Reliable Source for Quality Lathe Parts: Partner with SourcifyChina for Your Factory Needs

Looking for dependable lathe parts for your factory? Discover the reliability and excellence of SourcifyChina, your trusted source for high-quality machining components. Ensure seamless production with precision-engineered parts tailored to meet your specific requirements.

SourcifyChina Factory offers unrivaled expertise in the production of high-quality lathe parts. With advanced technology and stringent quality control measures, they ensure each part meets international standards, providing reliability and durability for various industrial applications.

Choosing SourcifyChina Factory means benefiting from competitive pricing without compromising on quality. Their efficient manufacturing processes and bulk production capabilities help in reducing costs, ensuring affordability for buyers without sacrificing product integrity.

Customer satisfaction is a priority at SourcifyChina Factory. They offer excellent customer service, ensuring timely responses to inquiries, transparent communication throughout the purchasing process, and post-sale support, making the entire experience seamless and efficient.

By partnering with SourcifyChina Factory, buyers gain access to a wide range of customizable lathe parts. Their engineering team can adapt and innovate designs to meet specific requirements, providing solutions tailored to each client’s unique needs and project demands.

Logistics and delivery are handled proficiently by SourcifyChina Factory. They have robust arrangements with leading shipping companies, ensuring timely and safe delivery of lathe parts to any location across the globe, allowing buyers to focus on their core business operations.

SourcifyChina’s commitment extends beyond just providing lathe parts. Their sustainable manufacturing practices, compliance with ethical standards, and continuous efforts in improving their environmental impact reflect a responsible corporate ethos, which buyers can confidently support.

For buyers seeking reliable, high-quality, and cost-effective lathe parts from China, SourcifyChina Factory stands as the optimal choice. With a blend of expertise, customer-centric services, competitive pricing, and commitment to sustainability, they ensure a superior purchasing experience tailored to the needs of every client.

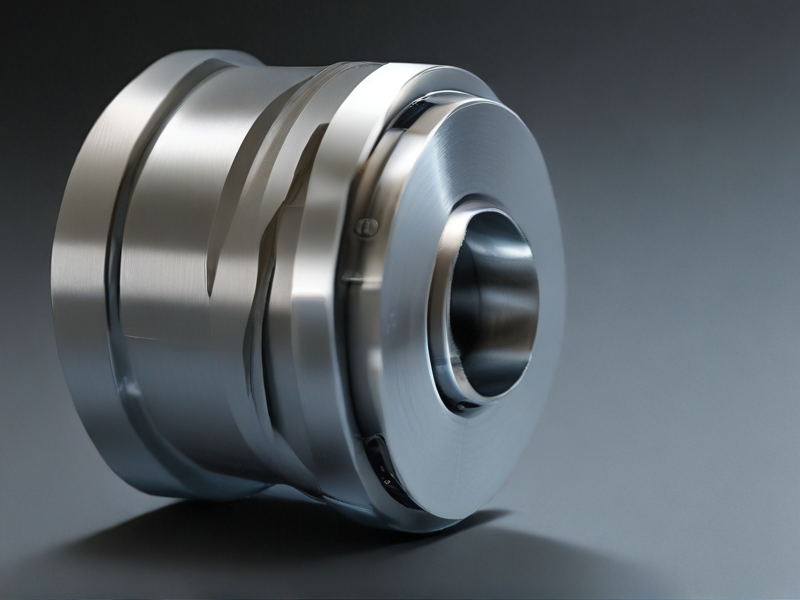

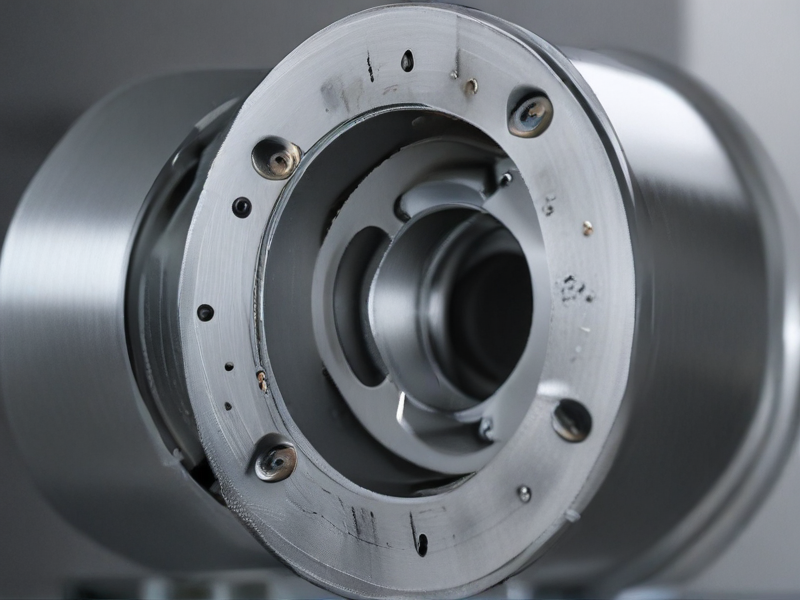

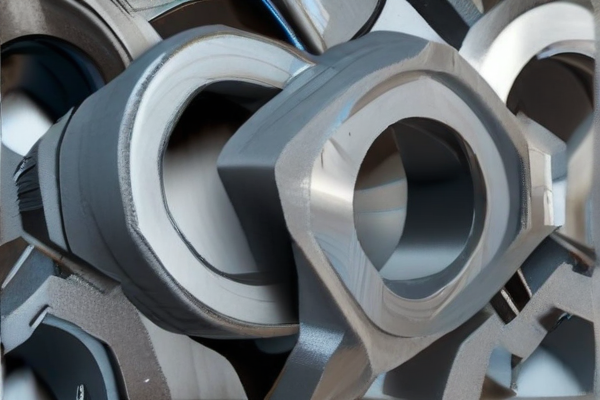

A lathe part refers to any of the components used within a lathe machine, vital for turning operations. Different types of lathe parts enable various functions crucial for precise machining tasks.

– Headstock: Houses the spindle and motor that drive the workpiece.

– Tailstock: Supports the other end of the workpiece, often fitted with a center or tooling.

– Carriage: Moves the cutting tool along the workpiece, includes apron, saddle, and cross-slide.

– Tool Post: Holds the cutting tool securely in place.

– Chuck: Clamps the workpiece to the spindle, options include three-jaw, four-jaw, and collet chucks.

– Faceplate: Attaches large or irregularly shaped workpieces.

– Steady Rest: Provides additional support for long workpieces during machining.

– Follow Rest: Travels with the carriage to support long or slender workpieces.

– Lead Screw: Drives the carriage for threading operations.

– Feed Shaft: Powers the carriage for regular cutting operations.

– Compound Rest: Allows for angled cuts and precision machining.

– Apron: Contains the control mechanisms and gears for carriage movement.

– Bed: The main frame supporting all components and ensuring stability.

– Lathe Centers: Align and support the workpiece at each end.

– Back Gear: Reduces spindle speed for high-torque applications.

Lathe parts are essential for diverse machining tasks, each tailored for specific functions, accuracy, and efficiency in turning operations.

Lathe parts are essential components in various industries for shaping, cutting, and forming materials with high precision and efficiency. They are critical in manufacturing operations.

– Aerospace Industry: Creating precise components for aircraft and space exploration.

– Automotive Industry: Producing engine parts, gear components, and other critical elements.

– Medical Sector: Crafting surgical tools, prosthetic parts, and dental implants.

– Woodworking: Shaping intricate designs and components in furniture making.

– Metalworking: Forming complex shapes and intricate designs in different metal types.

– Jewelry Making: Crafting detailed and small-scale components with precision.

– Oil and Gas Industry: Manufacturing parts for drilling equipment and pipelines.

– Electronics: Producing precise components for devices and circuit boards.

– Military: Crafting high-precision components for weapons and defense equipment.

– Robotics: Creating parts for high-functioning robotic arms and machinery.

SourcifyChina offers premium lathe parts made from robust materials to ensure durability and performance. Each component is designed to meet high standards of precision and efficiency.

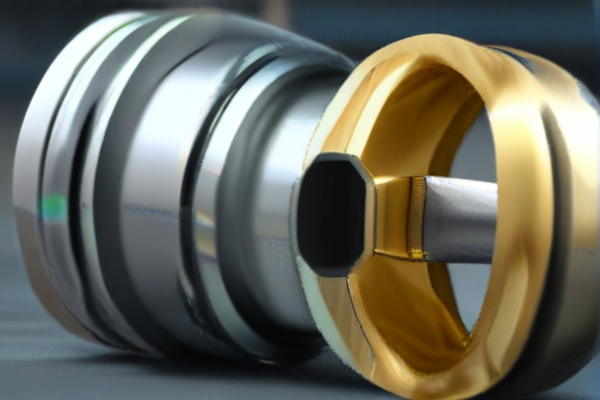

The most common material used is high-speed steel (HSS), known for its excellent cutting capabilities and resistance to wear. HSS ensures long service life and reliability, even under extreme operating conditions.

Another crucial material is carbide-tipped steel. This blend provides enhanced hardness and thermal resistance, making it ideal for machining tough materials. It helps in achieving smoother finishes and superior accuracy in the final product.

Stainless steel is also frequently utilized, prized for its corrosion resistance and strength. This material ensures the components can withstand harsh environments, extending the lifespan of the lathe parts.

SourcifyChina’s adoption of aluminum alloys offers a balance of strength and lightweight properties. These alloys enhance the performance of components without adding unnecessary weight, crucial for high-speed operations.

In summary, SourcifyChina utilizes a variety of high-quality materials, including high-speed steel, carbide-tipped steel, stainless steel, and aluminum alloys. Each material is carefully chosen to meet specific machining requirements, ensuring top-notch performance and longevity of lathe parts.

SourcifyChina places high emphasis on quality control in the manufacturing of lathe parts. The process begins with rigorous selection of raw materials to ensure durability and performance. Each material undergoes a strict inspection to meet predefined standards.

Machining operations are undertaken by highly skilled technicians using state-of-the-art CNC machines. Precise measurements and tolerances are maintained to guarantee the accuracy and consistency of each lathe part produced. Real-time monitoring helps identify and correct deviations immediately.

Furthermore, SourcifyChina employs a multi-stage inspection protocol to maintain quality. This includes first-article, in-process, and final inspections. Sophisticated metrology tools like CMM (Coordinate Measuring Machines) and gauges are utilized to verify dimensional accuracy.

To ensure long-term functionality, all lathe parts undergo stress testing and surface finishing assessments. These tests evaluate the parts’ endurance under various operational conditions, checking for deformities, fatigue, or surface imperfections.

SourcifyChina also incorporates feedback loops from both internal audits and customer feedback to continually improve their quality control processes. Every detail, from packaging to delivery, is subjected to meticulous scrutiny to ensure the product arrives in optimal condition.

In addition, the company keeps its workforce updated with ongoing training programs that emphasize the latest quality control practices and industry standards. This ensures that every employee understands the critical nature of their role in the quality assurance process.

Customer satisfaction is paramount for SourcifyChina. By adhering to stringent quality control measures throughout the manufacturing process, they aim to deliver lathe parts that meet and exceed customer expectations, fostering trust and long-term relationships.

SourcifyChina stands out in the industry for its exceptional lathe part capabilities. Its cutting-edge technology ensures high precision and consistency in manufacturing, catering to diverse industrial needs with efficacy.

With a highly skilled workforce, SourcifyChina excels in producing intricate lathe parts. Their expertise extends to complex geometries and tight tolerances, meeting rigorous industry standards and specifications without sacrificing quality.

Leveraging state-of-the-art machinery, SourcifyChina offers scalable production solutions. Whether it’s a prototype or large-scale manufacturing, they ensure timely delivery and adherence to client requirements, reflecting their commitment to excellence.

Customer satisfaction is paramount at SourcifyChina. They maintain stringent quality control measures and provide comprehensive support, ensuring that every lathe part meets the highest benchmarks, fostering long-term partnerships.

A lathe part plays a crucial role in various machining operations, offering precision, efficiency, and versatility. Here are some key benefits:

– Precision: Provides high accuracy in shaping and cutting materials.

– Versatility: Suitable for turning, knurling, drilling, and threading.

– Efficiency: Increases productivity with quicker setup times.

– Durability: Made from robust materials to withstand heavy use.

– Consistency: Ensures uniformity in mass production.

– Cost-effective: Reduces operational costs through enhanced performance.

– Customization: Allows for tailored designs to meet specific requirements.

– Ease of Use: User-friendly interfaces reduce the learning curve.

– Safety: Modern lathes incorporate advanced safety features.

– Maintenance: Requires minimal upkeep, extending lifespan.

Overall, a lathe part significantly enhances the quality and efficiency of manufacturing processes, making it indispensable in modern machining.

A lathe is a versatile machine tool used in metalworking, woodworking, and other sectors for shaping materials. Some of the key features of a lathe include:

– Bed: The foundation of the lathe, providing stability and support for the entire assembly.

– Headstock: Attached to the bed, it holds the spindle and drive mechanisms.

– Tailstock: Positioned opposite the headstock, it can support long workpieces and hold tools.

– Carriage: Moves along the bed and holds the cutting tools.

– Spindle: Rotates the workpiece, driven by the motor.

– Feed Mechanisms: Control the movement of the carriage.

– Tool Post: Holds and positions the cutting tools.

– Chuck: Clamps the material being machined.

– Lead Screw: Facilitates precise movement of the carriage for threads.

– Compound Rest: Adjustable platform for holding tools at precise angles.

SourcifyChina offers specialized lathe parts for a variety of custom products and projects. Leveraging cutting-edge technology and industry expertise, the company provides precision-machined components tailored to meet diverse industrial needs. Each part undergoes rigorous quality checks to ensure durability and high performance, catering to sectors such as automotive, aerospace, and manufacturing.

Clients can rely on SourcifyChina for fast turnaround times and cost-effective solutions, thanks to their efficient supply chain management and established partnerships with reliable manufacturers. The team’s commitment to excellence ensures that each project is delivered within the stipulated timeframe and budget.

Customization options are extensive, allowing clients to specify their exact requirements down to the finest detail. Whether it’s a unique prototype or a mass-production run, the company adapts its processes to meet client expectations. This flexibility ensures optimal functionality and compatibility with existing machinery and systems.

SourcifyChina’s customer service is top-notch, offering continuous support throughout the design, production, and delivery phases. Client feedback is highly valued, and continuous improvements are made to enhance service quality. By prioritizing client satisfaction, SourcifyChina builds long-term relationships and fosters loyalty.

Overall, SourcifyChina stands out as a trusted provider of custom lathe parts, excelling in quality, precision, and customer service. Their comprehensive approach ensures that every project, regardless of size or complexity, meets the client’s exact specifications and exceeds expectations.

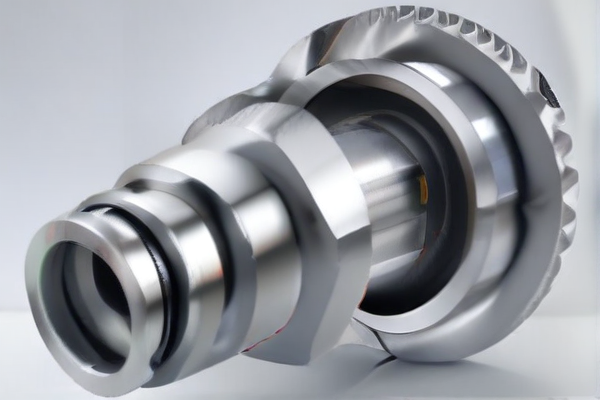

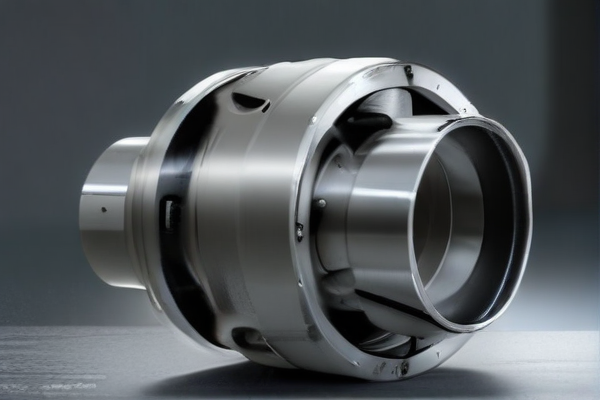

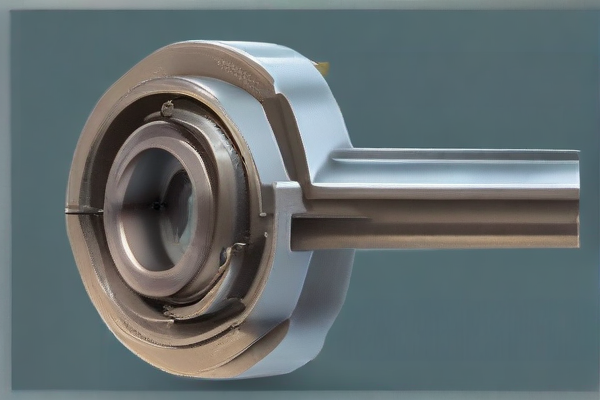

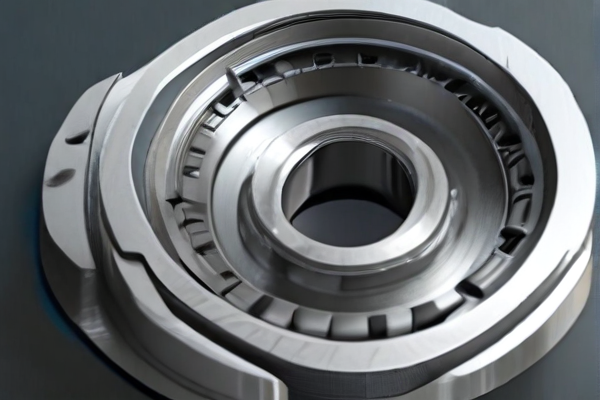

SourcifyChina is a distinguished company specializing in the production and supply of high-quality lathe parts tailored to meet the diverse needs of industries worldwide. With a strong emphasis on precision engineering and durability, the company has solidified its reputation as a reliable partner for businesses seeking robust lathe components. SourcifyChina combines state-of-the-art manufacturing techniques with stringent quality control processes to ensure each part meets the highest standards of performance and reliability. Their product range includes an extensive array of lathe parts such as chucks, spindles, gears, and tool holders, all meticulously crafted to enhance the efficiency and longevity of lathe machines. Catering to both small enterprises and large-scale industrial operations, SourcifyChina offers customized solutions that align with specific technical requirements and operational demands. Furthermore, the company’s customer-centric approach, underscored by responsive support and timely delivery, has earned it a loyal clientele across various sectors. As a forward-thinking entity, SourcifyChina is continually investing in research and development to innovate and expand its product offerings, ensuring they remain at the forefront of the industry.

In the aerospace industry, lathe parts play a crucial role in the manufacturing and maintenance of various components such as engine parts, landing gear, and structural components. Precision is paramount in aerospace applications, and lathe machines are specifically engineered to meet the high tolerance levels required. For instance, turbine shafts and other rotating components must adhere to stringent specifications to ensure optimal performance and safety. The materials used, such as titanium and high-strength aluminum alloys, are carefully selected for their strength-to-weight ratios, and lathes equipped with advanced CNC (Computer Numerical Control) technology enable the precise machining of these materials to achieve the desired specifications.

In the defense sector, lathe parts are integral to the production of weaponry, vehicles, and support equipment. Components like gun barrels, missile casings, and various fittings used in armored vehicles undergo lathe machining to attain the necessary durability and precision. The rigorous demands of military applications necessitate that lathe parts are produced to withstand extreme conditions, including high pressures, temperatures, and mechanical stresses. Similarly, in marine applications, lathe parts are used in the construction and maintenance of ship components, such as propeller shafts, engine parts, and drive systems. The marine environment requires materials that can resist corrosion and wear, often achieved through precision machining and the use of specialized alloys. Overall, the versatility and precision of lathe machines make them indispensable across these high-stakes industries.

In the automotive industry, lathe parts play a critical role in the development and manufacture of essential components such as engine parts, drive shafts, and brake drums. The precision and consistency afforded by CNC (Computer Numerical Control) lathes allow for the creation of intricate geometries and tight tolerances required in high-performance automotive components. For instance, crankshafts and camshafts, which are pivotal in converting linear motion to rotational motion and optimizing airflow in combustion engines respectively, are typically fabricated using lathes. The reliability of these lathe-manufactured parts ensures the smooth operation and longevity of vehicles, directly contributing to the overall performance, safety, and efficiency of modern automobiles.

In the electronics industry, lathe parts are indispensable in the production of various hardware components including connectors, insulators, and enclosures. High-precision lathes are used to machine components from materials such as aluminum, brass, and plastic, which are integral to maintaining the functionality and integrity of electronic devices. For example, connector pins and sockets, which are vital for establishing electrical connections in devices like smartphones, computers, and industrial machines, are often turned on precision lathes. The capability to produce extremely fine and accurate parts is essential in the densely packed configurations of contemporary electronics, where space is at a premium and minuscule errors can lead to significant performance degradation. As technology advances, the demand for precise lathe parts in electronics continues to grow, underscoring their significance in modern manufacturing.

A lathe part is fundamental in the construction industry due to its precision and versatility in shaping materials. Construction projects often require metal or wooden components with exact specifications to ensure structural integrity and uniformity. Lathe machines, equipped with varying lathe parts, come into play by meticulously shaping and resizing materials such as steel, aluminum, or timber. For instance, crafting custom bolts, screws, and other fasteners is expedited and simplified by the lathe’s ability to turn materials to precise diameters and thread patterns, thus ensuring secure connections in construction frameworks. Additionally, lathe parts enhance the fabrication of architectural details like railings, columns, and decorative moldings, which demand intricacy and exactitude to meet design blueprints. The precision offered by lathe parts thereby underpins the reliability and aesthetic quality of construction projects.

In the realm of energy applications, lathe parts are indispensable for manufacturing components that ensure the efficient operation of energy systems. The energy sector encompasses a variety of machinery and infrastructure, from wind turbines to nuclear reactors, necessitating high-precision parts for optimal performance. For example, the rotors and shafts in wind turbines require accurate machining to ensure they can withstand high rotational speeds and mechanical stress. Lathe machines, utilizing different lathe parts, facilitate the production of these components by enabling tight tolerances and smooth finishes that reduce friction and wear. Similarly, in the production of piping systems for oil and gas, lathe parts are employed to create fittings and connectors with exact diameters and thread patterns, ensuring leak-proof and enduring joints. By delivering high-precision outcomes, lathe parts contribute significantly to the durability, efficiency, and safety of energy-producing and -transporting equipment, thus playing a critical role in sustaining the global energy supply.

The industrial equipment industry heavily relies on lathe parts due to their precision and versatility in shaping various materials. Lathes, which rotate a workpiece on its axis to perform operations such as cutting, sanding, drilling, and deformation, are fundamental in the manufacturing of complex components. These parts are integral in producing high-quality machined items with consistent dimensions and surface finishes—a necessity in sectors such as automotive, aerospace, and heavy machinery. The accuracy with which lathe parts can create threads, contours, and cylindrical shapes ensures that components meet stringent specifications, enhancing overall product performance and reliability. Additionally, advancements in CNC (Computer Numerical Control) technology have further amplified the capabilities of lathes, allowing for the production of intricate parts with minimal human intervention, thus increasing efficiency and reducing the risk of errors.

Beyond precision, the versatility of lathe parts is another key factor contributing to their widespread application in the industrial equipment industry. Lathes can handle a myriad of materials, including metals, plastics, and wood, making them indispensable in the fabrication of both prototype and mass-produced parts. For example, in the automotive industry, lathe parts are used to manufacture engine components, transmission systems, and braking mechanisms, all of which require high tolerance levels. In the aerospace industry, lathes are crucial for crafting turbine blades and landing gear parts, which must endure extreme conditions. The ability to quickly switch among different operations and material types not only streamlines production processes but also facilitates innovation, enabling manufacturers to experiment with new designs and materials. Consequently, the application of lathe parts in the industrial equipment industry is both broad and essential, driving advancements and maintaining high standards across various fields.

Lathe parts play a crucial role in the manufacturing of medical devices, serving as fundamental components that ensure high precision and rigorous standards required in the medical field. The versatility and accuracy of lathes make them ideal for creating intricate parts for devices such as orthopedic implants, surgical instruments, and diagnostic equipment. Given the demanding nature of medical applications, the components machined on a lathe must adhere to stringent tolerances and exacting specifications to ensure patient safety and device functionality. Materials like titanium, stainless steel, and high-grade polymers are often utilized in lathe operations to produce durable and biocompatible parts.

In addition to their precision, lathe parts offer the flexibility needed to meet the diverse requirements of the medical industry. Lathes can perform various machining operations such as turning, threading, drilling, and knurling, enabling the production of complex geometries and fine details necessary for advanced medical devices. For example, in the fabrication of bone screws and dental implants, the finely threaded components produced by a lathe are essential for achieving secure and stable fixation within the body. Similarly, surgical instruments like scalpels and forceps benefit from the rigidity and sharpness that can be consistently reproduced through lathe machining. As medical technology continues to advance, the role of lathes in the creation of precise, reliable, and innovative medical devices remains indispensable.

Lathe machinery plays a pivotal role in the machining and manufacturing sectors, primarily due to its versatility and precision. A lathe is ingeniously designed to rotate a workpiece along its axis while various cutting tools shape it to the desired specifications. This fundamental process, known as turning, is essential for creating cylindrical objects such as shafts, bolts, and bushings. Lathes can handle a myriad of materials, including metals, plastics, and wood, making them indispensable in sectors ranging from automotive to aerospace. They allow for the production of high-tolerance and intricate parts with smooth finishes, ensuring products meet stringent quality standards. Moreover, the advent of Computer Numerical Control (CNC) lathes has dramatically enhanced production capabilities, enabling automated, precise, and repeatable operations that significantly boost productivity and efficiency.

In the broader context of manufacturing, lathe parts are integral to both custom and mass production environments. Custom manufacturing often requires the creation of unique, one-off components tailored to specific applications. Here, the adaptability of lathes allows for quick and accurate production, even for complex geometries. In contrast, mass production settings benefit from the consistency and speed of CNC lathes, where large volumes of uniform parts are needed. These machines reduce cycle times and minimize human error, thus lowering production costs and ensuring rapid turnaround. From the small machine shops to large-scale production plants, the application of lathe parts is crucial for maintaining competitive edge and innovation. By providing the capability to efficiently produce durable and precise components, lathes continue to be a cornerstone of modern machining and manufacturing industries.

FAQ for Manufacturing Lathe Part Quality Work from SourcifyChina Factory

Q1: What materials can SourcifyChina work with for lathe parts?

A1: SourcifyChina specializes in machining a variety of materials, including but not limited to, aluminum, stainless steel, brass, and plastics. Our expertise ensures the highest quality output regardless of the material used.

Q2: What is the typical lead time for an order?

A2: Lead times vary depending on the complexity and quantity of the order. Standard lead times are typically 2-4 weeks. For urgent requirements, expedited services are available upon request.

Q3: How do you ensure the quality of lathe parts?

A3: Quality assurance is achieved through a combination of experienced personnel, state-of-the-art machinery, and rigorous inspection protocols. Each part undergoes thorough inspections, including dimensional checks and surface finish evaluations.

Q4: Can I get a prototype before mass production?

A4: Yes, SourcifyChina offers prototyping services to validate designs before proceeding to mass production. This service helps to identify and resolve potential issues early in the manufacturing process.

Q5: What are the communication channels available for customer support?

A5: Customers can reach out through multiple channels including email, phone, and live chat on our website. Additionally, a dedicated project manager is assigned to each client to ensure seamless communication and coordination.

Q6: Do you offer finishing services for lathe parts?

A6: Absolutely. SourcifyChina provides various finishing services such as anodizing, powder coating, and polishing to meet the specific requirements of each project.

Q7: Is there a minimum order quantity (MOQ)?

A7: The minimum order quantity depends on the specific part and material used. However, SourcifyChina is flexible and willing to work with clients on both small and large projects.

Q8: What is the process for getting a quote?

A8: To get a quote, simply provide detailed drawings or specifications of the part via our website or email. Our team will review the details and respond with a comprehensive quote within 48 hours.

Q9: How does SourcifyChina handle confidentiality of designs?

A9: We take confidentiality very seriously. Non-disclosure agreements (NDAs) are signed to protect client designs and proprietary information.

Certainly! If you’re considering manufacturing lathe parts at SourcifyChina factory, here are some key tips to ensure a successful partnership:

1. Detailed Specifications: Provide comprehensive design files, including CAD drawings and material specifications. Clear details prevent manufacturing errors.

2. Prototype Agreement: Start with a prototype or a small batch to verify quality before committing to large-scale production. This helps to identify any necessary adjustments early.

3. Material Selection: Discuss material options with the factory. Select materials that offer the right balance between cost, durability, and performance for your application.

4. Quality Control: Implement stringent quality control measures. Request in-process inspections and final product quality checks to ensure standards are met.

5. CNC Precision: Ensure the factory utilizes advanced CNC technology. High-precision machines allow for consistent and accurate output, reducing waste and rework.

6. Communication: Maintain open lines of communication with the factory managers. Regular updates on production status help address issues promptly.

7. Lead Time: Clarify lead times for production and shipping. Build in some buffer time to account for potential delays in the manufacturing process.

8. Cost Estimates: Get a detailed cost breakdown, considering all factors including raw materials, machining time, labor, and finishing processes.

9. Compliance: Ensure that the factory complies with relevant industry standards (ISO, CE) and follows environmental regulations.

10. Customization and Flexibility: Discuss the potential for custom solutions. SourcifyChina may offer flexible options tailored to your specific needs.

11. After-Sales Support: Inquire about support services post-delivery. Quality after-sales service can address any defects or issues that arise after receipt.

Building a robust relationship with SourcifyChina factory, coupled with thorough planning and clear communication, will enhance your experience and ensure the success of your lathe part manufacturing projects.

Sure, here are some frequently asked questions (FAQ) with answers regarding sourcing lathe parts from SourcifyChina factory:

Q: What types of lathe parts does SourcifyChina factory supply?

A: SourcifyChina provides a wide range of lathe parts including but not limited to chuck jaws, tool posts, tailstocks, drive belts, gears, and precision components made from various materials such as steel, aluminum, and brass.

Q: How can I get a quotation for lathe parts?

A: To get a quotation, visit the SourcifyChina website and fill out the request form with detailed specifications, including material, dimensions, tolerances, and quantity. Alternatively, you can email or call their sales team for a customized quote.

Q: What is the minimum order quantity (MOQ) for lathe parts from SourcifyChina?

A: The MOQ varies depending on the part type and complexity. Generally, the minimum starts at 100 pieces. It’s best to contact SourcifyChina directly to discuss your specific requirements.

Q: What is the lead time for manufacturing and delivery?

A: Lead times vary based on order size and complexity but generally range from 3 to 6 weeks for manufacturing. Shipping times depend on your location and the shipping method chosen.

Q: Does SourcifyChina provide samples before full-scale production?

A: Yes, you can request samples before committing to a large order. Sample costs and shipping fees will be applicable and can often be deducted from your bulk order cost.

Q: Are the lathe parts manufactured by SourcifyChina compliant with international standards?

A: Yes, the factory adheres to international manufacturing standards and can comply with specific standards required by your industry, such as ISO, ASTM, or DIN.

Q: What quality control measures does SourcifyChina implement?

A: SourcifyChina employs rigorous quality control measures including in-process inspections, final product evaluations, and testing to ensure all parts meet the required specifications and standards.

Q: What shipping options are available for international orders?

A: SourcifyChina offers various shipping options including air freight, sea freight, and express courier services like DHL, FedEx, and UPS. Shipping costs and times vary depending on your location and selected method.

Q: What payment methods are accepted?

Sourcing lathe parts from SourcifyChina factory can be efficient if done correctly. Here are some tips to help streamline the process within 300 words:

1. Define Requirements Clearly: Specify the type of lathe part, material, dimensions, tolerances, and any quality standards required. This helps avoid confusion and ensure the supplier understands your needs.

2. Research the Supplier: Check SourcifyChina’s reputation through reviews and testimonials. Ensure they have experience with your specific lathe part and understand industry standards.

3. Request Samples: Ask for sample parts to evaluate the quality before placing a bulk order. This helps verify that the supplier can meet your specifications and quality expectations.

4. Evaluate Communication: Ensure clear and consistent communication with the supplier. They should respond to inquiries promptly and provide comprehensive answers.

5. Negotiate Terms: Discuss terms such as pricing, payment options, and delivery schedules. Ensure you agree upon Incoterms (e.g., FOB, CIF) and include them in the contract.

6. Quality Assurance: Implement quality control measures. Specify testing and inspection protocols in the contract to ensure parts meet your standards.

7. Lead Time Management: Confirm the lead time for production and shipping. Account for potential delays and plan your inventory accordingly.

8. Use Escrow Services: For initial orders, use escrow services to protect your payment until the parts are verified.

9. Clarify Return Policies: Understand and agree on return policies for defective or substandard parts before finalizing the order.

10. Legal Compliance: Ensure all transactions comply with both Chinese export regulations and your country’s import regulations.

By following these steps, you can source high-quality lathe parts from SourcifyChina effectively and efficiently.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.