Technology and Applications of machines screw

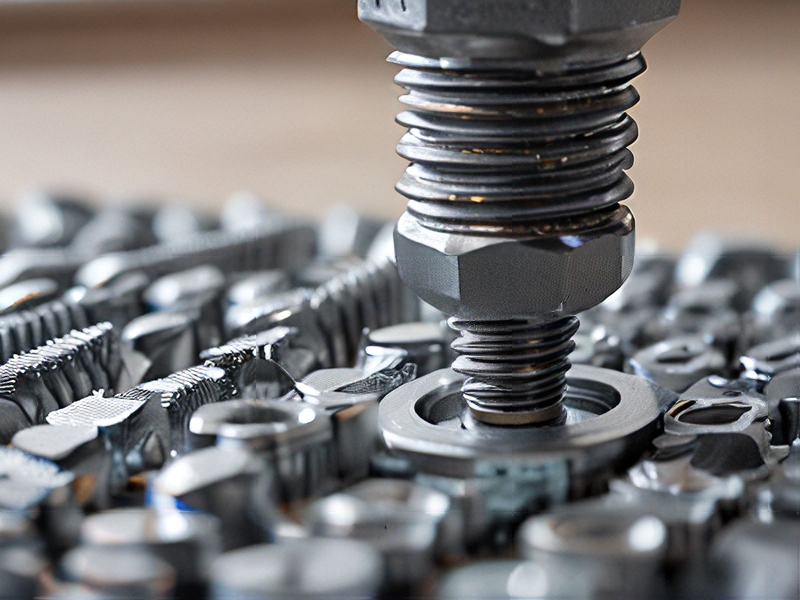

Machine screws are specialized fasteners used in various engineering and mechanical applications. They are designed to be inserted into pre-threaded holes or matched with nuts. Their technology and applications are integral to many industries, including manufacturing, construction, and electronics.

Technology

Machine screws are produced through a process that includes cold forming, thread rolling, and heat treatment. Cold forming shapes the screw without heating the metal, resulting in a stronger and more durable fastener. Thread rolling creates the screw’s threads by pressing the metal between two dies, which enhances the threads’ precision and strength. Heat treatment further strengthens the screws, ensuring they can withstand significant stress and wear.

Applications

1. Electronics: Machine screws are vital in assembling electronic devices, securing components onto circuit boards and enclosures. Their precision and small sizes make them ideal for these applications.

2. Automotive: In the automotive industry, machine screws are used extensively to hold together parts of engines, transmissions, and other critical components. Their ability to withstand high levels of vibration and heat is crucial in these settings.

3. Construction: In construction, machine screws are employed to fasten together metal structures, such as steel frameworks and support beams. They provide a secure and durable connection that is essential for structural integrity.

4. Machinery: Various types of machinery, from industrial equipment to home appliances, rely on machine screws for assembly and maintenance. They ensure parts are securely fastened and can be easily removed for repairs or upgrades.

5. Medical Devices: Precision-engineered machine screws are used in medical devices and equipment, where reliability and strength are paramount. They are often made from materials like stainless steel or titanium to prevent corrosion and ensure biocompatibility.

In summary, machine screws are a fundamental component in many technological and industrial applications. Their strength, precision, and versatility make them indispensable in assembling and securing a wide range of products and structures.

Quality Testing Methods for machines screw and how to control quality

Quality Testing Methods for Machine Screws

1. Visual Inspection: This basic method involves checking screws for defects such as cracks, burrs, and surface irregularities. Inspectors use magnifying tools to detect imperfections that might affect performance.

2. Dimensional Inspection: This ensures screws meet specified dimensions. Tools like calipers, micrometers, and optical comparators measure length, diameter, thread pitch, and head size against standards.

3. Mechanical Testing:

– Tensile Testing: Measures the screw’s strength by pulling it until it breaks. This determines the maximum load it can withstand.

– Hardness Testing: Uses methods like Rockwell or Vickers to assess the material’s hardness, indicating resistance to deformation.

– Torque Testing: Ensures the screw can achieve and maintain the specified torque without stripping or breaking.

4. Thread Testing: Verifies that threads are properly formed and fit standardized gauges. Tools include go/no-go gauges and thread micrometers.

5. Material Analysis: Involves chemical and spectroscopic methods to verify the material composition, ensuring it meets the required specifications.

6. Plating and Coating Inspection: Assesses the uniformity and adhesion of coatings like zinc, to ensure corrosion resistance and longevity.

Quality Control Methods

1. Statistical Process Control (SPC): Uses statistical methods to monitor and control the manufacturing process. By analyzing production data, deviations from quality standards can be detected and corrected promptly.

2. Quality Assurance (QA) Programs: Implementing robust QA programs involves detailed process documentation, regular audits, and adherence to standards such as ISO 9001. This ensures consistent production quality.

3. Automated Inspection Systems: Utilizing cameras and sensors for real-time inspection can detect defects and dimensional inconsistencies immediately, reducing reliance on human inspectors.

4. Supplier Quality Management: Regularly auditing and qualifying suppliers to ensure they adhere to quality standards helps in maintaining the quality of raw materials and components.

By combining these testing methods and quality control practices, manufacturers can ensure machine screws meet high standards of reliability and performance.

Tips for Procurement and Considerations when Purchasing from machines screw

When procuring machine screws, several critical tips and considerations can ensure optimal quality, cost-effectiveness, and suitability for your needs:

1. Material and Finish

– Material: Choose the right material (e.g., stainless steel, carbon steel, brass, or aluminum) based on the application requirements. Stainless steel offers corrosion resistance, while carbon steel provides strength.

– Finish: Consider finishes like zinc plating, black oxide, or anodizing to enhance durability and appearance.

2. Dimensions and Specifications

– Size: Ensure the screw dimensions (diameter, length) match your requirements. Refer to standards such as ISO, DIN, or ANSI for precise measurements.

– Thread Type: Select the appropriate thread type (coarse or fine) and thread fit (Class 1, 2, or 3) for the application.

3. Strength and Load Requirements

– Grade and Hardness: Check the grade of the screws, indicating their strength. Higher grades (e.g., Grade 8) provide better tensile strength.

– Load Capacity: Ensure the screws can handle the load and stress in your application, especially in high-stress environments.

4. Supplier Reliability

– Reputation: Choose suppliers with a good track record for quality and reliability. Look for reviews or certifications like ISO 9001.

– Consistency: Ensure the supplier can provide consistent quality and timely deliveries.

5. Cost Considerations

– Bulk Purchase: Buying in bulk can reduce costs, but ensure storage conditions prevent corrosion.

– Total Cost of Ownership: Consider the long-term costs, including maintenance and potential replacements.

6. Compliance and Standards

– Certifications: Verify that the screws meet industry standards and certifications, which ensures safety and performance.

– Compliance: Ensure compliance with relevant regulations, such as RoHS for environmental considerations.

7. Additional Features

– Coatings: Consider additional coatings for enhanced properties, such as anti-galling or anti-seizing coatings.

– Custom Requirements: If standard screws don’t meet your needs, explore custom manufacturing options.

By carefully considering these factors, you can ensure that the machine screws you purchase will meet your specific requirements and provide long-lasting performance.

FAQs on Sourcing and Manufacturing from machines screw in China

FAQs on Sourcing and Manufacturing Machine Screws in China

1. Why should I source machine screws from China?

China offers competitive pricing, a wide variety of suppliers, advanced manufacturing technology, and high production capacity. This makes it a cost-effective and efficient option for sourcing machine screws.

2. How do I find reliable suppliers?

Use platforms like Alibaba, Global Sources, and Made-in-China. Verify suppliers through customer reviews, ask for samples, and consider factory visits. Trade shows and professional networks can also provide trustworthy recommendations.

3. What are the common types of machine screws available?

Common types include flat head, round head, pan head, hex head, and socket head screws. They come in various materials like stainless steel, brass, and carbon steel.

4. What should I know about MOQ (Minimum Order Quantity)?

MOQ varies by supplier. Some may require large orders, while others can accommodate smaller quantities. It’s essential to negotiate MOQs that align with your business needs.

5. How do I ensure quality control?

Implement strict quality control measures. Request quality certificates (ISO, RoHS), conduct factory audits, and hire third-party inspection services to check the products before shipment.

6. What are the typical lead times for manufacturing?

Lead times can range from a few weeks to several months, depending on the order size and complexity. Confirm lead times with your supplier and factor in additional time for shipping.

7. What are the payment terms and methods?

Common payment methods include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. Negotiate payment terms carefully, often involving a deposit upfront and the balance upon shipment.

8. How do I handle logistics and shipping?

Choose between sea freight, air freight, or courier services based on your budget and urgency. Work with reliable freight forwarders and be aware of customs regulations and duties in your country.

9. What are the risks and how can I mitigate them?

Risks include quality issues, delays, and communication barriers. Mitigate these by establishing clear contracts, maintaining regular communication, and using trusted intermediaries for quality checks and logistics.

10. How can I build long-term relationships with suppliers?

Maintain consistent communication, honor payment terms, provide feedback, and visit suppliers periodically. Building trust and mutual respect fosters long-term, beneficial partnerships.