Technology and Applications of metal file for metal

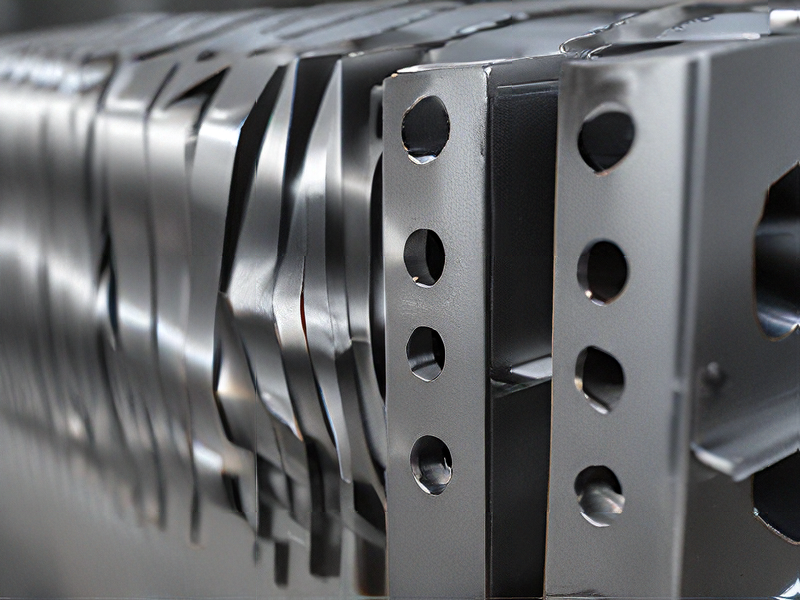

Metal files are essential tools in various industries, primarily for shaping, smoothing, and finishing metal surfaces. Made from high-carbon steel or carbide, these files come in various shapes (flat, round, triangular) and sizes to cater to specific tasks.

Applications of Metal Files:

1. Machining and Metalworking: Used for deburring and finishing machined components to achieve desired dimensions and surface finishes.

2. Jewelry Making: Fine files help in intricate shaping and detailing of metal pieces, ensuring precision and quality.

3. Automotive Industry: Commonly used to refine parts, repair worn-down components, and adjust metal fittings for better performance.

4. Tool and Die Making: Essential for creating dies and molds, where precision is paramount.

5. Hobbyist and Crafting: Used in model-making and DIY projects for precise adjustments and finishes on metal parts.

Technology Enhancements:

Modern metal files often incorporate advanced materials and coatings to improve durability and efficiency. Diamond-coated files offer superior cutting efficiency and a longer lifespan compared to traditional steel files. Ergonomic designs enhance user comfort, reducing fatigue during prolonged use.

Conclusion:

Metal files are indispensable in both professional and hobbyist settings, ensuring precision in various applications. With advancements in technology, the efficiency and functionality of these tools continue to evolve, meeting the demands of modern metalworking.

Quality Testing Methods for metal file for metal and how to control quality

Quality testing methods for metal files involve several standardized procedures to ensure consistency, durability, and performance. Key methods include:

1. Visual Inspection: Examine the file for defects such as cracks, poor finish, and dimensional inaccuracies. This initial step helps identify obvious physical issues.

2. Hardness Testing: Use Rockwell or Brinell hardness tests to measure the hardness of the steel. A harder file maintains its cutting edge longer, making this a critical quality metric.

3. Microstructure Analysis: Employ optical microscopy or scanning electron microscopy to assess the microstructure of the file material. Proper heat treatment and alloying can enhance performance and lifespan.

4. Tensile Testing: Conduct tensile tests to determine the material’s strength and ductility. This helps ensure that the file can withstand the forces encountered during use.

5. Surface Roughness Testing: Measure the surface finish using profilometers. A finer surface finish reduces friction and increases efficiency when used on metals.

6. Wear Resistance Testing: Perform tests such as the pin-on-disc method to measure resistance to wear over time, ensuring the file’s longevity.

To control quality, implement a robust quality management system (QMS) based on ISO 9001 standards. This includes:

– Incoming Material Inspection: Ensure raw materials meet specifications before production.

– In-Process Monitoring: Use statistical process control (SPC) to monitor production processes and detect variations early.

– Final Product Testing: Adhere to established testing protocols before packaging and shipping.

– Feedback Loops: Collect customer feedback and incorporate findings into the quality improvement process, creating a cycle of continuous enhancement.

By systematically applying these testing methods and quality control practices, the performance and reliability of metal files can be assured.

Tips for Procurement and Considerations when Purchasing from metal file for metal

When procuring metal files, several key considerations can enhance your purchasing decisions:

1. Material Type: Metal files come in various materials like high-carbon steel, stainless steel, and carbide. Choose a material that suits your application; for instance, high-carbon steel is great for softer metals, while carbide is ideal for harder materials.

2. File Shape and Cut: Select the appropriate shape (flat, round, half-round, or triangle) based on the workpiece’s geometry. Consider the cut type (single, double, or rasp) to balance between aggressiveness and fineness. A double-cut file removes material faster, while a single-cut file provides a smoother finish.

3. File Size: Size matters depending on the size of the material being worked on. Larger files are better for broad surfaces, while smaller files are more suited for precision work.

4. Durability and Maintenance: Check the file’s lifespan based on its material and construction quality. Invest in files that can endure regular use without deterioration. Additionally, consider maintenance requirements—files should be cleaned regularly to avoid clogging.

5. Ergonomics: Look for files with handles designed for comfortable grip and extended use. Ergonomics can greatly affect productivity and reduce fatigue during prolonged tasks.

6. Supplier Reputation: Source files from reputable suppliers or manufacturers to ensure quality. Research reviews or seek recommendations to avoid subpar products.

7. Cost vs. Value: While it may be tempting to select the cheapest option, consider long-term value. A higher quality file may have a greater initial cost but will save time and money in replacements over time.

By keeping these considerations in mind, you can ensure that your purchase of metal files will meet your specific needs effectively.

FAQs on Sourcing and Manufacturing from metal file for metal in China

FAQs on Sourcing and Manufacturing Metal Files in China

#### 1. Why source metal files from China?

China is a global manufacturing hub known for its cost-effective production capabilities, skilled labor, and vast supplier network. This can lead to significant cost savings and access to a wide range of products.

#### 2. What are the key factors to consider when choosing a supplier?

– Reputation and Experience: Check the supplier’s track record and years in business.

– Certifications: Look for ISO or other relevant certifications.

– Quality Control: Ensure they have robust quality control processes.

– Capacity: Confirm they can handle your volume requirements.

– Communication: Assess their responsiveness and language proficiency.

#### 3. How can I verify the quality of metal files?

– Samples: Request and evaluate product samples.

– Inspections: Use third-party inspection services.

– Factory Audits: Conduct or commission audits to assess production facilities and processes.

#### 4. What are the common manufacturing processes for metal files?

– Forging: Enhances strength and durability.

– Machining: Ensures precision and accuracy.

– Heat Treatment: Improves hardness and wear resistance.

– Surface Finishing: Includes processes like coating and polishing for better appearance and longevity.

#### 5. How do I handle logistics and shipping?

– Incoterms: Understand terms like FOB, CIF, and DDP.

– Shipping Partners: Choose reliable freight forwarders.

– Customs Clearance: Be prepared with proper documentation and compliance with regulations.

#### 6. What are the risks and how can they be mitigated?

– Quality Risks: Conduct thorough vetting and regular inspections.

– Delays: Maintain clear communication and have contingency plans.

– Cultural Differences: Be aware of and respect cultural nuances to foster good relationships.

#### 7. What is the typical lead time for manufacturing and delivery?

Lead times can vary but generally range from 30 to 60 days, depending on the complexity of the product and the production schedule.

Sourcing metal files from China can be highly beneficial if managed well, ensuring high-quality products at competitive prices.