Choosing “SourcifyChina” Factory for purchasing metal fabrication shops in China ensures access to expert manufacturers with extensive industry knowledge. Their experienced team assists buyers in navigating complex manufacturing processes, ensuring high-quality outcomes.

Partnering with “SourcifyChina” offers competitive pricing without compromising on precision or craftsmanship. Leveraging China’s cost-effective manufacturing landscape, they deliver exceptional value, helping buyers achieve optimal cost-efficiency for their projects.

“SourcifyChina” prioritizes stringent quality control measures, ensuring each product meets international standards. Detailed inspections and adherence to ISO certifications reflect their commitment to reliability and excellence.

Customer satisfaction is pivotal for “SourcifyChina.” Their responsive support team offers personalized assistance throughout the purchasing process, fostering strong client relationships and facilitating smooth transactions.

End-to-end supply chain management provided by “SourcifyChina” streamlines procurement. From material sourcing to final delivery, their coordinated approach minimizes delays, ensuring timely and efficient project completion.

Ultimately, choosing “SourcifyChina” for metal fabrication needs means partnering with a trusted, efficient, and quality-focused manufacturer in China, guaranteeing an exceptional purchasing experience from start to finish.

Metal Fabrication Shops

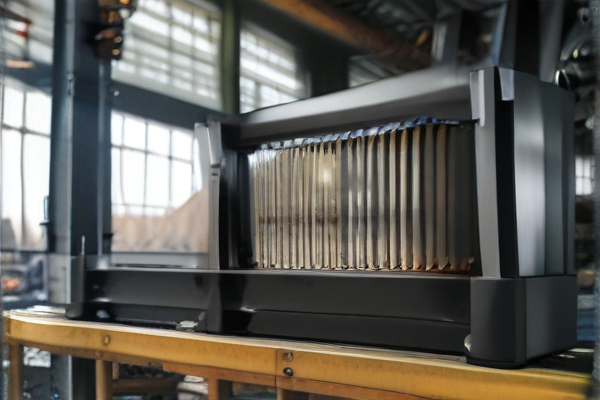

Metal fabrication shops specialize in creating metal structures by cutting, bending, and assembling processes. They offer services like welding, machining, and laser cutting, catering to various industrial needs.

Types and Options for Metal Fabrication Shops:

– Custom Fabrication: Tailored solutions for specialized projects, requiring unique designs and specifications.

– Large-Scale Production: High-volume manufacturing for industries like automotive and aerospace.

– Prototype Fabrication: Developing and testing prototypes before mass production.

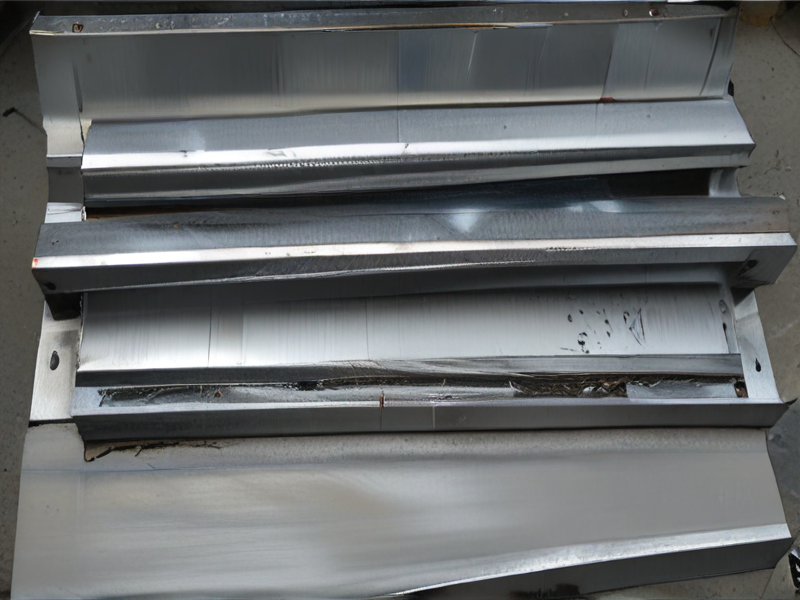

– Sheet Metal Fabrication: Cutting, bending, and assembling thin metal sheets into usable products.

– Heavy Metal Fabrication: Handling thicker, more robust materials for construction and large-scale projects.

– Precision Metal Fabrication: Producing highly accurate parts for industries such as medical devices and electronics.

– Structural Fabrication: Creating metal components for buildings, bridges, and other structures.

– Artistic Fabrication: Crafting metalworks for artistic and decorative purposes.

– Fab Shops with In-house Engineering: Offering design and engineering services alongside fabrication.

– Mobile Fabrication Shops: Providing on-site fabrication services for convenience and quick turnaround.

Services Offered:

– Welding: Joining metal parts using various welding techniques.

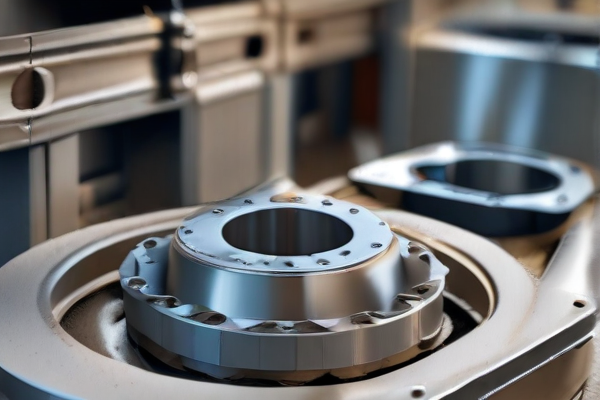

– Machining: Shaping metal parts with machines like lathes and milling machines.

– Laser Cutting: Precision cutting of metal using laser technology.

– CNC Punching: Computer-controlled punching for repeatability and efficiency.

– Bending: Forming metal into desired shapes using press brakes.

– Finishing: Surface treatments such as powder coating, painting, and polishing.

– Assembly: Putting together fabricated parts into the final product.

– Repair and Maintenance: Fixing and refurbishing existing metal structures.

Materials Used:

– Steel: Versatile, strong, and commonly used in many fabrication projects.

– Aluminum: Lightweight and corrosion-resistant, ideal for certain applications.

– Stainless Steel: Highly resistant to corrosion, perfect for hygienic and harsh environments.

– Copper and Brass: Used for their conductivity and aesthetic properties.

– Titanium: Strong and lightweight, used in high-performance applications.

In summary, metal fabrication shops offer diverse services and cater to a wide range of industries with various materials, ensuring that every project meets specific needs and standards.

Metal fabrication shops are essential in various industries, providing custom metal parts, assemblies, and structures through cutting, bending, welding, and assembling processes.

– Automotive Industry: Fabrication of frames, chassis, and custom parts.

– Construction: Structural beams, columns, and metallic frameworks.

– Aerospace: Precision components for aircraft and spacecraft.

– Energy Sector: Pipelines, wind turbine parts, and solar panel frames.

– Shipbuilding: Hulls, decks, and other maritime components.

– Medical Industry: Equipment housings, surgical instruments, and support structures.

– Agricultural Equipment: Machinery parts, storage facilities, and fencing.

– Oil and Gas: Rig components, storage tanks, and piping systems.

– Defense: Armored vehicles, weaponry housings, and military infrastructure.

– HVAC Systems: Ductwork and custom ventilation solutions.

– Furniture Manufacturing: Metal frames, custom fixtures, and decorative elements.

– Railways: Train body fabrication and station infrastructure.

– Electronics: Enclosures, brackets, and heat sinks.

– Transportation Infrastructure: Bridges, railings, and pedestrian walkways.

– Art and Sculpture: Metal art pieces and structural supports.

– Retail Displays: Custom shelving, racks, and stands.

– Food Processing: Stainless steel countertops, mixers, and storage units.

– Machinery and Industrial Equipment: Fabrication of machine parts and heavy-duty equipment.

– Mining: Structural supports, conveyors, and processing equipment.

– Renewable Energy: Frames for solar panels and hydroelectric turbines.

Metal fabrication shops offer versatile services crucial for modern industry, tailored to meet specific requirements and ensure durability, functionality, and aesthetic quality in various sectors.

SourcifyChina is renowned for its proficiency in metal fabrication, serving a multitude of industries with unmatched quality and precision. Their portfolio comprises a vast array of materials, including stainless steel, aluminum, copper, and various alloys, tailored to meet stringent client specifications. Each material is meticulously selected for its unique properties, ensuring durability and performance in end applications.

The fabrication process involves cutting-edge technology and skilled craftsmanship to manipulate these materials into precise components. Laser cutting, welding, bending, and stamping are among the techniques employed to achieve complex, custom designs. SourcifyChina guarantees high-strength and high-precision products through stringent quality control measures at every stage of production.

Environmental responsibility is also a key focus, with eco-friendly practices integrated into their operations. Sourcing recyclable metals and minimizing waste exemplify their commitment to sustainability. They emphasize efficient material utilization, reducing both costs and environmental impact, while maintaining superior product quality.

Client collaboration is paramount at SourcifyChina. They provide tailored solutions, working closely with clients from concept to completion to ensure every detail meets exact requirements. Their expertise extends to various industries, including automotive, aerospace, construction, and electronics, showcasing their versatility and dedication to meeting diverse needs.

In essence, SourcifyChina metal fabrication shops stand out for their expertise, technological sophistication, and unwavering commitment to quality and sustainability. Their advanced processes and material selection make them a leader in the metal fabrication industry, delivering reliable, high-performance solutions to a global clientele.

SourcifyChina metal fabrication shops are renowned for their stringent quality control processes. Each step in their production line is meticulously monitored to ensure top-grade outputs, adhering to both local and international standards.

The quality control process begins with the careful selection of raw materials. Only materials that meet specific criteria are used, ensuring that the foundations of the product are of the highest quality. These materials undergo rigorous inspection upon arrival.

During the fabrication process, state-of-the-art machinery is employed to maintain consistency and precision. Regular machine calibration and maintenance schedules are strictly followed to avoid any deviations in production quality, ensuring that all products meet specified tolerances.

Human oversight is equally important. Skilled inspectors regularly examine the products at various stages of fabrication. Using advanced measurement tools and techniques, they ensure that each piece meets the exact specifications required.

Finished products are subjected to a final round of inspections. This phase includes dimensional checks, surface inspections, and mechanical testing, guaranteeing that the products are free from defects and ready for market. Any item failing to meet criteria is reworked or discarded.

Continuous improvement is a cornerstone of SourcifyChina’s quality control. Feedback loops from clients and in-house audits help identify areas for enhancement, promoting a culture of perpetual quality improvement. This proactive approach ensures long-term reliability and client satisfaction.

Thus, SourcifyChina’s metal fabrication shops maintain high standards throughout their manufacturing process. Their dedication to quality control not only meets customer expectations but also sets them apart as leaders in precision metal fabrication.

SourcifyChina’s metal fabrication shops are renowned for their exceptional precision and quality. Equipped with state-of-the-art machinery, they offer comprehensive services such as cutting, bending, welding, and assembly, ensuring top-tier results for their clients.

Advanced technology is a cornerstone of SourcifyChina’s operations. Utilizing CNC machines, laser cutters, and robotic welders, the shops deliver unmatched accuracy and efficiency. Such high-tech equipment guarantees rapid prototype development and scalable production runs.

Expert craftsmanship is evident in every project handled by SourcifyChina. Skilled workers bring years of experience to the table, ensuring meticulous attention to detail and adherence to stringent quality standards, meeting diverse industry needs.

Versatility is another key strength of SourcifyChina’s metal fabrication shops. They work with a variety of materials, including steel, aluminum, and brass, providing custom solutions tailored to specific client requirements. Their flexibility caters to different sectors like automotive, aerospace, and construction.

Commitment to sustainability defines SourcifyChina. The metal fabrication shops implement eco-friendly practices such as recycling scrap materials and utilizing energy-efficient processes. This demonstrates their dedication to reducing environmental impact while maintaining high production standards.

In conclusion, SourcifyChina metal fabrication shops’ capabilities span advanced technology, expert craftsmanship, versatility, and sustainable practices. This multifaceted approach ensures they meet a wide range of client needs, producing exceptional metal components and assemblies with efficiency and accuracy, making them a trusted partner in the industry.

Metal fabrication shops offer numerous advantages, including precision, customization, and efficiency in producing high-quality metal components. Their expertise supports a variety of industries, enhancing both functionality and design.

Key Benefits:

– Customization and Flexibility: Metal fabrication shops can create bespoke designs tailored to meet specific project requirements, providing unique solutions for diverse industries.

– Advanced Technology: Utilization of state-of-the-art machinery and tools ensures high precision and high-quality output, which is crucial for industries demanding exact specifications.

– Time and Cost Efficiency: Streamlined processes and skilled labor result in reduced production time and cost, making it economically beneficial for businesses requiring bulk orders.

– High-Quality Materials: Access to a variety of metals and alloys ensures the strength and durability of the fabricated components, suitable for long-term usage.

– Expertise and Experience: Skilled professionals in metal fabrication shops offer proficient services, ensuring that the design and manufacturing processes meet the highest standards.

– Prototype Development: These shops can assist in creating prototypes, enabling companies to test and refine their designs before committing to mass production.

– Repair and Maintenance Services: Fabrication shops often provide repair and maintenance services, prolonging the life of metal products and reducing the need for replacements.

– Safety Standards Compliance: Professional shops comply with industry safety standards, reducing risks associated with poor-quality manufacturing and ensuring safer end products.

– Versatility: Able to work on a wide array of projects from automotive parts to construction structures, enhancing service diversity.

– Enhanced Aesthetics: Use of modern techniques not only improves functionality but also offers aesthetically pleasing finishes, beneficial for consumer-facing products.

The cumulative benefits offered by metal fabrication shops underscore their essential role in modern manufacturing, driving innovation and efficiency across multiple sectors.

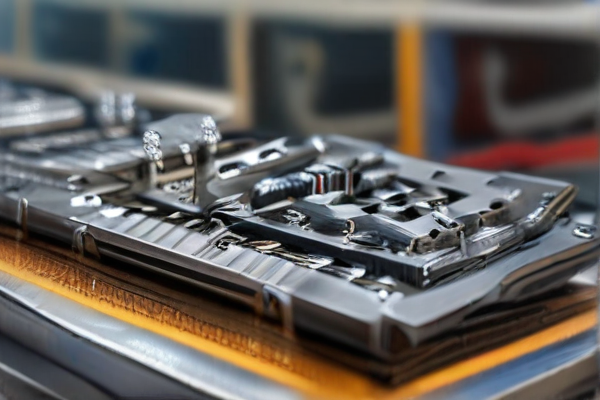

Metal fabrication shops specialize in the creation of metal structures and components through various processes such as cutting, welding, and forming. They offer a range of services and capabilities essential for numerous industries.

– Cutting and Shearing: Advanced machinery for precision cutting, including laser cutters, plasma cutters, and shearing tools.

– Welding Services: Proficient in different welding techniques like MIG, TIG, and Stick welding.

– Forming and Bending: Equipment such as press brakes for precise bending and shaping of metal parts.

– Machining: Computer Numerical Control (CNC) machining centers for high-precision parts.

– Finishing Services: Includes painting, powder coating, and anodizing for corrosion resistance and aesthetic enhancements.

– Metal Stamping: High-speed stamping presses to form metal parts quickly and efficiently.

– Prototyping and Custom Fabrication: Ability to produce prototypes and custom fabricated parts tailored to specific requirements.

– Assembly and Installation: Services to assemble fabricated components and install them as needed.

– Material Handling: Cranes, forklifts, and conveyor systems for the safe movement and storage of heavy materials.

– Quality Control: Rigorous quality testing procedures to ensure all metal parts meet specified standards and tolerances.

– Inventory Management: Keeping a varied stock of raw materials such as steel, aluminum, and titanium to ensure quick project turnaround.

– CAD/CAM Capabilities: Utilizing computer-aided design and manufacturing software for precise planning and execution.

– Safety Protocols: Adherence to strict safety guidelines to protect workers and maintain project integrity.

– Repair and Maintenance Services: Offering repair and maintenance for existing metal structures and components.

Metal fabrication shops are indispensable in various sectors due to their expertise, versatility, and comprehensive range of services.

SourcifyChina specializes in connecting clients with premier metal fabrication shops across China. These facilities are renowned for their cutting-edge technology and skilled workforce, ensuring the highest quality in every project.

The custom products offered by SourcifyChina range from precision-engineered automotive parts to intricately designed architectural structures. Each product undergoes rigorous quality control, meeting international standards and client specifications.

With a focus on versatility, SourcifyChina’s metal fabrication teams handle small to large-scale projects. From prototypes to mass production, they offer tailored solutions to fit diverse industrial needs, ensuring timely and cost-effective delivery.

Collaborating closely with clients, SourcifyChina ensures all custom requirements are met. Through transparent communication and project management, they build trust and long-lasting partnerships, making client satisfaction their top priority. Clients benefit from comprehensive support at every stage, from initial design to final delivery, ensuring a seamless and efficient fabrication process.

SourcifyChina metal fabrication shops are renowned for delivering high-quality, precision-engineered metal products to a global clientele. Located in the heart of China’s industrial sector, these facilities leverage state-of-the-art technology and a highly skilled workforce to produce a wide array of metal components tailored to meet diverse industry specifications. Equipped with advanced machinery such as CNC machines, laser cutters, and robotic welding systems, SourcifyChina ensures that every product meets rigorous quality standards. The company is committed to innovation and sustainability, continuously investing in modern equipment and eco-friendly practices to enhance production efficiency and reduce environmental impact. By offering competitive pricing, timely delivery, and comprehensive customer support, SourcifyChina has built a reputation for reliability and excellence in the metal fabrication industry. Whether for automotive, aerospace, construction, or custom engineering projects, SourcifyChina provides a seamless, end-to-end service solution that adds value at every step of the supply chain.

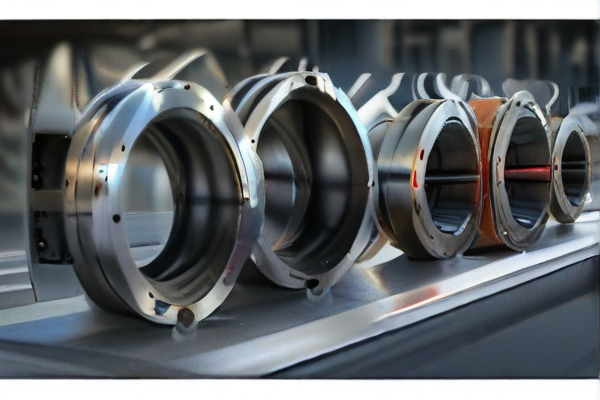

Metal fabrication shops play a pivotal role in the Aerospace, Defense, and Marine industries, providing essential components and structures that meet stringent safety, performance, and durability standards. In aerospace, these shops are responsible for fabricating parts used in aircraft, from airframes and engine components to intricate structural elements. Utilizing materials like aluminum, titanium, and high-strength steel, metal fabrication shops ensure lightweight yet robust constructions critical for aviation. Precision in fabrication is paramount, as even the smallest deviation can affect aerodynamics and overall flight safety. Advanced techniques such as CNC machining, laser cutting, and welding are employed to achieve the exact specifications required, underscoring the vital contribution these shops make to maintaining quality and performance in aerospace applications.

In the defense sector, metal fabrication shops are instrumental in producing a wide array of equipment and mechanisms, ranging from armored vehicle parts to missile components and military-grade hardware. The ability to fabricate metal parts with high precision and strength is crucial for developing defensive technologies capable of withstanding extreme conditions and delivering reliable performance in critical situations. Similarly, in the marine industry, metal fabrication shops provide essential services, constructing hulls, structural supports, and other integral components for ships and submarines. Corrosion-resistant materials and specialized fabrication processes are necessary to endure harsh marine environments. Overall, the expertise and advanced capabilities of metal fabrication shops are indispensable, ensuring that aerospace, defense, and marine industries are equipped with components that are both highly reliable and precisely engineered.

Metal fabrication shops play a crucial role in the automotive industry by providing essential components and structures that enhance the performance, safety, and aesthetics of vehicles. These shops are responsible for producing a wide array of parts, ranging from chassis and framework to intricate engine components. Advanced techniques such as laser cutting, CNC machining, and welding enable fabricators to achieve precise tolerances and high-quality finishes necessary for modern automotive applications. Furthermore, with the rise of electric vehicles (EVs), metal fabrication shops are increasingly producing lighter, more efficient parts using materials like aluminum and high-strength steel, which contribute to improved fuel economy and reduced emissions. Customization services offered by metal fabrication shops also allow automotive manufacturers to innovate rapidly and bring new models to market more efficiently.

In the electronics industry, metal fabrication shops are equally indispensable, as they provide the essential enclosures, heatsinks, and structural components that house and protect sensitive electronic components. High-precision fabrication techniques are required to create the small, complex structures that modern electronic devices demand. This includes producing durable casings for consumer electronics such as smartphones, laptops, and home appliances, as well as robust frames and mounts for industrial equipment and medical devices. Moreover, with the rapid advancement of Internet of Things (IoT) technologies and the escalating demand for miniaturized and more powerful electronics, metal fabrication shops must continuously innovate to provide materials and solutions that meet thermal management, electromagnetic protection, and mechanical stability requirements. Through these specialized services, metal fabrication shops significantly contribute to the reliability and longevity of electronic devices across various sectors.

Metal fabrication shops play a critical role in the construction industry by providing a wide array of custom-fabricated metal components essential for building structures. These shops use processes such as cutting, welding, and machining to create beams, girders, panels, and trusses, among other structural elements. By delivering precisely measured and tailor-made parts, they ensure the structural integrity and aesthetic appeal of buildings. Additionally, metal fabrication shops contribute to the efficient erection of buildings by supplying prefabricated components, which significantly reduces construction time and labor costs. Their ability to work with various metals, including steel, aluminum, and copper, allows them to cater to the diverse needs of modern architectural designs and green building practices, thereby enhancing overall construction quality and sustainability.

In the energy sector, metal fabrication shops are indispensable for the assembly and maintenance of equipment used in power generation, transmission, and distribution. These shops manufacture vital components for wind turbines, solar panel frameworks, oil rigs, and pipelines, among other infrastructure. Precision and durability are paramount in these applications, as the fabricated parts must withstand extreme conditions and harsh environments. Metal fabricators are adept at producing high-performance materials that meet rigorous industry standards. For example, using advanced welding techniques and corrosion-resistant alloys, they ensure the longevity and reliability of offshore drilling platforms and power plant machinery. By providing robust and custom solutions, metal fabrication shops support the growing demand for renewable energy sources and the modernization of existing energy systems, ultimately contributing to a more sustainable future.

Metal fabrication shops play a pivotal role in the industrial equipment industry by providing the essential components and structures necessary for a multitude of applications. These specialized facilities undertake processes such as cutting, bending, welding, and assembling metal sheets to create custom parts that are integral to the functioning of various industrial machines. For instance, metal fabrication shops produce frames, enclosures, and brackets that are used in the construction of machinery for manufacturing plants, automotive assembly lines, and heavy equipment sectors. Their ability to deliver precise, durable, and high-quality metal products ensures that the industrial equipment can withstand rigorous operational demands, leading to enhanced productivity and operational efficiency.

Furthermore, metal fabrication shops contribute to the innovation and evolution of the industrial equipment industry by enabling the creation of bespoke solutions tailored to specific needs. Through advancements in technologies like computer numerical control (CNC) machining and laser cutting, these shops can achieve unparalleled precision, allowing for the development of complex components with tight tolerances. This capability is crucial for industries that require meticulous specifications and reliability, such as aerospace, defense, and energy sectors. Additionally, metal fabrication shops often work closely with engineers and designers to prototype and refine new equipment designs, thus accelerating the innovation cycle. By reducing lead times and minimizing costs associated with traditional manufacturing methods, metal fabrication shops not only support current industrial demands but also drive future advancements through continuous improvement and adaptability.

Metal fabrication shops play a critical role in the medical devices industry by providing essential components and assemblies that meet stringent healthcare standards. These shops utilize advanced techniques such as precision machining, laser cutting, welding, and CNC milling to create high-quality parts for a diverse range of medical devices. From surgical instruments like scalpels, forceps, and clamps to complex diagnostic machines and prosthetic components, metal fabrication shops ensure that every part is crafted with utmost accuracy and reliability. The ability to work with various metals, including stainless steel, titanium, and aluminum, allows these shops to cater to the specific needs of the medical sector, ensuring durability, biocompatibility, and corrosion resistance in the final products.

Moreover, metal fabrication shops contribute significantly to innovation in the medical field. They collaborate closely with medical device manufacturers in the design and prototyping phases, offering expertise on material choices, manufacturability, and cost efficiency. By leveraging state-of-the-art technology and skilled craftsmanship, these shops produce prototypes and custom parts that go through rigorous testing and validation processes. This collaborative effort accelerates the development of innovative solutions, such as minimally invasive surgical tools, advanced imaging equipment, and precision implants, which ultimately enhance patient care and outcomes. The integration of metal fabrication expertise into the medical devices industry not only supports the production of high-quality, reliable medical instruments and machinery but also drives continuous advancement in medical technology.

Metal fabrication shops play a critical role in machining and manufacturing by providing specialized conditions for the transformation of raw metal materials into precise, high-quality components used in various industries. These facilities are equipped with advanced machinery such as CNC (Computer Numerical Control) machines, laser cutters, and welding equipment, allowing for precise cutting, shaping, and joining of metal parts. The capabilities of metal fabrication shops extend to various machining operations such as milling, drilling, turning, and grinding, which are essential in crafting intricate and durable components. The use of such sophisticated tools and technologies ensures that the finished products meet stringent dimensional and functional tolerances, which is crucial for applications in aerospace, automotive, medical devices, and other high-tech industries.

In the broader manufacturing domain, metal fabrication shops serve as integral partners in the production pipeline, often working closely with design engineers and product developers to prototype and refine parts before mass production. Their ability to swiftly produce custom parts and undertake small-batch productions provides flexibility and innovation, enabling manufacturers to respond rapidly to market changes and consumer demands. Additionally, these shops often incorporate quality control processes, such as inspections and material testing, ensuring that the metal parts exhibit high performance and durability. This collaboration not only enhances product reliability but also reduces time-to-market, providing a competitive edge in the fast-paced manufacturing landscape. Through these contributions, metal fabrication shops are indispensable in driving forward technological advances and maintaining the high standards of modern manufacturing practices.

Sure, here are some frequently asked questions (FAQ) along with their answers regarding quality work from SourcifyChina factory for metal fabrication shops.

Q1: What types of metal fabrication services does SourcifyChina offer?

A1: SourcifyChina provides a comprehensive range of metal fabrication services, including laser cutting, welding, bending, rolling, punching, and assembly. We cater to various industries and can customize our services to meet specific project requirements.

Q2: How does SourcifyChina ensure the quality of its metal fabrication work?

A2: Quality is our top priority. SourcifyChina uses state-of-the-art equipment operated by skilled technicians. We follow stringent quality control processes, including regular inspections, real-time monitoring, and final checks to ensure all products meet international standards.

Q3: What materials can SourcifyChina work with in metal fabrication?

A3: We work with a wide range of metals, including stainless steel, carbon steel, aluminum, and various alloys. Our versatility allows us to handle diverse projects, from simple components to complex assemblies.

Q4: Can SourcifyChina handle custom metal fabrication projects?

A4: Absolutely! We specialize in custom metal fabrication tailored to your specifications. Provide us with your designs, drawings, or ideas, and our team will work closely with you to bring your vision to life.

Q5: What lead times can we expect for metal fabrication projects?

A5: Lead times depend on the complexity and size of the project. SourcifyChina is committed to timely delivery and works diligently to meet deadlines. We provide estimated lead times upfront and keep you informed throughout the process.

Q6: How can I request a quote for my metal fabrication project?

A6: To request a quote, simply contact SourcifyChina through our website or email. Provide details about your project, including specifications, materials, and quantities. Our team will review your request and provide a comprehensive quote promptly.

Q7: Does SourcifyChina offer international shipping?

A7: Yes, SourcifyChina offers international shipping. We handle all logistics to ensure your fabricated metal products arrive safely and on time, no matter where you are located.

We hope these FAQs help you understand how SourcifyChina factory can support your metal fabrication needs with quality and reliability.

When looking to collaborate with metal fabrication shops, particularly through platforms like SourcifyChina, several key factors can enhance your manufacturing experience and outcomes:

1. Thorough Vetting: Use SourcifyChina’s resources to meticulously vet potential fabrication shops. Check for certifications, visit recent project portfolios, and read customer reviews to ensure credibility and quality standards.

2. Clear Communication: Establish clear, concise communication channels. Language barriers and time zone differences can be mitigated with detailed project briefs, visual aids (like CAD drawings), and frequent video conferences.

3. Technical Expertise: Ensure the shop has experience with your specific type of metal and fabrication processes (welding, cutting, bending, etc.). This ensures precision in manufacturing complex components.

4. Quality Control: Implement rigorous quality control measures. Use third-party inspection services if necessary. Defining quality benchmarks and conducting regular checks can minimize defects and delays.

5. Prototyping: Before full-scale production, request prototypes. Prototyping helps in identifying potential design or manufacturing issues early on, saving time and costs in the long run.

6. Lead Time: Discuss and agree on lead times. Reliable shops will provide realistic timelines and stick to them. Factor in potential delays in shipping when planning your project schedule.

7. Cost Management: While competitive pricing is important, prioritize quality and reliability. Understand the breakdown of costs (materials, labor, tooling) to ensure transparency and avoid unexpected expenses.

8. Sustainability: If sustainability is a priority, choose shops that practice environmentally friendly methods and have certifications like ISO 14001.

9. After-Sales Support: Opt for fabrication shops that offer robust after-sales support. Whether it’s for handling defects, rework, or future modifications, dependable partners enhance long-term project success.

Partnering with metal fabrication shops via SourcifyChina, while navigated thoughtfully, can leverage cost efficiencies and high-quality production, contributing significantly to your manufacturing objectives.

Sure, here are some FAQs with answers for sourcing metal fabrication shops from SourcifyChina factory:

Q: What types of metal fabrication services does SourcifyChina factory offer?

A: SourcifyChina factory offers a wide range of metal fabrication services, including laser cutting, welding, stamping, machining, and assembly. They also provide surface treatments like powder coating, anodizing, and plating to meet your specific requirements.

Q: How can I verify the quality of the products from SourcifyChina factory?

A: SourcifyChina factory implements stringent quality control measures throughout the production process. They provide material certificates, inspection reports, and adhere to ISO quality standards. You can also request samples to verify quality before placing a bulk order.

Q: What materials can SourcifyChina factory work with?

A: SourcifyChina factory specializes in fabricating products from various metals such as stainless steel, aluminum, carbon steel, brass, and copper. They can accommodate custom material requests based on your project’s needs.

Q: What is the typical lead time for an order?

A: The lead time depends on the complexity and volume of the order. Generally, it ranges from 2 to 6 weeks. For a more accurate estimate, provide detailed specifications and required quantities when contacting SourcifyChina factory.

Q: Does SourcifyChina factory offer prototyping services?

A: Yes, SourcifyChina factory offers prototyping services to help you validate designs before full-scale production. This allows you to make adjustments and ensure the final product meets your expectations.

Q: How do I get a quotation for my project?

A: To get a quotation, send detailed drawings, specifications, material requirements, and volume estimations to SourcifyChina factory. They will review your information and provide a comprehensive quote, including costs and production timelines.

Q: What are the payment terms when ordering from SourcifyChina factory?

A: SourcifyChina factory typically requires a deposit before beginning production, with the balance payable upon completion and prior to shipment. Specific payment terms can be negotiated based on the order size and your company’s credit history.

Q: Can SourcifyChina factory handle large-scale production runs?

A: Yes, SourcifyChina factory is equipped to manage both small and large-scale production runs. They have advanced machinery and skilled labor to handle high-volume orders efficiently.

Q: What shipping options are available?

Sourcing metal fabrication shops from SourcifyChina Factory can streamline your search and ensure quality and reliability. Here are some concise tips:

1. Define Your Requirements: Clearly list the types of metal fabrication you need (e.g., cutting, welding, assembly), materials, tolerances, and order volumes.

2. Use Specific Keywords: When searching on Sourcify, use precise terms like “aluminum welding,” “CNC machining,” or “custom metal parts” to refine your results.

3. Check Factory Profiles: Evaluate factory profiles for experience, capabilities, certification, and past client reviews. Factories with ISO certifications often adhere to higher quality standards.

4. Request Quotes: Contact multiple suppliers to get detailed quotes. Compare prices, but also consider lead times, minimum order quantities, and payment terms.

5. Inspect Samples: Always request sample parts to assess quality. Evaluating initial samples can prevent issues with large-scale production.

6. Visit the Factory: If possible, visit the factories to verify their capabilities and standards. Utilize video calls or third-party inspection services if travel is not feasible.

7. Audit Quality Control: Ensure the factory has robust quality control processes. Look for documentation and consistency in their quality checks.

8. Review Logistics: Analyze the logistics for shipping and delivery times. Consider factories that offer integrated logistics solutions for ease of transport and lower costs.

9. Negotiate Terms: Negotiate for favorable terms, but be clear about your quality and delivery expectations to avoid misunderstandings.

10. Build Relationships: Establish long-term relationships with trustworthy suppliers. A reliable partnership can lead to better pricing, priority production, and superior service.

By following these tips, you can efficiently source reliable metal fabrication shops through SourcifyChina Factory, ensuring you receive high-quality products and services.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.