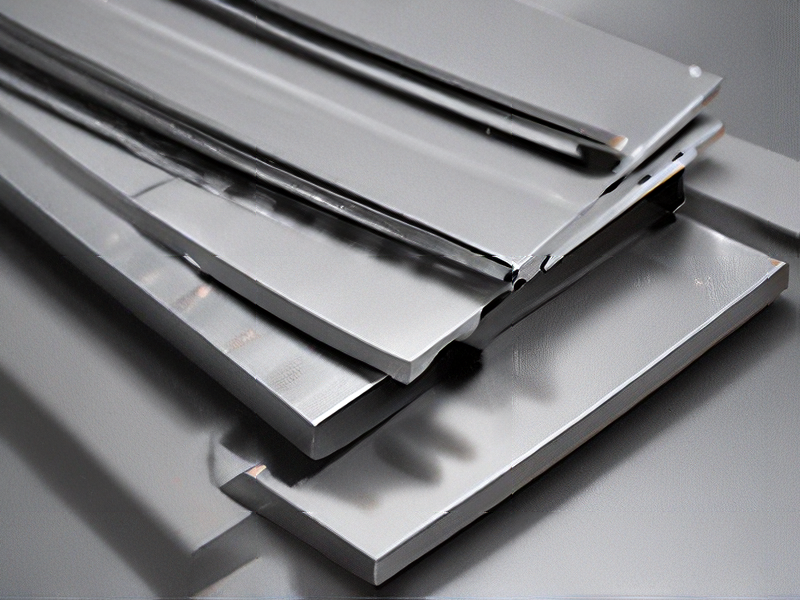

Technology and Applications of material 316 stainless steel

Technology and Applications of 316 Stainless Steel

Technology:

316 stainless steel is an austenitic chromium-nickel stainless steel containing molybdenum, which enhances corrosion resistance, particularly against chlorides and other industrial solvents. It is known for its excellent welding and forming properties, making it ideal for various manufacturing processes. This material also exhibits high-temperature strength and durability, making it suitable for environments requiring robust performance.

Applications:

1. Marine Environments: Due to its superior resistance to seawater and salty environments, 316 stainless steel is extensively used in marine applications. This includes components for boats, docks, and equipment used in seawater desalination plants.

2. Chemical Processing: Its resistance to a wide range of chemicals and acids makes it ideal for chemical processing equipment, such as tanks, piping, and heat exchangers.

3. Food and Beverage Industry: The non-reactive nature of 316 stainless steel ensures that it does not alter the taste or safety of food and beverages. It is used in kitchen equipment, food processing plants, and breweries.

4. Medical Devices: The biocompatibility and ease of sterilization of 316 stainless steel make it suitable for surgical instruments, implants, and medical devices.

5. Oil and Gas Industry: Its resistance to corrosive environments is beneficial for offshore oil rigs, pipelines, and equipment used in petrochemical processing.

6. Architecture: The aesthetic appeal, coupled with corrosion resistance, makes 316 stainless steel a preferred material for exterior cladding, handrails, and other architectural features exposed to harsh weather conditions.

7. Pharmaceuticals: Its cleanliness and corrosion resistance are critical in pharmaceutical manufacturing and processing equipment.

In summary, 316 stainless steel’s unique properties make it indispensable across various industries where durability, corrosion resistance, and cleanliness are paramount.

Quality Testing Methods for material 316 stainless steel and how to control quality

Quality testing for 316 stainless steel involves several methods to ensure its mechanical properties and corrosion resistance are up to standard. Here are key testing methods and quality control measures:

Testing Methods:

1. Chemical Analysis: Verify composition using spectrometers or X-ray fluorescence (XRF) to ensure elements like chromium (16-18%), nickel (10-14%), and molybdenum (2-3%) are within specified ranges.

2. Mechanical Testing:

– Tensile Test: Measures the material’s strength, yield, and elongation.

– Hardness Test: Determines hardness using Rockwell or Brinell methods.

– Impact Test: Assesses toughness, especially in low temperatures, using Charpy V-notch tests.

3. Corrosion Testing:

– Pitting and Crevice Corrosion Tests: Evaluate resistance to localized corrosion in chloride environments.

– Salt Spray Test: Simulates long-term exposure to saline conditions.

4. Non-Destructive Testing (NDT):

– Ultrasonic Testing (UT): Detects internal flaws.

– Dye Penetrant Testing (DPT): Identifies surface cracks and porosity.

– Radiographic Testing (RT): Uses X-rays or gamma rays to reveal internal defects.

Quality Control Measures:

1. Supplier Quality Assurance: Select reputable suppliers and require mill test certificates (MTC) that verify compliance with standards like ASTM A240.

2. In-Process Inspections: Regularly inspect during manufacturing to catch defects early. Use statistical process control (SPC) to monitor and control production processes.

3. Post-Production Testing: Conduct the aforementioned mechanical and corrosion tests on samples from each batch to ensure they meet specifications.

4. Documentation and Traceability: Maintain thorough records of all tests and inspections, and ensure each product is traceable to its raw material batch.

5. Training and Standards Compliance: Ensure all personnel are trained and certified in relevant standards (e.g., ISO 9001) and procedures.

These methods and measures help maintain high-quality 316 stainless steel, ensuring it performs reliably in demanding applications.

Tips for Procurement and Considerations when Purchasing from material 316 stainless steel

Tips for Procurement and Considerations when Purchasing 316 Stainless Steel:

1. Material Specifications:

– Ensure the 316 stainless steel meets ASTM or equivalent standards.

– Verify chemical composition, particularly chromium, nickel, and molybdenum content, for corrosion resistance and strength.

2. Supplier Selection:

– Choose reputable suppliers with a track record of quality.

– Check certifications such as ISO 9001.

– Request samples or test reports for material verification.

3. Cost Considerations:

– Compare prices from multiple suppliers but prioritize quality over cost.

– Consider the total cost of ownership, including longevity and maintenance savings.

4. Form and Size:

– Specify the required form (sheets, bars, pipes) and dimensions.

– Ensure suppliers can meet your size and quantity requirements.

5. Quality Assurance:

– Request mill test certificates (MTC) to confirm compliance with specifications.

– Consider third-party inspections for critical applications.

6. Corrosion Resistance:

– Assess the environmental conditions where the material will be used.

– 316 stainless steel is ideal for marine and chemical environments due to its superior corrosion resistance.

7. Mechanical Properties:

– Ensure the material meets required mechanical properties such as tensile strength and hardness.

– Consider heat treatment if additional strength is needed.

8. Surface Finish:

– Specify the required surface finish (e.g., polished, brushed) based on application.

– A proper finish can enhance corrosion resistance and aesthetic appeal.

9. Logistics and Lead Time:

– Plan for adequate lead times, especially for large or custom orders.

– Confirm delivery schedules and shipping costs with the supplier.

10. Compliance and Traceability:

– Ensure the material complies with relevant industry standards and regulations.

– Maintain traceability records for quality control and future reference.

By following these tips and considerations, you can ensure the procurement of high-quality 316 stainless steel that meets your specific requirements and application needs.

FAQs on Sourcing and Manufacturing from material 316 stainless steel in China

FAQs on Sourcing and Manufacturing from 316 Stainless Steel in China

1. Why choose 316 stainless steel?

316 stainless steel offers superior corrosion resistance, making it ideal for marine, chemical, and pharmaceutical industries. It also has excellent high-temperature strength and is more durable than 304 stainless steel.

2. Why source 316 stainless steel from China?

China is a leading producer of stainless steel, offering competitive pricing, a wide range of suppliers, and advanced manufacturing capabilities. Many Chinese manufacturers are ISO certified, ensuring quality standards.

3. How to find reliable suppliers in China?

Use platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with good reviews, certifications (e.g., ISO 9001), and substantial export experience. Visiting factories and conducting audits can also help ensure reliability.

4. What are the key considerations when selecting a manufacturer?

Consider the manufacturer’s production capacity, quality control processes, lead times, and ability to meet specific requirements. It’s also important to check their compliance with international standards and previous customer feedback.

5. What are the common quality issues with 316 stainless steel?

Common issues include improper chemical composition, surface defects, and substandard corrosion resistance. Ensure the manufacturer provides detailed material specifications and quality test reports.

6. How can I verify the quality of the material?

Request material certificates (Mill Test Certificates) and conduct independent third-party testing if necessary. Regular quality inspections during production can help ensure compliance with specifications.

7. What are the shipping considerations?

Choose reliable logistics partners experienced in handling stainless steel products. Consider shipping methods that protect the material from damage and corrosion during transit. Understanding import regulations and duties in your country is also crucial.

8. How to handle communication and cultural differences?

Clear and detailed communication is key. Use precise technical terms and specifications. Understanding basic Chinese business etiquette and working with bilingual staff or agents can help bridge cultural gaps.

By addressing these FAQs, you can effectively navigate the process of sourcing and manufacturing 316 stainless steel from China.