SourcifyChina Factory, renowned for its expert craftsmanship, offers top-notch metal marking solutions. Their reputation is built on consistent quality and cutting-edge technology. Exporting globally, they ensure each product meets international standards.

SourcifyChina Factory prioritizes customer service, addressing specific requirements and customizations efficiently. Their skilled team understands market trends, ensuring your purchases stay competitive. They foster transparency in communication and transactions.

Competitive pricing at SourcifyChina Factory ensures value for money without compromising on quality. Leveraging economies of scale, they provide significant cost savings. Their rigorous quality control processes guarantee that each item surpasses your expectations.

Partnering with SourcifyChina means enjoying streamlined logistics and timely deliveries. Their robust supply chain management minimizes lead times and potential delays. Your business can rely on their punctuality and professionalism.

Ultimately, choosing SourcifyChina Factory for metal marking needs ensures comprehensive support, superior quality, and cost-efficiency. Their commitment to excellence makes them a trustworthy partner for your business growth and success.

Metal marking involves various methods to inscribe text, logos, or designs on metal surfaces. Techniques vary based on the type of metal, the required durability, and the desired precision.

– Laser Marking:

– Optical Technology

– Precise and permanent

– Suitable for various metals

– Non-contact process

– Etching:

– Acid or electrochemical process

– Good for detailed designs

– Permanent but slower process

– Engraving:

– Mechanical or CNC machines

– Creates deeper marks

– Durable but may cause material stress

– Stamping:

– High-pressure tool impact

– Quick and cost-effective

– Suitable for high-volume needs

– Dot Peen:

– Pneumatic or electric

– Creates a series of dots

– Controlled depth and spacing

– Plasma Marking:

– High-temperature arc

– Suitable for thick materials

– Very durable

– Chemical Marking:

– Uses masking and chemical baths

– Effective for large areas

– Less environmentally friendly

– Inkjet Printing:

– Non-contact process

– Good for temporary marks

– Suitable for barcodes and serial numbers

Each of these metal marking methods has distinct advantages and considerations, making them suitable for specific applications based on needs such as precision, volume, and durability.

Metal marking has diverse applications across various industries, including manufacturing, automotive, aerospace, and medical. It ensures traceability, quality control, and compliance with regulatory standards.

– Manufacturing: Identification of parts, tools, and machinery.

– Automotive: VIN (Vehicle Identification Numbers) engraving for tracking.

– Aerospace: Part serialization and safety marking.

– Medical: Marking surgical instruments for hygiene and identification.

– Electronics: Circuit board labeling.

– Jewelry: Personalized engravings.

– Defense: Marking weaponry and components for traceability.

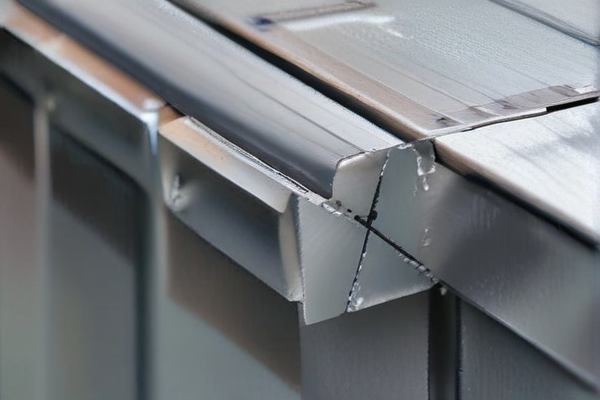

– Construction: Marking and identifying steel beams and structures.

– Consumer Goods: Branding on metal products like appliances.

– Art and Craft: Decorative engravings on metal artworks.

– Energy: Marking pipes and equipment in oil and gas industries.

– Logistics: Barcoding and tracking inventory.

– Marine: Marking components in shipbuilding for maintenance and repair.

– Renewable Energy: Marking components in wind turbines and solar panels.

– Food and Beverage: Engraving logos and information on packaging machinery.

These applications highlight the essential role of metal marking in enhancing operational efficiency and product authenticity across a wide range of sectors.

SourcifyChina offers an extensive range of metal marking materials that cater to diverse industrial needs. Their product portfolio includes metals like aluminum, stainless steel, and brass, each renowned for their durability and reliability in various applications.

The aluminum materials from SourcifyChina are lightweight yet incredibly strong, making them ideal for aerospace and automotive industries. They also resist corrosion, ensuring longevity even in harsh environments.

Stainless steel materials stand out for their excellent resistance to rust and staining. These qualities make them perfect for medical instruments, kitchenware, and construction projects requiring hygiene and strength.

Brass materials are prized for their malleability and acoustic properties, commonly used in musical instruments and decorative items. They also exhibit antimicrobial properties, making them suitable for plumbing fixtures.

SourcifyChina’s commitment to quality ensures that all metal marking materials undergo rigorous testing. This guarantees superior performance, enhancing their clients’ operational efficiency and product lifespan, thus positioning SourcifyChina as a trusted partner in the industry.

SourcifyChina excels in quality control for its metal marking manufacturing process. The company implements rigorous inspections at every production stage to maintain high standards. This method guarantees that every product is meticulously checked for defects.

The first phase involves raw material verification. Raw materials undergo comprehensive checks to meet the required specifications. They are inspected for durability and compatibility, ensuring that only high-grade materials proceed to production.

Precision is paramount in the machining process. SourcifyChina employs state-of-the-art technology and skilled technicians. This ensures that every cut, engraving, and mark meets precise specifications and customer requirements.

Post-machining inspections follow, where each piece is evaluated for accuracy. This involves dimensional checks and surface finish inspections, ensuring that the metal markings are flawless. Any discrepancies are promptly addressed to prevent further issues.

Finally, comprehensive final quality checks are conducted. Each item undergoes thorough inspections to verify that it meets all required standards and specifications. Packaging is also scrutinized to protect products during transit.

SourcifyChina’s quality control system not only ensures product excellence but also customer satisfaction. By maintaining stringent checks throughout the manufacturing process, SourcifyChina delivers durable and precisely marked metal products. This meticulous approach positions the company at the forefront of the industry.

SourcifyChina specializes in advanced metal marking technologies, providing high precision and reliability for various industrial applications. Their expertise encompasses laser engraving, etching, and dot peen marking, meeting stringent quality standards.

Leveraging state-of-the-art laser technology, SourcifyChina ensures clear, durable, and precise markings on a variety of metals. Their laser marking process is suitable for intricate designs and detailed graphics, supporting applications in the automotive, aerospace, and medical industries.

Etching services offered by SourcifyChina provide deep, permanent marks on metal surfaces, ideal for part identification and branding. This process is adept for both small-scale customizations and large-scale productions, offering versatility and efficiency.

Dot peen marking is another key capability of SourcifyChina, offering robust and tamper-resistant marks. This process is widely used for creating highly legible serial numbers, barcodes, and data matrices, essential for asset tracking and regulatory compliance.

Customer satisfaction is a priority for SourcifyChina, as they provide tailored solutions based on specific client needs. Their profound expertise, coupled with cutting-edge technology, delivers impeccable metal marking services, assuring quality, consistency, and prompt delivery.

Metal marking offers precise, permanent, and versatile identification solutions for various industries, enhancing traceability, asset management, and quality control.

– Durability: Metal markings are long-lasting and resistant to wear, corrosion, and harsh environmental conditions, ensuring information remains readable over time.

– Traceability: Enhances traceability in manufacturing processes by marking serial numbers, batch numbers, and barcodes, assisting in tracking and quality assurance.

– Branding: Enables clear branding and logos on products, providing a professional finish and increasing brand visibility.

– Regulatory Compliance: Helps in meeting industry standards and regulatory requirements by marking essential details like material specifications and safety information.

– Inventory Management: Aids in efficient inventory management by enabling quick identification of parts and components.

– Counterfeit Prevention: Deters counterfeiting by providing unique identification marks that are challenging to replicate.

– Customization: Allows for the customization of designs, texts, and graphics, catering to specific client needs and preferences.

– Cost-Effective: Reduces the need for labeling and re-labeling, offering a cost-effective solution with minimal material wastage.

– Safety: Enhances operational safety by clearly marking equipment and machinery with critical information and hazards.

– Aesthetic Appeal: Provides an aesthetically pleasing and professional look to metal products, elevating perceived value and quality.

Metal marking involves using various techniques to create detailed, durable inscriptions on metal surfaces. These practices are crucial in industries for identification, branding, and traceability purposes.

– Laser Marking: Utilizes highly concentrated laser beams to etch patterns, text, or codes directly on metals.

– Electrochemical Etching: Employs an electrolyte solution and electrical current to mark the metal surface.

– Dot Peen Marking: Uses a stylus to create precisely controlled dot patterns.

– Stamping: Involves pressing predefined designs or text onto metals using high pressure and dies.

– Engraving: Employs mechanical tools or CNC machines to carve designs directly into the metal.

– Inkjet Marking: Sprays ink onto the metal surface to create temporary or sometimes permanent marks.

– Annealing: Heats the metal surface to change its color, producing dark or light marks without penetration.

– Thermal Printing: Applies heat to transfer ribbons, imprinting marks on metal surfaces.

– Chemical Etching: Uses strong acids or bases to etch away parts of the metal surface for detailed designs.

– Micro-percussion: Employs small strikes to create dots forming characters or graphics on the metal.

Each method offers distinct advantages in terms of precision, durability, and suitability for various types of metals and applications.

SourcifyChina specializes in providing custom metal marking services tailored to meet diverse client needs. Their advanced technology ensures precise and durable markings, perfect for any project. High-quality standards and attention to detail set them apart.

They offer solutions for various industries, including automotive, aerospace, and electronics. From serial numbers to intricate logos, their metal marking techniques enhance product identification and traceability, which can be crucial for compliance and quality control.

In addition to standard marking services, SourcifyChina also collaborates on bespoke projects. Their experienced team works closely with clients to develop custom solutions that align with specific operational and aesthetic requirements.

Versatility is one of SourcifyChina’s hallmarks. They handle small and large-scale orders with equal efficiency, maintaining fast turnaround times without compromising on quality. This ensures that clients can meet tight production schedules and market demands.

Customer satisfaction is paramount at SourcifyChina. They provide continuous support throughout the project lifecycle, from initial consultation to post-delivery assistance. This commitment to excellent service fosters long-term client relationships and repeat business.

Beyond marking metals, SourcifyChina employs sustainable practices to minimize their environmental footprint. Their eco-friendly methods and materials align with global standards, offering clients an ethical choice for their metal marking needs without sacrificing quality or performance.

SourcifyChina Metal Marking is an innovative leader in the field of metal marking solutions, offering a comprehensive range of services that cater to diverse industrial needs. Headquartered in the bustling manufacturing hub of China, the company specializes in cutting-edge technologies such as laser engraving, dot peen marking, and electrochemical etching. These advanced techniques ensure high precision and durability, making them ideal for applications across automotive, aerospace, electronics, and heavy machinery sectors. SourcifyChina’s commitment to quality and customer satisfaction is evident in their stringent quality control processes and personalized customer service. They assist clients from the initial consultation phase through to post-production support, ensuring that each marking solution is tailored to specific requirements. By integrating the latest advancements in metal marking technology with a deep understanding of industrial demands, SourcifyChina Metal Marking has positioned itself as a trusted partner for businesses seeking reliable and efficient marking solutions on a global scale.

Metal marking plays a critical role in the aerospace, defense, and marine industries, providing essential capabilities for tracking, identification, and compliance. In aerospace, metal marking is used to engrave serial numbers, barcodes, and component specifications on parts and assemblies. This ensures traceability and conformity with stringent regulatory standards, enhancing safety and reliability of aircraft. Techniques such as laser marking and dot peen marking deliver precision and durability, remaining legible even under extreme conditions of pressure, temperature, and vibration encountered in flight. The ability to mark metals accurately aids in lifecycle management, maintenance schedules, and in the case of recalls, ensures swift identification of affected components.

In defense and marine applications, metal marking serves to identify equipment, ordnance, and structural components, such as hulls of ships and submarines or parts of military vehicles. The stringent requirements in these sectors demand markings that can withstand harsh environments including salty sea conditions, extreme temperatures, and the wear and tear of combat situations. Laser marking provides a non-contact method that does not compromise the integrity of materials, crucial for maintaining the strength and resilience of defense equipment. Additionally, metal markings help in inventory management, maintenance, and repair work, offering detailed information that facilitates quicker turnaround times and reduces the risk of misidentification, which is pivotal in mission-critical scenarios. Through these applications, metal marking enhances operational efficiency, compliance, and safety across these high-stake industries.

Metal marking, a process that involves engraving or etching unique identifiers or designs onto metal surfaces, plays a crucial role in the automotive industry. In this sector, it is primarily used for traceability and quality control. Automotive parts, from engine components to chassis structures, often bear serial numbers, barcodes, or QR codes etched onto their surfaces. These markings ensure that parts can be tracked through the entire manufacturing process and throughout their service life. This traceability is vital for quality assurance, recalls, and compliance with stringent industry standards. Additionally, metal marking can enhance anti-counterfeiting measures, as it allows for the creation of detailed and tamper-proof identifiers that are difficult to replicate. Emblems, logos, and other brand-specific designs are also often applied using metal marking, providing a durable and aesthetically pleasing finish that withstands the rigors of automotive environments.

In the electronics industry, metal marking serves a similar but distinct set of functions. Circuit boards, connectors, and various electronic components require precise labeling to convey information such as part numbers, batch codes, and manufacturer details. This ensures proper assembly and maintenance, as well as traceability for quality control and warranty purposes. Laser marking is particularly favored in electronics for its ability to produce high-resolution, legible marks on small, intricate components without causing damage. The permanence and precision of metal marking technology also enable the application of detailed graphics and logos, which are essential for branding and product differentiation in a competitive market. Furthermore, as electronics continue to shrink in size, the need for miniaturized yet still-readable markings becomes even more critical, and advanced metal marking techniques rise to meet this challenge, supporting the ongoing innovation in the electronics sector.

Metal marking plays a vital role in the construction industry, where precision and accuracy are paramount. In construction, metal components such as beams, pipes, and panels are often marked to ensure they are cut, shaped, and assembled correctly. These markings typically include measurements, alignment points, and identification codes that facilitate efficient and error-free assembly on-site. For example, laser marking on steel beams helps workers quickly identify the correct pieces and their orientation, significantly reducing the likelihood of mistakes and speeding up the overall construction process. Additionally, metal marking can include information about the grade and origin of the material, which is critical for quality control and compliance with building regulations.

In the energy sector, metal marking is equally indispensable, particularly in the manufacture and maintenance of machinery and infrastructure used in oil, gas, and renewable energy projects. High-precision markings are used to identify components, track serial numbers, and indicate critical information such as maximum operating pressures and temperatures. For instance, in the fabrication of wind turbines, each metal part is marked with crucial data that ensures correct assembly and maintenance. Similarly, in the oil and gas industry, pipeline sections are often marked to indicate their specifications, including material grade, wall thickness, and manufacturing date, which is essential for safety inspections and regulatory compliance. Overall, metal marking enhances traceability, improves safety, and helps maintain high standards of operational efficiency in both construction and energy industries.

The industrial equipment industry relies heavily on metal marking for a myriad of applications, primarily focused on tracking and identification of components. With the advancement in technology, metal marking has evolved from simple stamping to complex laser marking techniques. Industries such as automotive, aerospace, and heavy machinery use metal marking to engrave serial numbers, barcodes, QR codes, and other essential identification marks on parts and machinery. This ensures that every component can be traced back to its origin, providing an essential layer of quality control and facilitating inventory management. Laser marking, in particular, offers high precision and durability without compromising the integrity of the material, making it an indispensable tool for the industry.

Beyond identification, metal marking is also crucial for compliance with regulatory standards and enhancing the longevity and safety of industrial equipment. Specific industries are mandated to mark their products to provide information about material composition, operational guidelines, and maintenance schedules. This information is vital for end-users and maintenance teams to ensure that the equipment is operated within specified parameters, minimizing the risk of malfunctions and enhancing safety. Moreover, the permanence of metal markings ensures that critical information remains legible and intact throughout the product’s lifecycle, even under harsh industrial conditions. Thus, the application of metal marking in the industrial equipment sector not only streamlines operations but also fortifies the industry’s commitment to safety and compliance.

Metal marking plays a crucial role in the medical devices industry, ensuring traceability, compliance, and safety. With stringent regulations requiring traceability of each component, metal marking methods like laser engraving, dot peen marking, and electrochemical etching are extensively employed to mark medical instruments and implants with unique identifiers, serial numbers, and barcodes. These permanent marks facilitate tracking of devices through their lifecycle, from manufacturing to distribution, and eventually in patient use. This aids in monitoring device performance, managing recalls effectively, and complying with regulatory standards set by bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Additionally, clear and precise markings ensure that healthcare professionals can easily identify and differentiate between various surgical instruments and implants, minimizing errors during medical procedures.

Furthermore, metal marking enhances the durability and biocompatibility of medical devices. Techniques like laser marking produce high-quality, corrosion-resistant marks that do not compromise the integrity of sensitive materials commonly used in medical devices, such as stainless steel, titanium, and cobalt-chrome alloys. This is particularly important for implants and instruments that are regularly sterilized through high-temperature autoclaving or chemical processes. The non-contact nature of laser marking, for instance, ensures that there are no mechanical stresses or contaminants introduced during the marking process, maintaining the sterility and functionality of the device. As medical technology continues to advance, the importance of reliable and precise metal marking in ensuring the safety and efficacy of medical devices is only set to grow.

Metal marking is a critical process in both machining and manufacturing, serving various essential functions. In machining, precision and traceability are of paramount importance, and metal marking plays a pivotal role in ensuring these aspects. By applying permanent markings such as serial numbers, batch codes, or barcodes onto metal components, manufacturers can effectively trace the history and specifications of each part throughout the production line. This not only aids in quality control but also facilitates prompt identification and resolution of any manufacturing defects or discrepancies. Advanced techniques such as laser marking, dot peen marking, and engraving are widely employed due to their accuracy and ability to produce clear, durable marks that can withstand harsh environments and mechanical stresses.

In the broader manufacturing context, metal marking enhances the overall efficiency and reliability of supply chain management. As products move from raw materials to finished goods, consistent and identifiable markings enable better inventory control and logistical planning. This is particularly crucial in industries such as aerospace, automotive, and medical devices, where stringent regulatory standards demand meticulous documentation and traceability. Metal marking also supports anti-counterfeiting measures by providing unique identifiers that are difficult to replicate. Furthermore, it assists in the seamless integration of digital manufacturing technologies, where automated systems rely on precise identification to execute complex production tasks accurately. Overall, metal marking is indispensable for maintaining the integrity and accountability of components throughout the machining and manufacturing processes, ultimately contributing to higher quality and safer end products.

Sure, here are some frequently asked questions (FAQ) with answers about metal marking quality work from SourcifyChina factory:

1. What metal marking services does SourcifyChina factory offer?

SourcifyChina factory provides a variety of metal marking services, including laser engraving, etching, embossing, and debossing. These services can be customized based on the specific requirements of the client’s project.

2. What materials can be marked at SourcifyChina factory?

The factory marks a wide range of metals such as stainless steel, aluminum, brass, copper, and titanium. If you have any specific material requirements, it’s best to consult with our team to ensure compatibility.

3. How can I ensure high-quality marking on my metal products?

Quality is ensured through advanced machinery, precise engineering, and rigorous quality control processes at each stage of production. SourcifyChina factory uses state-of-the-art equipment and experienced technicians to deliver top-quality results.

4. What is the lead time for metal marking projects?

Lead times vary depending on the project size and complexity. Generally, the turnaround time ranges from 1 to 3 weeks. For urgent requests, please contact our customer service team for expedited options.

5. Can I get a sample before full production?

Yes, SourcifyChina factory offers sample production to ensure the marking meets your specifications. Samples can be provided at a nominal cost, which is often refundable against the final order.

6. Is there a minimum order quantity (MOQ) for metal marking?

Minimum order quantities depend on the specifics of the project. Typically, smaller runs are possible but may incur higher per-unit costs. Please discuss your needs with our sales team for precise information.

7. How are the marked metal products shipped?

Products are carefully packaged to prevent damage during transit. We offer various shipping options, including air freight, sea freight, and express couriers, based on your requirements and budget.

8. What information do I need to provide for a quote?

To receive an accurate quote, please provide detailed project specifications including the type of metal, dimensions, marking design, quantity, and any specific requirements. Additional details about the intended use and deadlines are also helpful.

9. Can SourcifyChina factory help with design and layout for marking?

Yes, our factory offers design assistance to ensure your marking is optimized for both aesthetics and functionality. Our design team works closely with you to create a layout that meets all your criteria.

When considering metal marking manufacturing from SourcifyChina factory, focusing on the following tips can yield excellent results:

1. Understand Your Needs: Before engaging, clearly define the type of metal and the specific marking requirements. This will help SourcifyChina match you with the best-suited process, whether it’s laser marking, engraving, or stamping.

2. Quality and Precision: SourcifyChina emphasizes high quality and precision. Ensure that the factory uses the latest technology and maintains strict quality control standards to meet your specifications consistently.

3. Customization Options: Check if SourcifyChina offers customization in terms of design, depth of marking, and finishes. Customization ensures your products stand out in the market.

4. Material Compatibility: Confirm that the factory is experienced with the type of metal you need marked. Different metals require different handling and marking techniques.

5. Sample Runs: Request sample runs for your initial orders. This can help you verify the quality and make necessary adjustments before committing to a larger order.

6. Lead Times and Capacity: Inquire about their lead times and production capacity to ensure they can meet your deadlines. This is crucial for maintaining your supply chain schedules.

7. Cost Efficiency: Compare the costs with other providers. SourcifyChina is known for competitive pricing, but ensure there are no hidden fees that could impact your budget.

8. Communication: Maintain clear and constant communication with the factory. Good communication can help track progress, handle issues swiftly, and ensure project requirements are accurately met.

9. Documentation and Compliance: Ensure that all documentation, including compliance certificates, are in order. This helps in smooth customs clearance and adherence to local regulations.

10. Feedback and Continuous Improvement: After receiving your orders, provide feedback. This enables SourcifyChina to continually improve its services and align more closely with your needs.

Leveraging these tips can enhance your experience with SourcifyChina and ensure superior metal marking outcomes.

Q: What types of metal marking services does SourcifyChina factory offer?

A: SourcifyChina offers a variety of metal marking services, including laser engraving, chemical etching, dot peen marking, and CNC engraving. These methods cater to different needs, such as durability, precision, and cost-effectiveness.

Q: What metals can SourcifyChina factory mark?

A: SourcifyChina can mark a wide range of metals, including stainless steel, aluminum, brass, copper, titanium, and various alloys. They accommodate both common and specialized metals used in different industries.

Q: What is the lead time for metal marking orders?

A: The lead time typically ranges from 5 to 15 business days, depending on the order’s complexity and quantity. Custom projects may require additional time for design and approval.

Q: Can I provide my own design for marking?

A: Yes, you can provide your own design. SourcifyChina accepts various file formats and works closely with you to ensure the design meets your specifications and looks as expected on the chosen metal.

Q: What is the minimum order quantity (MOQ) for metal marking services?

A: The MOQ varies by the type of marking service and material. Generally, it starts from as low as 10 pieces, but larger orders often benefit from reduced per-unit costs.

Q: How does SourcifyChina ensure quality control?

A: SourcifyChina adheres to strict quality control processes, including initial assessments, in-process inspections, and final reviews. They use high-precision equipment and skilled technicians to maintain high standards.

Q: What industries does SourcifyChina serve?

A: SourcifyChina serves various industries, including aerospace, automotive, electronics, medical, and industrial manufacturing. Their flexible solutions cater to both standard and specialized requirements.

Q: Is international shipping available?

A: Yes, SourcifyChina offers international shipping. They work with reputable logistics partners to ensure timely and secure deliveries worldwide. Shipping costs and times vary based on destination and order size.

Q: How can I request a quote?

A: To request a quote, you can visit SourcifyChina’s website or contact their customer service team. Provide details such as the type of metal, marking method, quantity, and any specific requirements for an accurate quote.

Sourcing metal marking from SourcifyChina factory efficiently involves several key steps and considerations:

1. Research and Verification: Start by thoroughly researching SourcifyChina factory’s reputation. Look for reviews, testimonials, and business ratings to confirm their reliability and quality standards.

2. Clear Requirements: Define your requirements clearly. Specify the type of metal, marking techniques (e.g., laser engraving, etching), dimensions, volume, and quality standards. This helps in avoiding misunderstandings and ensuring the factory can meet your needs.

3. Communication: Maintain clear and frequent communication. Use detailed emails, video calls, or instant messaging apps (like WeChat) to discuss your project details with the factory. Language barriers can be minimised using translation tools or hiring a local agent.

4. Samples and Prototypes: Request samples or prototypes before placing a bulk order. This allows you to inspect the quality and ensure it meets your specifications.

5. Negotiation: Negotiate terms of pricing, payment (preferably through secure methods like PayPal or Alibaba’s Trade Assurance), and delivery timelines. Ensure all agreements are documented in a contract.

6. Quality Control: Implement a quality control process. This can include on-site inspections or third-party quality assurance services. Consistent quality checks help in maintaining standards throughout the production run.

7. Logistics and Shipping: Plan for logistics by discussing shipping options, costs, and timelines with the factory. Consider using freight forwarders for efficient and reliable shipping solutions.

8. Legal and Compliance: Ensure that the factory complies with international manufacturing standards and certifications. This reduces risks associated with substandard or non-compliant products.

9. After-Sales Service: Establish terms for after-sales support and warranty. This is crucial for addressing any post-delivery issues or defects.

By following these steps, you can effectively source high-quality metal marking products from SourcifyChina factory, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)