Technology and Applications of machining slots

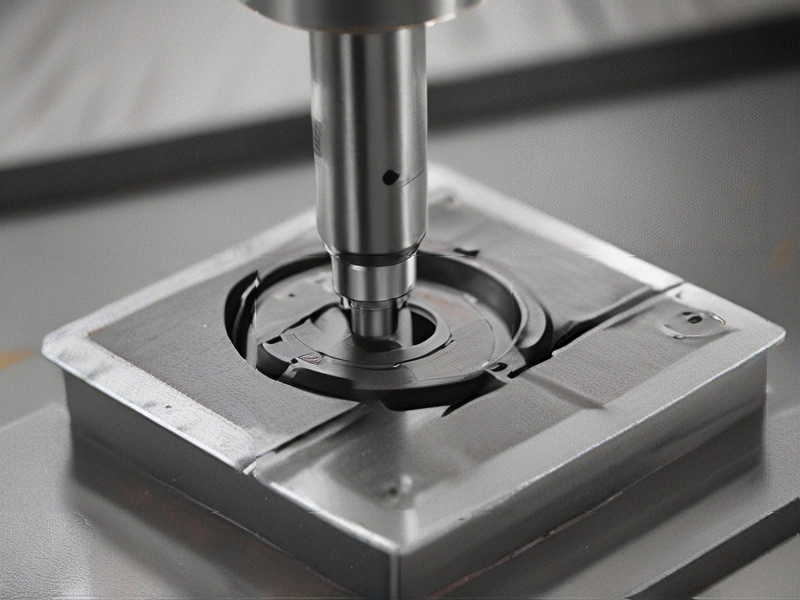

Machining slots involves creating grooves or recesses in various materials using various machining processes such as milling, drilling, or EDM (Electrical Discharge Machining). These slots are essential in manufacturing components for different industries, including automotive, aerospace, and electronics.

Technologies:

1. CNC Milling: Computer Numerical Control (CNC) milling machines are commonly used for slot machining. They employ rotating cutting tools to remove material precisely, allowing for intricate slot designs and varying depths.

2. EDM: This technique uses electrical discharges to shape conductive materials. EDM is particularly useful for creating complex slots in hard materials that are challenging to machine with conventional tools.

3. Laser Cutting: Lasers can be employed to create clean and precise slots in thin materials. This method is particularly advantageous for applications requiring minimal thermal distortion.

4. Waterjet Cutting: Utilizing high-pressure water mixed with abrasives, waterjet cutting can create slots in various materials without the heat-affected zone, preserving the material’s integrity.

Applications:

– Mechanical Assemblies: Slots are often used for alignment and positioning, allowing components to fit together accurately.

– Heat Sinks: In electronics, slots can enhance cooling efficiency by increasing surface area and airflow.

– Guides and Tracks: In machinery, slots are used as guiding paths for moving parts, ensuring smooth operation.

– Keyways and Features: In shafts and other rotating elements, slots (like keyways) enable secure fastening of components, preventing slippage.

In summary, the technology of slot machining plays a crucial role in modern manufacturing, enabling precise, versatile, and efficient production of components across various industries.

Quality Testing Methods for machining slots and how to control quality

Quality testing methods for machining slots are essential to ensure precision and reliability in manufactured components. Here are some effective methods and controls:

1. Visual Inspection: Conduct a preliminary visual check to identify surface defects, dimensional accuracy, or inconsistencies in finish. This method is quick and can reveal obvious defects.

2. Dimensional Measurement: Utilize calipers, micrometers, and gages to measure key dimensions of the slots, such as width, depth, and length. Coordinate Measuring Machines (CMM) can provide high precision measurements for complex geometries.

3. FIT Testing: If the slots are meant to accommodate specific components (like pins or shafts), perform fit tests to ensure proper insertion without excessive force.

4. Surface Roughness Measurement: Use a surface roughness tester to evaluate the finish quality, ensuring it meets specified standards for the application, which can affect sealing and load characteristics.

5. Functional Testing: For slots that serve a specific function (e.g., guiding components), conduct functional tests to confirm that the slots perform as intended under operational conditions.

6. Statistical Process Control (SPC): Implement SPC techniques by collecting data on key process parameters and outputs. This allows for real-time monitoring and identification of variances, facilitating immediate corrective actions.

To ensure consistent quality, establish clear specifications and tolerances for slot machining. Regularly calibrate measuring equipment and train personnel in quality standards. Implement a robust documentation system to track inspections and test results, aiding in traceability and continuous improvement. By combining these methods and controls, manufacturers can effectively maintain high-quality standards in slot machining operations.

Tips for Procurement and Considerations when Purchasing from machining slots

When procuring machining slots, several key considerations can optimize your purchasing process and ensure quality outcomes.

1. Define Requirements: Clearly outline the specifications needed for the machining slots, including dimensions, tolerances, materials, and finishes. This clarity will help suppliers provide accurate quotations and help you avoid costly errors later.

2. Supplier Selection: Research potential suppliers to assess their capabilities, certifications, and reputation in the industry. Look for suppliers experienced in producing similar slots and those who can provide references or case studies.

3. Cost vs. Quality: While it’s tempting to opt for the lowest price, consider the long-term value of quality. Higher-quality machining slots can lead to better performance, increased durability, and reduced maintenance costs.

4. Lead Times and Flexibility: Understand the lead times associated with different suppliers and their ability to handle changes in order quantity or specifications. Reliable suppliers should be able to accommodate your schedule and provide timely delivery.

5. Communication: Maintain open lines of communication with suppliers throughout the procurement process. Discuss any concerns or specific requirements to avoid misunderstandings later.

6. Sample Testing: Whenever possible, request samples or prototypes before making a larger commitment. This allows you to assess quality and compatibility with your project requirements.

7. Total Cost of Ownership (TCO): Consider all associated costs beyond the purchase price, such as shipping, handling, potential rework, or downtime. Evaluating TCO can provide a clearer picture of the overall financial commitment.

By keeping these factors in mind, you can streamline your procurement process and make more informed purchasing decisions for machining slots.

FAQs on Sourcing and Manufacturing from machining slots in China

FAQs on Sourcing and Manufacturing Machined Slots in China

1. Why consider sourcing machined slots from China?

China offers competitive pricing, advanced manufacturing capabilities, and an extensive supplier network. This allows for high-quality machined products at lower costs due to economies of scale.

2. What materials are commonly used for machining slots?

Common materials include aluminum, stainless steel, brass, and various plastics. The choice depends on the intended application and mechanical properties required.

3. How do I find reliable manufacturers?

Research online directories like Alibaba, Global Sources, or industry-specific platforms. It’s crucial to check reviews, request samples, and communicate directly to assess capabilities and reliability.

4. What are the typical lead times for production?

Lead times vary based on order size and complexity, usually ranging from 2 to 6 weeks. Custom orders may take longer, so it’s essential to clarify timelines upfront.

5. How do I ensure quality control?

Implement an inspection process, including third-party quality checks, before shipment. Request documentation of certifications and quality assurance processes from your manufacturer.

6. What shipping options are available?

Options include air freight for fast delivery and sea freight for cost-effectiveness. Shipping methods depend on urgency, budget, and order size.

7. Are there language barriers?

While many Chinese manufacturers have English-speaking staff, clear communication is essential. Use simple language and consider a translator if necessary to clarify technical details.

8. What are the potential risks?

Risks include quality inconsistencies, delays in production, and potential intellectual property issues. Thorough vetting and establishing contracts can help mitigate these risks.

For successful sourcing in China, clear communication, detailed specifications, and regular engagement with your manufacturer are key.