Technology and Applications of milling machines

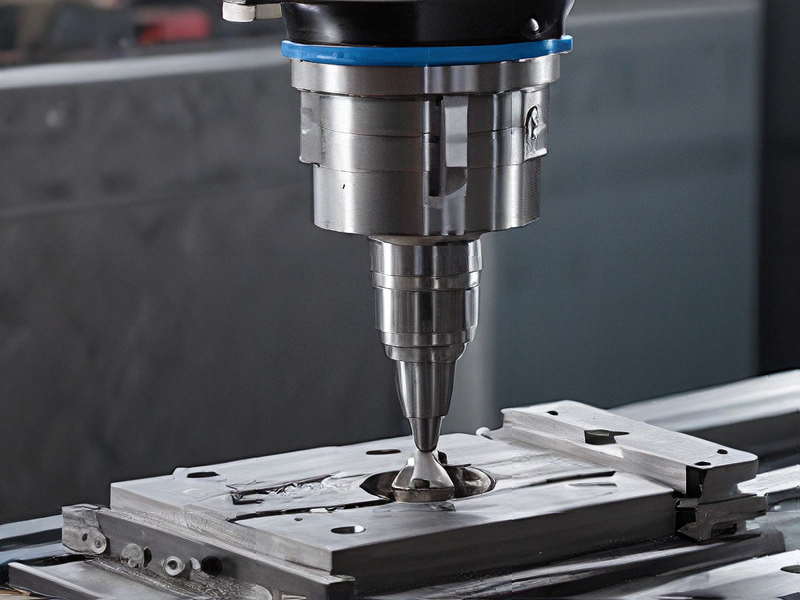

Milling machines are versatile manufacturing tools used to shape and fabricate materials, primarily metals, through the removal of material via rotary cutters. Their applications span various industries, including aerospace, automotive, and medical device manufacturing, making them essential for precision engineering.

Technology Overview

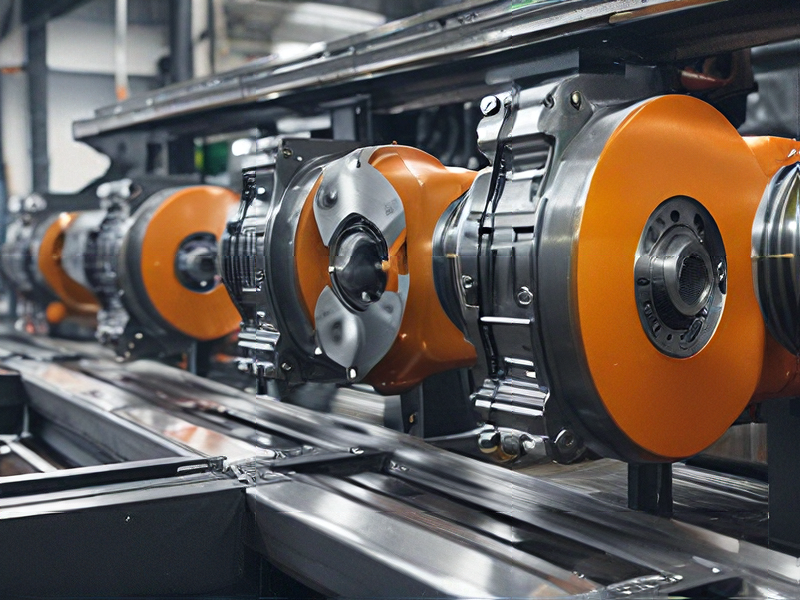

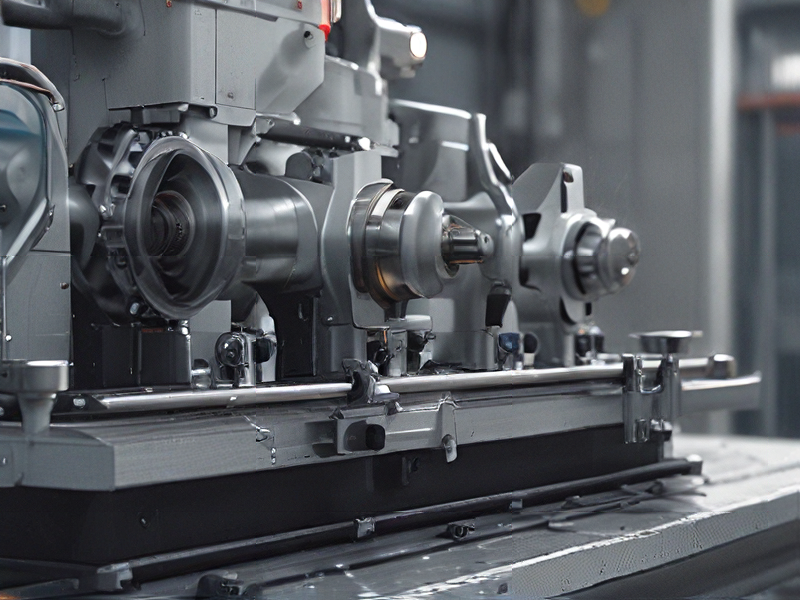

Milling machines operate on a three-axis or multi-axis system, allowing for intricate designs and complex geometries. They can be classified into vertical and horizontal milling machines, with vertical mills being more common for their ease of use and versatility. CNC (Computer Numerical Control) technology has revolutionized milling, enabling automated, high-precision machining. CNC mills can execute complex operations with minimal human intervention, improving efficiency and reducing errors.

Applications

1. Prototype Creation: Milling machines are utilized in rapid prototyping, enabling designers to create functional prototypes quickly for testing and validation.

2. Part Production: They are employed for producing high-precision components, including gears, brackets, and housings in various sizes.

3. Tooling: Milling machines are essential in producing custom tools and fixtures to aid in production processes.

4. Repair and Maintenance: They are used to refurbish worn-out components by machining to restore dimensions and functionality.

5. Customization: Milling enables customized machining operations, catering to specific customer requirements, particularly in low-volume production.

6. Education and Research: Milling machines are commonly used in educational settings for teaching machining principles and in research for developing new manufacturing processes.

In conclusion, milling machines continue to play a crucial role across multiple sectors through advanced technology and applications, driving innovation and enhancing productivity in manufacturing.

Quality Testing Methods for milling machines and how to control quality

Quality testing for milling machines is crucial to ensure precision, performance, and reliability. Here are some effective quality testing methods and control strategies:

Testing Methods:

1. Dimensional Inspection: Use calipers, micrometers, and CMM (Coordinate Measuring Machines) to measure the dimensions of machined parts. Ensure they meet specified tolerances.

2. Surface Roughness Measurement: Employ surface roughness testers to assess the texture of the machined surface. This ensures compliance with required surface finish standards.

3. Vibration Analysis: Monitor vibration levels of the milling machine during operation. Excessive vibration can indicate misalignment or wear, affecting machining quality.

4. Load Testing: Conduct load tests to evaluate machine stability and operational performance under maximum load conditions, ensuring the machine can handle specified workloads.

5. Tool Condition Monitoring: Regularly inspect cutting tools for wear and damage. Implement tool life monitoring systems to predict and schedule tool replacements.

Quality Control Strategies:

1. Standard Operating Procedures (SOPs): Establish clear SOPs for machine operation and maintenance to minimize human error.

2. Training and Certification: Provide ongoing training for operators to ensure they understand machine capabilities and best practices.

3. Regular Maintenance: Implement a routine maintenance schedule to address wear and tear, optimizing machine performance and longevity.

4. Statistical Process Control (SPC): Use SPC techniques to monitor production processes and identify variations that may affect quality, enabling prompt corrective actions.

5. Feedback Loops: Create a system for operators to report quality issues, fostering a culture of continuous improvement.

By incorporating these testing methods and control strategies, manufacturers can significantly enhance the quality of their milling machines and the components produced.

Tips for Procurement and Considerations when Purchasing from milling machines

When procuring milling machines, it’s essential to consider several key factors to ensure you make an informed purchase that meets your operational needs.

1. Purpose and Specifications: Clearly define the primary purpose of the milling machine. Consider the types of materials you’ll be processing and the desired precision level. This will guide you in selecting the right specifications, such as spindle speed, table size, and power requirements.

2. Type of Milling Machine: Different machines serve varied applications. Choose between vertical, horizontal, or CNC milling machines based on your specific needs. CNC machines are ideal for high precision and automation, while manual machines may suffice for simpler tasks.

3. Quality and Durability: Invest in a machine from reputable manufacturers known for quality. Examine the build materials and overall construction, as these factors influence the machine’s longevity and performance.

4. Support and Maintenance: Research the availability of technical support and maintenance services from the manufacturer or supplier. Machines often require calibration and repairs, so having access to reliable service can minimize downtime.

5. Budget and Total Cost of Ownership: Establish a budget that includes not just the initial purchase cost but also operational costs, such as energy consumption, maintenance, and potential downtime.

6. Features and Technology: Evaluate the features offered, such as automation, user interface, and safety mechanisms. Innovations like digital readouts and tool path simulation enhance user experience and efficiency.

7. Reviews and Recommendations: Seek reviews or testimonials from existing users. Networking with industry peers can provide insights into the reliability and performance of specific models.

By considering these factors, you can make a well-informed procurement decision that enhances your operational efficiency and productivity.

FAQs on Sourcing and Manufacturing from milling machines in China

FAQs on Sourcing and Manufacturing Milling Machines in China

1. Why source milling machines from China?

China is a global manufacturing hub, known for competitive pricing, diverse suppliers, and advanced manufacturing technologies. Sourcing from China can result in lower production costs and a wide range of options.

2. How do I find reliable suppliers?

Use platforms like Alibaba, Made-in-China, or Global Sources. Verify suppliers through background checks, customer reviews, and ratings. Attend trade shows or industry fairs to connect with reputable manufacturers.

3. What should I consider when selecting a manufacturer?

Look for manufacturers with proven experience, quality certifications (like ISO), and a solid portfolio. Assess their production capacity, lead times, and after-sales support.

4. How can I ensure product quality?

Request samples before making large orders. Consider hiring a third-party inspection service to conduct quality checks at various production stages to ensure compliance with your specifications.

5. What are the payment terms when sourcing from China?

Common payment methods include wire transfers, PayPal, and letters of credit. Be cautious with upfront payments—negotiating favorable terms and using escrow services can mitigate risks.

6. What import duties and regulations should I be aware of?

Research your country’s import regulations and tariffs on machinery. This ensures compliance and prevents unexpected costs. Work with a customs broker if needed.

7. How long does the sourcing process take?

The timeline can vary based on supplier responsiveness, production schedules, and shipping logistics, typically ranging from a few weeks to several months.

8. What is the best way to communicate with suppliers?

Utilize clear, concise communication. Use email or messaging apps, and consider time zone differences. Always confirm understanding in negotiations and specifications.