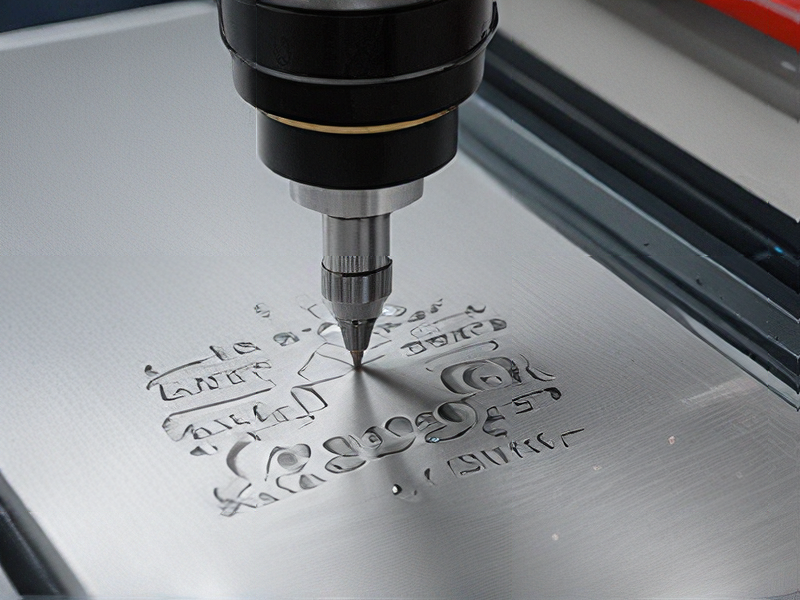

Technology and Applications of laser metal engraving machine

Laser metal engraving machines utilize focused laser beams to etch or engrave designs, patterns, or text onto metal surfaces. These machines are highly versatile and find applications across various industries:

1. Precision Engraving: Laser machines offer high precision, allowing intricate designs with fine details to be engraved on metals like steel, aluminum, brass, and titanium. This precision is crucial in industries such as jewelry making, firearms manufacturing, and aerospace.

2. Versatility: They can engrave on flat, curved, or irregular surfaces, making them suitable for engraving on tools, medical instruments, and automotive parts.

3. Speed and Efficiency: Laser engraving is faster compared to traditional methods like mechanical engraving. It reduces production time and allows for mass customization.

4. Non-contact Process: Unlike mechanical methods, laser engraving is a non-contact process, which reduces wear and tear on the equipment and minimizes the risk of damage to delicate materials.

5. Wide Range of Applications: Apart from industrial uses, laser engraving machines are also used in personalization services for items like awards, gifts, and promotional items.

6. Customization: They enable easy customization by engraving serial numbers, logos, and barcodes on metal components, facilitating traceability and branding.

7. Automation and Integration: Laser engraving machines can be integrated into automated production lines, enhancing productivity and consistency in output.

8. Environmental Considerations: Laser engraving is a clean process that produces minimal waste and emissions, aligning with environmental regulations and sustainability goals.

Overall, laser metal engraving machines combine precision, speed, and versatility, making them indispensable tools across industries where detailed and durable engraving on metal surfaces is required.

Quality Testing Methods for laser metal engraving machine and how to control quality

Quality testing for laser metal engraving machines involves several methods to ensure precision, durability, and consistency:

1. Visual Inspection:

– Magnification Tools: Use microscopes or magnifying glasses to check for engraving accuracy, edge quality, and any surface imperfections.

– Surface Finish: Evaluate the smoothness and consistency of the engraved surface.

2. Dimensional Accuracy:

– Calipers and Micrometers: Measure the depth, width, and overall dimensions of the engraving to ensure they meet specifications.

– Coordinate Measuring Machines (CMM): Provide precise 3D measurements of the engraved features.

3. Material Analysis:

– Hardness Testing: Check the hardness of the engraved area to ensure the material properties are intact.

– Microstructural Analysis: Use metallographic techniques to examine any changes in the metal’s microstructure.

4. Surface Roughness Measurement:

– Profilometers: Measure the surface roughness to ensure a smooth finish, important for both aesthetic and functional purposes.

5. Adherence Testing:

– Tape Test: Apply and remove adhesive tape to check if the engraving adheres properly without chipping or peeling.

– Environmental Testing: Expose samples to temperature, humidity, and corrosion conditions to test durability.

Quality Control Methods

1. Standard Operating Procedures (SOPs):

– Develop and follow detailed SOPs for machine operation, material handling, and post-processing to maintain consistency.

2. Calibration and Maintenance:

– Regularly calibrate the laser machine and maintain it according to the manufacturer’s guidelines to ensure optimal performance.

3. Training and Certification:

– Ensure operators are well-trained and certified to handle the equipment and interpret results accurately.

4. Statistical Process Control (SPC):

– Implement SPC techniques to monitor and control the engraving process. Use control charts to detect and address any process variations.

5. Documentation and Traceability:

– Keep detailed records of all processes, inspections, and maintenance activities for traceability and continuous improvement.

By combining these testing and control methods, manufacturers can ensure the quality and reliability of laser metal engravings.

Tips for Procurement and Considerations when Purchasing from laser metal engraving machine

When purchasing a laser metal engraving machine, several key considerations can help ensure you make an informed procurement decision:

1. Laser Type and Power: Determine the laser type (CO2, fiber, or others) based on the materials you’ll engrave. Fiber lasers are excellent for metals due to their high power and precision.

2. Engraving Area and Size: Evaluate the machine’s bed size to ensure it accommodates the dimensions of the items you intend to engrave. This impacts production efficiency and versatility.

3. Accuracy and Resolution: Look for machines with high-resolution capabilities for intricate designs and fine details. Accuracy in engraving depth and positioning is crucial for quality output.

4. Speed and Productivity: Consider the machine’s engraving speed, as it directly affects production throughput. Balance speed requirements with engraving quality.

5. Software and Compatibility: Check the compatibility of the machine with design software you currently use or plan to use. User-friendly software can streamline workflow and training.

6. Maintenance and Support: Investigate the manufacturer’s reputation for reliability and the availability of technical support, including training and servicing.

7. Safety Features: Ensure the machine meets safety standards and includes features like enclosures, interlocks, and exhaust systems for fume management, especially important in enclosed environments.

8. Cost and ROI: Evaluate the initial cost alongside long-term benefits and return on investment (ROI) based on expected productivity gains and reduced operational costs.

9. User Feedback and Reviews: Read reviews from other users to gauge reliability, performance, and customer support experiences.

10. Training and Integration: Plan for operator training and integration into your current production processes to maximize efficiency and minimize downtime.

By considering these factors, you can select a laser metal engraving machine that meets your operational needs, enhances productivity, and delivers high-quality results consistently.

FAQs on Sourcing and Manufacturing from laser metal engraving machine in China

Certainly! Here are some FAQs regarding sourcing and manufacturing from laser metal engraving machines in China:

1. What are the typical lead times for laser metal engraving machines from China?

Lead times vary based on specifications and manufacturers but generally range from 2 to 6 weeks for standard models. Customized machines may take longer.

2. What quality standards should I expect from Chinese manufacturers?

Reputable manufacturers adhere to international quality standards such as ISO 9001. It’s advisable to request samples and visit facilities if possible to ensure quality.

3. How can I ensure product reliability and performance?

Conduct thorough due diligence on manufacturers by checking customer reviews, requesting references, and possibly hiring a third-party inspection service.

4. What are the typical payment terms?

Payment terms usually involve a deposit (30-50%) with the balance due upon shipment or upon receipt of goods. Secure payment methods like letters of credit are advisable.

5. Are there import duties or regulations to consider?

Yes, import duties, taxes, and regulatory compliance (e.g., CE certification) should be factored into your budget and planning. Work with a freight forwarder for guidance.

6. What after-sales support can I expect?

Reliable manufacturers offer warranties and technical support. Clarify terms of warranty, return policies, and availability of spare parts before purchasing.

7. How can I communicate effectively with Chinese manufacturers?

Clear communication is crucial. Use translators if necessary, maintain detailed written records, and establish a single point of contact for streamlined communication.

Navigating the sourcing and manufacturing process in China requires careful planning and due diligence to ensure quality, reliability, and compliance with international standards.