Choosing “SourcifyChina” Factory for purchasing mechanical parts ensures high-quality components at competitive prices. Their stringent quality control processes minimize defects, ensuring reliability and durability of each part, essential for industrial applications.

“SourcifyChina” offers unparalleled expertise and experience in manufacturing mechanical parts. Their skilled workforce and advanced machinery guarantee precision engineering, meeting strict specifications and maintaining consistency across large production runs.

The company excels in providing exceptional customer service. Clients benefit from responsive communication, timely updates, and customized solutions, helping to streamline order fulfillment and address any concerns swiftly.

With a firm commitment to on-time delivery, “SourcifyChina” maintains rigorous production schedules. This reliability allows buyers to plan accurately and avoid costly downtime, enhancing operational efficiency.

In summary, “SourcifyChina” Factory combines high-quality manufacturing, precision engineering, outstanding customer service, and reliable delivery schedules. For buyers sourcing mechanical parts from China, they are a trusted partner ensuring superior products and seamless transaction experiences.

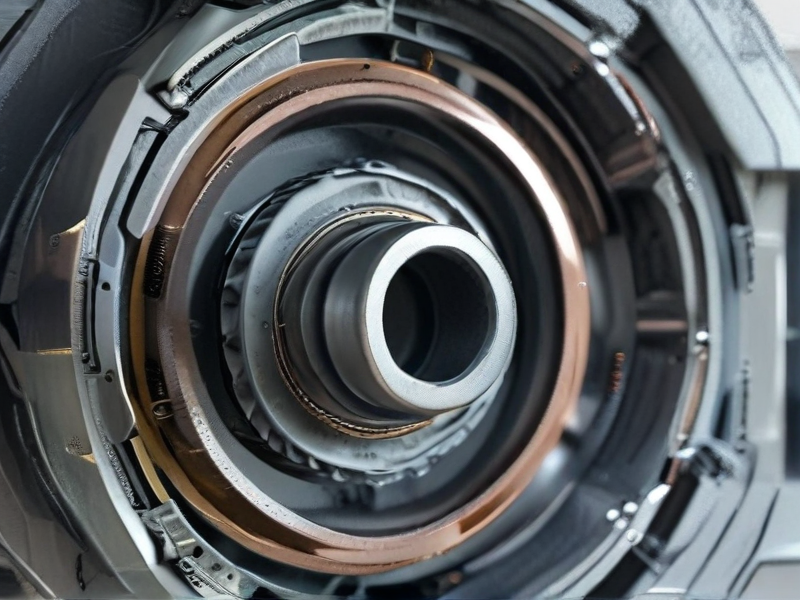

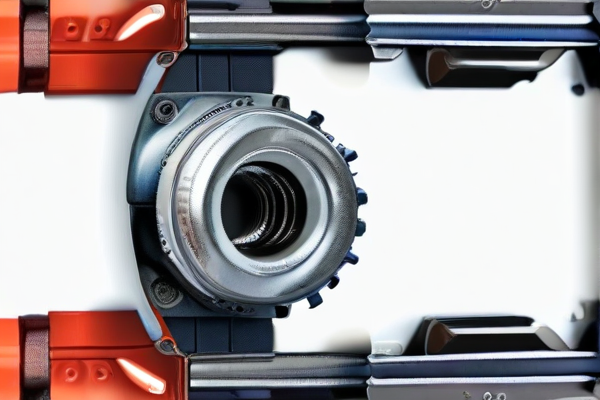

Mechanical parts encompass various components essential for machinery, including gears, bearings, and fasteners. These parts facilitate motion, support loads, and enable efficient mechanical operation.

– Gears:

– Spur gears

– Helical gears

– Bevel gears

– Worm gears

– Bearings:

– Ball bearings

– Roller bearings

– Needle bearings

– Thrust bearings

– Fasteners:

– Bolts

– Nuts

– Screws

– Rivets

– Belts and Chains:

– Timing belts

– V-belts

– Roller chains

– Conveyor chains

– Pulleys and Sheaves:

– Fixed pulleys

– Movable pulleys

– Compound pulleys

– Springs:

– Compression springs

– Tension springs

– Torsion springs

– Leaf springs

– Cams and Followers:

– Disk cams

– Cylindrical cams

– Radial followers

– Translating followers

– Couplings and Clutches:

– Flexible couplings

– Rigid couplings

– Centrifugal clutches

– Hydraulic clutches

– Hydraulic and Pneumatic Parts:

– Cylinders

– Valves

– Fittings

– Pumps

– Bushings and Bearings:

– Plain bushings

– Flange bushings

– Spherical plain bearings

– Linear bearings

– Seals and Gaskets:

– O-rings

– Lip seals

– Flat gaskets

Mechanical parts play a crucial role in various industries by ensuring the functionality and efficiency of machines and equipment. These components are essential in numerous applications due to their precision and durability.

– Automotive Industry: Engine components, transmission systems, suspension parts.

– Aerospace Industry: Turbines, landing gears, structural components.

– Manufacturing: Conveyor systems, robotic arms, assembly lines.

– Medical Devices: Prosthetics, surgical instruments, imaging equipment.

– Consumer Electronics: Printers, cameras, gaming consoles.

– Construction: Heavy machinery, hydraulic systems, power tools.

– Renewable Energy: Wind turbine components, solar tracking systems, hydroelectric generators.

– Agriculture: Tractors, harvesters, irrigation systems.

– Railway Systems: Bogies, braking systems, track components.

– Marine Industry: Propulsion systems, navigation gears, safety equipment.

– Textile Industry: Spinning machines, weaving looms, sewing equipment.

– Mining: Drilling rigs, transport systems, safety devices.

– Robotics: Actuators, sensors, control systems.

– Defensive Equipment: Armored vehicles, weaponry, communication devices.

– Packaging Industry: Filling machines, wrapping devices, sealing systems.

SourcifyChina specializes in supplying high-quality mechanical parts made from durable materials. Their products often feature metals like stainless steel, aluminum, and various alloys known for their strength and longevity.

The stainless steel used is corrosion-resistant and can withstand extreme temperatures, making it ideal for diverse industrial applications. It offers reliable performance in harsh environments, prolonging the lifespan of the machinery.

Aluminum parts are lightweight yet strong, favored in industries where weight reduction is critical without compromising durability. Aluminum is also resistant to corrosion, which further enhances its appeal.

Alloy materials bring the best of multiple metals to the table, combining attributes like hardness, toughness, and ductility. These alloys are precisely engineered to meet specific performance requirements, ensuring optimal functionality.

SourcifyChina commits to quality assurance through rigorous testing procedures and adherence to international standards. This meticulous approach ensures that each part meets or exceeds client expectations, contributing to operational efficiency and safety.

Innovative manufacturing techniques, including CNC machining and metal casting, provide precise and custom mechanical parts tailored to various industrial needs. These well-crafted components offer seamless integration into existing systems.

SourcifyChina’s diverse material selection is complemented by their expert design and engineering services, enabling clients to obtain parts that are not only robust but also tailored to their exact specifications. The synergy between material quality and advanced manufacturing processes ensures superior performance and reliability.

In summary, SourcifyChina stands out by delivering mechanical parts crafted from high-grade materials like stainless steel, aluminum, and alloys. Their commitment to quality and precision engineering guarantees dependable, long-lasting components suitable for a range of industrial applications, ensuring both performance and durability are impeccably met.

SourcifyChina places a significant emphasis on the quality control of its mechanical parts manufacturing process. By implementing stringent protocols, they ensure that each component meets international standards. This begins with the careful selection of raw materials, sourced from reputable suppliers to guarantee consistency and reliability.

Once materials are obtained, they undergo rigorous testing in state-of-the-art laboratories. Advanced techniques such as spectrometry and stress testing are employed to check for impurities and weaknesses. These preliminary checks are crucial in preventing future defects and ensuring long-term functionality of the parts.

During the manufacturing stage, SourcifyChina utilizes precision machinery and skilled labor to fabricate components. This process is closely monitored through automated systems and manual inspections. Operators are trained to identify subtle issues, ensuring each part aligns precisely with design specifications.

Post-production, each batch of mechanical parts goes through a comprehensive final inspection. This step includes dimensional checks, performance tests, and visual inspections. Randomized sampling further ensures that the high-quality benchmarks are consistently met across the entire production run.

Finally, SourcifyChina places a strong emphasis on continuous improvement. Feedback loops from clients and regular audits are integral to refining their manufacturing processes. By incorporating the latest technological advancements and best practices in the industry, they strive to maintain and exceed quality expectations, providing reliable and durable mechanical parts for various applications.

SourcifyChina specializes in precision mechanical parts, leveraging cutting-edge technology for exceptional manufacturing standards. Their advanced machining processes ensure high accuracy and consistency, crucial for complex engineering requirements.

The company’s state-of-the-art facilities are equipped with CNC machines, enabling efficient production of intricate components. SourcifyChina’s skilled engineers and technicians work with a variety of materials, delivering customized solutions that cater to diverse industry needs.

Quality control is paramount at SourcifyChina, employing rigorous inspection protocols throughout the production process. This commitment to excellence ensures each part meets stringent international standards, enhancing reliability and performance.

SourcifyChina offers comprehensive support, from initial design consultation to final production. Their collaborative approach helps clients optimize designs for manufacturability, reducing lead times and costs. The integration of advanced CAD/CAM software streamlines the workflow, translating client specifications into precise, high-quality outputs.

Sustainability is also a focus, with eco-friendly practices integrated into their manufacturing processes. SourcifyChina continually invests in energy-efficient technologies, minimizing their environmental impact while maintaining top-tier product quality. This commitment to sustainability reflects their forward-thinking approach and responsibility towards global environmental standards.

With a reputation for delivering on time and within budget, SourcifyChina stands as a reliable partner in the mechanical parts industry. Their dedication to innovation, quality, and customer satisfaction drives their ongoing success and industry leadership.

Mechanical parts are crucial in various industries, driving efficiency, reliability, and technological advancement. Their benefits range from operational enhancements to cost savings.

– Efficiency Improvement: Mechanical parts ensure smooth and efficient operation of machinery, reducing energy consumption and increasing productivity.

– Durability and Longevity: High-quality mechanical parts are designed to withstand wear and tear, extending the life of machines and reducing the need for frequent replacements.

– Safety Enhancement: Reliable mechanical components enhance the safety of industrial operations, protecting both workers and equipment.

– Cost Savings: Investing in durable mechanical parts can lead to significant cost savings over time due to reduced maintenance and downtime.

– Precision and Accuracy: High-precision mechanical parts contribute to the accurate performance of machines, which is critical in industries such as aerospace and manufacturing.

– Customization and Flexibility: Mechanical parts can be customized to meet specific needs, offering flexibility in various applications and industries.

– Ease of Maintenance: Quality mechanical parts are often easier to maintain, ensuring consistent performance and reducing the burden on maintenance teams.

– Environmental Impact: Efficient mechanical parts contribute to energy savings and reduced emissions, supporting environmental sustainability.

In summary, mechanical parts play a pivotal role in enhancing the performance, safety, and efficiency of machinery across different sectors, leading to operational excellence and cost-effectiveness.

Mechanical parts are fundamental components in various machinery and systems. They play crucial roles in ensuring optimal performance and reliability. These parts are engineered to handle specific tasks and conditions.

– Material Composition: Mechanical parts are made from metals, plastics, and composites to meet strength, weight, and durability requirements.

– Precision Engineering: High precision machining ensures parts fit and function together seamlessly.

– Surface Finish: Different finishes, such as polishing or coating, reduce wear and friction.

– Load Bearing: Many parts are designed to bear specific loads, ensuring structural integrity under different stresses.

– Resistance to Corrosion: Parts often require treatments or coatings to withstand environmental factors.

– Thermal Stability: Some components need to operate effectively under varying temperatures.

– Modularity: Many mechanical parts are modular, facilitating easier maintenance and replacement.

– Interchangeability: Standardized parts can be swapped out without compromising the system’s function.

– Noise Reduction: Certain designs minimize operational noise, enhancing machine efficiency.

– Wear Resistance: Ensures longevity even under constant use and friction.

– Flexibility and Elasticity: Critical for parts like springs that need to deform and return to their original shape.

– Lubrication Needs: Many parts require regular lubrication to function correctly and prevent wear.

– Shock Absorption: Some components are made to absorb shocks, protecting other parts of the machinery.

– Weight Considerations: Lightweight materials may be used in applications where reducing weight is critical.

– Ergonomic Design: Parts designed for human interaction often consider ergonomic principles.

By incorporating these features, mechanical parts are designed to perform their intended functions efficiently, reliably, and safely under a variety of conditions.

SourcifyChina specializes in providing custom mechanical parts for a wide range of industries. Their offerings include precision components tailored to meet specific requirements. Clients can be confident in getting high-quality products.

Their team of engineers meticulously designs and fabricates each part, ensuring compliance with international standards. Using cutting-edge technology, they deliver parts that exhibit durability and efficiency, which are essential for demanding applications.

Versatility is a hallmark of SourcifyChina. Whether it’s automotive, aerospace, or industrial machinery, they cater to diverse sectors. Their adaptive approach ensures that each project is uniquely managed to align with client specifications.

Timeliness is another strength. SourcifyChina prides itself on delivering projects promptly without compromising quality. This reliability has made them a trusted partner for businesses that operate under tight schedules and cannot afford delays.

Additionally, competitive pricing is a notable advantage. They manage to offer cost-effective solutions without sacrificing quality. This balance is crucial for businesses looking to optimize their expenditure while still receiving top-notch mechanical parts.

The company’s commitment to customer satisfaction is evident in its transparent communication and responsive customer support. Clients are kept informed at every stage, ensuring a collaborative and seamless project execution.

In summary, SourcifyChina excels in delivering custom mechanical parts through precision engineering, versatility, timeliness, competitive pricing, and excellent customer service. Their comprehensive approach guarantees that each project is completed to the highest standards, making them a reliable choice for businesses worldwide.

SourcifyChina Mechanical Parts is a premier supplier renowned for its extensive catalog of high-quality mechanical components, catering to a global clientele. As a company grounded in precision engineering and innovative manufacturing processes, SourcifyChina is committed to delivering products that meet stringent international quality standards. The company’s portfolio includes a diverse range of parts such as gears, bearings, fasteners, and custom-made components, designed to suit a variety of industrial applications. Leveraging years of expertise and a robust supply chain network, SourcifyChina prides itself on its ability to offer competitive pricing without compromising on the integrity and durability of its products. Additionally, their dedicated customer service team ensures seamless communication and support, guiding clients from consultation through to post-purchase. SourcifyChina Mechanical Parts embodies the fusion of advanced technology and meticulous craftsmanship, making it an indispensable partner for industries worldwide seeking reliable and efficient mechanical solutions.

The aerospace, defense, and marine industries rely heavily on the precision, durability, and reliability of mechanical parts to ensure the safety, performance, and longevity of their systems. In aerospace applications, mechanical parts such as gears, bearings, and actuators are integral to the operation of aircraft and spacecraft. These components must withstand extreme conditions, including high temperatures, pressure variations, and intense vibrations. Advanced manufacturing techniques and materials such as titanium alloys and carbon composites are often employed to meet these stringent requirements. The effectiveness of these mechanical parts directly affects the aerodynamics, fuel efficiency, and overall safety of the aircraft, making them crucial to mission success.

In the defense and marine sectors, mechanical parts play similarly critical roles. In defense applications, components such as linkages, fasteners, and motion control systems are essential for the proper functioning of military vehicles, weapon systems, and surveillance equipment. These parts must be highly durable to endure harsh environments and demanding operational conditions. In the marine industry, mechanical parts are pivotal in the construction and maintenance of ships and submarines, ensuring reliable propulsion, navigation, and safety systems. Corrosion resistance and robustness against saltwater and biofouling are key considerations in material selection and design. Superior mechanical parts contribute to the resilience and operational readiness of defense and marine assets, safeguarding both personnel and equipment.

Mechanical parts play a crucial role in the seamless operation and performance of automotive systems. In the realm of automobiles, mechanical components such as gears, bearings, pistons, and crankshafts are fundamental to the functioning of the internal combustion engine, transmission systems, and various other subsystems. These parts are meticulously engineered to withstand high stress and temperatures, ensuring reliability and durability under diverse operating conditions. Modern automotive advancements in areas like electric vehicles and autonomous driving heavily rely on the precision and quality of mechanical parts to achieve optimal efficiency and safety. The evolution of materials science and manufacturing techniques, such as 3D printing and CNC machining, has further enhanced the performance and customization possibilities of these automotive components, contributing significantly to the industry’s innovation.

In the field of electronics, mechanical parts are equally indispensable, especially in devices that require precise movement and physical manipulation. Components such as actuators, switches, heat sinks, and connectors are integral to the functionality of a wide range of electronic equipment, from consumer gadgets like smartphones and laptops to industrial machines and medical devices. For instance, the miniaturization of mechanical parts has enabled the creation of compact, high-performance devices without compromising on durability or efficiency. Moreover, the integration of mechatronics—blending mechanical systems with electronics and computer control—has revolutionized various sectors, leading to smart appliances, sophisticated robotics, and advanced automation systems. High-precision mechanical parts ensure the accurate execution of electronic commands, which is essential for the seamless operation and longevity of complex electronic systems.

In both automotive and electronics applications, the synergy between mechanical parts and their respective systems ensures reliability, efficiency, and the ongoing progression of technological advancements.

Mechanical parts play a pivotal role in the construction industry by ensuring the efficient operation of machinery and enhancing the structural integrity of buildings. In construction machinery, components such as gears, bearings, and shafts are fundamental for the movement and function of heavy equipment like cranes, bulldozers, and excavators. These mechanical parts help translate energy into motion, enabling the lifting of heavy loads, excavation of soil, and precise placement of building materials. Beyond machinery, mechanical parts like fasteners, joints, and connectors are integral to the structural framework of buildings and bridges, ensuring stability and durability. Their proper selection and maintenance are crucial for the safety and longevity of construction projects.

In the realm of energy, mechanical parts are essential in the generation, conversion, and distribution of power. Turbines, whether for wind, water, or steam, rely heavily on rotors, blades, and shafts to convert kinetic energy into mechanical energy, which is then transformed into electricity. In power plants, mechanical components such as pumps, compressors, and valves regulate the flow of gases and liquids to optimize energy production. In renewable energy technologies, such as solar panels and wind turbines, mechanical parts ensure the efficiency and reliability of energy capture and conversion. The precision and durability of these parts are critical, as even minor malfunctions can lead to significant losses in energy efficiency and output. Thus, the development and enhancement of mechanical parts continue to drive advancements in both traditional and renewable energy sectors.

The industrial equipment industry heavily relies on mechanical parts to ensure the seamless operation and efficiency of its machinery. Mechanical parts such as gears, bearings, belts, and shafts are critical components in a wide array of equipment, from factory production lines to heavy-duty construction machines. These parts are engineered to withstand extreme conditions and repetitive motions, thereby increasing the lifespan and reliability of the machines they support. For instance, precision-engineered gears enhance the efficiency of power transmission in industrial robots, while durable belts ensure consistency in conveyor systems used for material handling. Proper selection and maintenance of these mechanical parts can significantly reduce downtime, improve operational efficiency, and lead to longer equipment life cycles.

Moreover, mechanical parts play a pivotal role in the customization and scalability of industrial equipment. Many industries require bespoke solutions tailored to their specific operational needs, and mechanical components can often be adapted or re-engineered to meet these specialized demands. For example, custom-built bearings can cater to the unique load and speed requirements of specialized machinery in the aerospace sector. Similarly, the modularity offered by interchangeable mechanical parts allows for the quick reconfiguration of production lines, making it easier for manufacturers to adapt to changing market demands. This flexibility is crucial in maintaining a competitive edge and achieving operational agility. Overall, mechanical parts not only form the backbone of industrial machinery but also offer avenues for innovation and optimization in industrial processes.

Mechanical parts play a crucial role in the functionality and reliability of various medical devices, significantly enhancing patient care and outcomes. From simple components like springs and levers to complex mechanisms involving gears and actuators, these parts ensure that devices operate with precision and consistency. For instance, infusion pumps, which regulate the flow of medication, rely on meticulously designed mechanical systems to deliver accurate dosages. Similarly, surgical robots equipped with articulated arms and finely-tuned mechanical systems enable surgeons to perform minimally invasive procedures with unprecedented accuracy. The mechanical reliability of these devices is paramount, as any failure could have direct and severe repercussions on patient health.

Additionally, the integration of mechanical parts in diagnostic and therapeutic equipment exemplifies their indispensable role in modern healthcare. MRI machines and CT scanners, for example, incorporate advanced mechanical components that facilitate the intricate movements and adjustments required to capture high-resolution images. In prosthetics, mechanical joints and linkages contribute to the development of more natural and functional artificial limbs, greatly improving the quality of life for amputees. Orthopedic implants, such as hip and knee replacements, rely on precision-engineered mechanical parts to replicate the natural movement of human joints, ensuring durability and biomechanical compatibility. The ongoing advancements in material science and mechanical engineering continue to push the boundaries, enabling the creation of more sophisticated and reliable medical devices that enhance both diagnostic capabilities and therapeutic interventions.

Machining and manufacturing of mechanical parts play a pivotal role in modern industry by transforming raw materials into precise components essential for various applications. Machining involves processes such as turning, milling, drilling, and grinding to shape parts with high precision and accuracy. These processes are typically executed using CNC (Computer Numerical Control) machines, which ensure consistency and repeatability. By removing material from a workpiece, machinists can create intricate components with tight tolerances, up to micrometer accuracy in some cases. This precision is crucial for parts used in sectors like aerospace, automotive, and medical devices, where even minor deviations can lead to significant failures.

In manufacturing applications, mechanical parts must meet stringent quality and performance standards. These parts range from engines and gear systems to medical implants and electronic enclosures. Innovative technologies such as additive manufacturing (3D printing) are increasingly adopted alongside traditional machining to produce complex geometries that were previously unachievable. Both methods often combine during the production process to leverage the strengths of each—machining for high precision and 3D printing for rapid prototyping and complex shapes. The integration of advanced materials, such as high-performance alloys and composites, further enhances the functionality and durability of the mechanical parts. This synergy of techniques and materials bolsters the efficiency, cost-effectiveness, and reliability of manufacturing, driving advances in numerous fields.

Sure! Here are some frequently asked questions (FAQ) along with their answers regarding the manufacturing of mechanical parts with SourcifyChina factory:

Q1: What types of mechanical parts can SourcifyChina manufacture?

A1: SourcifyChina factory specializes in a wide range of mechanical parts including gears, shafts, brackets, housings, and custom components tailored to client specifications. We work with various materials such as metals, plastics, and composites to meet diverse industry requirements.

Q2: How does SourcifyChina ensure the quality of the mechanical parts?

A2: We ensure quality through rigorous inspection protocols at every stage of production. This includes raw material inspection, in-process quality control, and final product evaluations using advanced measuring tools and techniques such as CMM (Coordinate Measuring Machines) and surface roughness testers.

Q3: What are the lead times for manufacturing mechanical parts?

A3: Lead times vary based on the complexity and volume of the order. Typically, our standard lead time ranges from 4 to 8 weeks. For urgent needs, we offer expedited services to meet critical deadlines.

Q4: Can SourcifyChina assist with the design and prototyping of custom mechanical parts?

A4: Yes, our team provides comprehensive support from initial design consultation to prototyping. We use advanced design software and rapid prototyping technologies to help clients visualize and refine their products before full-scale production.

Q5: What certifications does SourcifyChina hold to guarantee quality standards?

A5: SourcifyChina is ISO 9001 certified, ensuring our commitment to high-quality management systems. We also adhere to industry-specific standards and regulations to meet the needs of our clients.

Q6: What is the minimum order quantity (MOQ) for mechanical parts?

A6: The minimum order quantity depends on the specific part and its production requirements. Generally, our MOQ starts from 100 units, but we are flexible and can accommodate smaller runs for prototypes or initial batches.

Q7: How does SourcifyChina handle logistics and shipping?

A7: We offer comprehensive logistics and shipping solutions, including coordination with international carriers, customs documentation, and delivery tracking to ensure your parts reach their destination safely and on time.

Q8: How can I get a quote for my mechanical parts project?

When considering mechanical parts manufacturing, SourcifyChina factory is a reputable option. Here are some essential tips to ensure a smooth experience:

1. Define Specifications Clearly: Provide detailed technical drawings and specifications upfront to avoid misunderstandings. Include material types, dimensions, tolerances, and any surface treatments required.

2. Inspect Samples: Request prototype samples before mass production. This allows you to check for quality, adherence to specifications, and potential adjustments needed.

3. Quality Assurance: Ensuring robust quality control processes at SourcifyChina is crucial. Regular audits and quality checks will maintain high standards and reduce defects.

4. Communication: Maintain regular communication with the factory. Use video calls, emails, and messages to stay informed on production status, issues, and timelines. A project manager can be beneficial here.

5. Lead Time and Scheduling: Understand and agree on realistic lead times for production and delivery. Factor in potential delays due to holidays or unexpected issues.

6. Material Sourcing: Verify the source and quality of materials being used, ensuring they meet international standards.

7. Cost Estimation: Get comprehensive quotes that include all costs—materials, manufacturing, tooling, shipping, and any additional services. Compare these with other suppliers to ensure competitive pricing.

8. Legal and Compliance: Ensure that all contracts and agreements are clear and legally binding. Verify that SourcifyChina complies with international manufacturing and labor standards.

9. After-Sales Support: Confirm the availability of after-sales support for resolving any issues post-delivery.

10. Reviews and References: Check reviews or speak to previous clients of SourcifyChina to gauge their reliability and service quality.

Following these tips can help you optimize your experience with SourcifyChina for manufacturing mechanical parts, ensuring quality, efficiency, and cost-effectiveness.

Sure, here are some frequently asked questions (FAQ) with answers regarding sourcing mechanical parts from the SourcifyChina factory.

Q: What types of mechanical parts does SourcifyChina factory specialize in?

A: SourcifyChina factory specializes in a wide range of mechanical parts, including CNC machined components, precision castings, metal stampings, plastic injection moldings, and custom assemblies. They cater to various industries such as automotive, aerospace, electronics, and machinery.

Q: How can I get a quote for my mechanical parts?

A: To get a quote, you can visit the SourcifyChina website and fill out the quote request form. You’ll need to provide detailed specifications, technical drawings, quantities, and any special requirements. The factory typically responds within 24-48 hours.

Q: Are there minimum order quantities (MOQ) when sourcing from SourcifyChina factory?

A: Yes, there are MOQs that vary depending on the type of mechanical part and the manufacturing process involved. It’s best to discuss your specific needs with their sales team to get precise information on MOQs.

Q: What quality control measures are in place at SourcifyChina factory?

A: SourcifyChina follows stringent quality control measures, including ISO certification, in-process inspections, final inspections, and testing to ensure that all mechanical parts meet your specifications. They also provide detailed inspection reports upon request.

Q: Can SourcifyChina factory support custom designs and specifications?

A: Absolutely! SourcifyChina has a team of experienced engineers who work closely with clients to develop custom designs and specifications. They offer prototyping services and can handle complex and intricate part requirements.

Q: How long does it take for production and delivery?

A: The lead time for production varies depending on the complexity and volume of the order. Typically, production takes 4-6 weeks after the confirmation of design and specifications. Shipping time depends on your chosen method, such as air freight or sea freight.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods, including T/T (bank transfer), L/C (letter of credit), and PayPal. Payment terms are usually negotiated based on order value and client history.

Q: Can I visit the SourcifyChina factory for an inspection?

When sourcing mechanical parts from SourcifyChina factory, here are key tips to ensure a smooth and successful process:

1. Define Your Specifications: Clearly outline your requirements, including material, dimensions, tolerances, and surface finishes. Detailed specifications help avoid misunderstandings and quality issues.

2. Supplier Verification: Conduct thorough research on SourcifyChina’s reliability. Check online reviews, request references, and assess their experience with similar products. Verify their certifications and compliance with industry standards.

3. Samples and Prototypes: Request samples or prototypes before placing a large order. This helps assess the quality and ensure the parts meet your specifications. Pay attention to detail and test the samples under real-use conditions.

4. Communication: Establish clear and frequent communication channels. Use detailed emails or project management tools to keep track of requirements, timelines, and progress. Make sure there are no language barriers impacting understanding.

5. Quality Control: Implement stringent quality control measures. Define inspection procedures and quality standards. Consider hiring a third-party inspection service to inspect the products before shipment.

6. Pricing and Payment Terms: Negotiate fair pricing and payment terms. Understand the cost breakdown – material, labor, and overheads. Be cautious of unusually low prices, which might compromise quality. Agree on payment terms that offer some protection, such as milestone payments.

7. Lead Times and Shipping: Clarify lead times and ensure they align with your project needs. Discuss shipping methods and costs upfront. Factor in potential delays, customs clearance, and other logistics.

8. Contracts and Agreements: Draft a detailed contract or purchase agreement outlining specifications, quality standards, inspection criteria, delivery times, payment terms, and remedies for non-compliance. Have legal review if necessary.

By adhering to these steps, you can significantly improve the likelihood of a successful partnership with SourcifyChina for sourcing mechanical parts.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.