Choosing “SourcifyChina” Factory for purchasing metal stamping companies from China ensures superior quality and competitive pricing. They offer advanced technology and experienced craftsmanship, enhancing production efficiency and product durability.

Moreover, “SourcifyChina” provides rigorous quality control measures to meet international standards. Their robust supply chain management minimizes risks and ensures timely delivery of parts.

Their customer-centric services include personalized consultations, assisting buyers in sourcing the most suitable manufacturers. Comprehensive after-sales support guarantees a seamless purchasing experience, reinforcing long-term business relations.

Ultimately, partnering with “SourcifyChina” Factory offers a strategic advantage in accessing high-quality, cost-efficient metal stamping solutions. Enhanced productivity and reliability make them a preferred choice.

Metal stamping companies offer a range of services including progressive die stamping, deep drawing, and four-slide stamping, catering to automotive, aerospace, and electronics industries. They provide options like custom tooling, prototyping, and high-volume production.

– Progressive Die Stamping:

– Ideal for high-volume production.

– Multiple operations in a single die.

– High precision and efficiency.

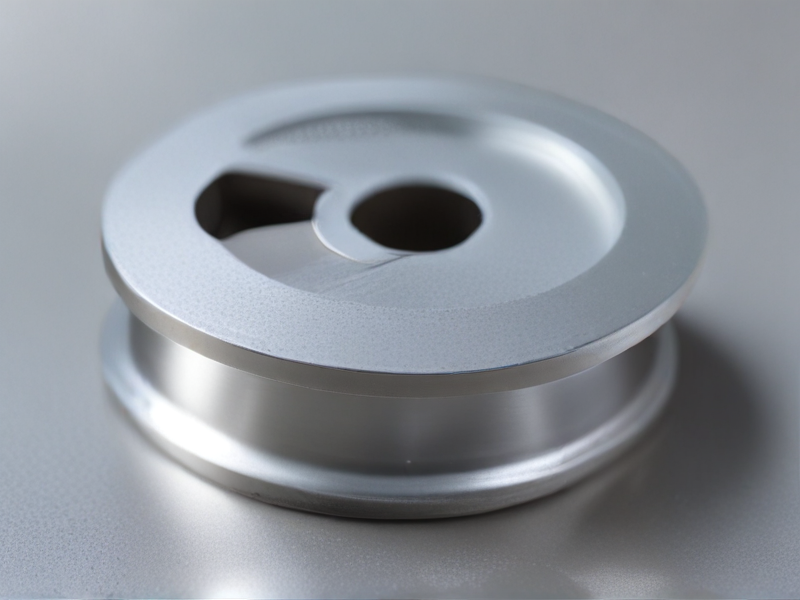

– Deep Drawing:

– Produces complex shapes.

– Suitable for cylindrical or cup-shaped parts.

– Used in the automotive and aerospace sectors.

– Four-Slide Stamping:

– Versatile and flexible.

– Can create intricate bends and forms.

– Efficient for medium to high-volume production.

– Custom Tooling:

– Tailored to specific project needs.

– Ensures compatibility and optimization.

– Can reduce waste and increase efficiency.

– Prototyping:

– Allows for design testing and refinement.

– Facilitates small-batch production.

– Essential for ensuring final product quality.

– High-Volume Production:

– Cost-effective for large quantities.

– Utilizes advanced machinery and automation.

– Quick turnaround times.

– Materials:

– Commonly used metals include steel, aluminum, brass, and copper.

– Material selection based on project requirements.

– Considerations for strength, conductivity, and corrosion resistance.

– Quality Control:

– Rigorous inspection protocols.

– Compliance with industry standards (ISO, AS9100, etc.).

– Ensures product reliability and consistency.

– Industry Applications:

– Automotive: Engine components, chassis parts.

– Aerospace: Structural elements, brackets.

– Electronics: Connectors, terminals.

– Medical: Surgical instruments, implants.

– Additional Services:

– Secondary operations like threading, tapping, and assembly.

– Surface treatments and coatings for enhanced durability.

– Logistics support for timely delivery.

Choosing the right metal stamping company involves considering their technical expertise, range of services, and ability to meet industry standards. The right partner can significantly impact the efficiency and quality of manufacturing processes.

Metal stamping companies play a critical role in various industries, providing precision-manufactured components essential for the production of durable and high-quality products.

– Automotive Industry: Metal stamping companies produce components such as body panels, brackets, and exhaust systems, crucial for vehicle manufacturing.

– Aerospace Industry: They supply intricate and high-strength components for aircraft and spacecraft, ensuring safety and performance.

– Electronics: Companies manufacture metal parts for electronic devices, including connectors, battery components, and shielding enclosures.

– Medical Devices: They produce parts for medical equipment, such as surgical instruments, implants, and diagnostic devices.

– Consumer Goods: Metal stamping companies create parts for household appliances, tools, and various consumer products, enhancing functionality and design.

– Construction Industry: They provide metal components for building structures, roofing, and HVAC systems, contributing to infrastructure development.

– Military and Defense: Companies manufacture high-precision components for military vehicles, weapons systems, and defense equipment, meeting strict standards.

– Renewable Energy: They produce parts for wind turbines, solar panels, and other renewable energy systems, supporting sustainable energy solutions.

– Telecommunications: Metal stamping companies create components for telecom infrastructure, such as antennas, towers, and enclosures, facilitating communication networks.

– Packaging: They manufacture metal packaging components, including cans, caps, and closures, ensuring product safety and preservation.

Metal stamping companies are integral to advancements across multiple fields, driven by the need for precision, durability, and efficiency. Their ability to customize components to exact specifications supports innovation and technological progress in a wide range of applications.

SourcifyChina collaborates with leading metal stamping companies that specialize in various metals, including aluminum, brass, copper, stainless steel, and carbon steel. Each material offers unique benefits tailored to distinct industrial needs.

Aluminum is lightweight and corrosion-resistant, making it ideal for automotive, aerospace, and consumer electronics applications. Its versatility and ease of fabrication are key advantages.

Brass and copper provide excellent electrical conductivity and thermal resistance. These materials are often used in electrical components, plumbing, and decorative items due to their appealing aesthetics and functional properties.

Stainless steel and carbon steel offer exceptional strength and durability. Stainless steel is known for its corrosion resistance, making it suitable for medical devices, kitchenware, and construction. Carbon steel, conversely, is valued for its high tensile strength and is commonly utilized in heavy machinery, structural components, and tools.

The metal stamping companies associated with SourcifyChina employ advanced technology and precision engineering to ensure high-quality production. They focus on maintaining rigorous quality control standards, ensuring that each stamped part meets exact specifications and industry requirements.

SourcifyChina’s partnerships emphasize innovation, reliability, and efficiency. By leveraging an extensive network of skilled manufacturers, they can offer competitive pricing and timely delivery, catering to global clients across diverse market sectors.

Overall, SourcifyChina connects businesses with top-tier metal stamping companies capable of producing high-precision, custom parts. Their diverse material offerings ensure that clients receive the most appropriate solutions tailored to their specific needs, enhancing performance and product longevity.

SourcifyChina metal stamping companies excel in quality control, ensuring all processes meet industry standards. They use advanced technology to monitor the production stages meticulously. This begins with raw material inspection to verify composition and quality.

Next, precise tooling calibration plays a crucial role in maintaining accuracy and consistency. Qualified engineers regularly calibrate and maintain equipment to adhere to tight tolerances, reducing defects and enhancing production efficiency.

In-process inspection is another critical stage. Continuous monitoring during stamping operations identifies and resolves issues in real-time. This step ensures that parts meet the required specifications and eliminates any anomalies early in the process.

Final inspection and testing are stringent, involving dimensional checks and performance tests. Parts undergo rigorous scrutiny to ensure they meet customer specifications and industry standards. This stage confirms the integrity and functionality of each stamped component.

Moreover, feedback loops and corrective actions are integral to the quality control process. Any deviations detected prompt immediate investigation and rectification to prevent recurrence. This closed-loop system guarantees continuous improvement and maintains high-quality standards.

Documenting each step provides traceability and accountability. Comprehensive records ensure any issues can be traced back to their origin, allowing for efficient problem resolution and quality assurance.

Finally, SourcifyChina’s commitment to quality is evident in its customer satisfaction and repeat business. Their meticulous quality control manufacturing process ensures that every product leaving the facility meets stringent criteria, fostering trust and long-term partnerships with clients worldwide. This holistic approach to quality control defines SourcifyChina’s reliability and excellence in the metal stamping industry.

SourcifyChina metal stamping companies boast state-of-the-art facilities equipped with advanced machinery capable of producing a wide range of metal components. These companies specialize in high-precision stamping techniques, offering both single and progressive dies to meet varying production needs.

Their capabilities extend to working with diverse metals, including aluminum, brass, steel, and stainless steel, ensuring versatility in application. They excel in prototyping and mass production, providing customized solutions tailored to client specifications while maintaining stringent quality control standards.

Additionally, SourcifyChina metal stamping companies emphasize efficiency and cost-effectiveness. Using lean manufacturing principles, they minimize waste and optimize production timelines without compromising on quality. This ensures prompt delivery and adherence to customer schedules.

Moreover, these companies are committed to continuous innovation and improvement. They invest in ongoing staff training and technology upgrades to maintain their competitive edge and adapt to emerging market demands. They also focus on sustainable practices to minimize environmental impact.

In summary, SourcifyChina metal stamping companies offer comprehensive, high-quality, and innovative solutions. Their commitment to precision, efficiency, and sustainability makes them reliable partners in the metal stamping industry, catering to various sectors with expertise and dedication.

Metal stamping companies offer a wide array of benefits, making them indispensable to various industries. Their services ensure precision, cost-effectiveness, and accelerated production timelines.

– Precision Engineering: Metal stamping companies utilize advanced technologies to produce highly accurate and intricate parts, ensuring top-notch quality and reliability.

– Cost-Effective Solutions: By employing efficient production methods and economies of scale, these companies can offer competitive pricing.

– High Production Volume: Metal stamping allows for the rapid production of large quantities, meeting high-demand needs effortlessly.

– Material Versatility: They can work with a broad range of metals, providing customized solutions for diverse applications.

– Reduced Waste: Advanced techniques optimize material usage, minimizing waste and promoting sustainability.

– Consistency and Uniformity: Ensuring that each stamped part is identical, these companies provide unparalleled consistency.

– Time Efficiency: Speedy production processes significantly reduce lead times, enhancing project turnaround.

– Innovative Techniques: By leveraging the latest in stamping technology, these companies stay ahead of the curve, offering cutting-edge solutions.

– Scalability: From prototype development to full-scale production, metal stamping companies can scale operations to meet varying project sizes.

– Quality Assurance: Rigorous testing and quality control measures ensure that the final products meet stringent standards and specifications.

All these factors make metal stamping companies key players in supply chains, driving forward innovation and efficiency across numerous sectors.

Metal stamping companies play a crucial role in manufacturing by transforming sheet metal into precise components used across various industries. They offer a range of services and employ advanced technologies to ensure high-quality products. Key features include:

– Custom Design: Ability to create bespoke parts tailored to specific client requirements.

– High Precision: Utilization of advanced machinery for exact measurements and intricate designs.

– Material Versatility: Capability to work with diverse materials such as aluminum, steel, copper, and more.

– Volume Production: Proficiency in handling both small and large-scale production runs efficiently.

– Rapid Prototyping: Fast turnaround times for prototype development to streamline the design process.

– Quality Assurance: Rigorous testing and inspection procedures to maintain product standards.

– Cost-Effective Solutions: Implementation of cost-efficient practices without compromising quality.

– Diverse Applications: Components produced are used in automotive, aerospace, electronics, and other sectors.

– Technical Support: Offering expert consultation and technical support throughout the production process.

– Sustainability Practices: Adoption of eco-friendly methods and materials to minimize environmental impact.

– Advanced Software: Employment of CAD/CAM software for precise design and manufacturing processes.

– Skilled Workforce: Deployment of trained professionals well-versed in the latest stamping technologies.

– Cold and Hot Stamping: Capabilities to perform both cold and hot stamping to cater to different project needs.

– Tool and Die Making: In-house tool and die creation to ensure high tool quality and quick maintenance.

– Global Reach: Ability to serve international markets with reliable shipping and logistics.

Sourcify specializes in connecting businesses with top-tier metal stamping companies in China. This service ensures quality production, cost efficiency, and reliable timelines, suitable for both bulk and custom orders. These companies leverage advanced technology and skilled labor to provide precision stamping services. From simple components to intricate designs, their capabilities cover a wide range.

Custom projects are a particular forte, where clients can specify exact material types, dimensions, and tolerances. Whether it’s automotive parts, electronic components, or industrial hardware, the focus remains on delivering products that meet stringent quality standards.

One of the compelling aspects of SourcifyChina is the ability to manage complex projects seamlessly. Multiple phases from prototyping to final delivery are coordinated to achieve flawless execution. Regular quality inspections and adherence to international standards ensure products that exceed expectations.

SourcifyChina metal stamping companies also place significant emphasis on sustainability. Using eco-friendly materials and processes, these companies contribute to responsible manufacturing practices. This commitment not only meets regulatory requirements but also appeals to environmentally conscious businesses.

Furthermore, the excellent customer service offered ensures smooth communication throughout the entire process. Clients receive regular updates, detailed reports, and instant support for any issues that may arise. This transparent approach builds trust and long-term partnerships.

In conclusion, SourcifyChina’s metal stamping companies provide an unmatched blend of quality, customization, sustainability, and customer support. Their comprehensive approach to managing custom projects makes them an invaluable partner for businesses seeking reliable and precise metal stamping solutions.

SourcifyChina, a leading name in the metal stamping industry, epitomizes the prowess of Chinese manufacturing with its commitment to precision, quality, and innovation. Specializing in a diverse range of metal stamping services, the company caters to various industries, including automotive, aerospace, electronics, and consumer goods. With state-of-the-art facilities and a robust supply chain, SourcifyChina ensures that every product meets the stringent standards of global markets. The company’s expertise lies in its ability to offer customized solutions, leveraging advanced technology and skilled craftsmanship to deliver high-precision components. SourcifyChina prides itself on its customer-centric approach, providing comprehensive support from the initial design phase to final production. This dedication to excellence has earned it a reputation for reliability and consistency, making it a preferred partner for businesses seeking top-tier metal stamping solutions.

Metal stamping companies play a pivotal role in the aerospace, defense, and marine sectors by providing highly precise and durable components essential for a myriad of applications. In the aerospace industry, precision and reliability are paramount, given the extreme conditions aircraft and spacecraft must endure. Metal stamping companies produce intricate parts such as brackets, clips, and fasteners that meet rigorous standards for weight, strength, and resistance to corrosion. These components contribute to the structural integrity and safety of aircraft, ensuring they can withstand the stresses of flight. Similarly, in the defense sector, metal stamping is employed to manufacture essential elements for weaponry, vehicles, and communication systems. High-quality stamped metal parts are required to ensure the functionality and survivability of defense equipment in the most demanding environments, from the harsh conditions of the battlefield to the precise requirements of advanced electronic systems.

In the marine industry, the need for robust and corrosion-resistant components is critical due to the continuous exposure to harsh, salty environments. Metal stamping companies deliver custom parts such as hull components, engine parts, and marine hardware that must endure prolonged exposure to water and corrosive elements. The precision and durability of stamped metal products ensure that ships, submarines, and other marine vessels operate safely and efficiently. Furthermore, the cost-effectiveness and scalability of metal stamping allow for the production of high volumes of parts, meeting the mass production needs of these industries while adhering to stringent quality standards. By leveraging advanced materials and technologies, metal stamping companies enable the development and maintenance of complex systems critical to aerospace, defense, and marine applications, ensuring longevity, performance, and safety.

Metal stamping companies play a crucial role in the automotive industry, providing precision-engineered components that are essential for vehicle production. These companies use advanced stamping techniques to create a multitude of parts, including chassis, engine components, transmission parts, and body panels. The accuracy of metal stamping ensures that each component meets stringent quality and safety standards, imperative for automotive applications. The ability to produce large volumes of identical parts efficiently allows automotive manufacturers to maintain consistency and reliability in their vehicles. Furthermore, metal stamping companies often employ innovative materials and processes to enhance the durability and lightweight properties of automotive parts, contributing to improved fuel efficiency and overall vehicle performance.

In the electronics sector, metal stamping companies are indispensable due to their capacity to produce highly precise and complex components required for various electronic devices. These companies manufacture parts such as connectors, shielding, brackets, and enclosures that are critical for the functionality and protection of electronic circuits. The miniaturization trend in electronics demands extremely tight tolerances, which metal stamping processes are well-suited to achieve. Additionally, the versatility of metal stamping allows for the use of materials with excellent conductivity and heat dissipation properties, essential for high-performance and reliable electronic applications. With consistent advancements in electronic technology, metal stamping companies continuously innovate to meet the evolving requirements, ensuring that devices remain efficient, compact, and robust.

Metal stamping companies play a pivotal role in the construction industry, providing a range of components essential for building robust structures. These companies specialize in producing high-precision, custom metal parts that are used in various construction applications. From structural supports such as beams and braces to intricate components in HVAC systems, metal stamping companies ensure that each piece meets stringent industry standards for durability and safety. The speed and efficiency of the stamping process also enable the mass production of these parts, which is crucial for large-scale construction projects. By offering a versatile range of materials, including steel, aluminum, and copper, these companies can cater to the specific needs of different construction projects, enhancing the overall structural integrity and performance of buildings.

In the energy sector, metal stamping companies contribute significantly by manufacturing components used in renewable energy systems and traditional energy infrastructures. For instance, stamped metal parts are integral in the production of solar panels, wind turbines, and energy storage systems. Precision and reliability are paramount in this field, as these components must withstand harsh environmental conditions and operate efficiently over extended periods. Furthermore, metal stamping is instrumental in the creation of parts for electrical grids, transformers, and other power distribution systems, ensuring the seamless transmission of energy from power plants to end-users. By utilizing advanced stamping techniques and materials, metal stamping companies help to enhance the efficiency and sustainability of energy systems, paving the way for innovations in green technology and contributing to the global push for cleaner energy solutions.

Metal stamping companies play a crucial role in the industrial equipment industry by providing precision-engineered components that are essential for various machinery and tools. These companies utilize advanced metal stamping techniques, such as deep drawing, bending, embossing, and coining, to create complex shapes and intricate designs from sheet metal. The resulting stamped parts are integral to the assembly of industrial engines, pumps, motors, and automation systems, ensuring their structural integrity and functionality. The ability of metal stamping companies to produce large volumes of high-quality parts with tight tolerances at relatively low costs makes them indispensable to industrial equipment manufacturers, who rely on these components to maintain efficiency and durability in their products.

Moreover, metal stamping companies contribute significantly to innovation and customization in the industrial equipment sector. By leveraging progressive dies and advanced computer-aided design (CAD) software, these companies are able to produce bespoke components tailored to the specific needs of industrial machinery developers. This capability is particularly valuable in industries such as aerospace, automotive, and heavy machinery, where the performance and reliability of equipment are paramount. Furthermore, with the growing emphasis on sustainability and energy efficiency, metal stamping companies are increasingly utilizing eco-friendly materials and processes to minimize environmental impact. This alignment with industry trends not only helps in meeting regulatory standards but also enhances the overall value proposition for industrial equipment manufacturers seeking to innovate and stay competitive in the market.

Metal stamping companies play a critical role in the production of medical devices, providing precise and reliable components essential for various applications. Metal stamping involves the process of converting flat metal sheets into specific shapes through techniques such as punching, blanking, bending, and embossing. These companies supply parts for a wide range of medical devices including surgical instruments, orthopedic implants, and diagnostic equipment. Given the stringent requirements for biocompatibility and precision in the medical field, metal stamping companies often work with high-quality materials like stainless steel, titanium, and specialized medical-grade alloys. Their ability to produce large volumes of consistent, high-precision parts ensures that medical devices can be manufactured efficiently and meet rigorous standards.

Moreover, advancements in metal stamping technology such as progressive die stamping and deep drawing enable the production of complex medical components with tight tolerances and intricate geometries. This precision is vital for ensuring the reliability and safety of medical devices, which can significantly impact patient outcomes. Metal stamping companies also invest in cleanroom manufacturing environments to avoid contamination, ensuring the sterility of components intended for invasive procedures. Their expertise not only supports existing medical technologies but also fosters innovation, allowing for the development of new and improved medical devices. Thus, metal stamping companies are indispensable partners in the medical sector, contributing to advancements in healthcare technology and the overall efficacy of medical treatments.

Metal stamping companies play a pivotal role in the machining and manufacturing sectors, specializing in the creation of intricate metal components through stamping processes. Utilizing dies and high-pressure machinery, these companies can efficiently produce a wide array of parts to precise specifications. This process involves feeding rolls of metal sheet into a stamping press, which forms the metal into the desired shape using a combination of cutting, bending, and pressing operations. Metal stamping companies are instrumental in producing parts that require high repeatability and tight tolerances, making them indispensable in industries such as automotive, aerospace, electronics, and consumer goods. The precision and efficiency of the metal stamping process minimize material waste and reduce manufacturing costs, contributing to the overall sustainability and economic viability of industrial operations.

In addition to their core stamping capabilities, many metal stamping companies offer secondary services that enhance the value and functionality of the finished products. These services can include heat treating, surface finishing, coating, and assembly, allowing for the creation of components that meet rigorous performance and aesthetic standards. Advanced machining technologies, such as CNC machining and laser cutting, are often integrated into the metal stamping workflow to achieve more complex geometries and higher levels of detail. As a result, metal stamping companies are not only manufacturers of parts but also solution providers that support end-to-end production needs. Their expertise in material properties, tooling design, and process optimization ensures that components are not only manufactured efficiently but also meet the demanding standards of various high-tech and high-performance industries. This comprehensive approach enables manufacturers to maintain a competitive edge by delivering quality products that adhere to exacting industry specifications.

Below are some frequently asked questions (FAQ) with answers regarding manufacturing quality work from “SourcifyChina” factory, especially for metal stamping companies:

Q1: What is the scope of metal stamping services provided by SourcifyChina factory?

A1: SourcifyChina factory specializes in a wide range of metal stamping services including progressive die stamping, deep drawing, and precision stamping. We handle both small and large production runs catering to various industries such as automotive, electronics, and machinery.

Q2: How does SourcifyChina ensure the quality of its metal stamping products?

A2: SourcifyChina utilizes a comprehensive quality management system adhering to international standards like ISO 9001:2015. Our quality assurance process includes rigorous in-process inspections, final product inspections, and the use of advanced measurement tools to ensure precision and consistency.

Q3: What materials can SourcifyChina work with for metal stamping projects?

A3: SourcifyChina is capable of working with a variety of materials including stainless steel, aluminum, brass, copper, and various alloys. We choose materials based on the specific requirements of each project to ensure optimal performance and durability.

Q4: Can SourcifyChina provide custom metal stamping solutions?

A4: Yes, SourcifyChina offers customized metal stamping solutions tailored to meet unique client specifications. Our engineering team collaborates closely with clients to design and develop bespoke stamping parts that match their exact needs.

Q5: What industries does SourcifyChina serve with its metal stamping products?

A5: SourcifyChina serves a broad spectrum of industries including automotive, aerospace, electronics, medical devices, and consumer goods. Our versatile metal stamping capabilities allow us to meet diverse industrial requirements.

Q6: How does SourcifyChina handle large volume production orders?

A6: SourcifyChina is equipped with state-of-the-art machinery and experienced staff to efficiently manage large volume production orders. We streamline our production processes to ensure timely delivery without compromising on quality.

Q7: What is the lead time for metal stamping orders from SourcifyChina?

A7: Lead time varies depending on the complexity and volume of the order. Typically, it ranges from 4 to 8 weeks. For urgent requirements, expedited services may be available.

When considering metal stamping companies manufacturing from a Sourcify-chosen factory in China, it’s essential to optimize both quality and cost-effectiveness. Here are some succinct tips:

1. Supplier Verification: Ensure the factory is reputable. Sourcify can facilitate this by vetting the factory’s credentials, quality certifications (like ISO 9001), and previous client testimonials.

2. Clear Specifications: Provide detailed drawings and specifications for your parts. This includes dimensions, tolerances, materials, finishes, and any other special requirements.

3. Samples and Prototyping: Request samples or prototypes before committing to large production runs. This can help you verify the quality and make necessary adjustments early on.

4. Communication: Maintain clear and consistent communication. Use detailed Purchase Orders (POs) and ensure there is mutual understanding regarding all aspects of production, timelines, and payment terms.

5. Quality Control: Implement a strict quality control process. Schedule regular inspections or hire third-party inspection services to ensure products meet your standards before shipping.

6. Logistics Management: Understand the logistics involved in shipping from China. Work with experienced freight forwarders to handle duties, tariffs, and ensure timely delivery.

7. Cost Analysis: Compare quotes from multiple suppliers to ensure competitive pricing without compromising quality. Consider all costs, including materials, labor, shipping, and potential tariffs.

8. Manufacturing Capabilities: Verify that the factory’s capabilities align with your requirements. This includes the types of metal stamping services they offer, such as progressive die stamping, deep drawing, or precision stamping.

9. Lead Times: Clarify lead times for production and shipping. Factor in potential delays and plan your inventory needs accordingly.

10. Sustainability and Ethics: Ensure the factory adheres to ethical standards and environmental regulations, reflecting positively on your brand.

Partnering with Sourcify can simplify sourcing from China, leveraging their expertise to mitigate risks and enhance efficiency.

Q: What is SourcifyChina factory?

A: SourcifyChina is a platform that helps businesses source and connect with manufacturers in China, including metal stamping companies.

Q: How can I find metal stamping companies on SourcifyChina?

A: You can utilize SourcifyChina’s search function, filter by industry, and specifically look for metal stamping companies. If you need assistance, their customer support is also available to help.

Q: What information do I need to provide to get quotes from metal stamping companies?

A: Typically, you will need to provide detailed specifications of the products you need, including materials, dimensions, quantities, and any additional requirements.

Q: How do I ensure the quality of metal stamping from SourcifyChina’s listed factories?

A: SourcifyChina usually vets and verifies its suppliers. Additionally, you can request samples, check certifications, and ask for quality control reports to ensure you are getting top-quality products.

Q: Is it possible to get custom metal stamping services through SourcifyChina?

A: Yes, many of the metal stamping companies on SourcifyChina offer custom manufacturing according to your specific needs and designs.

Q: What are the typical lead times for metal stamping orders?

A: Lead times can vary depending on the complexity and quantity of your order. It’s best to discuss directly with the suppliers for accurate timelines.

Q: What should I consider when choosing a metal stamping company on SourcifyChina?

A: Consider factors such as the company’s expertise, production capacity, quality control measures, lead times, and pricing. Reviews and ratings from other businesses can also be a good indicator.

Q: How can I communicate effectively with the metal stamping companies on SourcifyChina?

A: SourcifyChina provides communication tools through their platform. Clear and detailed communication regarding your requirements is essential. Many suppliers also have English-speaking representatives.

Q: What are the payment terms generally for metal stamping companies on SourcifyChina?

A: Payment terms can vary, but they typically include options such as a percentage upfront with the remainder upon delivery, or through escrow services. Always clarify the payment terms before placing an order.

Q: What do I do if I encounter issues with a supplier from SourcifyChina?

A: SourcifyChina often provides dispute resolution services and customer support to help resolve any issues you might encounter with your supplier.

Sourcing metal stamping companies through platforms like Sourcify in China can streamline the process of finding reliable manufacturing partners. Here are some concise tips to help you effectively source metal stamping companies:

1. Clear Requirements: Clearly define your project specifications, including materials, dimensions, tolerances, and quantities. This helps manufacturers understand your needs, ensuring accurate quotations.

2. Use Detailed Filters: Utilize Sourcify’s filtering options to narrow down your search to metal stamping companies. Look for attributes such as industry expertise, certification standards (e.g., ISO), and production capacities.

3. Review Portfolios: Examine the companies’ portfolios to see previous projects and assess their proficiency in metal stamping. Pay attention to the complexity and precision of their past work.

4. Request Samples: Ask for samples to evaluate the quality and craftsmanship firsthand. This also allows you to test if the company can meet your standards.

5. Check References: Seek testimonials or case studies from past clients. Reliable feedback can provide insights into the company’s reliability, punctuality, and problem-solving capabilities.

6. Evaluate Communication: Effective communication is crucial. See how promptly and clearly the company responds to your inquiries. Good communication can indicate a smoother collaboration down the line.

7. Visit the Facility: If possible, arrange a visit to the manufacturing facility. It gives you a direct view of their operations, quality control processes, and working conditions.

8. Negotiate Terms: Discuss and negotiate terms including pricing, turnaround times, and payment conditions. Ensure all agreements are transparent and documented to avoid misunderstandings.

Using these strategies, you can leverage Sourcify’s resources to find competent metal stamping companies in China that meet your manufacturing needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)