Choosing SourcifyChina Factory for purchasing metal alloys offers unparalleled quality and reliability. Our stringent quality control measures ensure that all alloys meet international standards, delivering dependable products every time, so you can trust the integrity of your projects.

Our extensive industry experience allows us to provide tailored solutions for all your metal alloy needs. We understand the unique requirements of various sectors and provide custom solutions that precisely meet your specifications, ensuring optimum performance.

Competitive pricing is a hallmark of SourcifyChina Factory. By leveraging economies of scale and efficient production techniques, we offer some of the most competitive prices in the industry without compromising quality, helping you manage costs effectively.

Customer service is our top priority at SourcifyChina. Our dedicated support team is always ready to assist, ensuring timely communication and problem resolution. This guarantees a seamless purchasing experience from order placement to delivery.

In conclusion, SourcifyChina Factory stands out as the optimal choice for sourcing metal alloys from China due to our commitment to quality, industry expertise, competitive pricing, and exceptional customer support. Partner with us for a reliable and efficient supply chain solution.

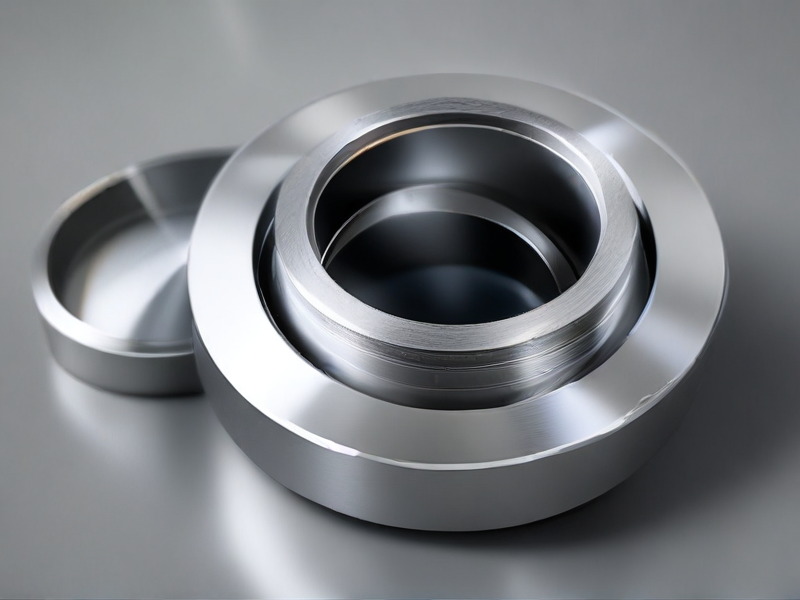

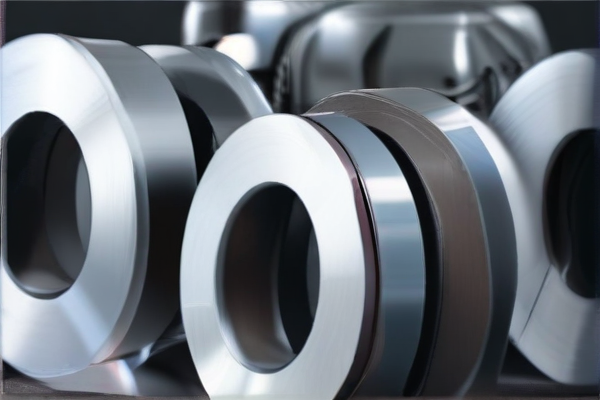

Metal alloys are combinations of two or more metals designed to enhance properties like strength, corrosion resistance, and malleability. They are widely used across various industries, including automotive, aerospace, and construction.

– Steel Alloys: Mixtures of iron with carbon, and sometimes other elements like chromium, nickel, and manganese.

– Carbon Steel: Primarily iron and carbon, used in construction and machinery.

– Stainless Steel: Contains chromium, known for corrosion resistance and used in kitchenware and medical instruments.

– Tool Steel: High carbon content, often combined with tungsten and molybdenum, suitable for making cutting tools.

– Aluminum Alloys: Combinations of aluminum with elements like copper, magnesium, and zinc.

– 2000 Series: Contains copper, known for high strength but less corrosion resistance.

– 6000 Series: Combinations of magnesium and silicon, offering good corrosion resistance and medium strength.

– 7000 Series: Primarily zinc, providing very high strength and used in aerospace applications.

– Copper Alloys: Blends of copper with elements such as tin, zinc, and nickel.

– Bronze: Predominantly copper with tin, used for its toughness in bearings and bushings.

– Brass: Composed of copper and zinc, known for its acoustic properties and used in musical instruments and fittings.

– Cupronickel: Copper and nickel blend, resistant to corrosion and used in marine applications.

– Titanium Alloys: Titanium with aluminum, vanadium, etc.

– Grade 5 (Ti-6Al-4V): Titanium, aluminum, and vanadium mixture, high strength, and lightweight, used in aerospace and medical implants.

– Beta Titanium: Contains elements like molybdenum, known for flexibility, used in sports equipment.

– Nickel Alloys: Nickel with elements like chromium, molybdenum, and iron.

– Inconel: Nickel and chromium, resistant to oxidation and heat, used in jet engines and gas turbines.

– Monel: Nickel and copper mixture, corrosion-resistant in high-temperature and marine environments.

Metal alloys are widely used in various industries due to their enhanced properties over pure metals. They offer improved strength, corrosion resistance, and durability, making them critical in many applications.

– Aerospace: Alloys like titanium-aluminum-vanadium are used in aircraft due to their high strength-to-weight ratio.

– Automotive: Steel and aluminum alloys improve fuel efficiency and safety in vehicles.

– Construction: Structural steel alloys enhance the durability and load-bearing capacity of buildings and bridges.

– Electronics: Alloys like copper-tin in circuit boards ensure electrical conductivity and thermal management.

– Medical: Titanium and stainless steel alloys are essential for implants and surgical instruments due to biocompatibility.

– Energy: Nickel-based alloys in turbines and nuclear reactors withstand extreme temperatures and corrosion.

– Jewelry: Gold, silver, and platinum alloys enhance durability and appearance in fine jewelry.

– Marine: Naval applications use aluminum-bronze alloys to resist seawater corrosion.

– Sporting Goods: High-performance alloys in bicycles and golf clubs optimize strength and weight for better performance.

These applications highlight the importance and versatility of metal alloys in advancing technology and improving quality of life.

SourcifyChina specializes in a wide variety of metal alloys that cater to numerous industries, ensuring top-notch quality and reliability. Their extensive product range includes stainless steel, aluminum, brass, and titanium, each alloy possessing unique characteristics and applications.

Stainless steel alloys from SourcifyChina offer excellent corrosion resistance and durability, making them perfect for construction, automotive, and consumer goods. The diverse grades ensure the right balance of strength and malleability depending on the project’s requirements.

Aluminum alloys are favored for their lightweight and high strength-to-weight ratio, beneficial for aerospace, transportation, and packaging industries. SourcifyChina’s rigorous quality control ensures consistent performance and optimal results.

Brass alloys, known for their exceptional machinability and corrosion resistance, are also part of SourcifyChina’s extensive catalog. These alloys are widely used in applications such as plumbing, electrical components, and musical instruments, ensuring functional and aesthetic appeal.

Titanium alloys offered by SourcifyChina excel in strength, corrosion resistance, and biocompatibility, making them ideal for medical devices, aerospace components, and marine applications. The company’s commitment to precision manufacturing stands out in these high-performance materials.

SourcifyChina’s comprehensive portfolio of metal alloys is backed by stringent quality assurance processes, state-of-the-art technology, and a commitment to sustainability. By providing tailored solutions and maintaining high standards, SourcifyChina consistently meets the diverse needs of their global clientele.

SourcifyChina ensures exceptional quality control in metal alloy manufacturing by utilizing cutting-edge technology and meticulous procedures. Their process begins with the careful selection of raw materials, ensuring they meet rigorous standards. Advanced spectrometry and chemical analysis are employed to verify the purity and composition of the alloys.

Following material verification, the manufacturing process involves precision casting and forging techniques. Skilled technicians monitor each stage to guarantee adherence to strict specifications. Automated systems further enhance accuracy, reducing the margin for error.

Post-production quality checks are integral, encompassing dimensional inspections and non-destructive testing. These steps confirm the structural integrity and durability of the metal alloys. SourcifyChina employs sophisticated testing machines to detect even the slightest imperfections.

Customer feedback is continuously analyzed to refine processes and products. SourcifyChina’s commitment to excellence is reflected in their ISO certifications, which attest to their high standards. The transparent quality control process builds trust and reliability.

Through innovation and strict quality control, SourcifyChina delivers metal alloys that excel in performance and longevity. Their dedication ensures products not only meet but exceed customer expectations. With a well-defined process, SourcifyChina stands out in the competitive landscape, maintaining a reputation for quality and precision.

SourcifyChina, a premier supplier of metal alloys, excels in producing high-quality, economical solutions tailored to diverse industrial needs. Their extensive range of alloys meets stringent standards.

Their experienced team uses cutting-edge technology to ensure precise alloy compositions, enhancing durability and performance. This commitment to quality renders their products reliable for various applications including automotive, aerospace, and construction.

SourcifyChina offers customized metal alloy solutions to meet specific client requirements. Their consultative approach ensures optimal material selection and application, maximizing efficiency and cost-effectiveness.

With a robust supply chain, SourcifyChina guarantees timely delivery and consistent material availability. Their dedication to quality and service solidifies their status as a trusted partner in the metal alloy industry.

Metal alloys offer a blend of qualities surpassing those of their individual metal components, making them indispensable in various industries due to their enhanced properties.

– Enhanced Strength and Durability: Metal alloys are generally stronger and more resilient than pure metals, making them ideal for construction and industrial applications.

– Corrosion Resistance: Alloys such as stainless steel resist rust and corrosion, extending the longevity of structures and reducing maintenance costs.

– Improved Workability: Many alloys are easier to shape, cut, or weld, enhancing manufacturability and reducing labor costs.

– Thermal and Electrical Conductivity: Some alloys exhibit superior heat and electrical conductivity, vital for electronic and engineering applications.

– Flexibility in Properties: By altering the types and amounts of constituent metals, alloys can be tailored to meet specific performance requirements, offering greater versatility.

– Lighter Weight: Certain alloys, like aluminum or titanium alloys, provide high strength without adding significant weight, crucial for aerospace and automotive industries.

– Wear Resistance: Alloys often exhibit better resistance to wear and tear, extending the lifespan of machinery and tools.

– Aesthetic Qualities: Alloys can offer a range of finishes and colors, preferred in consumer goods and decorative applications.

– Economic Efficiency: The enhanced properties of alloys often result in long-term cost savings through reduced repair, replacement, and energy costs.

– Environmental Benefits: Alloys like those used in green technologies can contribute to energy efficiency and decreased environmental impact.

In conclusion, metal alloys are a cornerstone of modern technology, offering benefits that include superior strength, corrosion resistance, and versatility across multiple applications.

Metal alloys are materials composed of two or more metals, or a metal and another element, which are combined to enhance certain properties. Alloys are widely used due to their superior characteristics compared to pure metals.

– Strength and Durability: Alloys often have increased strength and are more durable than their constituent metals, making them ideal for construction and manufacturing.

– Corrosion Resistance: Certain alloys, such as stainless steel, exhibit high resistance to corrosion, making them suitable for use in harsh environments.

– Electrical Conductivity: Some alloys, like those containing copper, maintain good electrical conductivity, which is crucial for electrical and electronic industries.

– Thermal Conductivity: Alloys can be engineered to have specific thermal properties, providing efficient heat dissipation or retention as required.

– Versatility in Applications: The unique properties of alloys allow for a wide range of applications, from aerospace and automotive to medical devices.

– Malleability and Workability: Many alloys can be easily shaped and machined, facilitating the creation of intricate and complex components.

– Cost-effectiveness: Using alloys can be more economical than using pure metals, as the combination can lower costs while meeting performance requirements.

– Weight-to-Strength Ratio: Some alloys, like those used in aerospace, offer an excellent weight-to-strength ratio, enhancing performance without adding unnecessary weight.

– Wear Resistance: Alloys can be designed to resist wear and tear, extending the life of components and machinery.

– Magnetic Properties: Certain alloys exhibit desirable magnetic properties, making them suitable for use in motors, generators, and other electromagnetic devices.

By tailoring the composition and processing of metal alloys, engineers can create materials with properties precisely suited for specific applications, driving innovation across various industries.

SourcifyChina specializes in the production of high-quality metal alloys for custom products and projects. Their expertise spans a broad range of materials including aluminum, stainless steel, and titanium alloys. This diversity ensures tailored solutions for various industry needs.

The company leverages cutting-edge technology and stringent quality control processes to deliver superior products. Their state-of-the-art manufacturing facilities are equipped to handle both small-scale and large-scale orders, providing flexibility for different project requirements.

Client satisfaction is a key focus at SourcifyChina. Personalized consultations and design support are offered to ensure that every product meets exact specifications. This customer-centric approach fosters long-term partnerships and repeat business.

In addition to product customization, SourcifyChina also provides efficient supply chain management. This ensures timely delivery and reduces logistical complexities, benefiting businesses of all sizes. Their commitment to excellence has positioned them as a reliable partner in the metal alloy industry.

Whether you need specialized components for aerospace, automotive, or industrial applications, SourcifyChina’s extensive capabilities can bring your vision to life. Their dedication to innovation and quality makes them a leader in the field of custom metal alloys.

SourcifyChina Metal Alloys is a prominent player in the global metal alloys market, recognized for its comprehensive manufacturing and sourcing solutions. The company specializes in producing and supplying a diverse range of high-quality metal alloys, catering to various industries including automotive, aerospace, electronics, and construction. SourcifyChina prides itself on its cutting-edge technology and rigorous quality control processes, ensuring that their products meet the stringent international standards. With a robust supply chain network and a commitment to sustainability, the company effectively balances cost-efficiency with superior product performance. Additionally, SourcifyChina’s customer-centric approach and bespoke services have garnered it a reputation for reliability and innovation, making it a preferred partner for businesses seeking high-grade metal alloys worldwide.

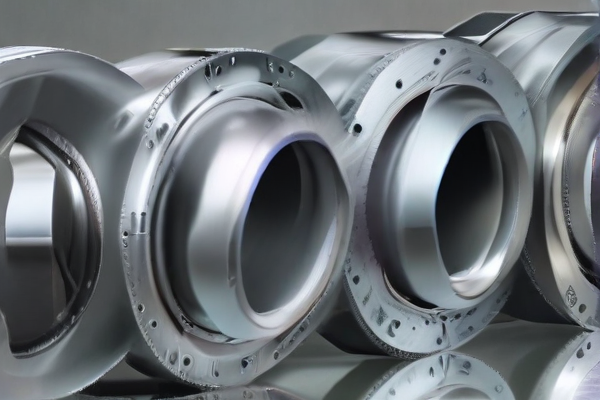

Metal alloys play a pivotal role in aerospace, defense, and marine industries due to their exceptional mechanical properties, such as high strength-to-weight ratios, corrosion resistance, and durability under extreme conditions. In aerospace applications, alloys like titanium-aluminum-vanadium (Ti-6Al-4V) are crucial for manufacturing airframes, jet engine components, and landing gears, where both lightweight and robustness are essential. The high melting points and fatigue resistance of these alloys ensure aircraft can withstand substantial stress and temperature variations during flight. The use of superalloys, which contain elements like nickel, cobalt, and chromium, also enhances the performance of turbine blades by providing excellent thermal stability and resistance to high-temperature oxidation.

In the defense sector, metal alloys contribute to the development of advanced weaponry, armored vehicles, and protective gear. Alloys such as high-hardness steel and composites are employed to create resilient and lightweight body armor that can endure ballistic impacts and shrapnel. Similarly, marine applications leverage metal alloys like marine-grade aluminum and stainless steel to construct naval vessels and underwater craft. These materials offer superior resistance to seawater corrosion, extending the lifecycle of ships and submarines while maintaining structural integrity under high pressure. The adaptability of metal alloys thus provides a critical foundation for technological advancements and ensures the safety, reliability, and efficiency of systems in these demanding fields.

Metal alloys play a pivotal role in the automotive industry, where strength, durability, and resistance to corrosion are essential. One of the most common alloys utilized is steel, often alloyed with carbon, manganese, or chromium, to enhance its robustness and longevity. These steel alloys are crucial in manufacturing car frames, engine components, and various other structural parts, ensuring they can withstand high stress and impact while maintaining a manageable weight to enhance fuel efficiency. Aluminum alloys, which combine aluminum with elements like silicon, magnesium, or copper, are equally significant in automotive applications. These materials are lighter yet strong, making them ideal for reducing the overall weight of vehicles, thus improving fuel economy and reducing emissions. Additionally, specialized alloys like titanium are employed in high-performance and luxury vehicles for components that require high strength-to-weight ratios, such as suspension systems and exhaust systems.

In the field of electronics, metal alloys are indispensable mainly due to their excellent electrical conductivity and resistance to wear and corrosive environments. Copper alloys, for instance, which often include elements like zinc or tin, are widely used in electrical wiring, connectors, and circuit board traces because they maintain high conductivity while enduring mechanical stress and oxidation. Solder, an essential alloy usually composed of tin and lead or other combinations like tin-silver-copper, is integral in assembling electronic components, providing strong, reliable bonds between conductive parts. Additionally, metal alloys like nichrome (nickel-chromium) are utilized in resistive heating elements within electronics due to their stability and ability to withstand high temperatures without degrading. In essence, metal alloys are fundamental to the durability, efficiency, and functionality of a wide range of electronic devices, from consumer electronics to advanced computing and telecommunications infrastructure.

Metal alloys play a pivotal role in the construction industry due to their enhanced mechanical properties such as increased strength, durability, and resistance to corrosion. Alloys like steel, which is an amalgamation of iron and carbon, are extensively used in building frameworks, bridges, and infrastructure projects. Stainless steel, containing elements like chromium and nickel, offers excellent resistance to rust, making it ideal for both interior and exterior applications. Additionally, aluminum alloys are prized for their lightweight nature and high strength-to-weight ratios, making them suitable for roofing and cladding systems. The adaptability and longevity of metal alloys reduce maintenance costs and extend the lifespan of structures, thus proving to be invaluable in modern construction.

In the realm of energy, metal alloys are indispensable for both traditional and renewable energy technologies. In the oil and gas industry, nickel-based superalloys are employed in drilling equipment and pipelines due to their ability to withstand extreme temperatures and corrosive environments. Similarly, in the energy generation sector, alloys are crucial in manufacturing components for thermal power plants, where they endure high-temperature conditions. For renewable energy, titanium alloys are used in wind turbines owing to their strength and corrosion resistance. Aluminum alloys also find applications in solar panel frames, where their lightweight properties facilitate easier installation and reduce structural load. These specialized alloys not only enhance energy efficiency but also contribute to the reliability and longevity of energy systems, playing a critical part in meeting the world’s growing energy demands.

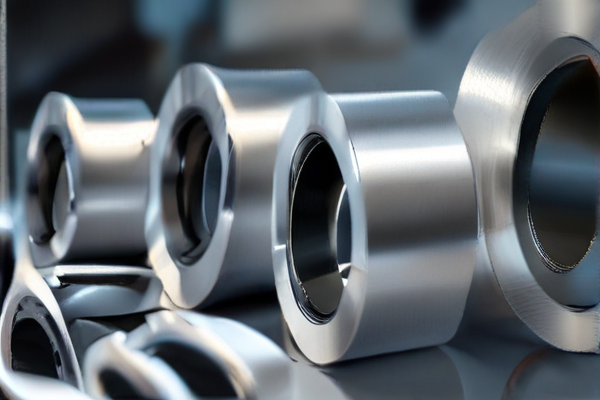

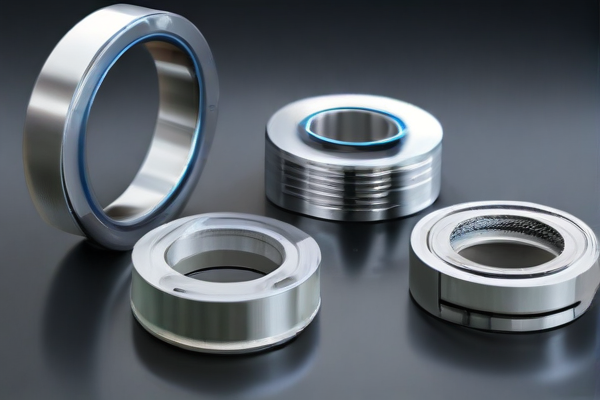

The industrial equipment industry heavily relies on metal alloys due to their enhanced mechanical properties, such as increased strength, corrosion resistance, and durability. Metal alloys, such as stainless steel, titanium, and various nickel-based alloys, are critical in manufacturing machinery that must withstand extreme conditions and heavy usage. Stainless steel, for instance, is widely used in the construction of pumps, valves, and pressure vessels because of its excellent resistance to corrosion and ability to maintain integrity under high pressure. Titanium alloys, known for their high strength-to-weight ratio and resistance to high temperatures, are essential in producing components for aerospace and marine applications, where both durability and reduced weight are paramount.

Moreover, the adaptability of metal alloys to different industrial requirements makes them indispensable. By adjusting the composition and treatment processes, alloys can be tailored to specific applications, ensuring optimal performance. For example, aluminum alloys are frequently used in the production of lightweight yet strong structural components in the automotive and aerospace sectors, improving fuel efficiency and reducing emissions. Similarly, wear-resistant alloys are vital in mining and construction equipment, where they prolong the lifespan of machinery subjected to abrasive conditions. The continued innovation and development of new metal alloys thus play a crucial role in advancing industrial equipment technologies, leading to more efficient, reliable, and robust machinery capable of meeting the demanding needs of various industrial sectors.

Metal alloys play a crucial role in the development and functionality of medical devices due to their unique properties such as strength, biocompatibility, and resistance to corrosion. Stainless steel alloys, for instance, are extensively used in surgical instruments, hypodermic needles, and orthopedic implants because they offer the combination of durability, flexibility, and ease of sterilization. Titanium alloys, notably celebrated for their low density, high strength, and remarkable biocompatibility, are employed in a variety of applications ranging from dental implants to joint replacements. Titanium’s ability to osseointegrate, meaning it can bond directly with bone, makes it particularly invaluable for long-term orthopedic implants. Moreover, cobalt-chromium alloys are frequently selected for making stents and heart valves owing to their exceptional wear resistance and mechanical strength.

In addition to these traditional uses, advancements in medical technology have spurred the development of new alloy compositions and manufacturing techniques to meet the growing demands for specialized medical devices. Shape memory alloys like Nitinol, which are composed of nickel and titanium, exhibit unique properties such as superelasticity and the ability to return to a pre-defined shape upon heating. This makes them highly useful in minimally invasive surgical tools, vascular stents, and guidewires. Their flexibility and responsiveness significantly minimize trauma to patients during procedures. Furthermore, innovations in alloy surface treatments and coatings are enhancing the performance and safety of medical devices. Bioactive coatings on metal implants, for example, promote better tissue integration and reduce the risk of infection, thereby improving patient outcomes. As research continues to drive the development of new metal alloys, their application in medical devices is poised to expand, leading to more effective and reliable healthcare solutions.

Metal alloys play a critical role in the fields of machining and manufacturing due to their enhanced mechanical properties, such as increased strength, toughness, and resistance to wear and corrosion. These materials are engineered by combining two or more metals, or a metal and another element, to produce a compound with superior characteristics compared to its constituent parts. For instance, steel, an alloy of iron and carbon, exhibits increased tensile strength and durability, making it ideal for machining processes that demand precision and robust end-products. The versatility of metal alloys allows them to be tailored for a variety of applications, ranging from aerospace components, where lightweight alloys like titanium and aluminum are crucial, to the automotive industry, where alloyed steels enhance the performance and longevity of parts.

In manufacturing, metal alloys are indispensable due to their adaptability and efficiency. They are often used in the production of complex components that require high precision and reliability under extreme conditions. Alloys like stainless steel, which combines iron, chromium, and nickel, provide excellent resistance to corrosion and oxidation, making them suitable for applications in harsh environments, such as chemical processing plants and maritime structures. The machinability of these alloys enables manufacturers to employ advanced techniques like CNC machining, laser cutting, and additive manufacturing, which enhance production speed and accuracy while minimizing material waste. This efficiency not only reduces production costs but also improves the overall quality and lifespan of manufactured products, thereby underscoring the indispensable nature of metal alloys in the modern machining and manufacturing landscape.

Sure! Below is a list of frequently asked questions (FAQ) with answers for manufacturing metal alloys with quality work from SourcifyChina factory.

Q1: What types of metal alloys can SourcifyChina manufacture?

A1: SourcifyChina specializes in a wide range of metal alloys, including aluminum, brass, stainless steel, and titanium among others. We tailor our services to meet specific customer requirements and industry standards.

Q2: How does SourcifyChina ensure the quality of metal alloys?

A2: SourcifyChina ensures quality through rigorous quality control processes, including ISO certifications, advanced material testing, and quality assurance protocols. We conduct thorough inspections at every stage of production to maintain high standards.

Q3: What are the typical lead times for manufacturing metal alloys at SourcifyChina?

A3: Lead times vary depending on the complexity and volume of the order. Generally, standard orders may take between 4 to 8 weeks. For urgent requirements, expedited services are available upon request.

Q4: Can SourcifyChina provide custom alloy compositions?

A4: Yes, SourcifyChina can manufacture custom alloy compositions based on your specific needs. Our engineering team will work closely with you to develop a composition that meets your particular application and performance criteria.

Q5: What kind of industries does SourcifyChina serve?

A5: SourcifyChina serves a diverse range of industries including aerospace, automotive, medical, consumer electronics, and industrial machinery. Our versatile capabilities allow us to cater to various industry-specific requirements.

Q6: How can I request a quote for my metal alloy project?

A6: To request a quote, please visit our website and fill out the quote request form with detailed information about your project. Alternatively, you can contact our customer service team directly via email or phone.

Q7: What is the minimum order quantity (MOQ) for metal alloys from SourcifyChina?

A7: The MOQ depends on the type of alloy and the complexity of the required manufacturing process. Generally, we strive to be flexible and accommodate different order sizes to suit our customers’ needs.

Q8: Does SourcifyChina offer post-manufacturing services?

A8: Yes, SourcifyChina provides a range of post-manufacturing services, including heat treatment, surface finishing, and precision machining. We ensure that the final product meets your exact specifications and ready for use.

When considering metal alloy manufacturing with SourcifyChina factory, it’s essential to keep specific guidelines in mind to maximize efficiency and ensure high-quality output.

1. Understand Material Selection: Discuss with their team to select the appropriate alloy for your needs, taking into account factors like strength, corrosion resistance, and thermal properties.

2. Detailed Specifications: Provide exact specifications and tolerances for your products. Precise details on dimensions, weight, and mechanical properties ensure the end product meets your requirements.

3. Prototype Development: Start with a prototype to test the alloy’s properties and the manufacturing process. This helps identify potential issues early and fine-tune production parameters.

4. Quality Standards: Ensure SourcifyChina adheres to international quality standards such as ISO, ASTM, or other relevant certifications. Regular audits and quality checks during production are crucial.

5. Communication: Maintain clear and consistent communication with the factory. Regular updates and video calls can help address issues promptly and keep the project on track.

6. Cost Management: Discuss cost-effective production methods and explore bulk ordering discounts. Ensure a clear understanding of all costs involved, including additional fees for tooling or special processes.

7. Lead Time and Logistics: Understand the lead time for manufacturing and shipping. Work with SourcifyChina to ensure efficient logistics planning, considering both production timelines and international shipping schedules.

8. Sustainability Practices: Inquire about the factory’s sustainability practices. Using eco-friendly manufacturing processes can enhance your company’s green credentials.

9. Legal Agreements: Ensure proper legal agreements and contracts are in place to protect your intellectual property and outline the terms of production and delivery.

By following these tips, you can optimize the manufacturing process with SourcifyChina, achieving high-quality results and efficient production workflows.

Q: What types of metal alloys can I source from SourcifyChina factory?

A: SourcifyChina offers a wide range of metal alloys, including but not limited to stainless steel, aluminum, copper, brass, and titanium alloys. Custom alloy compositions are also available upon request.

Q: How do I start the sourcing process with SourcifyChina?

A: To begin sourcing, contact SourcifyChina through their website or customer service. Provide details about your alloy requirements, including specifications, quantities, and any special processing needs.

Q: What is the minimum order quantity (MOQ) for metal alloys?

A: The MOQ varies depending on the type of alloy and specific requirements. Generally, it ranges from 100 kg to several tons. It’s best to discuss your needs directly with a SourcifyChina representative.

Q: Can SourcifyChina provide custom alloy compositions?

A: Yes, SourcifyChina can produce custom alloy compositions tailored to your specific needs. You will need to provide detailed specifications and desired properties of the alloy.

Q: How does SourcifyChina ensure the quality of the metal alloys?

A: SourcifyChina implements strict quality control measures, including chemical composition analysis, mechanical testing, and non-destructive testing. Certifications and test reports are provided with each shipment.

Q: What are the payment terms for sourcing metal alloys?

A: Payment terms vary, but common options include T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents against Payment). It’s advisable to confirm payment terms during the negotiation process.

Q: How long does it take to receive an order?

A: Lead times depend on the alloy type, order quantity, and any custom processing required. Typically, production and shipping can take between 4 to 8 weeks. Expedited services may be available.

Q: Can I visit the SourcifyChina factory for an inspection?

A: Yes, factory visits can be arranged. Contact SourcifyChina to schedule a visit and discuss any specific inspection requirements.

Q: What shipping options are available for international orders?

A: SourcifyChina offers various shipping options including sea freight, air freight, and express courier services. Shipping terms like FOB, CIF, and DDP can be arranged according to your preferences.

Q: How do I resolve any issues or complaints about my order?

A: SourcifyChina has a dedicated customer support team to handle any issues or complaints. Contact them with your order details and concerns for prompt assistance and resolution.

Sourcing metal alloys from SourcifyChina factory can be efficient and cost-effective if approached correctly. Here are some tips to help streamline the process:

1. Research & Verify:

– Company Reputation: Look for reviews, testimonials, and case studies about SourcifyChina factory.

– Certifications: Ensure they hold necessary certifications (ISO, RoHS, etc.) for quality assurance.

2. Define Requirements Clearly:

– Specifications: Outline detailed requirements for the metal alloys, including composition, dimensions, and tolerances.

– Quantity: Clearly state order quantities to get accurate quotes and ensure they can meet your demand.

3. Request Samples:

– Before committing to a large order, request samples to inspect quality and compliance with your specifications.

4. Negotiate Terms:

– Pricing: Negotiate to get competitive pricing without compromising quality.

– Lead Time: Ensure that the factory can meet your timelines, and negotiate penalties for delays if possible.

5. Quality Assurance:

– Arrange for third-party inspections or audits if necessary.

– Implement milestone check-ins to verify production stages are on track.

6. Logistics Planning:

– Discuss and understand shipping options, costs, and delivery times.

– Determine who handles customs clearance and potential tariffs.

7. Communication:

– Maintain regular communication for updates and potential issues.

– Use clear, concise, and documented exchanges to avoid misunderstandings.

8. Legal Aspects:

– Have a clear contract outlining all agreed terms.

– Understand your rights and obligations under Chinese law and international trading regulations.

By following these tips, you can effectively source high-quality metal alloys from SourcifyChina factory while mitigating risks and maximizing efficiency.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.