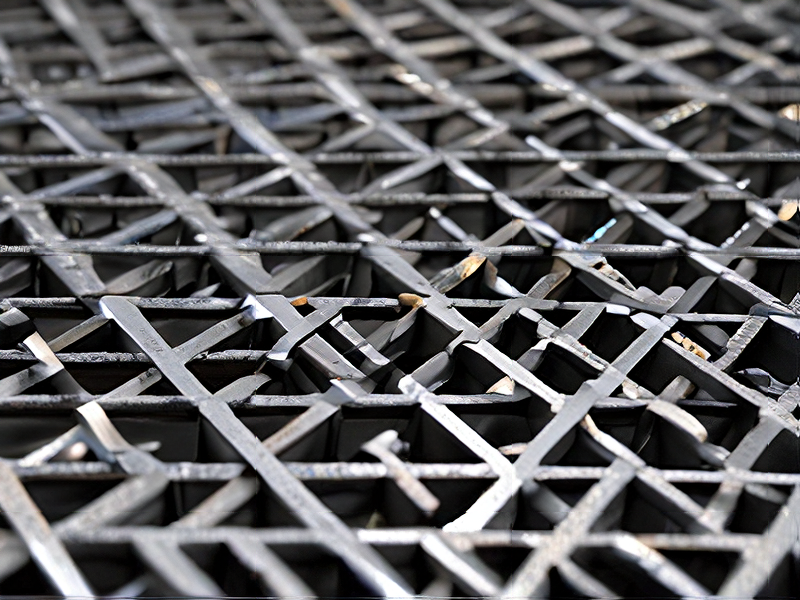

Technology and Applications of metal grate material

Metal grates are essential components in various industries due to their durability, strength, and versatility. They are typically made from materials such as steel, aluminum, or stainless steel, each offering distinct benefits depending on the application.

Technology:

1. Manufacturing Techniques: Metal grates are produced using methods like welding, casting, and forging. Welding involves joining metal bars to create a sturdy grid, while casting allows for intricate designs by pouring molten metal into molds. Forging involves shaping metal under high pressure, enhancing strength and durability.

2. Coating and Finishing: To enhance corrosion resistance and longevity, metal grates often undergo surface treatments such as galvanizing (zinc coating), painting, or powder coating. These treatments protect against environmental elements and wear.

Applications:

1. Industrial Use: Metal grates are widely used in industrial settings for flooring, platforms, and walkways. Their open design allows for drainage and ventilation, making them ideal for environments where spillage or airflow is a concern.

2. Infrastructure: In infrastructure, metal grates are essential for stormwater management. They are used as drainage covers on roads and sidewalks, preventing flooding and ensuring pedestrian safety.

3. Security: Metal grates provide security solutions in windows, doors, and barriers. Their robust construction deters unauthorized access while allowing visibility and airflow.

4. Architecture: Architectural applications include decorative facades, sunshades, and ventilation grilles. Metal grates can be designed to enhance aesthetic appeal while providing functional benefits like shading and air circulation.

5. Transportation: In transportation, they are used in the construction of vehicle platforms, ramps, and stairs. Their strength and non-slip properties are crucial for safety in these applications.

Metal grates combine functionality with durability, making them indispensable in various sectors. The choice of material and manufacturing technique depends on the specific requirements of the application, ensuring optimal performance and longevity.

Quality Testing Methods for metal grate material and how to control quality

Quality Testing Methods for Metal Grate Material

1. Visual Inspection: The first step involves a thorough visual examination to identify surface defects such as cracks, warping, and rust. This is a simple yet effective method to ensure initial quality.

2. Dimensional Checks: Using calipers, micrometers, and other measuring tools to verify that the grates meet specified dimensions and tolerances. Accurate dimensions are crucial for proper fit and function.

3. Material Testing:

– Chemical Composition Analysis: Spectroscopy methods like X-ray fluorescence (XRF) are used to ensure the metal’s chemical composition matches the specified alloy.

– Hardness Testing: Methods such as Rockwell, Brinell, or Vickers hardness tests determine the material’s resistance to deformation and wear.

4. Load Testing: Applying pressure to the grate to ensure it can withstand expected loads without deforming or breaking. This simulates real-world conditions.

5. Non-Destructive Testing (NDT):

– Ultrasonic Testing: Uses high-frequency sound waves to detect internal flaws or inconsistencies.

– Magnetic Particle Inspection: Detects surface and near-surface discontinuities in ferromagnetic materials.

– Dye Penetrant Inspection: Highlights surface cracks through capillary action of a dye solution.

6. Corrosion Resistance Testing: Exposure to corrosive environments, such as salt spray tests, to ensure durability in harsh conditions.

Quality Control Measures

1. Standard Operating Procedures (SOPs): Establish detailed SOPs for each stage of production and testing to maintain consistency and reliability.

2. Regular Audits: Conduct regular internal and external audits to ensure compliance with quality standards and identify areas for improvement.

3. Training and Certification: Ensure that personnel are adequately trained and certified in quality testing methods and equipment usage.

4. Statistical Process Control (SPC): Utilize SPC tools to monitor production processes in real-time, identifying variations and preventing defects before they occur.

5. Documentation and Traceability: Maintain comprehensive records of all tests and inspections for traceability and accountability.

6. Supplier Quality Management: Implement rigorous evaluation and monitoring of suppliers to ensure that raw materials meet required standards before production.

By integrating these methods and controls, the quality of metal grate materials can be consistently maintained and improved.

Tips for Procurement and Considerations when Purchasing from metal grate material

Procurement and purchase decisions for metal grate materials require careful consideration. Here are key tips:

Material Selection:

* Application: Determine the specific application (e.g., drainage, walkways, ventilation) to choose the appropriate material (e.g., steel, aluminum, stainless steel).

* Durability: Consider the environment’s impact (corrosion, weather exposure, heavy loads) and select a material with sufficient strength and resistance.

Design & Specifications:

* Load Capacity: Ensure the grate meets the anticipated load requirements.

* Opening Size: Choose a size appropriate for the application’s purposes (drainage, debris passage, safety).

* Profile & Configuration: Select a profile (flat bar, bar grating) and configuration (interlocking, welded) that suits the needs.

Procurement Process:

* Supplier Evaluation: Research reputable suppliers with experience in metal grate manufacturing.

* Quotations: Obtain detailed quotations from multiple suppliers, specifying precise requirements.

* Quality Control: Verify material certifications and quality standards.

* Delivery & Installation: Clarify delivery timelines, installation requirements, and associated costs.

By carefully evaluating these factors, you can make informed procurement decisions and select the optimal metal grate material for your project.

FAQs on Sourcing and Manufacturing from metal grate material in China

FAQs on Sourcing and Manufacturing Metal Grate Material in China

1. Why source metal grate material from China?

China offers competitive pricing, extensive manufacturing capabilities, and a wide range of suppliers with expertise in metal fabrication. This makes it an attractive destination for sourcing metal grate materials.

2. What types of metal grate materials are available?

Common types include steel (galvanized or stainless), aluminum, and cast iron. Each type offers different benefits in terms of strength, corrosion resistance, and weight.

3. How to find reliable suppliers in China?

Use online platforms like Alibaba, Made-in-China, and Global Sources. Attend trade shows like the Canton Fair. Verify suppliers through reviews, certifications, and factory visits.

4. What are the key considerations when selecting a supplier?

Consider the supplier’s experience, production capacity, quality control processes, certifications (ISO, CE), and past client reviews. Ensure they can meet your specifications and delivery timelines.

5. How to ensure the quality of metal grate materials?

Request samples for inspection, review material certifications, and consider third-party quality inspections. Establish clear quality standards and specifications in the contract.

6. What are the common manufacturing processes?

Processes include welding, cutting, galvanizing, and surface treatments. Advanced techniques like laser cutting and CNC machining may also be used depending on the design requirements.

7. What is the typical lead time for production?

Lead times vary based on order size, complexity, and current demand but generally range from 4 to 8 weeks. Discuss timelines upfront to align expectations.

8. How to handle shipping and logistics?

Work with experienced freight forwarders familiar with Chinese exports. Choose between sea and air freight based on budget and urgency. Ensure all customs documentation is accurately prepared.

9. What are the cost components?

Costs include material, manufacturing, quality inspection, packaging, and shipping. Factor in tariffs and import duties applicable in your country.

10. How to manage communication and potential issues?

Maintain regular communication through email, phone, or instant messaging apps. Clearly document all agreements and address issues promptly through negotiation or mediation if needed.

By considering these FAQs, you can effectively navigate the process of sourcing and manufacturing metal grate materials in China.