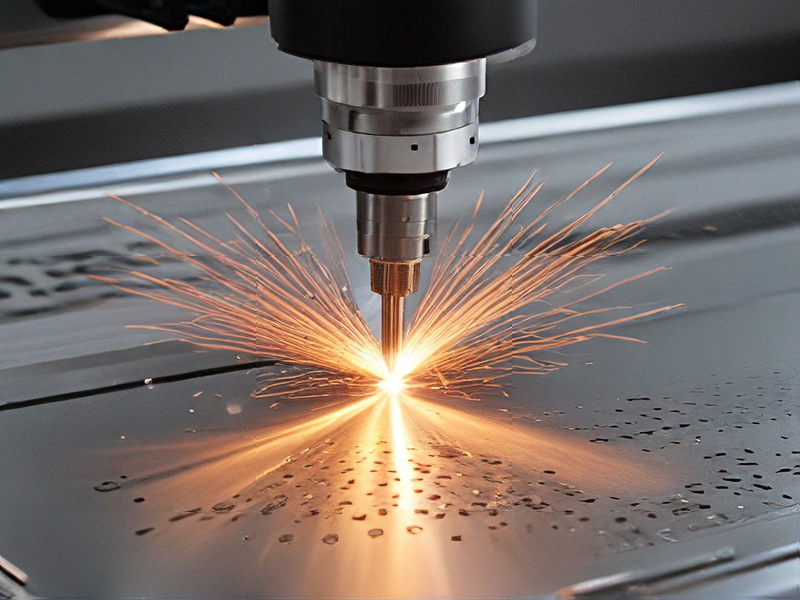

Technology and Applications of metal laser etching machine

Metal laser etching machines utilize high-powered lasers to precisely remove material from metal surfaces, creating detailed designs, markings, or patterns. This technology finds extensive applications in various industries, including manufacturing, aerospace, automotive, and jewelry making.

Key Technologies:

1. Laser Source: Typically, fiber lasers are used due to their high efficiency and ability to deliver intense beams required for precise etching.

2. Precision Optics: These direct the laser beam onto the metal surface with accuracy, ensuring the etching adheres to design specifications.

3. Computer Numerical Control (CNC): CNC systems control the movement of the laser beam according to digital designs, allowing for intricate and complex patterns.

Applications:

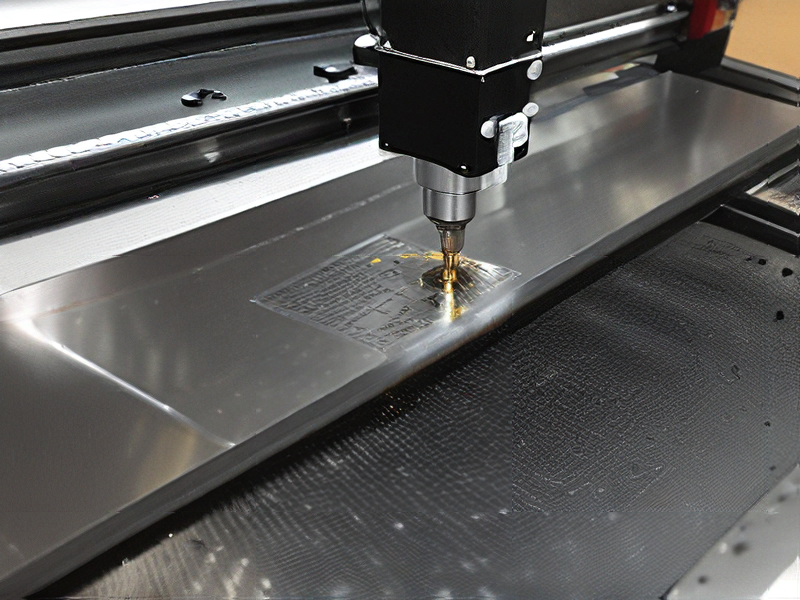

1. Product Marking and Identification: Manufacturers use laser etching to engrave serial numbers, logos, and product information directly onto metal parts, ensuring traceability and brand identity.

2. Personalization: In the jewelry and gift industry, laser etching customizes metal surfaces with names, dates, or personalized messages, enhancing product value.

3. Aerospace and Automotive Components: Critical components such as turbine blades, engine parts, and control panels benefit from laser etching for part numbers, QR codes, and safety markings.

4. Medical Devices: Implants and surgical instruments are marked with identification codes or patient-specific information, aiding in tracking and sterilization.

5. Art and Decorative Applications: Artists and designers use laser etching to create intricate designs on metal sculptures, decorative panels, and architectural elements.

Advantages:

– Precision and Consistency: Laser etching ensures high precision, repeatability, and consistency of markings compared to traditional methods.

– Non-contact Process: Minimizes physical contact with the material, reducing the risk of damage or contamination.

– Versatility: Capable of etching a wide range of metals including steel, aluminum, titanium, and alloys, accommodating diverse industry needs.

In conclusion, metal laser etching machines integrate advanced laser technology with precise control systems, enabling versatile applications across industries for marking, personalization, and intricate design on metal surfaces.

Quality Testing Methods for metal laser etching machine and how to control quality

Quality testing methods for a metal laser etching machine typically include:

1. Dimensional Accuracy: Using precision measuring tools like calipers or micrometers to verify the dimensions of etched features against design specifications.

2. Visual Inspection: Examining the surface for defects such as incomplete etching, over-etching, or inconsistent marking.

3. Durability Testing: Subjecting etched samples to environmental factors (e.g., temperature, humidity) to assess durability and resistance to wear.

4. Adhesion Testing: Evaluating how well the etched markings adhere to the metal surface using methods like tape tests or scratch tests.

5. Contrast and Legibility: Assessing the readability of the etched markings under different lighting conditions to ensure clarity and contrast.

To control quality:

– Standard Operating Procedures (SOPs): Develop and follow SOPs for machine setup, operation, and maintenance to ensure consistency.

– Calibration: Regularly calibrate the laser etching machine and measuring instruments to maintain accuracy.

– Training: Provide training to operators on proper machine operation, inspection techniques, and quality standards.

– Quality Control Checks: Implement regular checks during production to detect any deviations from quality standards early.

– Feedback Loop: Establish a feedback loop where issues identified during testing are used to improve processes and prevent recurrence.

By integrating these methods and controls into your quality management system, you can ensure consistent and high-quality metal laser etching outputs.

Tips for Procurement and Considerations when Purchasing from metal laser etching machine

When purchasing a metal laser etching machine, consider several key factors to ensure you make an informed decision:

1. Laser Type and Power: Choose a machine with a suitable laser type (fiber, CO2, etc.) and power rating based on the materials you’ll be etching and the depth/detail required.

2. Work Area Size: Ensure the machine’s work area accommodates the size of the metal sheets or parts you intend to etch.

3. Precision and Speed: Evaluate the machine’s precision level and speed, crucial for high-quality etching and productivity.

4. Software Compatibility: Check if the machine’s software is user-friendly and compatible with your existing workflow or CAD software for seamless operation.

5. Maintenance and Support: Consider the maintenance requirements and availability of technical support from the manufacturer or supplier.

6. Safety Features: Look for safety features like enclosed laser systems, emergency stop buttons, and interlocks to ensure safe operation.

7. Budget and Total Cost of Ownership: Besides the initial purchase price, factor in ongoing costs like maintenance, consumables (laser gases, lenses), and energy consumption.

8. Supplier Reputation: Choose a reputable supplier with a track record of quality products and good customer service.

9. User Reviews and References: Seek feedback from other users or references provided by the supplier to gauge the machine’s performance and reliability.

10. Training and Installation: Ensure the supplier offers adequate training and installation support to get your team up to speed quickly.

By carefully considering these factors, you can select a metal laser etching machine that meets your operational needs and provides long-term value for your procurement investment.

FAQs on Sourcing and Manufacturing from metal laser etching machine in China

Certainly! Here are some FAQs regarding sourcing and manufacturing from a metal laser etching machine in China:

1. What are the advantages of sourcing a metal laser etching machine from China?

– China offers competitive pricing due to lower manufacturing costs and access to advanced technology in laser etching.

2. How can I ensure the quality of the metal laser etching machine from Chinese suppliers?

– Conduct thorough supplier assessments, request samples, and utilize third-party inspection services to verify quality standards.

3. What are the typical lead times for manufacturing and delivery?

– Lead times vary but generally range from a few weeks to a couple of months, depending on customization and order volume.

4. Are there any regulatory considerations or certifications required for importing laser etching machines from China?

– Yes, ensure compliance with local regulations on laser safety and import requirements in your country.

5. What are the payment terms usually accepted by Chinese manufacturers?

– Common terms include T/T (Telegraphic Transfer) and sometimes L/C (Letter of Credit), negotiable based on the supplier.

6. How do I handle shipping and logistics for the metal laser etching machine?

– Coordinate with the supplier or a freight forwarder to manage shipping logistics, including customs clearance and transportation.

7. What after-sales support can I expect from Chinese suppliers?

– Suppliers often provide technical support, training, and warranties; clarify these terms before finalizing the purchase.

Navigating these FAQs can help streamline your sourcing process and ensure a smoother experience when procuring a metal laser etching machine from China.