Reliable SourcifyChina: High-Quality Laser Metal Cutting Services from Reputable Factories

Discover premium laser metal cutting solutions with SourcifyChina. Our network of trusted factories ensures precision, efficiency, and unparalleled quality for all your industrial needs. Trust SourcifyChina for reliable and cutting-edge manufacturing services.

Choosing SourcifyChina for purchasing laser metal cutting from China ensures unparalleled quality and reliability. With years of industry experience, they guarantee exceptional products that meet international standards.

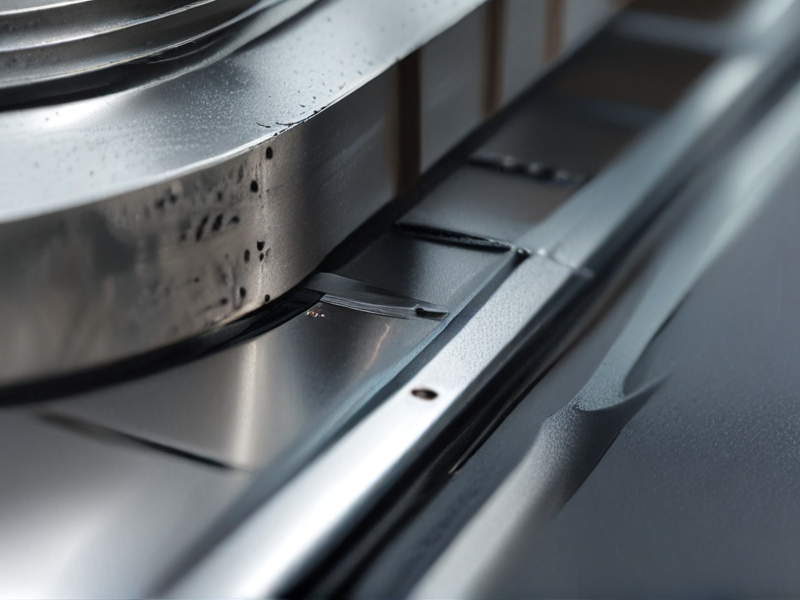

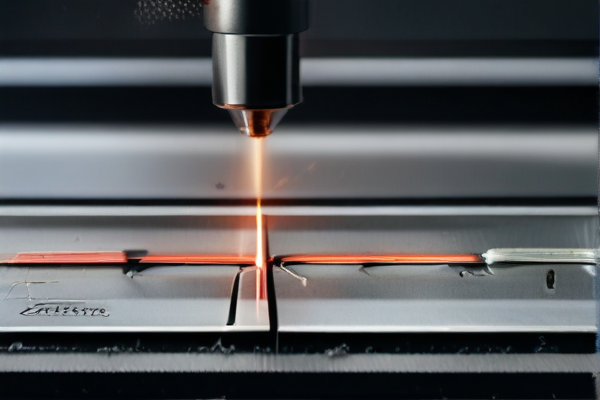

Their state-of-the-art facilities and cutting-edge technology enable precise and efficient metal cutting. This ensures that buyers receive high-quality, accurately manufactured components every time.

Moreover, SourcifyChina offers competitive pricing, providing excellent value without compromising on quality. They understand the budget constraints of buyers and strive to offer the best possible rates.

Customer service is a top priority at SourcifyChina. Their dedicated support team provides prompt and effective assistance, ensuring a smooth and hassle-free purchasing process for international buyers.

Choosing SourcifyChina factory for your laser metal cutting needs guarantees product excellence, competitive pricing, and exceptional customer support, making it the ideal partner for buyers in the global marketplace.

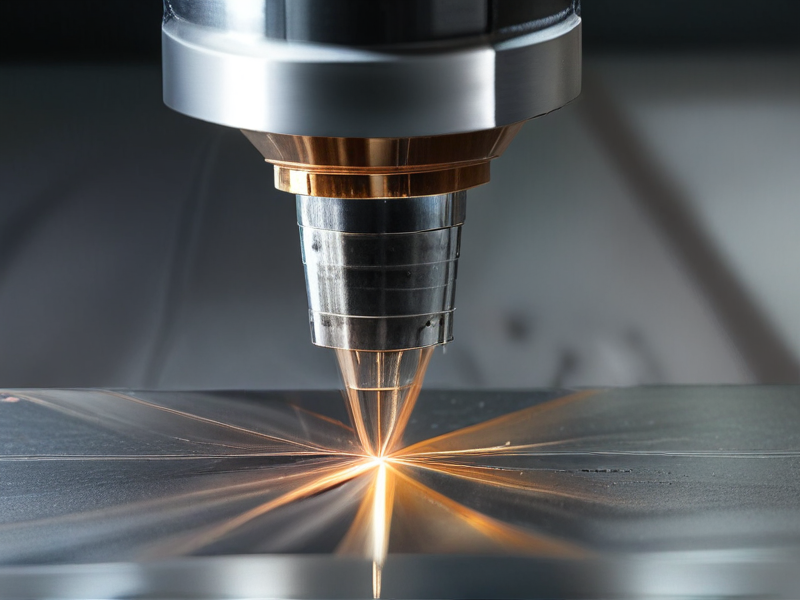

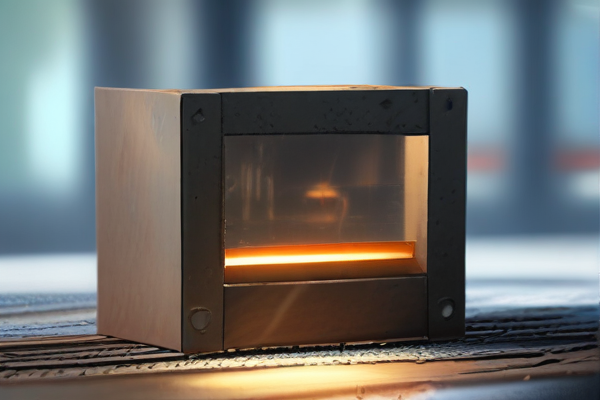

Laser metal cutting is a precise and efficient method for cutting metals using different types of lasers. The most common types include CO2, fiber, and Nd:YAG lasers, each offering unique advantages suited to various applications.

– CO2 Lasers:

– Excellent for cutting non-metallic materials and thicker metals.

– High power output.

– More affordable for larger cuts.

– Fiber Lasers:

– Ideal for cutting thinner metals.

– Higher cutting speeds, leading to increased productivity.

– Better energy efficiency compared to CO2 lasers.

– Suitable for demanding industrial applications.

– Nd:YAG Lasers:

– Perfect for both cutting and welding tasks.

– Effective for high-precision and fine-detail work.

– Suitable for reflective metals like aluminum and copper.

– Laser Cutting Methods:

– Fusion Cutting: Uses high-pressure gas to blow molten material out of the cut.

– Flame Cutting: Combines a laser with an oxygen jet to achieve high cutting speeds.

– Sublimation Cutting: Cuts by vaporizing material directly, resulting in smooth edges.

– Advantages of Laser Metal Cutting:

– High precision and accuracy.

– Reduced contamination and waste.

– Capability of cutting complex shapes and fine details.

– Minimal heat-affected zones, preserving material properties.

– Applications:

– Automotive parts manufacturing.

– Aerospace components production.

– Medical device fabrication.

– Jewelry and watchmaking industries.

– Custom metalwork and artistic creations.

– Factors to Consider:

– Material type and thickness.

– Required cutting speed and precision.

– Production volume and cost efficiency.

– Maintenance and operational costs of laser equipment.

Laser metal cutting continues to evolve, offering increasingly versatile and efficient solutions for a broad range of industries, ensuring high-quality, precision cuts tailored to specific requirements.

Laser metal cutting is a precise and efficient method used in various industries for creating intricate designs and functional components with minimal distortion.

– Manufacturing: Used for cutting parts in automotive, aerospace, and machinery industries.

– Construction: Employed in fabricating structural components like beams and frames.

– Jewelry: Creates detailed and intricate designs on metal pieces.

– Medical Devices: Produces precise surgical instruments and implants.

– Electronics: Cuts and shapes metal parts for circuit boards and enclosures.

– Art and Sculpture: Facilitates the creation of complex shapes and designs in metal artworks.

– Signage: Cuts letters and logos for high-precision metal signs.

– Prototyping: Used for rapid creation of metal prototypes for testing and development.

– Automotive: Produces parts like panels, brackets, and exhaust systems.

– Renewable Energy: Cuts components for wind and solar energy systems.

– Shipbuilding: Fabricates metal parts for the hull and other parts of a ship.

– Tool and Die Making: Creates precision tools and dies for manufacturing processes.

– Home Décor: Produces custom metal furniture and decorative items.

– Aerospace: Cuts components for airplanes, satellites, and other aerospace applications.

– Agriculture: Fabricates parts for farming machinery.

– Telecommunications: Creates metal parts for infrastructure and devices.

– Weaponry: Used in the production of cutting-edge military equipment.

– Custom Projects: Supports bespoke metal cutting requirements across various sectors.

– Educational Tools: Used in producing metal components for academic and research purposes.

SourcifyChina specializes in high-precision laser metal cutting services. They employ advanced laser technology to cut various types of metals, including aluminum, stainless steel, and carbon steel. This approach ensures clean, precise cuts with minimal material waste.

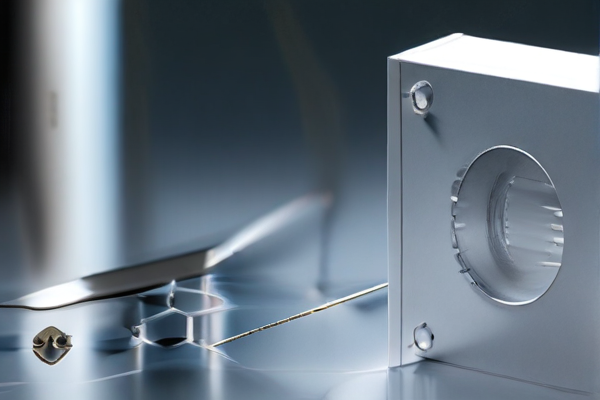

Their cutting equipment delivers unmatched accuracy and efficiency, capable of meeting both small-scale and large-scale production demands. By using state-of-the-art machinery, SourcifyChina achieves high level detailing, which is essential for industries like aerospace, automotive, and medical devices.

Additionally, SourcifyChina’s laser cutting process reduces the need for secondary finishing, saving time and costs. The non-contact method also minimizes deformation and maintains the integrity of the material, making it ideal for intricate designs.

Moreover, the company puts a strong emphasis on quality control. Every piece undergoes rigorous inspection to ensure it meets customer specifications and industry standards. This commitment to quality has earned them a reputation for reliability and excellence.

In conclusion, SourcifyChina’s laser metal cutting services offer precise, efficient, and cost-effective solutions for a variety of industries. Their advanced technology and quality assurance processes make them a trusted partner for all your metal cutting needs.

SourcifyChina’s laser metal cutting process emphasizes meticulous quality control to ensure precision and consistency. State-of-the-art laser machines are employed to achieve clean cuts with minimal tolerances, meeting stringent industry standards.

The initial phase involves detailed CAD/CAM programming, allowing for accurate design implementation. Technicians carefully scrutinize these designs before proceeding, guaranteeing that each blueprint adheres to client specifications.

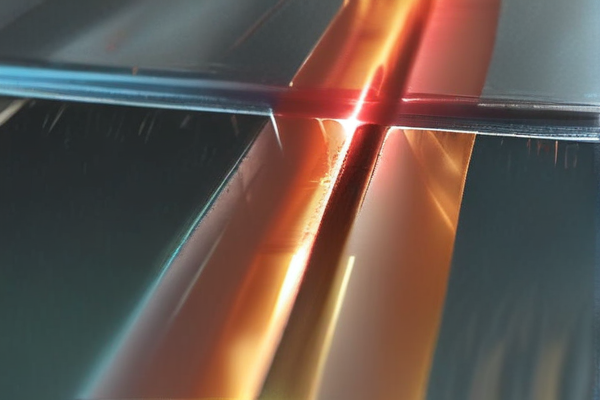

During production, in-process monitoring detects deviations and enables real-time adjustments, ensuring each piece meets the desired quality. Advanced laser technology ensures minimal thermal impact, preserving the material’s structural integrity.

Post-production, thorough inspections are conducted. Each part undergoes rigorous dimensional checks with high-precision measuring tools, and surface finishes are evaluated to confirm the absence of defects. Feedback from these inspections loops back into the process, fostering continuous improvement.

Quality control also extends to material selection and storage, ensuring that only premium, defect-free metals are used. Suppliers are regularly audited, and materials are tested for compliance with international standards before use.

Employee training is another critical component. SourcifyChina invests in comprehensive training programs for their workforce, ensuring that operators are skilled in both the machinery and the quality standards required for laser metal cutting.

Lastly, customer feedback is actively sought and analyzed. This feedback helps in refining processes, with the ultimate goal of achieving zero-defect production and enhanced customer satisfaction. By integrating stringent quality control measures throughout every stage of their laser metal cutting process, SourcifyChina maintains its reputation for excellence and reliability.

SourcifyChina excels in laser metal cutting, providing precision and efficiency for various industrial applications. Their state-of-the-art technology ensures accurate cuts on multiple types of metal, optimizing production processes.

Laser cutting capabilities include high-speed performance, enabling quick turnaround times without compromising quality. The technology can handle complex designs with intricate details, catering to diverse customer requirements with utmost precision.

The utilization of computer-aided design (CAD) software further enhances SourcifyChina’s capabilities, allowing for custom solutions tailored to specific project needs. This synergy of advanced technology and skilled technicians guarantees exceptional results for every job.

Additionally, SourcifyChina prioritizes material efficiency by minimizing waste and reducing excess through precise cuts. This eco-friendly approach not only conserves resources but also lowers overall costs, benefitting clients economically.

Durability and consistency are paramount at SourcifyChina, where every project undergoes rigorous quality checks. The firm commitment to excellence ensures that each cut meets the highest standards, providing reliable and long-lasting products.

Customer satisfaction is at the core of their operations. SourcifyChina’s dedicated support team is readily available to assist with inquiries, ensuring seamless communication and a smooth project experience from start to finish.

Investing in the latest technology and skilled workforce, SourcifyChina continuously innovates to stay ahead in the competitive market. Their commitment to improvement and excellence guarantees state-of-the-art solutions for all metal cutting needs.

In summary, SourcifyChina’s laser metal cutting capabilities combine advanced technology, precision engineering, and customer-centric service. Whether for complex designs or high-volume projects, they deliver unparalleled quality, efficiency, and reliability. This makes them a preferred partner for businesses seeking top-tier metal cutting services.

Laser metal cutting offers precise, efficient, and versatile solutions for various industrial applications, revolutionizing manufacturing processes and improving productivity.

– Precision: Delivers high-accuracy cuts with minimal material waste, ensuring intricate designs and clean edges.

– Speed: Significantly faster than traditional cutting methods, enhancing throughput and reducing production time.

– Versatility: Capable of cutting a wide range of metals, including steel, aluminum, and titanium, as well as different thicknesses.

– Cost-Effective: Reduces labor costs and material wastage, allowing for more efficient use of materials.

– Automation: Easily integrates with CNC (Computer Numerical Control) systems for automated and repeatable cutting operations.

– Safety: Minimizes direct human intervention, reducing the risk of accidents and enhancing workplace safety.

– Non-Contact Process: Eliminates physical wear and tear on the tools, extending the lifespan of the cutting equipment.

– Reduced Post-Processing: Produces smooth cuts that often require little to no additional finishing, saving time and effort.

– Environmentally Friendly: Decreased energy consumption and waste production compared to conventional methods, supporting sustainable manufacturing practices.

– Consistency: Offers repeatable and consistent quality in mass production, ensuring uniformity in every piece cut.

Overall, laser metal cutting is an indispensable technology in modern manufacturing, providing multiple benefits that drive efficiency, reduce costs, and maintain high-quality standards.

Laser metal cutting is a precision technique utilized to cut through various metals using a highly concentrated laser beam. It offers numerous advantages such as high accuracy and efficiency.

Key features of laser metal cutting include:

– Precision and Accuracy: Achieves intricate designs and fine cuts with tolerances typically within a few micrometers.

– Versatility: Suitable for cutting a wide range of metals like steel, aluminum, brass, and titanium.

– Speed and Efficiency: Faster than traditional cutting methods, especially for complex shapes.

– Non-Contact Process: Reduces the risk of material deformation and minimizes wear on tools.

– Automated Control: Integrates smoothly with CNC systems for consistent and repeatable cuts.

– Minimal Waste: Thin cut paths (kerf) result in less material waste.

– Thermal Influence Zone: Generates a small heat-affected zone, preserving the structural integrity of the material.

– Cost-Effective: Low operating costs due to reduced labor and material wastage.

– Clean Cuts: Produces smoother edges with no need for secondary finishing processes.

– Environmentally Friendly: Reduces energy consumption and minimizes the production of hazardous waste.

In conclusion, laser metal cutting is a highly advanced and efficient method bringing about a transformative impact across industries that require precision and speed in material fabrication.

SourcifyChina specializes in precision laser metal cutting, offering bespoke products tailored to client specifications. Utilizing state-of-the-art machinery, they ensure high-quality cuts and intricate designs suitable for various industrial applications.

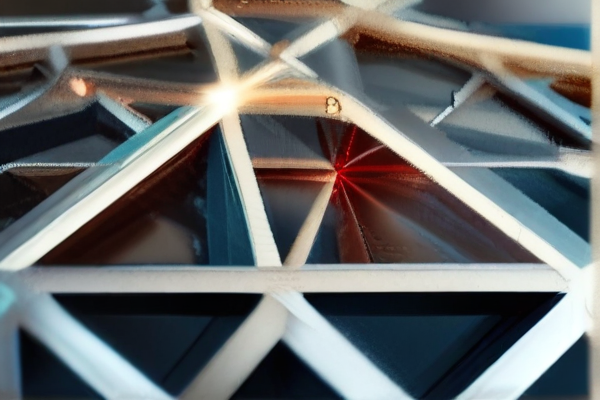

Their custom metal products range from intricate decorative panels to complex machine parts. Each item is meticulously crafted to meet the specific needs of clients, ensuring both functionality and aesthetic appeal. SourcifyChina’s laser technology guarantees clean edges, minimal waste, and superior efficiency.

In addition to product manufacturing, SourcifyChina excels in project management. They oversee every stage from initial design to final production. This comprehensive service ensures timely delivery and adherence to budget, making them a reliable partner for large-scale industrial projects.

SourcifyChina stands out for its commitment to quality and innovation in laser metal cutting. By continuously investing in advanced technology and skilled workforce, they maintain their position at the forefront of the industry. This dedication to excellence ensures that every custom product and project they undertake meets the highest standards of precision and durability.

SourcifyChina Laser Metal Cutting is a pioneering company that specializes in delivering high-precision metal cutting solutions through advanced laser technology. Focused on both small-scale custom projects and large industrial orders, the company leverages state-of-the-art laser equipment to ensure unparalleled accuracy and efficiency. SourcifyChina is renowned for its commitment to quality and customer satisfaction, rigorously adhering to international standards and continuously innovating to stay ahead in the competitive market. With a robust portfolio spanning automotive, aerospace, electronics, and heavy machinery sectors, the company provides tailored solutions to meet diverse cutting needs. Their dedicated team of engineers and technicians works closely with clients to optimize the cutting process, from initial design to final execution, ensuring timely delivery and cost-effectiveness. Through their expertise and unwavering dedication, SourcifyChina has established itself as a trusted partner for businesses seeking reliable and high-quality laser metal cutting services.

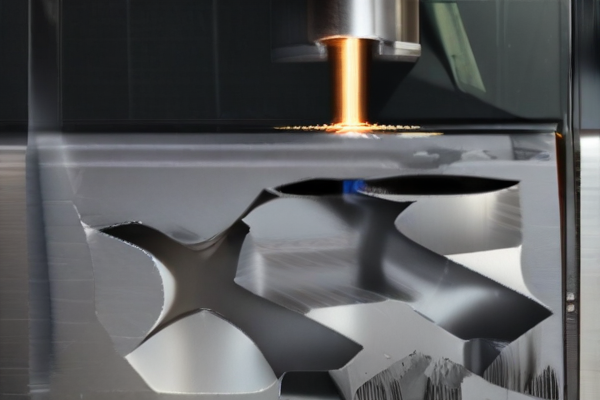

Laser metal cutting technology has made significant strides in the Aerospace, Defense, and Marine industries, revolutionizing how components are manufactured and assembled. In aerospace, precision is paramount as the industry demands lightweight yet robust materials that can withstand extreme conditions. Laser metal cutting offers high precision and minimal thermal distortion, essential for creating intricate components such as turbine blades, airframes, and structural elements. The technology’s ability to cut complex geometries from high-strength alloys and composites ensures safer, more efficient, and higher-performing aircraft. Additionally, its automation potential enhances production speed and consistency, crucial for meeting stringent regulatory standards and tight production schedules.

In the Defense and Marine sectors, laser metal cutting provides similar benefits of precision, durability, and efficiency. Defense applications often involve the production of armored vehicles, weapon systems, and sensitive electronic equipment, where exacting tolerances and material properties are critical. Laser cutting meets these demands by enabling accurate manufacturing processes and reducing material wastage, which translates to cost savings and more robust defenses. In the marine industry, where corrosion-resistant and high-strength materials are often used, laser cutting ensures high-quality fabrication of ship hulls, engine components, and structural supports. This technology not only increases the lifespan and performance of maritime vessels but also allows for more innovative design approaches, pushing the boundaries in naval architecture and engineering.

Laser metal cutting has revolutionized the automotive industry by providing unparalleled precision and efficiency in the fabrication of various components. In car manufacturing, the technology is employed to cut intricate shapes and designs into metal sheets that form the body structure, engine parts, and even intricate components like fuel injectors and sensors. The ability of laser cutting to produce clean edges and minimal thermal distortion enhances the mechanical properties of the automotive components, promoting both durability and safety. Moreover, the high-speed nature of laser cutting significantly reduces production time and material waste, helping manufacturers meet the growing demand for lightweight, fuel-efficient vehicles while maintaining cost-effectiveness and environmental responsibility.

In the realm of electronics, laser metal cutting plays a crucial role in the production of precision components required for various devices and systems. As electronics continue to miniaturize, the need for highly accurate and finely detailed metal parts has increased exponentially. Lasers can cut intricate patterns and micro-sized components used in printed circuit boards (PCBs), connectors, and semiconductor devices with extreme precision. This capability is especially vital in the production of smartphones, computers, and other consumer electronics that demand compact and reliable components. Furthermore, the non-contact nature of laser cutting ensures that the delicate electronic parts are not subjected to mechanical stress or contamination, thereby maintaining the integrity and performance of the final product. Consequently, laser metal cutting not only enhances productivity in the electronics industry but also pushes the boundaries of what is technically feasible in electronic design and functionality.

Laser metal cutting has become increasingly vital in the construction industry, offering unparalleled precision, efficiency, and versatility. The technology uses a high-powered laser beam to cut through various types of metals, allowing for intricate designs and complex structures to be realized with remarkable accuracy. In construction, this precision translates to fewer errors, reduced waste, and faster project completion times. Whether it’s for creating custom metal frameworks, decorative architectural elements, or specialized components, laser cutting enhances the quality and durability of structures. Additionally, the automation capabilities of modern laser cutting machinery mean that designs can be reproduced precisely, ensuring consistency in mass-produced elements like beams, panels, and brackets.

In the energy sector, laser metal cutting has similarly transformative applications. The industry often requires highly specialized components that must withstand extreme conditions, such as high temperatures and pressures. Laser cutting offers the precision necessary to manufacture these components with exacting standards, which is crucial for the efficiency and safety of energy production systems. For instance, parts for turbines, pipelines, and heat exchangers must be fabricated with minimal tolerances to ensure optimal performance. Furthermore, laser metal cutting is highly adaptable, capable of working with various metals including stainless steel, titanium, and specialized alloys, making it indispensable for renewable energy applications like wind turbines and solar panel frames. This advanced cutting technology not only accelerates the production process but also ensures the high quality and reliability essential for energy infrastructure.

The industrial equipment industry extensively employs laser metal cutting technology due to its precision, efficiency, and versatility. Laser cutting utilizes high-powered lasers to melt, burn, or vaporize material, producing intricate and high-quality cuts. This technology is pivotal in fabricating components for machinery, automotive parts, and aerospace equipment, ensuring tight tolerances and consistent quality. Unlike traditional mechanical cutting methods, laser cutting minimizes material waste and reduces the need for secondary finishing processes, thereby accelerating production timelines and lowering costs. The capability to handle a wide array of metals, including steel, aluminum, brass, and titanium, further enhances its applicability across diverse sectors within the industrial equipment industry.

Moreover, advancements in laser cutting technology, such as fiber lasers, have amplified the potential of this method. Fiber lasers offer higher efficiency, faster cutting speeds, and lower operational costs compared to CO2 lasers, making them suitable for large-scale industrial applications. The integration of automation and computer numerical control (CNC) systems with laser metal cutting machines has revolutionized production lines, enabling continuous operation, reduced human error, and increased throughput. Furthermore, the non-contact nature of laser cutting minimizes tool wear and maintenance, ensuring sustained precision over extended periods. As industries strive for higher productivity and superior quality, the adoption of laser metal cutting technologies continues to grow, underscoring its critical role in modern manufacturing ecosystems.

Laser metal cutting technology has significantly transformed the production of medical devices, offering precision and efficiency that traditional manufacturing techniques often struggle to match. This non-contact process employs focused laser beams to precisely cut and shape metal components with minimal thermal distortion, ensuring that the intricate designs required for medical instruments are achieved with high accuracy. From surgical instruments and orthopedic implants to tiny components in medical diagnostic equipment, laser cutting ensures the production of devices that meet stringent regulatory standards and perform reliably in critical healthcare settings. The ability to produce detailed and complex geometries with minimal margin of error is particularly invaluable in the medical field, where the quality and precision of instruments can directly impact patient outcomes.

Additionally, laser metal cutting streamlines the production process, reducing the time and labor costs associated with traditional machining methods. Due to its high degree of automation, laser cutting systems can operate continuously with minimal supervision, enabling manufacturers to achieve higher output rates while maintaining consistent quality. This efficiency is particularly beneficial for the mass production of disposable medical devices such as stents and catheters, which need to be manufactured quickly and cost-effectively. Furthermore, the technology’s versatility allows it to work with a wide range of biocompatible metals, thereby expanding the possibilities for innovation in medical device design and function. With the ongoing advancements in laser cutting technology, the medical device industry continues to evolve, driving improvements in patient care and surgical outcomes.

Laser metal cutting is a highly efficient technique widely utilized in the machining and manufacturing industries for its precision, versatility, and speed. The process involves directing a high-powered laser beam onto the metal surface to melt, burn, or vaporize the material, resulting in clean and precise cuts. This method is particularly advantageous for intricate and complex designs, allowing manufacturers to produce detailed components with minimal material wastage. Additionally, laser cutting is known for its non-contact nature, meaning there is no direct mechanical force exerted on the workpiece, which reduces the risk of material deformation and tool wear.

In manufacturing applications, laser metal cutting plays a pivotal role in industries ranging from automotive and aerospace to electronics and medical devices. It enables the production of vital parts with high accuracy and repeatability, enhancing both the quality and efficiency of the manufacturing process. For instance, in the automotive industry, laser cutting is employed to create intricate body parts and components, ensuring a perfect fit and finish. Similarly, in the electronics industry, this technology is crucial for cutting thin sheets and intricate patterns required for circuit boards. The versatility of laser metal cutting also extends to custom and prototype manufacturing, where quick adjustments and precise modifications are often necessary, demonstrating its indispensable role in modern industrial practices.

Sure! Here is a list of frequently asked questions (FAQ) with answers for manufacturing laser metal cutting quality work from SourcifyChina factory.

Q: What materials can SourcifyChina’s laser cutting process handle?

A: SourcifyChina’s laser cutting process can handle a wide range of materials, including stainless steel, carbon steel, aluminum, copper, brass, and other metals.

Q: What is the maximum thickness of metal that can be cut?

A: The capability of our laser cutting machinery allows us to cut metals up to a thickness of 20mm, depending on the type of metal being used.

Q: What tolerances can be expected with laser cutting from SourcifyChina?

A: Our high precision laser cutting technology typically offers tolerances within ±0.1mm, ensuring high accuracy and quality.

Q: How does SourcifyChina ensure the quality of the laser-cut parts?

A: We implement a rigorous Quality Control (QC) process that includes inspecting raw materials, monitoring the cutting process, and conducting a final inspection of the finished parts to ensure they meet the specified requirements.

Q: Can SourcifyChina handle large volume orders?

A: Yes, SourcifyChina is equipped with advanced laser cutting machines and a skilled workforce, allowing us to handle both small and large volume production efficiently.

Q: What is the typical lead time for an order?

A: The lead time varies based on the complexity and volume of the order, but our standard turnaround time is usually between 7 to 14 days.

Q: Can you provide custom designs and prototypes?

A: Absolutely, we offer custom design services and can produce prototypes based on your specifications to ensure the final product meets your expectations.

Q: What file formats do you accept for design submissions?

A: We accept a variety of file formats including DXF, DWG, AI, PDF, and others. If you’re unsure, our team can assist you in preparing the right format.

Q: What industries does SourcifyChina serve?

A: SourcifyChina serves a wide range of industries including automotive, aerospace, electronics, construction, and more.

Q: How can I request a quote?

A: To request a quote, you can visit our website and fill out the online form or contact our customer service team directly with your project details.

When considering laser metal cutting from SourcifyChina factory, several vital tips can optimize your manufacturing experience:

1. Understand Your Needs: Clarify the type and thickness of the metals you need to cut. This helps in selecting the appropriate laser cutting technology (fiber or CO2 lasers) and settings.

2. Material Quality: Ensure the metal sheets provided meet industry standards. Impurities in metals can lead to suboptimal cutting quality.

3. Customized Solutions: Discuss any specific design requirements or intricate patterns with SourcifyChina. Their experts can adjust the laser intensity and pace for precision and efficiency.

4. Production Volume: Communicate your projected order volumes clearly. This helps SourcifyChina prepare adequately, ensuring timely delivery without compromising quality.

5. Prototyping Services: Take advantage of prototype options before committing to large orders. This helps in validating designs and making necessary adjustments early.

6. Technological Proficiency: SourcifyChina employs advanced CNC (Computer Numerical Control) laser cutting machines, which offer high precision. Ensure their technology aligns with your project requirements.

7. Surface Finish: Specify any post-cutting finishes (like deburring, polishing) needed for your components. This ensures parts are ready for immediate use or further processing.

8. Quality Control: Confirm the factory’s quality control processes, such as regular inspections and strict adherence to tolerances.

9. Cost Transparency: Ensure you understand the pricing structure, which may include setup fees, material costs, cutting charges, and any additional finishes or services.

10. Lead Times and Logistics: Discuss lead times in advance and consider logistics. Reliable delivery schedules can prevent production downtimes at your end.

11. Sustainability: Ask about the factory’s environmental policies, especially recycling practices and energy efficiency, to align with your company’s sustainability goals.

These tips help ensure a seamless and efficient collaboration with SourcifyChina for your laser metal cutting needs.

Q: What is the minimum order quantity (MOQ) for laser metal cutting services from SourcifyChina factory?

A: The minimum order quantity for laser metal cutting services at SourcifyChina factory is typically 50 pieces. However, this may vary depending on the specific project requirements.

Q: What types of metals can SourcifyChina factory cut using lasers?

A: SourcifyChina factory can cut a wide range of metals including stainless steel, aluminum, carbon steel, and brass. They are equipped to handle different thicknesses and material grades.

Q: How precise is the laser cutting process at SourcifyChina factory?

A: The laser cutting process at SourcifyChina factory is highly precise, with tolerances up to ±0.1mm, ensuring high-quality and accurate cuts for each project.

Q: What is the lead time for laser metal cutting orders?

A: The lead time for laser metal cutting orders at SourcifyChina factory typically ranges from 7 to 15 days, depending on the complexity and volume of the order. Rush orders may be accommodated upon request.

Q: Can SourcifyChina factory handle custom designs?

A: Yes, SourcifyChina factory specializes in custom designs. Clients can submit their CAD or DXF files, and the factory will work closely with them to meet their specific requirements.

Q: Does SourcifyChina factory offer additional finishing services?

A: Yes, SourcifyChina factory provides additional finishing services such as powder coating, anodizing, and polishing, ensuring a complete end-to-end solution for their clients.

Q: What quality control measures are in place at SourcifyChina factory?

A: SourcifyChina factory has stringent quality control measures, including thorough inspections at each stage of the production process, to ensure that all products meet the highest standards.

Q: How can I get a quote for my laser metal cutting project?

A: To get a quote, you can visit the SourcifyChina factory website and submit your project details through their RFQ (Request for Quote) form. Alternatively, you can contact their customer service directly via email.

Sourcing laser metal cutting services from a factory in China, such as SourcifyChina, can be streamlined by following these tips:

1. Define Your Requirements: Outline the specifics of your project, including material type, thickness, design intricacies, and volume.

2. Research and Shortlist: Use platforms like Alibaba, Global Sources, and Made-in-China to identify potential suppliers. Focus on those that specialize in laser metal cutting and have verified credentials.

3. Check Credentials: Ensure the factory has relevant certifications such as ISO 9001 for quality management and CE for compliance with European standards.

4. Request Samples: Ask for samples to evaluate the factory’s cutting quality, precision, and finishing. This will provide a tangible benchmark for assessing their capabilities.

5. Assess Equipment: Verify the factory’s machinery and technology. Modern, well-maintained equipment often translates to better precision and efficiency.

6. Communication: Maintain clear and consistent communication. Language barriers can lead to misunderstandings, so be explicit about your needs and confirm details in writing.

7. Compare Quotes: Obtain detailed quotes from multiple suppliers. Ensure that the quotes include all aspects of the service, such as setup fees, cutting costs, finishing, and shipping.

8. Visit the Factory: If feasible, a visit to the factory can provide insights into their operations, quality control processes, and production capacity.

9. Quality Control: Establish a robust QC process. This might include third-party inspections to ensure that each batch meets your standards.

10. Payment Terms: Negotiate favorable and secure payment terms. A common practice is a deposit upfront with the balance paid after final inspection.

11. Logistics and Shipping: Coordinate with the factory on packaging and shipping. Ensure they have experience in international logistics to avoid delays and damages.

By methodically addressing these aspects, you can effectively source high-quality laser metal cutting services from SourcifyChina or any comparable factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.