“SourcifyChina” Factory offers unmatched expertise in machining die production. Our team comprises skilled professionals who ensure high-quality products that meet international standards. With advanced technology and rigorous quality control, we guarantee exceptional precision in every machining die we produce.

Our strategic location in China allows us to leverage local resources, minimizing manufacturing costs while maintaining top-notch quality. This cost-efficiency is passed on to our customers, making us a valuable partner for businesses seeking reliable, affordable tooling solutions.

Customer satisfaction is our priority at “SourcifyChina” Factory. We provide comprehensive support from initial consultation to final product delivery, ensuring that all client specifications are met. Our responsive customer service team is always available to address any concerns promptly.

At “SourcifyChina,” we adhere to strict timelines to meet our clients’ deadlines. Our efficient production processes enable us to handle bulk orders without compromising on quality or delivery schedules. This makes us a dependable choice for companies with tight production timelines.

Choosing “SourcifyChina” Factory for your machining die needs means partnering with a company committed to excellence. With our combination of quality, cost-efficiency, and outstanding customer service, we strive to be your trusted manufacturing ally in China.

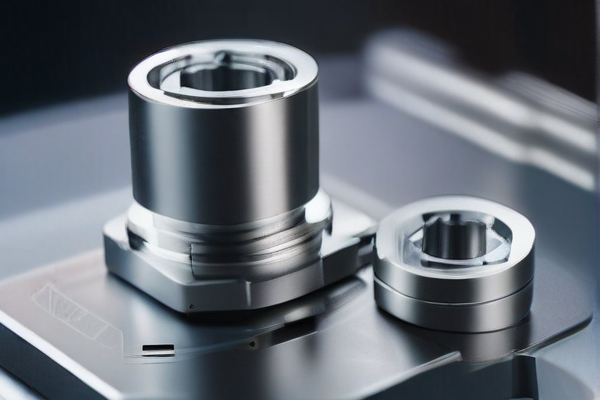

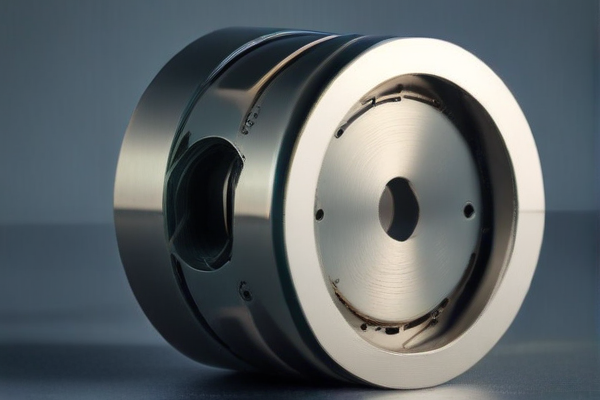

Machining dies are critical tools in manufacturing, used for shaping and forming materials. They come in various types, each suited for specific applications, and offer multiple options tailored to specific industrial needs.

Types and Options for Machining Dies:

– Progressive Dies: Perform multiple operations in a single press cycle.

– Transfer Dies: Move parts between stations, allowing for complex shapes.

– Compound Dies: Execute multiple operations with a single stroke.

– Forming Dies: Shape materials into desired configurations.

– Cutting Dies: Precision-cutting of materials.

– Blanking Dies: Cut out flat pieces from sheet materials.

– Drawing Dies: Stretch materials into thinner forms.

– Extrusion Dies: Force materials through shaped openings for profiles.

Material Options:

– Tool Steel: High durability and wear resistance.

– Carbide: Exceptional hardness and heat resistance.

– Ceramics: High-temperature capabilities.

– Diamond Coated: Enhanced precision and wear resistance.

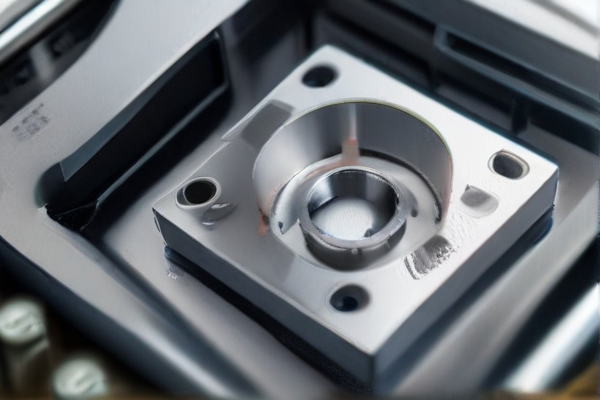

Customization Options:

– Coatings: To improve wear life and reduce friction.

– Cooling Channels: For temperature control during operations.

– Modularity: Interchangeable components for flexibility.

– Precision Engineering: Tailored for high-accuracy requirements.

By understanding the types and materials available, and considering customization, manufacturers can select the optimal machining die for their specific applications, improving efficiency and product quality.

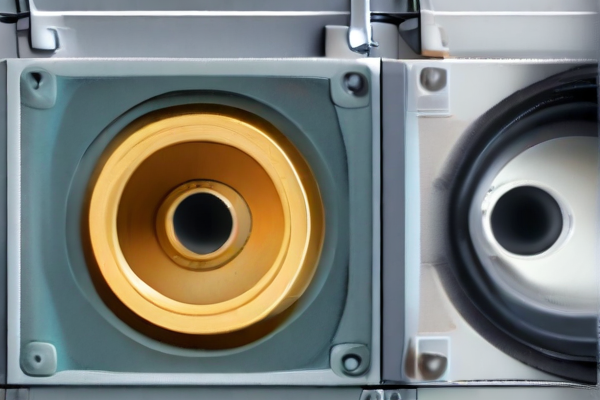

Machining dies are critical in manufacturing processes, enabling the mass production of complex, precise, and high-quality components. They are essential tools in various sectors, ensuring the consistency and accuracy of the finished products.

– Automotive Industry: Used for stamping, shaping, and cutting parts like body panels, engine components, and transmission systems.

– Aerospace Sector: Essential for producing high-tolerance parts such as turbine blades, landing gear, and structural components.

– Electronics Manufacturing: Utilized for creating intricate circuits, connectors, and housings with precise tolerances.

– Medical Device Production: Important for manufacturing surgical instruments, implants, and diagnostic equipment with high precision and consistency.

– Construction and Heavy Equipment: Used to fabricate structural components, brackets, and custom metal parts required in construction machinery.

– Consumer Goods: Employed in the production of plastic products, appliances, and everyday items through molding and stamping.

– Tool and Die Making: Fundamental in creating other specialized dies, molds, and tools necessary for various manufacturing processes.

– Packaging Industry: Applied in forming containers, caps, and seals used in packaging applications, ensuring high-speed production and uniformity.

– Textile Industry: Used to produce components for textile machinery, facilitating efficient and precise fabric processing.

– Renewable Energy Sector: Crucial for manufacturing components of wind turbines and solar panels, contributing to sustainable energy solutions.

Machining dies are versatile and integral to numerous manufacturing domains, optimizing production efficiency and product precision across various applications.

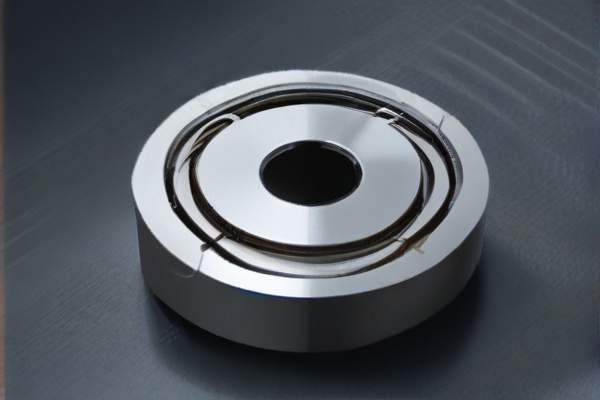

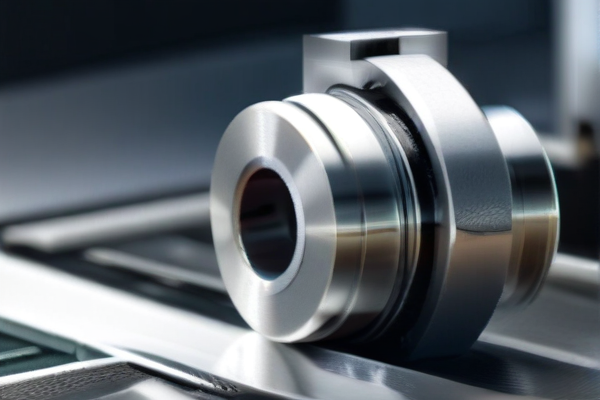

SourcifyChina machining dies are made from high-grade steel, known for its durability and resistance to wear and tear. This material ensures longevity and consistent performance under high-stress conditions.

The steel used in these dies often includes alloy elements like chromium and vanadium, enhancing its hardness and corrosion resistance. These alloys also contribute to the die’s ability to maintain a sharp edge, which is crucial for precision machining.

Additionally, the steel is heat-treated to achieve an optimal balance of strength and toughness. This process involves heating the material to a high temperature and then cooling it rapidly, resulting in a hardened surface that can withstand significant mechanical stress.

SourcifyChina also employs advanced coatings on their machining dies, such as titanium nitride or diamond-like carbon. These coatings further reduce friction and enhance the die’s durability, making them suitable for high-volume production runs.

Overall, the combination of high-grade steel, alloy elements, heat treatment, and advanced coatings ensures that SourcifyChina machining dies deliver exceptional performance and longevity in demanding industrial applications.

SourcifyChina ensures the highest quality control in its machining die manufacturing process. They meticulously select premium materials, focusing on durability. Each raw material batch undergoes strict inspections to confirm it meets industry standards.

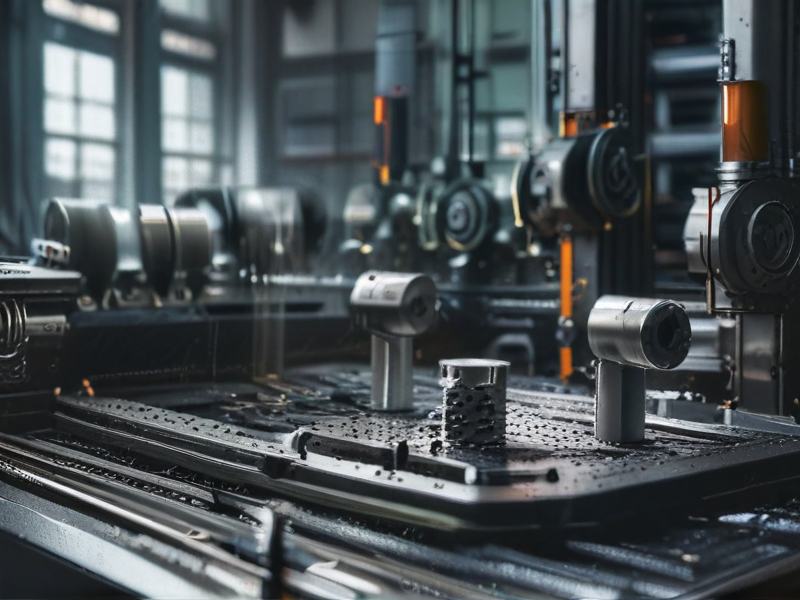

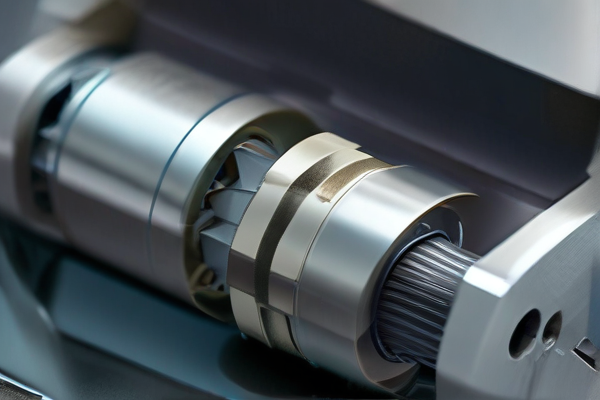

The production process incorporates cutting-edge technology and highly skilled labor. CNC machines maintain precision during machining, guaranteeing accuracy. Quality control officers oversee each step, from initial setup to final execution.

During production, periodic inspections and real-time monitoring are conducted. Any discrepancies are immediately addressed. Tools and machines undergo regular maintenance to prevent deviations in quality.

Post-production, each machining die undergoes rigorous testing. Dimensional accuracy, surface finish, and structural integrity are verified. Non-conforming products are analyzed and rectified before shipment to ensure customer satisfaction. This comprehensive quality control strategy ensures that SourcifyChina delivers unparalleled, reliable machining dies.

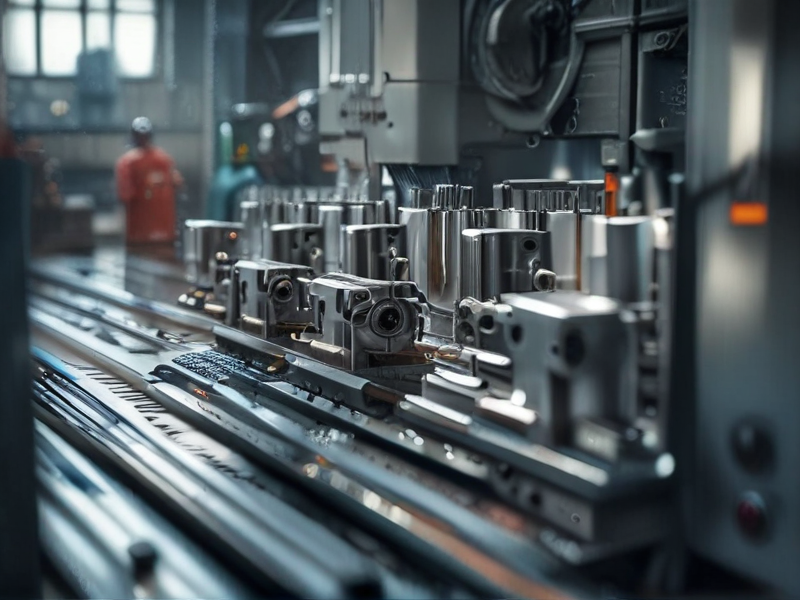

SourcifyChina is a leading company specializing in advanced machining die manufacturing. With state-of-the-art technology, they create highly precise and durable dies that cater to various industries including automotive, aerospace, and consumer goods.

Their machining capabilities include CNC milling, turning, and grinding, which ensure exceptional accuracy and consistency. SourcifyChina’s expertise allows for the production of complex geometries and tight tolerances, meeting the stringent requirements of international standards.

In addition to machining, SourcifyChina offers comprehensive services such as die design consultation, prototype development, and mass production support. Their skilled engineers work closely with clients to optimize designs for manufacturability and cost efficiency.

Quality assurance is a cornerstone of SourcifyChina’s operations. Rigorous inspection processes and use of high-quality materials ensure that every die produced meets or exceeds customer expectations. This commitment to excellence has made them a trusted partner in the global market.

By integrating advanced technologies and a customer-centric approach, SourcifyChina continuously improves its capabilities. Their focus on innovation and quality has established them as a leader in the machining die industry, making them the go-to choice for companies seeking reliable and high-performance die solutions.

Their comprehensive service and expert team make SourcifyChina stand out. Clients can count on them for end-to-end support, from conceptualization to final production, ensuring a seamless and efficient manufacturing process.

In summary, SourcifyChina’s machining die capabilities are characterized by precision, innovation, and reliability. Their advanced technology, skilled engineers, and commitment to quality position them as a premier provider in the industry. Whether for complex geometries or high-volume production, SourcifyChina is equipped to deliver exceptional results, making them an invaluable partner for any manufacturing needs.

Machining die is a crucial process in manufacturing, offering precision and efficiency in producing components for various industries.

– Precision and Accuracy: Machining dies provide high precision, ensuring components meet exact specifications and tolerances.

– Durability: Machined dies are typically made from robust materials, ensuring longevity and resistance to wear and tear.

– Efficiency: This process enables high-speed production, reducing manufacturing time and costs.

– Versatility: Machining can handle a wide range of materials, including metals, plastics, and composites.

– Customization: Allows for the creation of complex and custom designs, catering to specific industry needs.

– Consistency: Ensures uniformity in mass production, maintaining quality across all components.

– Reduced Waste: Precise machining minimizes material waste, promoting cost-efficiency and sustainability.

– Improved Surface Finish: Machining produces smooth surface finishes, enhancing the functionality and aesthetics of the components.

– Automation Integration: Easily integrates with automated systems, further boosting productivity and consistency.

Machining dies are critical tools in manufacturing, shaping materials into specific forms with high precision. They are designed to withstand high pressure and repetitive use, ensuring consistent quality and durability in the production process.

Features of Machining Dies:

– High Precision: Machining dies provide exact dimensions and tolerances, ensuring the final product meets stringent specifications.

– Durability: Made from high-strength materials like tool steel, they resist wear and deformation over prolonged use.

– Complex Shapes: Capable of producing intricate and complex shapes that would be difficult or impossible to achieve with other methods.

– Surface Finish: Provide a smooth surface finish on the molded parts, reducing the need for further processing.

– Heat Resistance: Designed to operate under high temperatures without losing integrity, essential for processes involving heat.

– Interchangeable Inserts: Allow for easy replacement of worn parts, extending the die’s overall lifespan.

– Cost-Effectiveness: While the initial investment is high, the durability and efficiency reduce long-term production costs.

– Customizability: Can be tailored to specific production needs, accommodating various materials and product designs.

– Automation Compatibility: Integrated with automated systems for enhanced productivity and reduced labor costs.

– Reduced Waste: Precisely controls material flow, minimizing waste and optimizing resource usage.

These features make machining dies indispensable in industries requiring high-volume, high-quality production.

SourcifyChina is renowned for delivering high-quality machining die custom products and projects tailored to diverse industrial needs. With precision engineering and advanced technology, they ensure exceptional accuracy and durability in every product.

Specializing in custom solutions, SourcifyChina accommodates specific client requirements, providing bespoke machining dies that boost operational efficiency. Their expert team guarantees that every project aligns perfectly with customer specifications.

Employing state-of-the-art machinery, SourcifyChina upholds rigorous quality standards in all manufacturing phases. This dedication to excellence has earned them a reputation for reliability and innovation within the industry.

Collaborative project management defines SourcifyChina’s approach, ensuring seamless communication and timely delivery. They offer continuous support throughout the project lifecycle, from initial design to final production.

SourcifyChina’s commitment to customer satisfaction is evident in its comprehensive service offerings. By prioritizing client needs and maintaining strict quality controls, they provide unmatched value in machining die custom products and projects.

SourcifyChina Machining Die epitomizes precision and efficiency in the realm of manufacturing, offering top-notch machining die solutions tailored to diverse industrial needs. Rooted in the rich manufacturing heritage of China, the company leverages advanced technology and skilled craftsmanship to produce high-quality dies that meet stringent international standards. Their comprehensive service portfolio includes die design, prototyping, and mass production, ensuring that every client’s specific requirements are meticulously catered to. SourcifyChina is renowned for its commitment to innovation, consistently upgrading its machinery and processes to stay ahead in a competitive market. Additionally, the company places a strong emphasis on sustainability, utilizing eco-friendly practices and materials wherever possible. With an unwavering focus on quality and customer satisfaction, SourcifyChina Machining Die has established itself as a reliable partner for businesses worldwide, helping them achieve operational excellence and precision in their manufacturing processes.

In the aerospace, defense, and marine industries, machining dies are crucial tools used in the manufacturing process to create high-precision components. These dies enable the mass production of complex parts with exacting tolerances, which is essential for ensuring the safety, reliability, and performance of aircraft, defense systems, and marine vessels. In aerospace, for example, dies are used to produce turbine blades, airframe components, and other critical parts that must withstand extreme conditions and stresses. The precision and repeatability afforded by machining dies ensure that each part meets stringent industry standards, contributing to the overall efficiency and effectiveness of aircraft production.

In defense applications, machining dies are instrumental in the fabrication of weapons systems, armored vehicles, and other military equipment. The ability to produce high-strength, durable parts with consistent quality is vital for the operational readiness and durability of defense hardware. Similarly, in the marine sector, machining dies are employed to manufacture components for shipbuilding, including engine parts, propellers, and structural elements. The harsh marine environment demands components that are not only precise but also resistant to corrosion and wear. Machining dies facilitate the production of such robust and reliable parts, ensuring the longevity and performance of marine vessels. Across these sectors, the use of machining dies enhances production efficiency, reduces costs, and maintains the high standards required for safety and functionality.

In the automotive industry, machining dies are indispensable tools in the mass production of vehicle components. These precision-engineered dies are used to shape and cut metal parts with high accuracy and consistency, ensuring that every piece meets stringent quality standards. Machining dies are integral in forming complex components such as engine blocks, transmission housings, and various body panels. The ability to produce large volumes of parts with exact specifications not only enhances manufacturing efficiency but also reduces material waste and production costs. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, have further revolutionized die-making processes, allowing for greater precision and the production of intricate designs that meet evolving automotive demands for lighter, stronger, and more fuel-efficient vehicles.

In the electronics sector, machining dies play a crucial role in the fabrication of components with high precision and miniaturization demands. Electronic devices, such as smartphones, laptops, and various IoT (Internet of Things) gadgets, require intricate metallic parts like connectors, frames, heat sinks, and enclosures. These components often necessitate tight tolerances and smooth finishes, which are achievable with high-precision machining dies. The dies ensure that each part fits together seamlessly, which is essential for the functionality and reliability of electronic devices. Furthermore, as the trend towards smaller and more compact devices continues, the need for sophisticated die-making techniques grows. Techniques like micro-machining, leveraging CNC technology, allow manufacturers to produce extremely small and intricate parts with the same high standards of quality and consistency, supporting the rapidly advancing field of electronics innovation.

Machining dies play a pivotal role in the construction industry, where precision and durability are paramount. Dies are used to shape and form construction materials, whether it’s metal, plastic, or composite materials, ensuring that various components fit together seamlessly. In applications such as concrete formwork, structural steel components, or intricate architectural details, machining dies ensure that each piece meets the exact specifications required for safe and efficient assembly. Advanced machining techniques allow for the production of highly complex die shapes, accommodating the bespoke needs of contemporary construction projects. This precision results in significant time savings during assembly and reduces labor costs, as well as minimizing wastage by ensuring that materials are cut or formed correctly the first time.

In the realm of energy applications, machining dies are instrumental in the manufacture of components for wind turbines, solar panels, and other green technologies. For instance, the blades of wind turbines require high-precision machining to ensure aerodynamic efficiency and structural integrity, and dies are essential in shaping these components. Similarly, in the production of photovoltaic cells for solar panels, dies are utilized to fabricate the intricate circuits and components that maximize energy conversion efficiency. Machining dies also contribute to the oil and gas industry by creating complex parts for drilling equipment and pipelines, which must withstand extreme conditions and high pressures. By ensuring that these components meet stringent tolerances and quality standards, machining dies help to enhance the performance, reliability, and lifespan of energy infrastructure, thereby supporting both traditional and renewable energy sectors.

The industrial equipment industry heavily relies on machining die technology to achieve precision and efficiency in manufacturing processes. Machining die involves the use of specialized tools and machines to shape and configure materials, such as metals, plastics, and composites, into desired forms. This technology is pivotal in producing components with high dimensional accuracy and intricate geometries that are essential for various industrial applications. For instance, in automotive manufacturing, machining die is used to create engine parts, transmission components, and intricate body panels, ensuring that each part meets stringent specifications for performance and safety. The precision provided by machining die also extends to the aerospace industry, where components such as turbine blades, airframe parts, and fuel systems demand exceptional accuracy and consistency to withstand high operational stresses.

Furthermore, the application of machining die in the industrial equipment industry streamlines production processes by enabling rapid prototyping and efficient mass production. Advanced computer numerical control (CNC) machines are often employed in machining die, allowing for automation, repeatability, and precision. This results in reduced labor costs, quicker turnaround times, and minimized material waste. Industries leverage machining die to adapt to the growing demand for customization and short production runs without compromising on quality. This adaptability is crucial for sectors such as medical device manufacturing, where customized implants and surgical tools are manufactured to meet patient-specific requirements. Overall, the integration of machining die technology enhances productivity, ensures high-quality output, and fosters innovation across various industrial domains.

The application of machining dies in the medical device industry is pivotal for the production of high-precision components essential for medical instruments. Machining dies are specialized tools used in processes such as injection molding, stamping, and extrusion to shape materials into intricate parts with stringent tolerances. In medical devices, these dies ensure the accurate and consistent production of components like surgical instruments, implants, and diagnostic equipment. The precision offered by machining dies is crucial, as even minor deviations can compromise the functionality and safety of medical devices, which must adhere to strict regulatory standards.

Moreover, the versatility of machining dies allows for the use of various materials such as stainless steel, titanium, and biocompatible polymers, each selected based on the specific requirements of the medical application. This capability is essential in creating devices that are not only durable and reliable but also safe for use within the human body. Advanced machining techniques, including CNC machining, facilitate the production of complex geometries and micro-scale features, enabling innovations in minimally invasive surgical tools and implantable devices. The high degree of customization and precision achieved with machining dies directly contributes to the advancements in medical technology, enhancing patient outcomes and expanding the possibilities for medical treatments.

Machining dies play a critical role in the realm of manufacturing, particularly in the metalworking and plastic molding industries. These precision-engineered tools are designed to shape, cut, and form material into desired configurations, leveraging high-speed machining processes such as milling, turning, and EDM (Electrical Discharge Machining). The functionality of machining dies lies in their ability to produce complex and intricate components with high levels of accuracy and repeatability. By utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, high-tolerance dies can be created for applications ranging from automotive components to consumer electronics. This technology not only enhances the precision and efficiency of mass production but also reduces material waste and operational costs.

In the broader scope of manufacturing applications, machining dies are instrumental in processes such as stamping, forging, and plastic injection molding. For example, in plastic injection molding, a die is employed to inject molten plastic into a mold cavity, solidifying into the desired shape swiftly and with consistent quality. Similarly, in metal forging, dies help shape heated metal under high pressure, which is essential for producing high-strength parts for aerospace, automotive, and heavy machinery industries. Integration of advanced materials like high-speed steel and carbide in the die construction has significantly improved their durability and performance. Moreover, continuous advancements in CNC (Computer Numerical Control) technologies ensure that dies can be designed and produced with unparalleled accuracy, resulting in shorter lead times and higher productivity. Overall, the utilization of machining dies in manufacturing underscores their indispensable value in achieving high-quality product outputs efficiently and cost-effectively.

Sure! Here is a concise FAQ for manufacturing machining die quality work from SourcifyChina factory:

Q1: What is SourcifyChina’s expertise in manufacturing machining dies?

A1: SourcifyChina specializes in producing high-quality machining dies leveraging state-of-the-art technology and skilled craftsmanship. We cater to various industries ensuring precision and durability in our products.

Q2: What materials are used in the machining dies produced by SourcifyChina?

A2: Our machining dies are typically made of high-grade tool steels, carbides, and other alloys to meet specific client requirements and ensure maximum performance and longevity.

Q3: What is the typical lead time for an order?

A3: The lead time varies depending on the complexity and volume of the order. Generally, it ranges from 4 to 8 weeks. We strive to maintain timely deliveries without compromising quality.

Q4: How does SourcifyChina ensure the quality of machining dies?

A4: SourcifyChina employs rigorous quality control processes, including initial material inspection, in-process checks, and final quality assurance to ensure each die meets industry standards and client specifications.

Q5: Can SourcifyChina handle custom die designs?

A5: Yes, we specialize in custom die designs. Our experienced engineering team collaborates with clients to understand their requirements and create tailored solutions.

Q6: Does SourcifyChina offer prototyping services?

A6: Yes, we offer rapid prototyping services to help clients visualize and test their designs before proceeding to full-scale production. This ensures accuracy and reduces potential modifications later.

Q7: What are the payment terms?

A7: Payment terms are usually 50% advance, with the remaining 50% payable upon delivery. We can discuss and accommodate other arrangements based on mutual agreement.

Q8: How does SourcifyChina handle shipping and logistics?

A8: We coordinate with reliable logistics partners to ensure secure and timely delivery of your order. We handle all necessary documentation and provide tracking information to keep you updated on your shipment’s status.

Q9: Can I visit the SourcifyChina factory for an inspection?

A9: Yes, we welcome client visits and factory inspections. Please contact us to schedule an appointment so we can ensure a productive and comprehensive tour.

Q10: How can I request a quote or additional information?

When sourcing machining die manufacturing from SourcifyChina factory, consider the following tips to ensure quality and efficiency:

1. Supplier Verification:

– Ensure the factory is certified and has a good track record. Look for ISO certifications and check client reviews.

– Request references from previous clients to verify their reliability and quality of work.

2. Clear Specifications:

– Provide detailed technical drawings and specifications. Include material requirements, tolerances, and any finishing processes.

– Use 3D models (CAD files) to avoid miscommunication and to ensure precise manufacturing.

3. Prototype and Sampling:

– Start with a prototype or sample order to evaluate the quality and accuracy.

– Inspect the samples thoroughly for any defects and ensure they meet your specifications.

4. Quality Control:

– Establish a clear quality control process. Define the standards and inspection methods.

– Consider third-party inspections to maintain unbiased quality checks.

5. Lead Times and Production Capacity:

– Confirm the lead times for production and ensure the factory can meet your deadlines.

– Assess the factory’s production capacity to handle your order volume without compromising quality.

6. Cost and Payment Terms:

– Get detailed quotes, including all potential additional costs (e.g., shipping, taxes).

– Negotiate payment terms that offer security, such as partial payments upon order placement and final payments after inspection.

7. Communication:

– Maintain open and clear communication. Use video calls and regular updates to monitor progress.

– Ensure there is no language barrier by having a translator if necessary.

8. Logistics and Shipping:

– Plan the logistics and shipping carefully. Factor in potential delays and customs processes.

– Choose reliable shipping partners to ensure timely and safe delivery.

By following these tips, you can streamline your sourcing process and ensure high-quality machining die manufacturing from SourcifyChina factory.

FAQ for Sourcing Machining Die from SourcifyChina Factory

Q1: What types of machining dies can SourcifyChina factory provide?

A1: SourcifyChina factory specializes in a wide range of machining dies, including stamping dies, extrusion dies, casting dies, and injection molds. They cater to various industries, including automotive, aerospace, electronics, and consumer goods.

Q2: What materials are used for making the machining dies?

A2: The factory uses high-quality materials such as tool steel, stainless steel, aluminum, and various alloys to ensure durability, precision, and performance of the machining dies.

Q3: What is the lead time for manufacturing and delivering machining dies?

A3: The standard lead time is typically 4-6 weeks, depending on the complexity of the die and the order quantity. Rush orders can be accommodated with prior arrangement.

Q4: Does SourcifyChina factory offer customization services?

A4: Yes, SourcifyChina factory provides extensive customization services. Clients can specify dimensions, materials, and any unique requirements. The factory’s engineering team collaborates with clients to ensure the final product meets exact specifications.

Q5: How does SourcifyChina ensure the quality of its machining dies?

A5: The factory employs strict quality control measures, including material inspection, precision machining, and final product testing. They also adhere to international standards like ISO 9001 to ensure consistent quality.

Q6: What are the payment terms?

A6: Payment terms typically include a 30% deposit upon order confirmation and the remaining balance before shipment. SourcifyChina accepts various payment methods, including wire transfers and letters of credit.

Q7: Can I request a sample before placing a large order?

A7: Yes, SourcifyChina can provide samples upon request. Sample costs and shipping charges may apply, which can be deducted from the total order value if a bulk order is placed.

Q8: How can I place an order?

A8: Orders can be placed by contacting the sales team through their website, email, or phone. Detailed specifications and requirements should be provided to facilitate a smooth ordering process.

Q9: Does SourcifyChina offer after-sales support?

Sourcing a machining die from SourcifyChina can be streamlined with the following tips:

1. Research and Vet Suppliers: Start by researching SourcifyChina’s listed suppliers. Check reviews, ratings, and past client feedback to ensure reliability.

2. Detailed Specifications: Clearly define your technical requirements such as material, dimensions, tolerance levels, and any specific machining processes needed. Providing detailed drawings or CAD files can be immensely helpful.

3. Request Samples: Before placing a large order, request samples to assess the quality of work and ensure it meets your standards.

4. Ask for Quotations: Get quotations from multiple suppliers to compare prices and terms. Make sure to factor in all costs including shipping, taxes, and potential tariffs.

5. Lead Time and Production Capacity: Confirm the lead time and ensure the supplier has the capacity to handle your order volume within your required timeline.

6. Quality Assurance: Inquire about the supplier’s quality control processes. Understand how they manage defects and their policies on returns and refunds.

7. Communication: Establish clear and consistent communication channels. Being able to easily reach the supplier can mitigate misunderstandings and expedite problem resolution.

8. Payment Terms: Negotiate favorable payment terms. It’s common to pay a deposit upfront with the balance due upon delivery or after a satisfactory inspection of the goods.

9. Legal and Compliance Checks: Verify that the supplier adheres to relevant industry standards and certifications. Ensure that all contracts and agreements are legally sound and clear.

10. Visit the Factory: If feasible, visiting the factory can provide deeper insights into their operational capabilities and quality standards.

By following these steps, you can efficiently source a machining die from SourcifyChina factory, ensuring a balance between quality, cost, and reliability.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.