Technology and Applications of metal 3d print

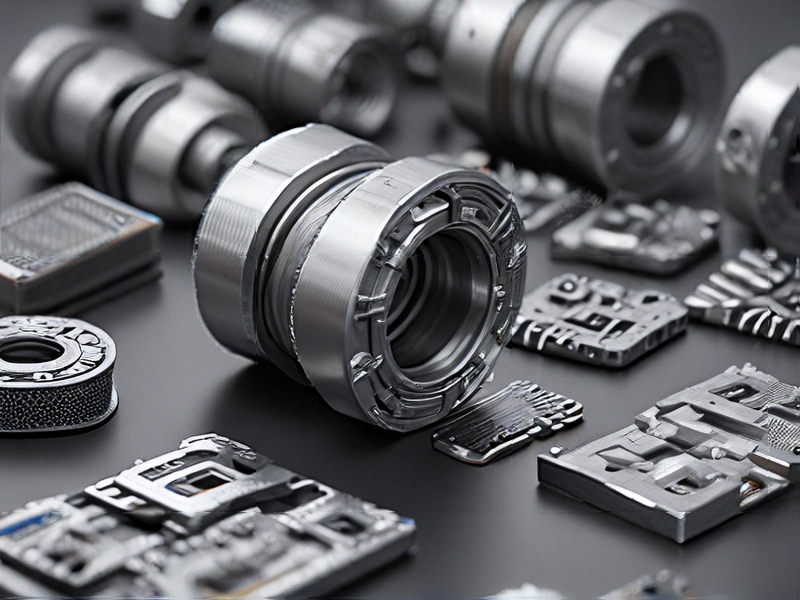

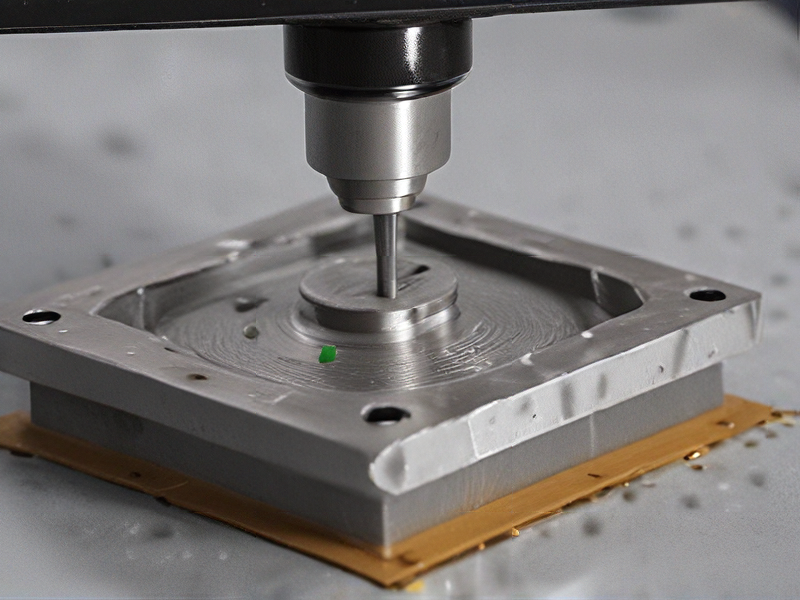

Metal 3D printing, or additive manufacturing, involves the layer-by-layer construction of metallic components using techniques like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Binder Jetting. This technology offers numerous advantages in various industries, including aerospace, automotive, and medical sectors.

One significant application of metal 3D printing is in aerospace, where it facilitates the production of lightweight, geometrically complex components that can enhance fuel efficiency. For instance, companies like GE Aviation have utilized 3D printing to create intricate fuel nozzles that reduce weight and improve performance.

In the automotive industry, metal 3D printing allows for rapid prototyping and customization of parts. This flexibility enables manufacturers to iterate designs quickly and reduce time-to-market for new vehicles. Additionally, it supports the production of low-volume, high-complexity parts that traditional methods struggle to produce economically.

The medical field benefits from personalized solutions through metal 3D printing, particularly in implantable devices. Custom titanium implants can be designed to fit individual patients’ anatomy, promoting better integration and outcomes.

Metal 3D printing also supports sustainable manufacturing practices by minimizing waste compared to subtractive manufacturing methods. As the technology continues to evolve, advancements in materials and processes will expand its applications, including potential uses in construction, tooling, and beyond.

Overall, metal 3D printing is revolutionizing the way components are designed and manufactured, combining efficiency, flexibility, and sustainability in modern production workflows. As industries adopt this technology, we can expect further innovations and transformations in manufacturing processes.

Quality Testing Methods for metal 3d print and how to control quality

Quality testing for metal 3D printing involves several methods to ensure that the final product meets desired specifications and standards. Key methods include:

1. Visual Inspection: This initial step checks for obvious defects such as surface irregularities, warping, or layer misalignment. It provides immediate feedback on the print’s condition.

2. Dimensional Measurement: Using tools like calipers and coordinate measuring machines (CMM), precise measurements are taken to ensure the part conforms to design specifications. Tolerances must be strictly adhered to.

3. Non-Destructive Testing (NDT): Techniques such as X-ray computed tomography (CT) or ultrasonic testing are used to identify internal defects without damaging the parts. These methods help reveal issues like porosity or inclusions.

4. Mechanical Testing: This can include tensile, fatigue, and impact testing to gauge the material properties of the printed metal. These tests are crucial for understanding how the material will behave under stress.

5. Microstructure Analysis: Scanning electron microscopy (SEM) or optical microscopy can be employed to evaluate the microstructural characteristics of the metal, revealing grain structure and any anomalies.

To control quality, it’s essential to implement a robust quality management system that includes:

– Process Monitoring: Continuously track printing parameters such as temperature, speed, and feed rates. Utilize sensors and software for real-time data analysis.

– Standard Operating Procedures (SOPs): Establish clear guidelines for the printing process, post-processing, and quality checks.

– Training: Ensure that operators are well-trained in both the technical aspects and the quality assurance protocols.

– Documentation: Maintain detailed records of each print run, including machine settings and inspection results, to trace any issues and improve future processes.

Implementing these methods and controls can significantly enhance the reliability and performance of metal 3D printed parts.

Tips for Procurement and Considerations when Purchasing from metal 3d print

When considering procurement for metal 3D printing, it’s essential to follow specific tips and considerations to ensure a successful purchase.

1. Material Selection:

Understand the properties of various metal powders (e.g., titanium, aluminum, stainless steel). Choose a material that aligns with your application’s strength, weight, and corrosion resistance requirements.

2. Printer Technology:

Familiarize yourself with different metal printing technologies, such as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). Each has unique strengths and weaknesses affecting part quality and production speed.

3. Supplier Reputation:

Research potential suppliers. Evaluate their experience, past projects, and client reviews. A reputable supplier should have certifications like ISO or AS9100, ensuring quality and compliance with industry standards.

4. Prototype Production:

Consider starting with prototyping. This allows you to assess the material behavior and part design without significant investment, reducing risks in bulk production.

5. Lead Times and Capacity:

Inquire about production lead times and whether the supplier can scale based on your demands. Understanding their capacity helps in planning your project timeline efficiently.

6. Post-Processing Requirements:

Assess any necessary post-processing, such as heat treatment or surface finishing. Post-processing can significantly impact turnaround time and cost.

7. Cost Analysis:

Prepare a comprehensive budget that includes materials, production, post-processing, and any potential shipping or handling fees. Compare quotes from different suppliers to find the best value.

8. Intellectual Property:

Ensure agreements are in place protecting your intellectual property, especially if proprietary designs are involved.

By considering these factors, you can optimize your procurement strategy for metal 3D printing and achieve successful outcomes for your projects.

FAQs on Sourcing and Manufacturing from metal 3d print in China

FAQs on Sourcing and Manufacturing Metal 3D Print in China

1. What are the advantages of sourcing metal 3D printed parts from China?

China offers competitive pricing, a vast network of experienced manufacturers, advanced technologies, and shorter lead times. The country’s established supply chain can also reduce logistics costs.

2. What types of materials can be used in metal 3D printing?

Common materials include stainless steel, aluminum, titanium, and cobalt-chrome alloys. Manufacturers may provide different alloys based on application requirements.

3. How do I select a manufacturer?

Consider factors such as certifications (e.g., ISO), technical capabilities, experience with your specific materials, and customer reviews. Request samples to evaluate quality.

4. What are the typical lead times for production?

Lead times can range from a few days to several weeks, depending on complexity, quantity, and material availability. Always clarify timelines upfront.

5. Are there quality assurance measures in place?

Reputable manufacturers implement quality control processes including X-ray inspection, mechanical testing, and surface finish checks to ensure compliance with specifications.

6. What are the shipping options?

Shipping can include air freight for faster delivery or sea freight for cost-effective bulk transport. Discuss with your manufacturer to choose the best option.

7. What should I be aware of regarding intellectual property?

Ensure that contracts include confidentiality clauses and consider registering patents in China. Investigate manufacturers’ practices regarding IP protection.

8. Can I communicate directly with the manufacturing team?

Many manufacturers offer direct communication with engineers, facilitating better understanding and adjustments throughout the process.

9. How do I manage costs?

Get detailed quotes and compare pricing among several manufacturers. Be clear about your requirements to avoid unexpected costs during production.