Technology and Applications of metal sheet fabrication

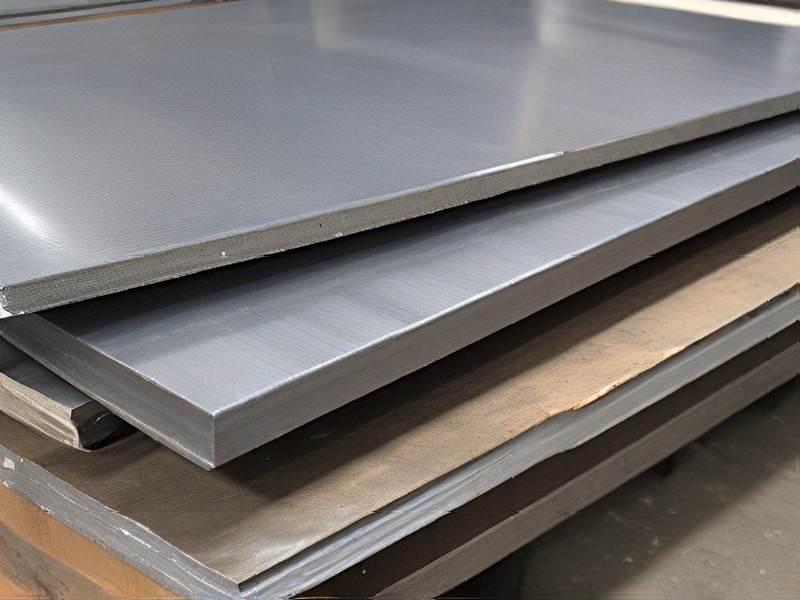

Metal sheet fabrication involves various processes used to create metal structures and components from flat sheets of metal. Key technologies in this field include cutting, bending, welding, and assembling.

1. Cutting: This initial stage often employs laser cutting, plasma cutting, or waterjet cutting techniques, which provide precision and efficiency. These methods ensure accurate shapes and sizes for components.

2. Bending: After cutting, sheets can be bent into desired angles and shapes using press brakes or other bending machines. This process is crucial for creating complex geometries needed in many applications.

3. Welding: Fabricated sheets may require joining multiple parts, typically achieved through methods such as MIG, TIG, or spot welding. This ensures structural integrity and durability of the final assembly.

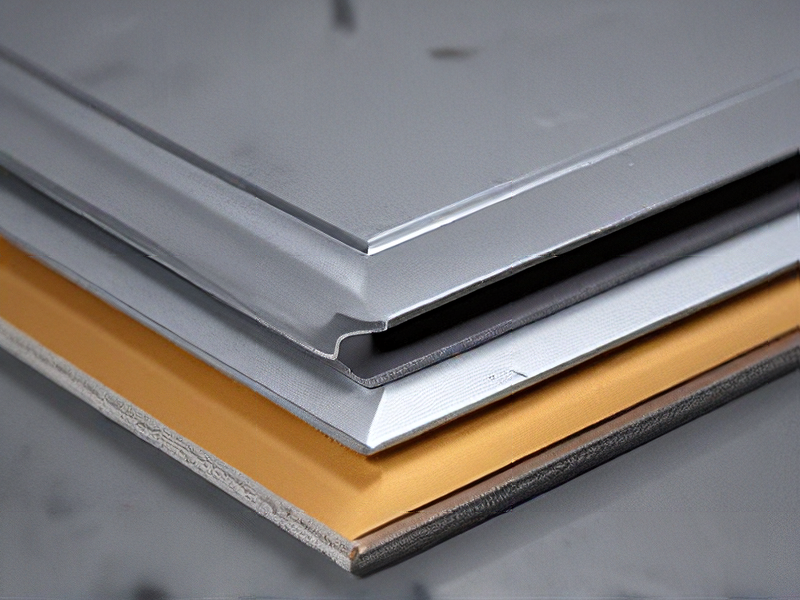

4. Finishing: Techniques like powder coating, anodizing, or galvanizing can enhance the metal’s appearance and resistance to corrosion, extending the lifespan of the product.

Applications: Metal sheet fabrication is widely used across various industries including automotive, aerospace, construction, and consumer electronics. In the automotive sector, it’s crucial for creating body panels and structural elements. In construction, fabricated sheets form roofs, walls, and facades, while the aerospace industry relies on high-strength, lightweight components for aircraft structures. Consumer electronics also utilize metal fabrication for enclosures and structural components, ensuring functionality and aesthetic appeal.

The evolution of technologies such as computer numerical control (CNC) has further streamlined processes, improving precision and reducing lead times. As manufacturing continues to embrace automation and innovative fabrication methods, the scope and efficiency of metal sheet fabrication are expected to grow, providing endless possibilities for engineering and design.

Quality Testing Methods for metal sheet fabrication and how to control quality

Quality Testing Methods for Metal Sheet Fabrication

1. Visual Inspection: The simplest method to detect obvious defects such as cracks, scratches, or surface irregularities.

2. Dimensional Inspection: Using tools like calipers, micrometers, and coordinate measuring machines (CMM) to ensure the fabricated parts meet specified dimensions and tolerances.

3. Non-Destructive Testing (NDT):

– Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws.

– Magnetic Particle Testing (MT): Detects surface and near-surface discontinuities in ferromagnetic materials.

– Dye Penetrant Inspection (DPI): Reveals surface-breaking defects by applying a penetrant dye and then a developer.

4. Destructive Testing:

– Tensile Testing: Determines the strength and ductility of the metal.

– Hardness Testing: Measures resistance to indentation, indicating material hardness.

– Bend Testing: Assesses ductility and the metal’s ability to withstand deformation.

5. X-Ray Fluorescence (XRF) and Spectrometry: For material composition analysis to ensure the correct alloy mix.

Quality Control in Metal Sheet Fabrication

1. Standard Operating Procedures (SOPs): Establish and adhere to detailed SOPs for each process step to maintain consistency.

2. Training and Certification: Ensure all personnel are properly trained and certified for their specific tasks.

3. Quality Management Systems (QMS): Implement systems like ISO 9001 to structure quality control processes and documentation.

4. Statistical Process Control (SPC): Utilize statistical methods to monitor and control the fabrication process, ensuring any variation is within acceptable limits.

5. In-Process Inspections: Regularly inspect products during the fabrication process to catch defects early.

6. Supplier Quality Management: Ensure that materials from suppliers meet specified quality standards through rigorous vetting and testing.

7. Final Inspection: Conduct thorough inspections before shipping products to ensure they meet all quality and specification requirements.

By integrating these methods and controls, manufacturers can ensure high-quality outcomes in metal sheet fabrication.

Tips for Procurement and Considerations when Purchasing from metal sheet fabrication

When procuring metal sheet fabrication services, consider the following tips:

Quality and Standards

– Material Quality: Ensure the metal sheets meet industry standards and specifications for your project.

– Certifications: Check for ISO certifications or other relevant quality assurances.

– Inspection and Testing: Confirm the supplier conducts regular quality inspections and provides test reports.

Supplier Evaluation

– Reputation: Research the supplier’s market reputation, client reviews, and case studies.

– Capacity and Capability: Ensure the supplier has the capacity and technical capabilities to handle your order size and complexity.

– Technology: Look for modern, well-maintained machinery and technology, which often translates to higher precision and efficiency.

Cost and Payment

– Transparent Pricing: Request detailed quotations that break down material, labor, and overhead costs.

– Negotiation: Leverage bulk orders or long-term contracts to negotiate better rates.

– Payment Terms: Discuss favorable payment terms that align with your cash flow, such as partial payments tied to delivery milestones.

Lead Time and Logistics

– Production Lead Time: Ensure the supplier can meet your delivery schedules without compromising quality.

– Inventory Management: Discuss the supplier’s inventory management practices to avoid supply chain disruptions.

– Logistics and Shipping: Confirm that the supplier has reliable logistics solutions and can handle shipping, especially if dealing with international orders.

Relationship Management

– Communication: Maintain open and clear communication channels for updates and issue resolution.

– Partnership Approach: Develop a long-term partnership for consistent quality and potential cost savings.

– Performance Reviews: Conduct regular performance reviews to address any issues and improve future transactions.

Compliance and Sustainability

– Regulatory Compliance: Ensure the supplier complies with all relevant regulations and standards.

– Sustainability: Consider suppliers with sustainable practices and materials to support your corporate social responsibility goals.

By focusing on these areas, you can optimize procurement processes, ensure high-quality outcomes, and build strong, reliable supplier relationships.

FAQs on Sourcing and Manufacturing from metal sheet fabrication in China

FAQs on Sourcing and Manufacturing from Metal Sheet Fabrication in China

1. Why choose China for metal sheet fabrication?

China offers competitive pricing, advanced technology, and extensive manufacturing capabilities, making it a preferred destination for metal sheet fabrication.

2. What materials are commonly used in Chinese metal sheet fabrication?

Common materials include stainless steel, aluminum, carbon steel, and galvanized steel, catering to a wide range of applications.

3. How do I find reliable manufacturers?

Use online platforms like Alibaba, Made-in-China, and Global Sources. Additionally, consider recommendations, trade shows, and third-party sourcing agents.

4. What are the typical lead times?

Lead times vary by project complexity and order size but typically range from 2-6 weeks, excluding shipping.

5. How can I ensure quality control?

Implement rigorous quality control processes such as inspections, material testing, and third-party audits. Request samples before mass production.

6. What are the common fabrication processes?

Processes include laser cutting, CNC machining, stamping, welding, and bending, allowing for precision and customization.

7. Are there any import/export considerations?

Understand import tariffs, duties, and compliance with international standards such as ISO, ASTM, and RoHS. Collaborate with experienced freight forwarders.

8. How do I handle intellectual property (IP) concerns?

Protect IP by working with reputable manufacturers, using non-disclosure agreements (NDAs), and considering legal actions if necessary.

9. What are the payment terms?

Common terms include a 30% deposit before production and 70% balance before shipment. Letter of Credit (L/C) and Trade Assurance are also options.

10. Can I get customized designs?

Yes, Chinese manufacturers offer extensive customization options. Provide detailed drawings, specifications, and requirements for accurate production.

11. How do I manage logistics and shipping?

Partner with reliable logistics companies. Plan for customs clearance, shipping methods (air, sea, or rail), and insurance.

12. What about sustainability practices?

Many manufacturers adopt sustainable practices. Verify their certifications and commitment to environmental standards.

By addressing these FAQs, you can navigate the complexities of sourcing and manufacturing metal sheet fabrication in China efficiently and effectively.