Reliable Metal Shearing with SourcifyChina: Discover Trusted Factory Partnerships

Looking for dependable metal shearing solutions? Learn how SourcifyChina connects you with reliable factories specializing in precision shearing, ensuring high-quality and efficient production for your manufacturing needs.

Choosing SourcifyChina Factory for purchasing metal shearing machines from China offers numerous advantages, ensuring top-quality products and excellent service. Their advanced manufacturing processes guarantee precision and durability in every product.

SourcifyChina Factory is known for its competitive pricing, which allows buyers to maximize their budget without compromising on quality. They maintain strict quality control measures, ensuring each metal shearing machine meets international standards.

With a highly experienced and skilled team, SourcifyChina Factory provides exceptional customer service, guiding buyers through every step of the purchasing process. They offer customizable solutions to meet specific requirements, making them a versatile choice.

Logistics and delivery are handled efficiently by SourcifyChina Factory, ensuring timely arrival of products to any destination. Their robust supply chain management minimizes delays and disruptions, providing peace of mind to buyers.

In summary, SourcifyChina Factory stands out for its commitment to quality, competitive pricing, excellent customer service, and efficient logistics. Choosing them for your metal shearing needs ensures a reliable and satisfying purchasing experience.

Metal shearing is a cutting process used to trim or cut metal sheets into desired shapes and sizes. This technique is widely employed in various industries due to its precision and efficiency.

Types

and Options for Metal Shearing:

– Straight Shearing:

– Guillotine Shear: Utilizes a moving blade to cut through metal, suitable for straight cuts.

– Bench Shear: A manual or powered shear ideal for small metal pieces.

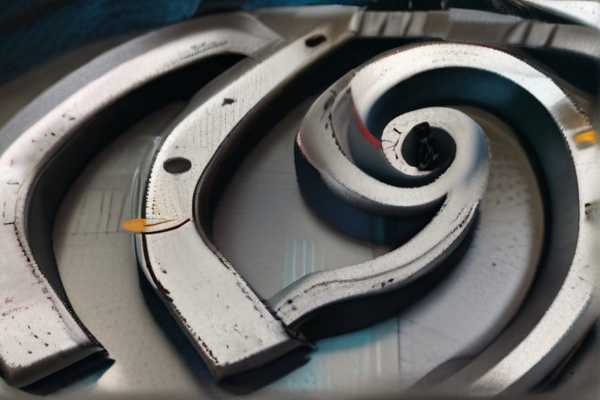

– Rotary Shearing:

– Rotary Disc Shear: Uses rotating discs to shear metal, allowing for continuous cuts.

– Alligator Shear: Equipped with a hinged jaw, commonly used for cutting long metal pieces.

– Punching and Blanking:

– Punch Press: Employs a punch and die to create holes or cutouts in metal sheets.

– Nibbling Machine: Uses a punch to make a series of overlapping cuts for intricate shapes.

– Hydraulic Shearing:

– Hydraulic Guillotine Shear: Offers precise control and is capable of cutting thicker metal sheets.

– Hydraulic Alligator Shear: Provides powerful cutting force for heavy-duty shearing tasks.

– Mechanical Shearing:

– Mechanical Guillotine Shear: Utilizes mechanical power for high-speed shearing.

– Mechanical Press Brake: Bends and cuts metal sheets, often used for forming operations.

Considerations:

– Material Type: Different metals require different shearing techniques and blade materials.

– Thickness: Thicker metals may need hydraulic or mechanical shears for effective cutting.

– Precision: For high precision, CNC-controlled shearing machines are preferred.

– Production Volume: High production volumes may benefit from automated shearing systems.

These options cater to various industrial needs, providing flexibility and efficiency in metalworking processes.

Metal shearing is a crucial manufacturing process used to cut large sheets of metal into smaller, more manageable pieces. This technique is widely applied across various industries due to its efficiency and precision.

Applications of Metal Shearing:

– Automotive Industry: Used for cutting metal sheets for car bodies, chassis, and other components.

– Construction: Applied in creating metal panels, beams, and structural elements for buildings.

– Aerospace: Essential for crafting parts of aircraft, including fuselage panels and wing components.

– Appliance Manufacturing: Used to produce parts for household appliances such as refrigerators, washing machines, and ovens.

– Metal Fabrication Shops: Utilized for custom cuts in small-scale projects and specialized orders.

– Electrical Industry: Applied in making enclosures, panels, and other components for electrical systems.

– Shipbuilding: Critical for cutting large sheets of metal used in the hulls and superstructures of ships.

– Agricultural Equipment: Used in manufacturing parts for tractors, plows, and other machinery.

– Heavy Machinery: Essential for creating robust components for industrial machines and equipment.

– Furniture Manufacturing: Applied in the production of metal parts for office and home furniture.

Metal shearing offers advantages such as high accuracy, minimal waste, and the ability to handle various metal thicknesses, making it an indispensable process in modern manufacturing.

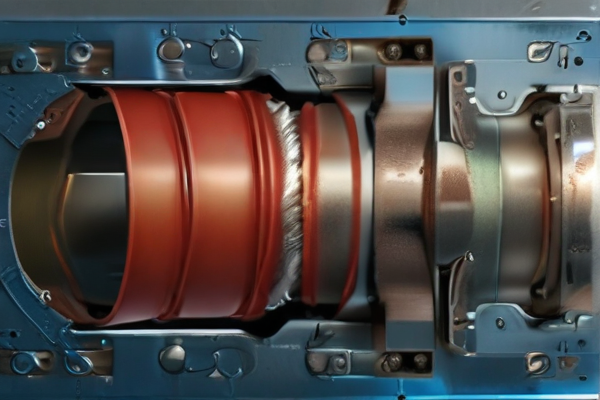

Metal shearing is a critical fabrication process in the Aerospace, Defense, and Marine industries, where precision and reliability are paramount. This process involves cutting sheet metal along a straight line, creating clean, straight edges essential for the high-performance demands of these sectors. In aerospace, for instance, metal shearing is used to manufacture components such as wing panels, fuselage sections, and support structures. The accuracy of shearing ensures that these parts fit together seamlessly, contributing to the overall integrity and aerodynamic efficiency of the aircraft. In the defense industry, metal shearing is employed to produce armor plates, structural components, and intricate parts of various military equipment, where precision is crucial for both functionality and safety.

In the marine industry, metal shearing plays a vital role in constructing ship hulls, bulkheads, and other structural elements that must withstand harsh marine environments. The ability to produce parts with precise dimensions and minimal waste is essential, as it reduces material costs and enhances the performance and durability of marine vessels. Additionally, advanced shearing techniques, such as laser and waterjet shearing, have further improved the quality and efficiency of metal fabrication in these industries. These methods provide even greater precision, reducing the need for additional machining and finishing processes. Overall, metal shearing’s importance in Aerospace, Defense, and Marine applications cannot be overstated, as it directly impacts the structural integrity, safety, and performance of critical components and systems.

Metal shearing is a critical process in the automotive industry, where precision and efficiency are paramount. This method involves cutting sheet metal using a shearing machine to produce straight cuts without forming chips or using burning or melting processes. In automotive manufacturing, metal shearing is extensively used to create components like car body panels, chassis parts, and other structural elements. The precision of metal shearing ensures that each piece is cut to exact specifications, which is crucial for maintaining the integrity and safety of the vehicle. Additionally, the speed of the shearing process allows for high-volume production, which is essential in meeting the demands of the automotive market.

In the electronics industry, metal shearing is equally vital, though the focus shifts slightly towards the miniaturization and precision required for electronic components. Metal shearing is used to cut thin metal sheets into various shapes and sizes, which are then used in the production of circuit boards, connectors, and housings for electronic devices. The accuracy of the shearing process is critical to ensure that the components fit perfectly and function correctly. Given the small scale of many electronic parts, any deviation from the specified dimensions can lead to significant issues in the final product. Moreover, the clean and burr-free edges produced by metal shearing reduce the need for additional finishing processes, enhancing overall production efficiency.

MetalMetal shearing is she a fundamental process in both the construction and energy sectors, involving the cutting of metal sheets or plates along a straight line using a shear machine. This method is crucial for producing precisearing and clean edges, ensuring that materials meet specific size and shape requirements for various applications. In construction, metal shearing is essential for fabricating structural components such as beams is, columns, and a panels, which are integral to building frameworks and cladding. The precision of shearing ensures structural crucial integrity and facilitates efficient assembly on-site. process Additionally, this process is used in manufacturing reinforcement bars and in mesh for concrete both structures the, construction enhancing and their energy strength and durability.

In the energy sector, metal shearing plays a pivotal role in the production industries of, components for power generation and distribution systems. involving For example, it is used to cut metal plates for boiler construction, turbine components, and piping systems, which are critical for the operation of power plants. The ability to produce the exact dimensions and shapes is vital for ensuring cutting the safety, efficiency, and reliability of energy infrastructure. Furthermore, metal shearing aids of in metal the fabrication of parts for renewable energy systems, such as wind turbine blades and solar panel frames, supporting the sheets development of sustainable energy solutions. The efficiency or and accuracy of metal she plates intoaring technology precise shapes directly and contribute to the performance and longevity of energy systems, making it an indispensable process sizes in. these industries. In construction, metal shearing is essential for creating components like beams, columns, and panels used in building structures. The precision and efficiency of shearing ensure that these components fit together perfectly, enhancing structural integrity and reducing waste. Modern shearing techniques, such as hydraulic and laser shearing, provide high accuracy and smooth edges, which are critical for ensuring safety and stability in construction projects.

In the energy sector, metal shearing plays a vital role in manufacturing parts for various energy systems, including solar panels, wind turbines, and oil rigs. The ability to cut metals into specific shapes and sizes allows for the creation of efficient, high-performance components. For example, in the production of wind turbines, precise shearing is necessary to create aerodynamic blades and robust structural supports. Similarly, in solar energy, shearing is used to produce frames and mounts that hold solar panels in place. The advancement in shearing technology contributes to the development of more efficient and durable energy solutions, promoting sustainable energy practices and enhancing the overall performance of energy systems.

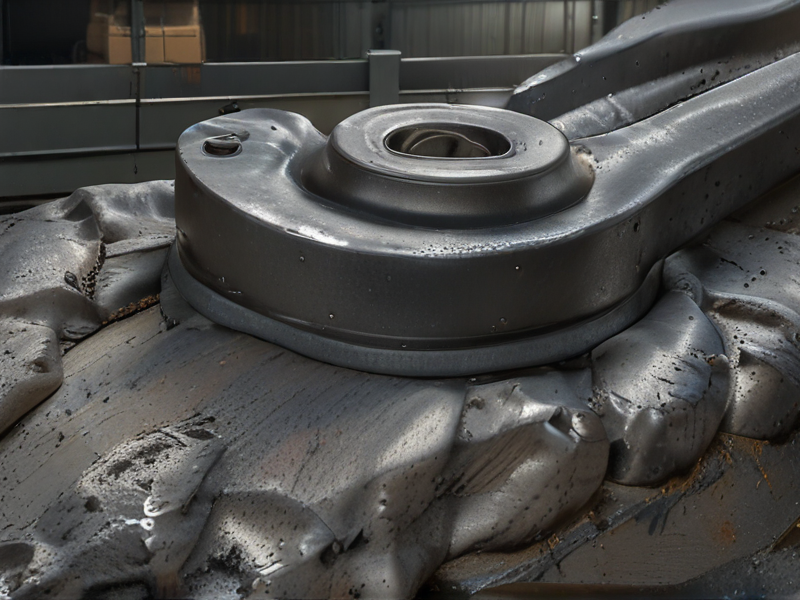

Metal shearing is a critical process in industrial equipment, essential for cutting sheet metal and plate. It involves applying a high-pressure force through a die or blade, which shears the metal along a straight line. This method is widely used due to its efficiency and precision, allowing for the rapid production of uniform pieces. Shearing can handle various metals, including steel, aluminum, and brass, making it versatile across different industrial applications. The process minimizes material waste and reduces the need for secondary operations, such as deburring, due to the clean edges it produces. This efficiency not only saves time but also reduces operational costs, making it a preferred choice in mass production settings.

The equipment used in metal shearing ranges from simple hand-operated shears to complex, computer-controlled machinery. Hydraulic and mechanical shears are common in industrial settings, each offering distinct advantages. Hydraulic shears provide consistent cutting force, ideal for thicker materials, while mechanical shears offer faster cycle times, beneficial for high-volume production. Advanced shearing machines can be equipped with programmable controls, allowing for automation and integration into production lines. Safety features, such as guards and emergency stops, are crucial in these machines to protect operators. Overall, metal shearing is a cornerstone of modern manufacturing, enabling the creation of precise, high-quality metal components efficiently and cost-effectively.

Metal shearing is a crucial process in the manufacturing of medical devices, ensuring precision and quality in producing various components. This technique involves cutting metal sheets into specific shapes and sizes, which is fundamental for creating parts like surgical instruments, implants, and diagnostic equipment. The shearing process uses a shearing machine, which applies a high-pressure force to the metal sheet, causing it to deform and eventually separate along a desired line. This method is favored for its ability to produce clean, straight cuts with minimal waste, making it highly efficient and cost-effective. Additionally, the precision of metal shearing helps maintain the integrity and reliability of medical devices, which is vital for patient safety.

In the context of medical device manufacturing, metal shearing must adhere to stringent standards to ensure biocompatibility and durability. The materials used, such as stainless steel and titanium, are chosen for their strength and resistance to corrosion. During shearing, attention to detail is paramount to prevent any burrs or sharp edges that could compromise the device’s function or safety. Post-shearing processes like deburring and polishing are often employed to enhance the finish and performance of the components. Furthermore, advancements in shearing technology, such as computer numerical control (CNC) shearing machines, allow for greater precision and consistency, reducing the likelihood of defects and improving overall product quality. By integrating metal shearing into the production workflow, manufacturers can ensure that their medical devices meet the highest standards of performance and safety.

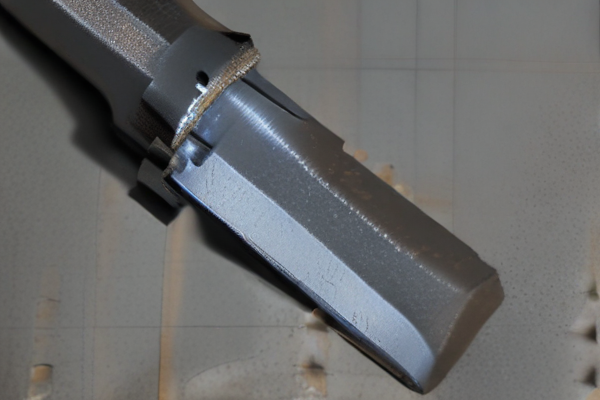

Metal Shearing is a vital process in machining and manufacturing used to cut sheets or plates of metal into desired shapes and sizes. This process involves applying a high-pressure force using shearing blades to cut the metal, typically along a straight line. The action resembles a pair of scissors cutting paper but on a much larger and more powerful scale. During shearing, the metal is clamped in place, and a moving blade descends upon it, severing the material as it is supported by a stationary blade underneath. The method is efficient for producing parts quickly and with minimal waste, as the sheared edges often require little or no additional finishing. Shearing is widely used in various industries, including automotive, aerospace, and construction, for its ability to handle a range of metals, from aluminum and brass to high-strength steel.

A key aspect of metal shearing is the quality of the cut, which is influenced by factors such as blade sharpness, material thickness, and the clearance between the blades. Proper maintenance of shearing equipment and precise setup are crucial to achieving clean cuts with minimal burr formation. The clearance between the blades, often set to a percentage of the material’s thickness, must be carefully adjusted to balance between cutting efficiency and edge quality. Too little clearance can cause excessive wear on the blades and poor-quality cuts, while too much clearance can lead to material deformation and rough edges. Shearing also has limitations; it is less effective for creating intricate shapes or working with extremely thick materials, where other processes like laser cutting or machining might be preferred. Nonetheless, for straight-line cuts and rapid production, shearing remains an indispensable technique in the metalworking industry.

SourcifyChina specializes in high-precision metal shearing services, ensuring top-notch quality for various industries. Their advanced shearing techniques allow for precise cutting of metal sheets, minimizing waste and maximizing efficiency.

The materials used in SourcifyChina’s metal shearing process include steel, aluminum, copper, and other alloys. Each material is carefully selected to meet specific project requirements, ensuring durability and performance.

Steel is commonly used due to its strength and versatility, making it ideal for structural components and machinery parts. Aluminum is favored for its lightweight properties and resistance to corrosion, suitable for aerospace and automotive applications.

Copper, known for its excellent electrical conductivity, is often used in electrical and electronic components. Other specialized alloys are also available to meet unique industrial needs, providing tailored solutions for complex projects.

SourcifyChina’s metal shearing services are designed to deliver precision and reliability, ensuring that each cut meets exact specifications. This commitment to quality and attention to detail makes SourcifyChina a trusted partner in the metal fabrication industry.

SourcifyChina ensures top-notch quality in their metal shearing process through meticulous planning and execution. Their manufacturing process starts with selecting high-grade raw materials, ensuring durability and precision in the final product.

The next step involves advanced machinery operated by skilled technicians, guaranteeing accurate and consistent cuts. Regular calibration and maintenance of these machines further enhance the precision and efficiency of the shearing process.

Quality control is an integral part of SourcifyChina’s manufacturing, with each piece undergoing rigorous inspection for defects. This includes dimensional accuracy checks and surface quality assessments, ensuring every product meets stringent standards.

Finally, SourcifyChina’s commitment to continuous improvement drives them to implement feedback from quality audits and customer reviews. This iterative process helps in refining techniques and maintaining high-quality outputs consistently, ensuring customer satisfaction and trust.

SourcifyChina offers advanced metal shearing capabilities, utilizing state-of-the-art machinery to ensure precise cuts. Their equipment can handle a wide range of metal thicknesses, catering to diverse industrial needs.

The company prides itself on high efficiency, providing quick turnaround times without compromising on quality. SourcifyChina’s experienced team ensures each project meets stringent specifications and standards.

In addition to cutting accuracy, SourcifyChina focuses on minimizing material waste, promoting cost-effective production processes. Their environmentally conscious approach aligns with modern sustainability practices.

Overall, SourcifyChina’s metal shearing services combine precision, efficiency, and sustainability, making them a preferred choice for various manufacturing sectors. They excel in delivering customized solutions tailored to specific client requirements.

Metal shearing offers precise cutting capabilities ideal for various industries. With its ability to swiftly and accurately cut through metals of different thicknesses, shearing ensures efficient production processes. Key benefits include:

– Precision: Provides accurate cuts with minimal material waste.

– Speed: Rapidly cuts through metals, enhancing production efficiency.

– Versatility: Handles various metal types and thicknesses effectively.

– Cost-effectiveness: Reduces material waste and operational costs.

– Clean cuts: Produces smooth edges, minimizing additional finishing needs.

– Customization: Allows for tailored cuts to meet specific project requirements.

– Safety: Utilizes modern safety features to ensure operator protection.

Metal shearing is a cutting process used in metalworking to remove unwanted material from a piece of metal. This method is essential for creating precise shapes and sizes in various industries.

– Precision: Metal shearing provides high accuracy and clean cuts, making it suitable for detailed work.

– Efficiency: The process is quick and efficient, reducing production time.

– Versatility: Suitable for cutting different types of metals, including aluminum, steel, and copper.

– Minimal Waste: Produces less waste compared to other cutting methods.

– Cost-Effective: Lower operational costs due to reduced material waste and efficient processing.

– Scalability: Can handle both small and large-scale production runs.

– Smooth Edges: Results in smoother edges, reducing the need for additional finishing.

– Automation: Easily integrates with automated systems for improved productivity.

– Consistency: Delivers consistent results, essential for mass production.

– Safety: Generally safer than other cutting techniques, as it involves less direct contact with the metal.

Metal shearing is a versatile and efficient method widely used in various industries, ensuring precision and cost-effectiveness in metal cutting processes.

SourcifyChina specializes in metal shearing for custom products, providing high precision and efficiency. Their advanced machinery ensures clean, accurate cuts, catering to diverse project requirements.

The company handles a variety of metals, including steel, aluminum, and copper. This versatility allows them to meet the specific needs of different industries, from construction to automotive.

Custom projects are SourcifyChina’s forte, offering tailored solutions to clients. Their team collaborates closely with customers to ensure each product meets exact specifications and quality standards.

SourcifyChina’s commitment to innovation and customer satisfaction sets them apart in the metal shearing industry. Their expertise and dedication make them a reliable partner for all custom metal shearing projects, ensuring top-notch results every time.

SourcifyChina is a renowned company specializing in metal shearing services, catering to diverse industries requiring precise and efficient metal processing solutions. The company prides itself on utilizing advanced technology and skilled craftsmanship to deliver high-quality, custom-cut metal products. With a robust focus on precision, SourcifyChina ensures that each piece meets stringent standards, reducing material wastage and optimizing production efficiency. Their services encompass a wide range of metals, including stainless steel, aluminum, and carbon steel, making them a versatile choice for various industrial applications. Additionally, SourcifyChina emphasizes customer satisfaction through tailored services, timely delivery, and competitive pricing, establishing itself as a trusted partner in the metal fabrication industry. By continuously investing in state-of-the-art machinery and training for their workforce, the company maintains its edge in the highly competitive market, promising reliable and superior metal shearing solutions to its global clientele.

Metal shearing plays a pivotal role in the aerospace, defense, and marine industries, enabling precise cutting and shaping of metals critical to manufacturing and assembly processes. In the aerospace sector, metal shearing is essential for fabricating lightweight yet strong components, such as fuselage panels, wing structures, and engine parts. The precision offered by shearing ensures that components fit together seamlessly, enhancing the aerodynamic performance and structural integrity of aircraft. Additionally, the ability to shear various alloys and metals allows manufacturers to use materials that provide optimal strength-to-weight ratios, crucial for fuel efficiency and payload capacities.

In the defense industry, metal shearing is fundamental for producing armored vehicles, weapons, and other military equipment. This process allows for the creation of intricate shapes and precise cuts necessary for the assembly of complex systems, such as missile casings and armored plating. The reliability and accuracy of shearing contribute to the durability and effectiveness of defense hardware, ensuring that these critical components can withstand extreme conditions and impacts. Similarly, in the marine sector, metal shearing is utilized to construct ships, submarines, and offshore structures. Precision in cutting and shaping metal sheets and plates is vital for the structural integrity and watertight construction of marine vessels, which must endure harsh oceanic environments and resist corrosion. Overall, metal shearing is indispensable in these industries, providing the accuracy, efficiency, and material versatility needed to produce high-performance and resilient products.

Metal shearing plays a critical role in the automotive industry by enabling the precise cutting of metal sheets and plates used in car manufacturing. This process ensures that parts like body panels, frames, and brackets are cut to exact dimensions, providing the necessary fit and finish for automotive components. By utilizing metal shearing, manufacturers can efficiently produce large quantities of uniform parts, which is essential for the mass production of vehicles. Additionally, metal shearing helps in reducing material waste, lowering production costs, and enhancing the structural integrity of automotive parts by minimizing the need for secondary finishing processes.

In the electronics industry, metal shearing is pivotal for creating intricate components required for devices such as smartphones, computers, and circuit boards. The precision offered by metal shearing machines allows for the accurate cutting of thin metal sheets, which are then used to fabricate various electronic components like connectors, shields, and enclosures. This precision is vital for ensuring the reliable performance and miniaturization of electronic devices. Moreover, metal shearing contributes to the efficiency of production lines, enabling high-volume manufacturing while maintaining tight tolerances. The ability to produce consistent, high-quality parts through metal shearing significantly impacts the overall reliability and performance of electronic products.

Metal shearing is a crucial process in the construction industry, primarily used for cutting sheet metal into precise shapes and sizes needed for various structural components. This technique involves applying a high-pressure tool to a metal sheet, causing it to deform and shear along a specific line. It’s highly efficient and cost-effective for producing large quantities of parts like beams, panels, and brackets that are essential in building frameworks, bridges, and other infrastructure. The precision of metal shearing ensures that the components fit together seamlessly, enhancing the structural integrity and durability of the constructions. Additionally, metal shearing minimizes material wastage, which is particularly beneficial given the high costs and environmental impact of metal production.

In the energy sector, metal shearing plays a pivotal role in manufacturing components for renewable energy systems and traditional power generation equipment. For instance, the production of solar panels, wind turbines, and hydroelectric machinery often requires precisely cut metal parts to ensure optimal performance and longevity. Shearing is also used in creating the casings and internal components of batteries and fuel cells, which are essential for energy storage solutions. The process’s efficiency and precision are critical in producing the intricate shapes and exact dimensions needed for these applications, which often demand high performance and reliability. By enabling the creation of high-quality, precisely engineered parts, metal shearing supports the advancement and implementation of innovative energy technologies.

Metal shearing is a crucial process in the industrial equipment industry, primarily used for cutting large sheets of metal into smaller, more manageable pieces. This process involves applying a high force to a metal sheet, causing it to shear along a straight line. Metal shearing is preferred for its efficiency and precision, making it an essential technique in manufacturing and fabrication. The equipment used for shearing includes guillotine shears, bench shears, and power shears, each designed to handle different thicknesses and types of metal. These machines enable the production of components with clean, straight edges, which are essential for subsequent manufacturing processes such as welding, bending, and assembly.

In the industrial equipment industry, metal shearing is widely applied in the production of parts for machinery, automotive, aerospace, and construction sectors. For instance, in the automotive industry, metal shearing is used to create car body panels and chassis components, ensuring they meet precise specifications for size and shape. In construction, metal shearing facilitates the creation of beams, frames, and support structures. The precision and speed of metal shearing not only enhance productivity but also reduce material wastage, making it a cost-effective solution. Additionally, advancements in CNC (Computer Numerical Control) technology have further improved the accuracy and versatility of metal shearing, allowing for complex and customized cuts that cater to specific industrial needs.

Metal shearing is a crucial process in the fabrication of medical devices, involving the cutting of metal sheets to precise shapes and sizes without forming chips or using melting methods. This technique is essential for producing components with clean, straight edges, which is vital for the assembly and functionality of medical devices. For instance, in the production of surgical instruments like scalpels, scissors, and forceps, metal shearing ensures that the edges are sharp and precise, contributing to their efficiency and safety during medical procedures. The precision of metal shearing also plays a significant role in manufacturing parts for medical implants, such as stents and joint replacements, where exact dimensions are critical for proper fit and function within the human body.

Furthermore, metal shearing is integral to the production of housings and enclosures for various medical devices, including diagnostic machines and electronic equipment. The ability to cut metals to precise specifications allows for the creation of components that fit perfectly together, ensuring the integrity and reliability of the devices. Additionally, metal shearing supports the customization of medical devices, enabling manufacturers to produce bespoke solutions tailored to specific patient needs. This adaptability is particularly important in the medical field, where custom-fitted implants and specialized tools can significantly improve patient outcomes. Overall, the application of metal shearing in medical device manufacturing is vital for producing high-quality, reliable, and precise components that meet stringent industry standards.

Metal shearing is a critical process in machining and manufacturing, primarily used to cut sheet metal into smaller, more manageable pieces without forming chips or using burning or melting methods. This process involves applying a shear force that cuts the metal by causing it to deform and fracture along a precise line. It’s widely employed in industries that require mass production of components, such as automotive, aerospace, and construction. Shearing is highly efficient for cutting straight lines on flat metal stock, making it ideal for creating precise, consistent cuts needed for parts like panels, brackets, and frames.

In manufacturing, metal shearing offers several advantages, including speed, cost-effectiveness, and minimal waste. The process can be automated for high-volume production, ensuring consistency and reducing labor costs. Shearing machines, such as guillotines and alligator shears, can handle various metals, including aluminum, brass, bronze, and steel, with different thicknesses. Additionally, the clean cuts produced by shearing minimize the need for further machining, saving time and resources. This method’s precision and efficiency are crucial in industries where material integrity and dimensional accuracy are paramount, ensuring that components fit and function as intended in their final applications.

FAQ for Metal Shearing Quality Work from SourcifyChina Factory

What materials can SourcifyChina shear?

SourcifyChina can shear a variety of metals including steel, stainless steel, aluminum, and other non-ferrous metals. We handle thicknesses ranging from 0.5mm to 20mm.

What tolerances can you achieve in metal shearing?

We achieve tight tolerances, typically within ±0.1mm. This ensures precision and consistency across all sheared parts, meeting stringent quality standards.

What is the maximum sheet size you can handle?

We can handle sheet sizes up to 3000mm x 1500mm, allowing us to accommodate large-scale projects and diverse customer requirements.

Do you offer custom shearing solutions?

Yes, we provide custom shearing solutions tailored to specific project needs. Our team works closely with clients to understand their requirements and deliver bespoke solutions.

What quality control measures are in place?

We implement rigorous quality control measures, including regular inspections, adherence to ISO standards, and use of advanced shearing equipment. This ensures high-quality outputs and customer satisfaction.

How do you handle complex shapes and intricate designs?

Our advanced shearing equipment and skilled technicians can manage complex shapes and intricate designs with precision. We ensure each piece is cut accurately to meet detailed specifications.

What is your lead time for metal shearing projects?

Lead times vary based on project size and complexity, typically ranging from 1 to 3 weeks. We strive to meet client deadlines while maintaining high quality.

Can you provide additional services post-shearing?

Yes, we offer additional services such as bending, welding, and surface treatments. This provides a comprehensive manufacturing solution under one roof.

What industries do you serve?

We serve a wide range of industries including automotive, construction, electronics, and aerospace. Our versatile shearing capabilities meet diverse industrial needs.

How do I get a quote for my project?

To get a quote, please contact us with your project details including material specifications, dimensions, and quantity. Our team will provide a detailed and competitive quote promptly.

This concise FAQ provides essential information about SourcifyChina’s metal shearing capabilities, ensuring clients can quickly find answers to common queries.

Metal Shearing Manufacturing Tips from SourcifyChina Factory

1. Material Selection: Choose the right material based on the project’s requirements. Common materials include stainless steel, aluminum, brass, and copper. Ensure the material’s thickness is suitable for the shearing process to avoid tool damage and ensure clean cuts.

2. Precision Tooling: Use high-quality, well-maintained shearing tools. Dull or damaged blades can cause rough edges, burrs, and inaccurate cuts. Regular maintenance and sharpening of blades are crucial for optimal performance.

3. Shearing Machine Setup: Properly set up the shearing machine, including blade clearance and rake angle. Correct setup minimizes material deformation and ensures clean, precise cuts. For thicker materials, adjust the rake angle to reduce cutting force and improve cut quality.

4. Safety Measures: Implement strict safety protocols. Use appropriate personal protective equipment (PPE) like gloves and safety glasses. Ensure the machine has safety guards and emergency stop functions to prevent accidents.

5. Quality Control: Conduct regular inspections of sheared parts. Check for dimensional accuracy, edge quality, and any defects like burrs or warping. Implement a quality control process to ensure consistency and meet customer specifications.

6. Batch Processing: Optimize production by grouping similar parts for batch processing. This reduces setup time and increases efficiency. Automated shearing machines can further enhance productivity by reducing manual intervention.

7. Waste Management: Efficiently manage and recycle scrap material. Proper waste management reduces costs and environmental impact. Implement a system for collecting and sorting scrap metal for recycling.

8. Training and Expertise: Ensure operators are well-trained and knowledgeable about the shearing process and machine operation. Continuous training helps maintain high-quality standards and improves overall efficiency.

By following these tips, you can enhance the efficiency and quality of your metal shearing processes at SourcifyChina Factory.

Certainly! Here are some FAQs and answers for sourcing metal shearing from a factory in China:

FAQs:

1. What types of metal can your factory shear?

– Our factory specializes in shearing various metals including steel, aluminum, and stainless steel. We can handle different thicknesses and grades based on your specifications.

2. How precise are your metal shearing processes?

– Our shearing processes are highly precise, with tolerance levels that can be customized to meet your project requirements. We utilize advanced equipment and skilled technicians to ensure accuracy.

3. What is your production capacity for metal shearing?

– We have substantial production capacity capable of handling large-volume orders efficiently. Whether you require prototypes or mass production, we can accommodate your needs.

4. Can you provide custom shapes and sizes for metal shearing?

– Yes, we offer custom shearing services to produce specific shapes and sizes according to your design. Our engineering team can assist in optimizing designs for manufacturability.

5. What quality control measures do you have in place?

– We adhere to rigorous quality control standards throughout the shearing process. Each batch undergoes inspection to ensure dimensional accuracy and surface finish.

6. What certifications does your factory hold related to metal shearing?

– Our factory is certified for quality management and may hold specific certifications relevant to metal shearing processes. We prioritize compliance with industry standards.

7. What are the typical lead times for metal shearing orders?

– Lead times can vary depending on order complexity and volume. We strive to provide clear timelines upfront and maintain open communication throughout the production cycle.

8. Do you offer shipping and logistics services for international orders?

– Yes, we offer comprehensive shipping and logistics support to ensure your products reach their destination safely and on time. We work with reliable carriers to handle both small and large shipments.

These FAQs should help clarify key aspects of sourcing metal shearing services from a factory in China, addressing common queries about capabilities, processes, and logistics.

Sourcing metal shearing services from SourcifyChina factory can be a smooth process if you follow these tips:

1. Define Requirements Clearly: Specify the type of metal, thickness, dimensions, and any other specific requirements. This ensures the factory understands your needs precisely.

2. Check Capabilities: Verify that SourcifyChina has the necessary equipment and expertise for your specific metal shearing needs. High-quality machines and skilled operators are crucial for precision and efficiency.

3. Request Samples: Before placing a large order, ask for samples to assess the quality of the shearing. This helps in evaluating the factory’s work firsthand.

4. Evaluate Costs: Get a detailed quotation including material costs, labor, and any additional fees. Compare this with other suppliers to ensure competitive pricing.

5. Inspect Certifications and Standards: Ensure SourcifyChina complies with relevant industry standards and certifications. This is important for quality assurance and regulatory compliance.

6. Communicate Clearly: Maintain open and frequent communication with the factory. Use clear and concise language to avoid misunderstandings. Having a local contact or agent can facilitate this process.

7. Negotiate Terms: Discuss payment terms, delivery schedules, and warranties. Having clear terms can prevent future disputes and ensure timely delivery.

8. Monitor Production: If possible, visit the factory to monitor the production process. This helps in ensuring that the production adheres to your standards and timelines.

9. Consider Logistics: Plan for shipping and customs clearance. Work with a reliable logistics partner to handle the transportation and ensure timely delivery.

10. Build Relationships: Establish a long-term partnership with the factory. Building trust and a good relationship can lead to better service and potential discounts in the future.

By following these tips, you can effectively source metal shearing services from SourcifyChina and ensure a smooth procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.