Technology and Applications of machine parts manufacturers

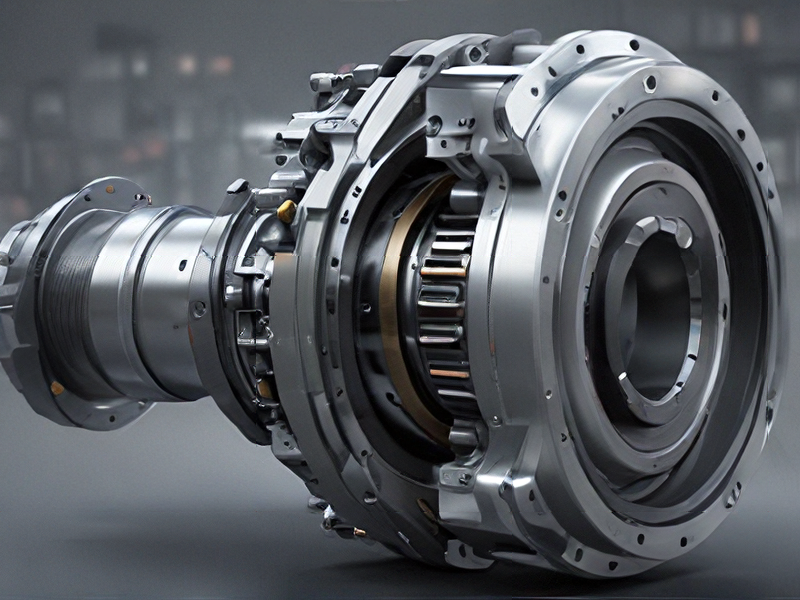

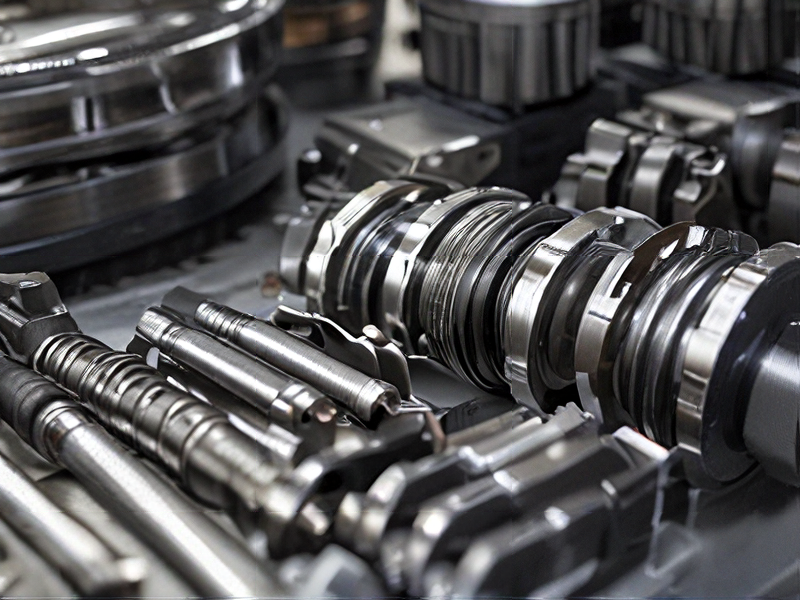

Machine parts manufacturers play a crucial role in supplying components essential for various industries, from automotive and aerospace to electronics and manufacturing. These manufacturers utilize advanced technology to design, produce, and deliver high-precision parts that meet stringent quality standards.

Technology:

Modern machine parts manufacturers employ a range of cutting-edge technologies:

1. Computer Numerical Control (CNC) Machining: CNC machines use computer programs to control machine tools, ensuring high accuracy and repeatability in production.

2. 3D Printing/Additive Manufacturing: Allows for rapid prototyping and production of complex geometries, reducing lead times and material waste.

3. Automation and Robotics: Automated systems streamline manufacturing processes, enhancing efficiency and reducing labor costs.

4. Advanced Materials: Utilization of high-performance materials such as composites, alloys, and polymers to meet specific application requirements.

Applications:

Machine parts find applications across diverse industries:

1. Automotive: Critical components like engine parts, transmission components, and chassis elements require precision manufacturing for performance and safety.

2. Aerospace: Demand for lightweight, durable parts with stringent safety standards drives innovation in materials and manufacturing processes.

3. Electronics: Small, intricate components for consumer electronics and industrial equipment require precise machining and assembly.

4. Medical Devices: From surgical instruments to implantable components, high-quality materials and precision machining ensure reliability and biocompatibility.

In conclusion, machine parts manufacturers leverage advanced technologies to meet the exacting demands of various industries. Their ability to innovate in materials, processes, and automation ensures they remain integral to the supply chain of modern manufacturing sectors.

Quality Testing Methods for machine parts manufacturers and how to control quality

Machine parts manufacturers employ several quality testing methods to ensure product reliability and customer satisfaction. Common methods include:

1. Dimensional Inspection: Using precise measurement tools like calipers, micrometers, or coordinate measuring machines (CMM) to verify part dimensions against design specifications.

2. Material Testing: Conducting tests such as hardness testing, spectroscopy, or metallography to ensure materials meet required standards for strength, durability, and composition.

3. Non-Destructive Testing (NDT): Techniques like ultrasonic testing, X-ray inspection, or magnetic particle testing to detect internal flaws or defects without damaging the part.

4. Functional Testing: Assessing parts under simulated operational conditions to verify performance, endurance, and compatibility with other components.

5. Statistical Process Control (SPC): Monitoring and controlling manufacturing processes using statistical methods to ensure consistency and detect deviations early.

To control quality effectively:

– Establish Clear Specifications: Define precise quality standards and specifications for materials, dimensions, and performance criteria.

– Implement Quality Management Systems (QMS): Adhere to standards like ISO 9001 to ensure systematic control and continuous improvement of manufacturing processes.

– Training and Skills Development: Equip personnel with training in testing methods and quality control procedures to maintain consistency and accuracy.

– Supplier Quality Management: Ensure suppliers meet quality standards through audits, inspections, and collaborative improvement efforts.

– Feedback and Continuous Improvement: Gather feedback from customers and internal stakeholders to identify areas for enhancement and implement corrective actions.

By employing these methods and strategies, machine parts manufacturers can uphold high standards of quality, minimize defects, and enhance overall product reliability and performance.

Tips for Procurement and Considerations when Purchasing from machine parts manufacturers

When engaging with machine parts manufacturers for procurement, several key considerations can streamline the process and ensure successful outcomes:

1. Quality Assurance: Prioritize suppliers with robust quality control measures and certifications (ISO, AS9100, etc.). Insist on material traceability and adherence to industry standards to guarantee reliability and durability of parts.

2. Technical Specifications: Clearly define and communicate your technical requirements. Ensure the manufacturer has the expertise and capability to meet these specifications, including material selection, tolerances, and performance standards.

3. Cost Efficiency: While cost is crucial, prioritize value over price alone. Evaluate total cost of ownership, including maintenance, downtime risks, and potential quality issues. Seek competitive pricing without compromising on quality.

4. Capacity and Lead Times: Assess the manufacturer’s production capacity and lead times. Ensure they can meet your demand volumes within required timelines. Transparent communication regarding production schedules and potential delays is essential.

5. Supplier Stability: Evaluate the manufacturer’s financial stability and track record. Longevity in the industry and positive customer references can indicate reliability and commitment to customer satisfaction.

6. Logistics and Support: Consider logistics aspects such as shipping options, packaging suitability, and after-sales support. A responsive customer service team and clear warranty terms enhance the overall procurement experience.

7. Ethical and Environmental Practices: Verify the manufacturer’s commitment to ethical sourcing, sustainability, and compliance with environmental regulations. This ensures alignment with your corporate values and regulatory requirements.

8. Continuous Improvement: Partner with manufacturers willing to collaborate on process improvements and innovation. A proactive approach to feedback and problem-solving fosters long-term partnerships and enhances product quality.

By focusing on these considerations, procurement professionals can mitigate risks, optimize costs, and foster productive relationships with machine parts manufacturers.

FAQs on Sourcing and Manufacturing from machine parts manufacturers in China

Certainly! Here are some common FAQs regarding sourcing and manufacturing machine parts from manufacturers in China:

1. What are the typical lead times for manufacturing machine parts in China?

Manufacturers in China often quote lead times ranging from 4-12 weeks, depending on the complexity and quantity of the parts ordered.

2. How can I ensure quality when sourcing from Chinese manufacturers?

It’s crucial to conduct thorough due diligence, including supplier audits, requesting samples, and implementing quality control measures throughout production.

3. What are the payment terms usually accepted by Chinese manufacturers?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and occasionally PayPal for smaller transactions. Negotiate terms that balance risk and convenience.

4. Can Chinese manufacturers handle custom or complex machine parts?

Yes, many Chinese manufacturers specialize in custom machining and can accommodate complex designs with CNC machining, casting, forging, and other techniques.

5. What should I consider when selecting a manufacturer in China?

Factors to consider include manufacturing capabilities, certifications (ISO, CE), production capacity, past client reviews, and proximity to shipping ports for logistics.

6. How do I navigate language and communication barriers?

Clear communication is key. Many manufacturers have English-speaking staff, and using detailed technical specifications and drawings can mitigate misunderstandings.

7. What are the typical shipping options and costs?

Shipping options range from sea freight (most economical for large volumes) to air freight (quicker but more expensive). Costs vary based on weight, volume, and urgency.

8. What are the risks and challenges of sourcing from China?

Risks include quality inconsistencies, intellectual property concerns, longer lead times due to shipping, and potential language barriers.

By addressing these FAQs, you can better navigate sourcing and manufacturing machine parts from Chinese manufacturers, ensuring a smoother and more informed process.