metal cutters offer numerous benefits that enhance the efficiency and quality of modern machining and manufacturing processes.

FAQ: Laser Metal Cutter Quality Work from SourcifyChina Factory

Q1: What types of metals can the laser cutter from SourcifyChina handle?

A1: SourcifyChina’s laser cutters are versatile and can handle various metals including stainless steel, aluminum, copper, brass, and carbon steel.

Q2: What is the precision level of the laser metal cutters?

A2: The laser metal cutters from SourcifyChina have a high precision level, typically within ±0.1mm, ensuring clean, accurate cuts for intricate designs.

Q3: How thick can the metal be for effective cutting?

A3: Depending on the laser cutter model, metals up to 20mm thickness can be effectively cut. Different machines are available for varying thickness requirements.

Q4: What quality control measures are in place at SourcifyChina?

A4: SourcifyChina implements stringent quality control measures, including pre-production inspections, in-process monitoring, and post-production testing to ensure all cuts meet high-quality standards.

Q5: What is the turnaround time for manufacturing orders?

A5: Turnaround times vary depending on order complexity and volume, but generally, standard orders are processed and shipped within 2-4 weeks.

Q6: Is customization available for specific requirements?

A6: Yes, SourcifyChina offers extensive customization options, allowing clients to specify dimensions, shapes, and other criteria to meet unique project needs.

Q7: Are there any certifications held by SourcifyChina that ensure quality?

A7: SourcifyChina holds pertinent certifications such as ISO 9001 for quality management and other industry-specific certifications, ensuring high standards are consistently met.

Q8: What support is available post-purchase?

A8: SourcifyChina provides comprehensive post-purchase support including technical assistance, maintenance services, and a warranty to ensure customer satisfaction.

Q9: How eco-friendly are the laser cutting processes used?

A9: The laser cutting processes at SourcifyChina are designed to be eco-friendly, utilizing efficient energy use and minimizing waste generation wherever possible.

Q10: How can I request a quote or place an order?

A10: To request a quote or place an order, you can contact SourcifyChina directly through their website or via email, providing details about your project requirements.

When selecting a laser metal cutter from SourcifyChina factory or any other manufacturer, it’s crucial to prioritize both quality and efficiency. Here are some tips to help you make an informed decision:

1. Understand Your Requirements: Clearly define the types of metals you intend to cut, as well as the desired thickness range. This will help you choose a laser cutter with appropriate power and capabilities.

2. Research the Technology: Familiarize yourself with different types of laser cutters, such as CO2, fiber, and disk lasers. Fiber lasers are typically more energy-efficient and better suited for cutting metals.

3. Evaluate the Manufacturer: Examine SourcifyChina’s reputation for quality and customer service. Look for reviews, testimonials, and case studies that provide insight into their reliability.

4. Check Certification and Compliance: Ensure the factory complies with international manufacturing standards and has necessary certifications, like ISO 9001. This ensures the products meet high-quality standards.

5. Assess the Machinery: Verify technical specifications and features of the laser cutter. Pay attention to laser power, cutting speed, precision, and software compatibility.

6. Inspect Sample Work: Request sample cuts or visit the factory to observe the machine in action. This offers a tangible sense of the cutter’s performance.

7. After-Sales Support: Inquire about the warranty, maintenance services, and availability of spare parts. Reliable after-sales support is crucial for minimizing downtime.

8. Cost vs. Value: Compare the pricing with other manufacturers but weigh it against the machine’s capabilities, durability, and the support offered. Sometimes, a higher initial investment can result in better long-term value.

9. Customization Options: Check if SourcifyChina offers customization to tailor the laser cutter to your specific needs, which can enhance productivity and operational efficiency.

10. Training and Operation: Ensure they provide comprehensive training for your team, as well as user-friendly operating instructions and safety protocols.

By following these tips, you can ensure a well-informed purchase that meets your metal cutting needs efficiently and effectively.

Sure! Here is a list of FAQs with answers for sourcing a laser metal cutter from SourcifyChina Factory:

Q: What types of laser metal cutters are available at SourcifyChina Factory?

A: SourcifyChina Factory offers a range of laser metal cutters, including fiber laser cutters, CO2 laser cutters, and hybrid machines that can handle various materials and thicknesses.

Q: How do I request a quote for a laser metal cutter?

A: To request a quote, you can visit the SourcifyChina Factory website, fill out the inquiry form with your specifications, or contact their sales team directly via email or phone.

Q: What information do I need to provide to get an accurate quote?

A: Provide details such as the type of laser cutter, material types, thickness, cutting area size, power requirements, and any additional features you may need.

Q: Can SourcifyChina Factory customize a laser metal cutter to my specifications?

A: Yes, they offer customization options to meet specific needs and requirements. Discuss your needs with their technical team to explore available customization options.

Q: What is the typical lead time for manufacturing and delivery?

A: The lead time varies depending on the complexity and customization of the order. Generally, it ranges from 4 to 8 weeks for standard models. Shipping time is additional.

Q: Are there any warranties and after-sales support provided?

A: SourcifyChina Factory offers a standard warranty period and provides comprehensive after-sales support, including installation guidance, training, and maintenance services.

Q: What are the payment terms?

A: Payment terms generally include a deposit upon order confirmation, with the balance paid before shipment. Specific terms can be discussed with the sales team.

Q: How can I ensure the quality of the laser metal cutter?

A: SourcifyChina Factory follows strict quality control procedures and standards. They also offer the option for third-party inspections and factory visits to verify quality before shipment.

Q: Do they provide training for operating the laser metal cutter?

A: Yes, SourcifyChina Factory provides both on-site and remote training sessions to ensure proper operation and maintenance of the laser metal cutter.

Q: How do I arrange for shipping and logistics?

A: SourcifyChina Factory can assist with shipping and logistics arrangements, providing options for sea, air, and land transportation according to your preferences and requirements.

Sourcing a laser metal cutter from a factory through SourcifyChina can be efficient and cost-effective if done correctly. Here are some concise tips to guide you through the process:

1. Define Specifications:

Clearly outline your requirements such as cutting power (e.g., 500W, 1000W), material type and thickness it can cut, precision, and any additional features.

2. Use Detailed Keywords:

When using SourcifyChina, search with specific terms like “industrial laser metal cutter,” “fiber laser cutter,” or “CO2 laser cutter” combined with power and material details.

3. Verify Suppliers:

Look for verified suppliers with positive ratings and reviews. Check their credentials, quality certifications (ISO, CE), and legal compliance.

4. Request Samples:

Ask for sample cuts of your specific material to evaluate the quality and precision of the cutter.

5. Compare Quotes:

Reach out to multiple suppliers to compare prices but also consider warranty, after-sales support, and spare parts availability. Don’t focus on price alone; quality and support matter.

6. Check Factory Information:

Verify the factory’s production capacity, experience in manufacturing laser cutters, and technological capability. Use third-party verification services if possible.

7. Communicate Clearly:

Establish clear communication with potential suppliers. Discuss your requirements, terms of trade, delivery times, payment terms, and logistical arrangements.

8. Understand Import Regulations:

Be aware of your country’s import regulations, duties, and taxes. Ensure that the supplier can provide necessary documentation like commercial invoices and packing lists.

9. Documentation:

Ensure all agreements and specifications are documented in the contract to avoid future disputes.

10. Visit If Possible:

If feasible, arrange a visit to the factory to see the production process and quality control in person.

By following these tips, you can efficiently source a high-quality laser metal cutter that meets your needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.