Technology and Applications of metal cut laser

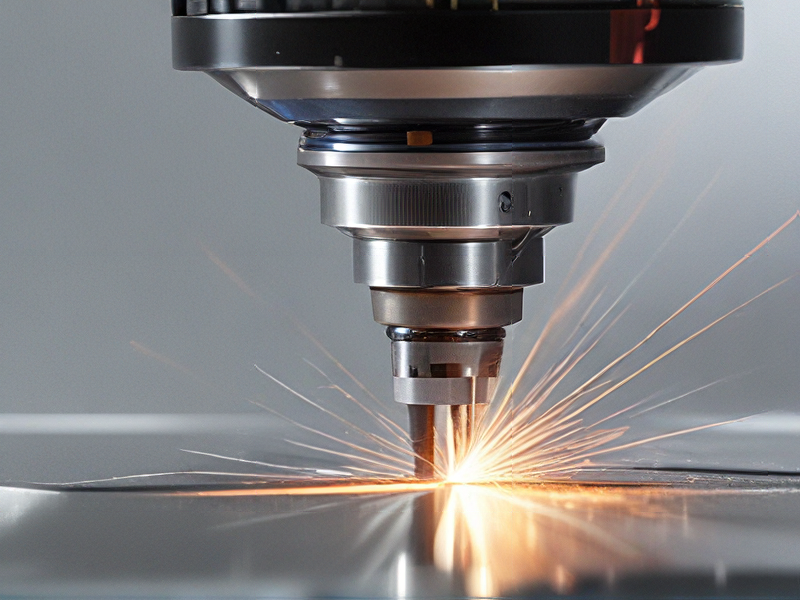

Metal-cutting lasers utilize high-powered lasers to melt, burn, or vaporize metal in precision cutting applications. These lasers are predominantly of two types: fiber lasers and CO2 lasers. Fiber lasers, utilizing a fiber optic cable to deliver the laser beam, are highly efficient and capable of cutting thin to thick metals with high precision. They are widely used in industries requiring rapid cutting speeds and cost-effective operation, such as automotive, aerospace, and electronics.

CO2 lasers, which use a gas mixture to generate the laser beam, are effective for cutting thicker metals and non-metallic materials due to their longer wavelength. They are versatile in applications such as signage, packaging, and fabricating.

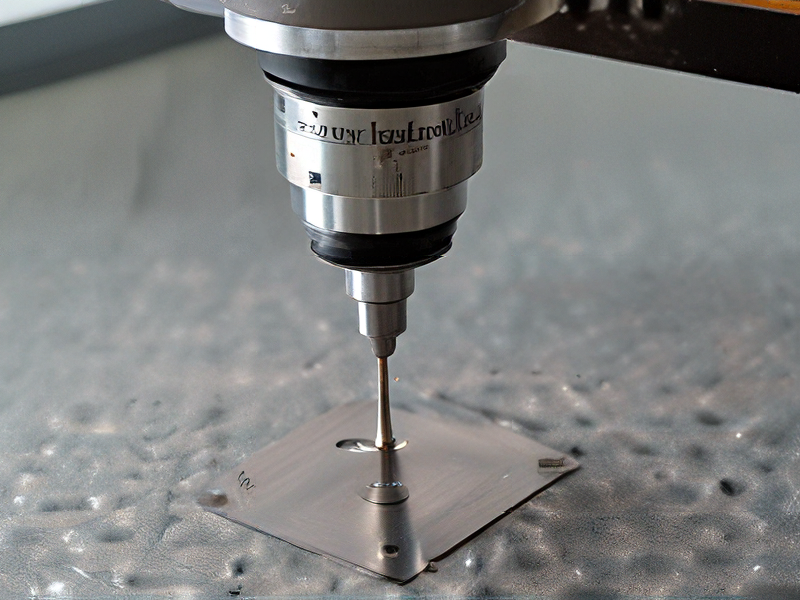

The technology works by focusing the laser beam onto the material’s surface, where it heats and melts or vaporizes the metal along a precise path determined by computer numerical control (CNC). This process allows for intricate designs and shapes to be cut with minimal material wastage and excellent edge quality. Additionally, the lack of physical contact between the laser and the material reduces mechanical stress on the workpiece, enabling the cutting of delicate materials.

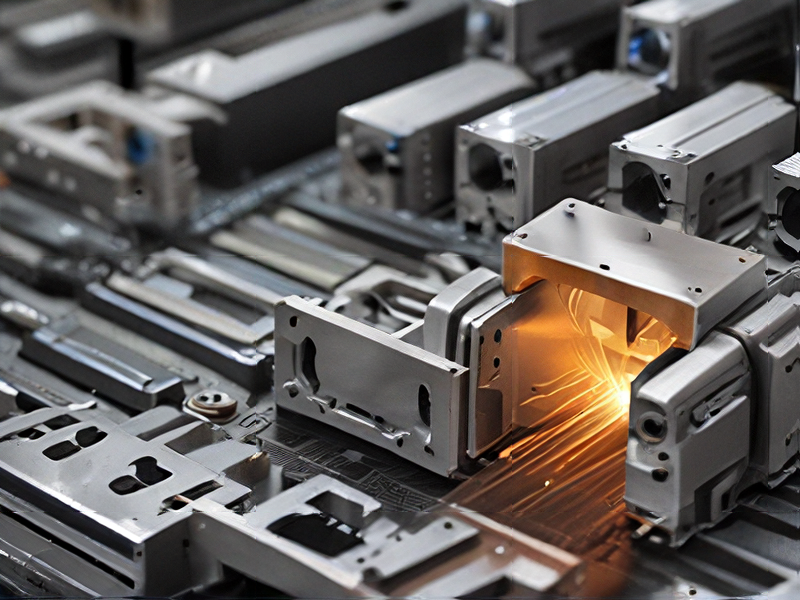

Applications include cutting sheet metal for automotive parts, aerospace components, electronics enclosures, and architectural components. The high precision and automation capabilities of laser cutting make it indispensable in industries requiring complex shapes and fast production times. Ongoing advancements in laser technology continue to improve efficiency, cutting speeds, and the range of materials that can be processed, further expanding its applications in modern manufacturing and fabrication.

Quality Testing Methods for metal cut laser and how to control quality

Quality control for laser-cut metal involves several key methods to ensure high precision and consistency:

1. Dimensional Inspection: Utilizing coordinate measuring machines (CMMs) or laser scanning to verify part dimensions against CAD models.

2. Visual Inspection: Examining cut edges and surfaces for defects such as burrs, dross, or discoloration that may affect quality.

3. Material Analysis: Conducting spectroscopic analysis to verify material composition and detect any impurities that could impact cut quality.

4. Edge Quality Assessment: Using specialized tools like profilometers to measure surface roughness and ensure edges meet required specifications.

5. Non-Destructive Testing (NDT): Employing methods like ultrasonic testing or X-ray inspection to detect internal defects or inconsistencies.

To control quality:

1. Process Parameters Monitoring: Regularly monitoring laser power, cutting speed, gas pressure, and focus position to maintain optimal cutting conditions.

2. Calibration of Equipment: Ensuring lasers, optics, and measuring instruments are calibrated regularly to maintain accuracy.

3. Operator Training: Providing comprehensive training for operators to understand machine capabilities, material properties, and quality standards.

4. Quality Assurance Plans: Developing and implementing QA plans that include inspection checkpoints and criteria to detect deviations early.

5. Feedback and Improvement: Collecting data from inspections and feedback from operators to continuously improve processes and reduce defects.

By integrating these methods and controls, manufacturers can achieve consistent high-quality laser-cut metal parts, meeting stringent industry standards and customer requirements.

Tips for Procurement and Considerations when Purchasing from metal cut laser

When procuring laser cutting services for metal, consider the following tips and key considerations:

1. Capabilities and Expertise: Ensure the vendor has the necessary experience and equipment to handle your specific requirements. Check their portfolio and customer reviews for similar projects.

2. Quality Assurance: Ask about their quality control measures. Certifications like ISO 9001 indicate adherence to quality standards. Inspect samples if possible.

3. Material Compatibility: Verify that the vendor can work with the type and thickness of metal you require. Different metals may require different laser cutting techniques.

4. Turnaround Time: Discuss turnaround times and ensure they can meet your project deadlines. Prompt delivery is crucial to keeping your own timelines intact.

5. Cost Considerations: Compare pricing structures among vendors, ensuring transparency in what is included (e.g., setup fees, material costs, finishing).

6. Customer Support: Evaluate their responsiveness and willingness to address your concerns. Clear communication channels are essential throughout the project.

7. Flexibility: Determine if the vendor can accommodate design changes or rush orders if needed. Flexibility is valuable in dynamic project environments.

8. Location and Logistics: Consider proximity to your location for easier logistics and potential cost savings in shipping.

9. Environmental and Ethical Practices: Inquire about their environmental policies and ethical business practices to align with your company’s values.

10. Long-Term Partnership Potential: Assess the vendor’s interest in building a long-term relationship. A reliable partner can offer consistency and improved service over time.

By focusing on these factors, you can effectively navigate the procurement process for laser cutting services, ensuring quality results and a smooth collaboration with your chosen vendor.

FAQs on Sourcing and Manufacturing from metal cut laser in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from Metal Cut Laser in China:

1. What services does Metal Cut Laser offer?

Metal Cut Laser provides laser cutting, CNC bending, welding, and finishing services for various metals like stainless steel, aluminum, and mild steel.

2. Can Metal Cut Laser handle large production volumes?

Yes, Metal Cut Laser is equipped to handle both small prototype runs and large-scale production orders efficiently.

3. What quality control measures does Metal Cut Laser employ?

Metal Cut Laser implements rigorous quality control processes throughout production, including material inspection, in-process checks, and final inspections to ensure high-quality output.

4. Does Metal Cut Laser offer custom manufacturing services?

Yes, Metal Cut Laser specializes in custom manufacturing. They can work with clients to produce parts and components according to specific designs and requirements.

5. What are Metal Cut Laser’s lead times for manufacturing?

Lead times can vary depending on the complexity and volume of the order. Metal Cut Laser provides estimated lead times based on project specifications.

6. Does Metal Cut Laser ship internationally?

Yes, Metal Cut Laser has experience shipping products globally. They can arrange shipping and logistics based on customer preferences.

7. What are the payment terms with Metal Cut Laser?

Payment terms typically involve a deposit or upfront payment, with the balance due upon completion of the order or as agreed upon in the contract.

8. How does Metal Cut Laser ensure intellectual property protection?

Metal Cut Laser respects intellectual property rights and can sign non-disclosure agreements (NDAs) to protect client designs and proprietary information.

9. Can Metal Cut Laser assist with design optimization for manufacturing?

Yes, Metal Cut Laser offers design for manufacturability (DFM) feedback to optimize designs for efficient production and cost-effectiveness.

10. What are Metal Cut Laser’s environmental and sustainability practices?

Metal Cut Laser adheres to local environmental regulations and strives to minimize waste and energy consumption in its manufacturing processes.

These FAQs provide a comprehensive overview of Metal Cut Laser’s capabilities and services, addressing common inquiries from potential customers interested in sourcing and manufacturing in China.