Technology and Applications of machinery parts manufacturers

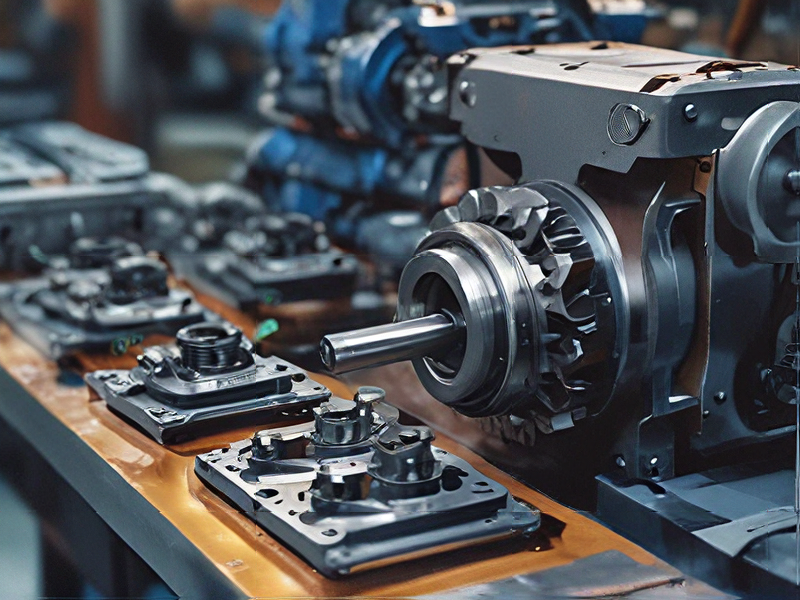

Machinery parts manufacturers play a crucial role in the industrial landscape by producing components vital for various applications across sectors such as automotive, aerospace, construction, and manufacturing. These manufacturers utilize advanced technologies and materials to ensure the reliability, durability, and precision of their products.

1. Advanced Manufacturing Technologies: Machinery parts manufacturers often employ advanced manufacturing technologies such as CNC machining, 3D printing, and robotic automation. CNC machining allows for high precision and repeatability in producing metal and plastic parts. 3D printing, on the other hand, enables rapid prototyping and customization of complex geometries. Robotic automation streamlines production processes, reducing costs and improving efficiency.

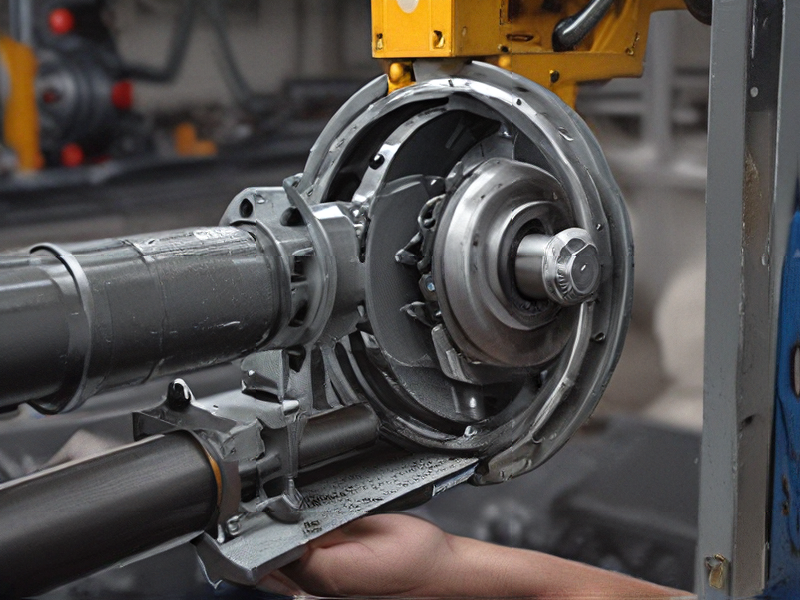

2. Materials and Processes: The choice of materials is critical in machinery parts manufacturing. High-performance metals like stainless steel, aluminum alloys, and titanium are preferred for their strength and corrosion resistance. Advanced processes like forging, casting, and injection molding are used to shape and form these materials into components that can withstand harsh operating conditions.

3. Quality Control and Testing: Ensuring the quality of machinery parts is paramount. Manufacturers implement rigorous quality control measures, including dimensional inspection, non-destructive testing (NDT), and material analysis. These processes guarantee that parts meet specifications and perform reliably over their lifecycle.

4. Applications: Machinery parts manufactured are used in a wide range of applications. In automotive industries, they contribute to engine components, transmission systems, and chassis parts. In aerospace, they are critical for aircraft structures, landing gear, and propulsion systems. In construction and manufacturing, they support heavy equipment, machine tools, and industrial automation.

5. Innovation and Sustainability: Manufacturers are increasingly focusing on sustainability by adopting eco-friendly materials and processes. They also innovate by integrating IoT (Internet of Things) technologies for predictive maintenance, enhancing the longevity and performance of machinery parts.

In conclusion, machinery parts manufacturers drive industrial progress through innovation, precision engineering, and adherence to high-quality standards, ensuring their components meet the demanding requirements of modern applications across diverse industries.

Quality Testing Methods for machinery parts manufacturers and how to control quality

Quality Testing Methods for Machinery Parts Manufacturers

1. Visual Inspection:

– Description: Initial check to identify visible defects.

– Implementation: Use magnifying glasses, microscopes, and surface comparators.

2. Dimensional Inspection:

– Description: Ensures parts meet specified dimensions.

– Implementation: Employ calipers, micrometers, coordinate measuring machines (CMM), and gauges.

3. Non-Destructive Testing (NDT):

– Description: Detects internal defects without damaging the part.

– Types:

– Ultrasonic Testing: Uses high-frequency sound waves.

– Radiographic Testing: X-rays or gamma rays identify internal flaws.

– Magnetic Particle Testing: Detects surface and near-surface defects in ferromagnetic materials.

– Dye Penetrant Testing: Reveals surface defects using dye.

4. Destructive Testing:

– Description: Assesses part properties by causing permanent damage.

– Types:

– Tensile Testing: Measures strength and ductility.

– Hardness Testing: Determines resistance to deformation.

– Impact Testing: Evaluates toughness.

5. Material Analysis:

– Description: Ensures material composition meets specifications.

– Implementation: Spectroscopy, chemical analysis, and microscopy.

Quality Control Methods

1. Statistical Process Control (SPC):

– Description: Uses statistical methods to monitor and control production.

– Tools: Control charts, histograms, and Pareto charts.

2. Six Sigma:

– Description: Methodology focused on reducing defects and variability.

– Tools: DMAIC (Define, Measure, Analyze, Improve, Control) framework.

3. Total Quality Management (TQM):

– Description: Organization-wide approach to long-term success through customer satisfaction.

– Implementation: Continuous improvement, employee training, and customer feedback.

4. Quality Audits:

– Description: Regular reviews of the quality management system.

– Types: Internal audits, external audits, and third-party audits.

5. Root Cause Analysis:

– Description: Identifies and addresses the underlying causes of defects.

– Tools: Fishbone diagrams, 5 Whys analysis, and failure mode and effects analysis (FMEA).

Implementing these methods ensures machinery parts manufacturers maintain high standards of quality, leading to reliable and durable products.

Tips for Procurement and Considerations when Purchasing from machinery parts manufacturers

When procuring machinery parts, careful consideration is essential to ensure quality, cost-effectiveness, and reliability. Here are key tips and considerations:

Research and Due Diligence

1. Vendor Reputation: Investigate the manufacturer’s reputation. Look for reviews, references, and their track record in the industry.

2. Certifications and Standards: Ensure the manufacturer adheres to industry standards and certifications (e.g., ISO, CE) which guarantee quality and safety.

Quality and Specifications

1. Material Quality: Verify the materials used in parts production. High-quality materials often result in more durable and reliable parts.

2. Technical Specifications: Match parts specifications precisely with your machinery requirements to ensure compatibility and optimal performance.

Cost and Value

1. Total Cost of Ownership: Consider the initial cost, maintenance expenses, lifespan, and operational efficiency to determine the total cost of ownership.

2. Bulk Purchasing and Discounts: Evaluate the benefits of bulk purchasing, which might reduce costs. Negotiate for discounts and favorable payment terms.

Lead Time and Delivery

1. Delivery Timelines: Confirm the lead times and reliability of delivery schedules to prevent operational delays.

2. Supply Chain Reliability: Assess the manufacturer’s supply chain stability to avoid disruptions.

After-Sales Support

1. Warranty and Return Policies: Check for robust warranty terms and clear return policies to safeguard against defective parts.

2. Technical Support: Ensure availability of technical support and customer service for troubleshooting and assistance.

Compliance and Sustainability

1. Regulatory Compliance: Verify compliance with relevant regulations and standards in your region.

2. Sustainability Practices: Consider manufacturers with sustainable practices and environmentally friendly materials.

Documentation and Agreements

1. Clear Contracts: Have detailed contracts specifying all terms, conditions, and expectations.

2. Documentation: Maintain comprehensive documentation for traceability and future reference.

By adhering to these guidelines, you can make informed decisions that enhance the efficiency and reliability of your machinery, thereby supporting the overall success of your operations.

FAQs on Sourcing and Manufacturing from machinery parts manufacturers in China

When sourcing and manufacturing machinery parts from manufacturers in China, here are some frequently asked questions:

1. What should I consider when selecting a manufacturer in China?

– Look for manufacturers with a proven track record in producing machinery parts.

– Verify their certifications, quality control processes, and adherence to international standards.

2. How do I ensure product quality?

– Conduct thorough due diligence on potential manufacturers.

– Request samples and perform quality inspections.

– Consider hiring a third-party inspection service to verify quality.

3. What are the typical lead times?

– Lead times can vary based on complexity and quantity of parts.

– Discuss lead times upfront and establish clear expectations with the manufacturer.

4. How can I manage communication effectively?

– Use clear and concise communication methods.

– Consider hiring a translator if language barriers exist.

– Use project management tools to track progress and milestones.

5. What about intellectual property protection?

– Ensure your agreements with the manufacturer include confidentiality clauses.

– Register your intellectual property in China if necessary.

6. What are the payment terms?

– Negotiate payment terms that align with industry standards.

– Consider using a letter of credit or secure payment methods to mitigate risks.

7. What should I know about import regulations and duties?

– Familiarize yourself with import regulations in your country.

– Factor in duties, taxes, and shipping costs when calculating total landed costs.

Navigating sourcing and manufacturing machinery parts from China requires careful planning, communication, and attention to quality assurance processes to ensure a successful partnership.