Technology and Applications of metal laser marking machine

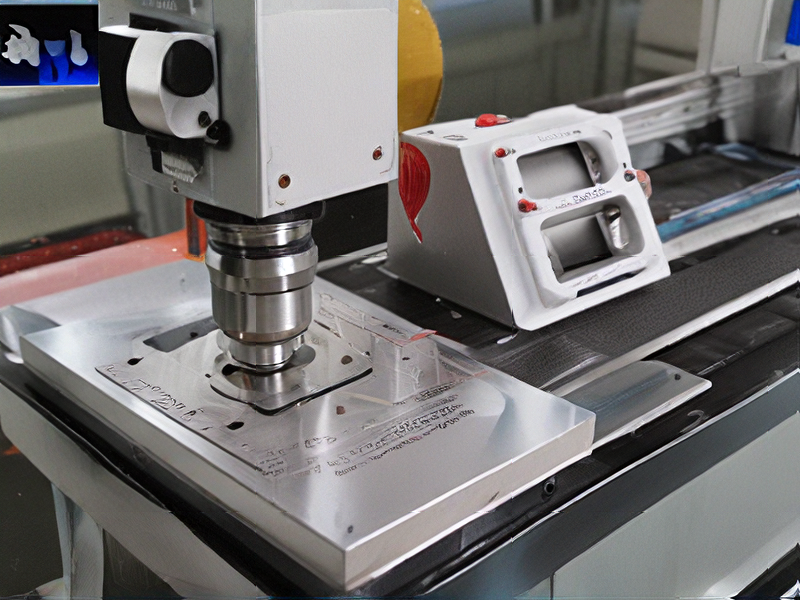

Metal laser marking machines utilize laser beams to engrave or mark surfaces of various metals. This technology offers several advantages over traditional marking methods such as chemical etching or mechanical engraving. Laser marking provides high precision and accuracy, allowing for intricate designs, small fonts, and detailed images to be etched onto metal surfaces without causing damage or deformation.

Applications of metal laser marking machines are extensive across industries like automotive, aerospace, medical devices, electronics, and jewelry. In automotive manufacturing, these machines are used to mark serial numbers, barcodes, and logos on engine parts or chassis components for traceability and quality control. In aerospace, laser marking ensures parts are marked with permanent, high-contrast identifiers that withstand harsh environmental conditions.

Medical device manufacturers utilize laser marking for unique device identification (UDI) compliance, enabling product traceability throughout its lifecycle. In electronics, microchips and circuit boards are marked with laser for component identification and branding. Even in jewelry making, intricate designs and personalized engravings are achieved using laser marking technology, adding value and customization to products.

The versatility of metal laser marking machines extends to a wide range of materials including stainless steel, aluminum, titanium, and various alloys. Different types of laser technologies such as fiber lasers, CO2 lasers, and Nd:YAG lasers offer flexibility to accommodate various metal types and marking requirements.

Overall, metal laser marking machines contribute significantly to manufacturing efficiency, product traceability, and aesthetic appeal across diverse industries, making them indispensable tools for modern industrial applications.

Quality Testing Methods for metal laser marking machine and how to control quality

Quality testing methods for metal laser marking machines typically involve several key approaches to ensure the accuracy, durability, and consistency of markings:

1. Visual Inspection: Directly examining the marked metal surface for legibility, precision of marking, and any signs of defects or inconsistencies.

2. Dimensional Accuracy: Measuring the dimensions of marked features against specified tolerances using precision instruments like calipers or micrometers.

3. Contrast and Visibility: Assessing the contrast between the marked area and the metal substrate to ensure readability under various lighting conditions.

4. Durability Testing: Subjecting marked samples to environmental stresses such as abrasion, corrosion, or temperature variations to evaluate the permanence of the markings.

5. Barcode and Data Matrix Verification: Verifying the accuracy and readability of barcodes or data matrices marked by the laser, often using specialized verification equipment.

6. Image and Graphics Quality: Evaluating the clarity and fidelity of complex images or graphics marked onto the metal surface.

To control quality effectively:

– Standard Operating Procedures (SOPs): Establish clear protocols for machine setup, marking parameters, and inspection criteria.

– Regular Calibration: Ensure the laser machine is regularly calibrated to maintain marking precision and consistency.

– Training and Skill Development: Train operators in proper machine operation, inspection techniques, and interpretation of quality standards.

– Documentation and Traceability: Maintain comprehensive records of marking parameters, inspection results, and any corrective actions taken.

– Continuous Improvement: Implement feedback mechanisms to address any quality issues identified during testing, aiming for ongoing enhancement of marking quality.

By employing these methods and controls, manufacturers can ensure that metal laser marking machines consistently produce high-quality, reliable markings that meet customer expectations and regulatory requirements.

Tips for Procurement and Considerations when Purchasing from metal laser marking machine

When purchasing a metal laser marking machine, consider the following key tips and considerations:

1. Technology and Specifications: Assess the laser marking technology (fiber, CO2, etc.) based on your material and marking requirements. Check specifications like laser power, wavelength, and marking speed to ensure they meet your needs.

2. Marking Quality: Evaluate sample markings for clarity, precision, and depth consistency. This ensures the machine can achieve the desired marking quality on your specific metal materials.

3. Software and Compatibility: Verify the compatibility of the machine’s software with your existing systems for seamless integration. User-friendly software with customization options can enhance operational efficiency.

4. Ease of Use and Maintenance: Consider the machine’s user interface and ease of maintenance. Intuitive controls and accessibility to critical components simplify operation and upkeep.

5. Durability and Reliability: Choose a machine from a reputable manufacturer known for reliability and durability. Look for robust construction and proven performance in industrial environments.

6. Support and Service: Assess the availability of technical support, training, and warranty terms. Responsive customer service ensures prompt assistance in case of issues or maintenance needs.

7. Safety Features: Ensure the machine complies with safety standards and includes features like enclosures, interlocks, and ventilation for safe operation.

8. Cost and ROI: Evaluate the total cost of ownership, including initial purchase price, operating costs (energy, consumables), and potential ROI through increased productivity or expanded capabilities.

9. Reviews and References: Seek feedback from other users or industry reviews to gauge the machine’s performance, service reliability, and overall satisfaction.

10. Future Scalability: Consider future needs and scalability. Choose a machine that can accommodate future upgrades or changes in production requirements.

By carefully considering these factors, you can select a metal laser marking machine that aligns with your operational needs, budget, and long-term goals effectively.

FAQs on Sourcing and Manufacturing from metal laser marking machine in China

When sourcing a metal laser marking machine from China, several FAQs commonly arise:

1. Quality Assurance: Ensure the supplier meets international standards like ISO. Request samples or visit their facility to assess quality.

2. Customization: Can the machine be tailored to specific needs? Discuss customization options and any associated costs.

3. Lead Times: What are the production and delivery times? Clarify these to plan your procurement schedule.

4. Support and Training: Does the supplier offer training on machine operation and maintenance? Inquire about technical support availability.

5. Warranty and Service: What are the warranty terms? Understand coverage, duration, and conditions for service or repairs.

6. Compliance and Certification: Ensure the machine complies with safety and regulatory standards in your country.

7. Cost Breakdown: Request a detailed quote including shipping costs, taxes, and any potential import duties.

8. Payment Terms: Discuss payment methods, schedules, and whether there are any milestones tied to production.

9. After-Sales Support: How responsive is the supplier for after-sales queries or issues?

10. References: Request references from other customers who have purchased similar equipment.

By addressing these FAQs, you can navigate the process of sourcing and manufacturing a metal laser marking machine from China more effectively, ensuring a smoother procurement experience.