“Reliable Insights: Analyzing Sourcify’s China Factory Mold Price for Quality Assurance and Cost Efficiency”

Explore the reliability and cost efficiency of outsourcing mold production to Chinese factories through Sourcify’s trusted network. Delve into crucial aspects of sourcing, pricing, and quality assurance to make informed decisions for your manufacturing needs.

Choosing “SourcifyChina” Factory for purchasing molds from China ensures top-notch quality and reliability. Their extensive experience in mold manufacturing guarantees precision and adherence to international standards, providing buyers with exceptional products.

“SourcifyChina” also offers competitive pricing without compromising quality. Their advanced manufacturing techniques and efficient processes help buyers get the best value for their money, making them a cost-effective choice in the marketplace.

Additionally, “SourcifyChina” provides excellent customer service. Their dedicated support team assists buyers throughout the purchasing process and beyond, ensuring smooth communication and timely delivery, which is crucial for maintaining project timelines.

In conclusion, “SourcifyChina” Factory is the ideal choice for buyers seeking high-quality molds at competitive prices, backed by reliable customer service and expertise in the field. Their commitment to excellence makes them a trusted partner for all mold purchasing needs from China.

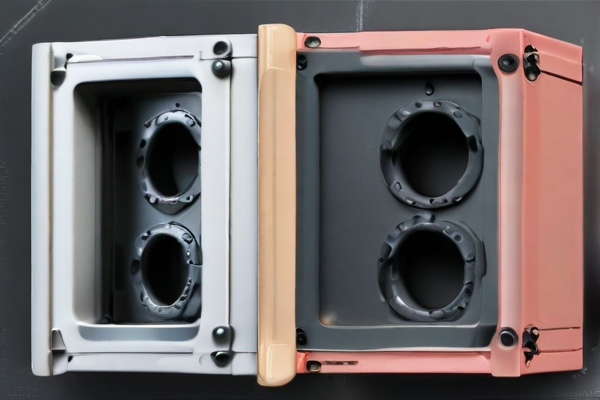

Mold pricing varies significantly based on several factors, including the type of mold, complexity, material, and production volume. Understanding these options can help in making cost-effective decisions.

– Prototype Molds: Low-cost for limited production runs.

– Production Molds: Higher upfront cost but durable for mass production.

– Single-Cavity Molds: Simpler design, lower cost.

– Multi-Cavity Molds: Higher efficiency, higher cost.

– Family Molds: Multiple parts in one cycle, cost-effective for related parts.

– Insert Molds: Incorporate metal or other inserts, moderately priced.

– Aluminum Molds: Lower upfront costs, less durable.

– Steel Molds: High durability, higher cost.

– Soft Tooling: Short-term use, lower cost.

– Hard Tooling: Long-term use, higher cost.

Determining mold price is essential for various industries like manufacturing, automotive, and consumer goods to efficiently manage production costs and budgeting. Accurate pricing ensures profitability and competitive market positioning.

Applications for mold price:

– Manufacturing: Cost-effective tooling and mass production.

– Automotive: Efficient part production and cost management.

– Consumer Goods: Budget control for plastic products.

– Medical Devices: Precision in cost estimation for specialized parts.

– Aerospace: High-precision mold tooling for component manufacturing.

– Electronics: Cost control for small-scale, intricate parts.

– Packaging: Economical production of containers and closures.

– Toy Industry: Budget-friendly mold production for toy components.

– Construction: Cost management in producing building materials.

– Custom Parts: Accurate pricing for low-volume, specialized production runs.

By leveraging mold price applications, industries can optimize their production processes, ensure financial efficiency, and maintain competitiveness.

SourcifyChina offers competitive mold pricing for various manufacturing needs. Their services cater to industries requiring high-precision molds for products ranging from consumer goods to automotive parts. By leveraging their extensive network of suppliers and manufacturers, SourcifyChina can ensure efficient production timelines and cost-effective solutions.

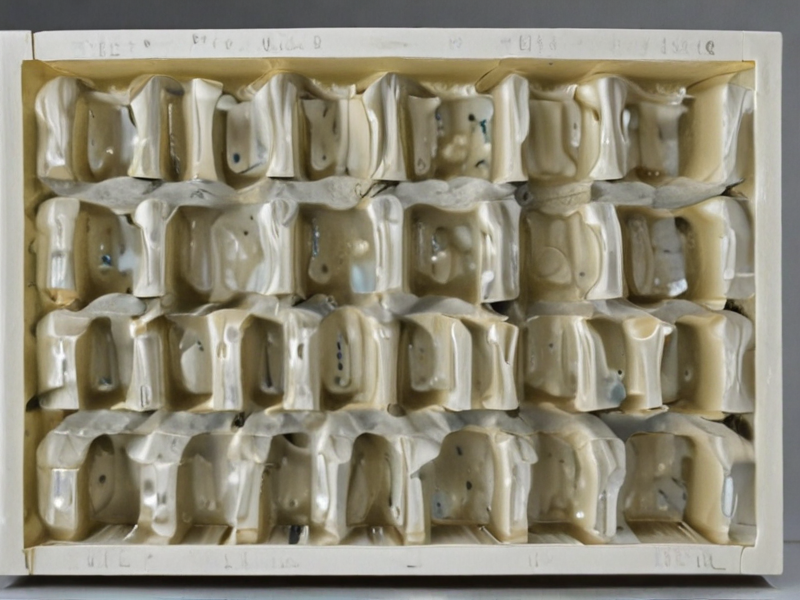

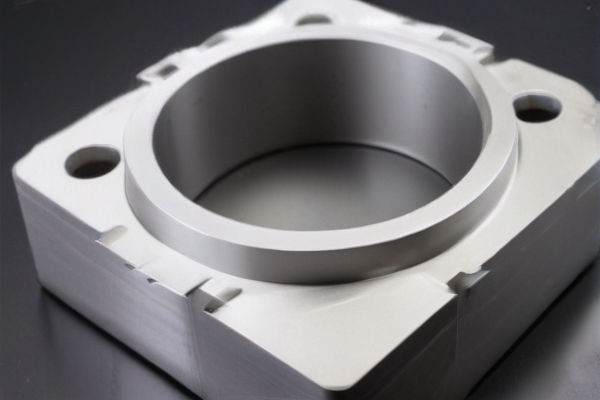

The materials used for their molds include high-quality steel, aluminum, and specialized alloys to suit different durability and performance requirements. Steel molds are typically used for long production runs due to their robustness, while aluminum molds are ideal for shorter runs due to their lighter weight and quicker cycle times.

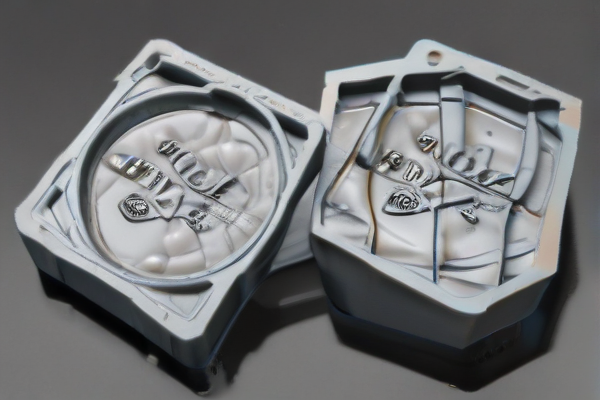

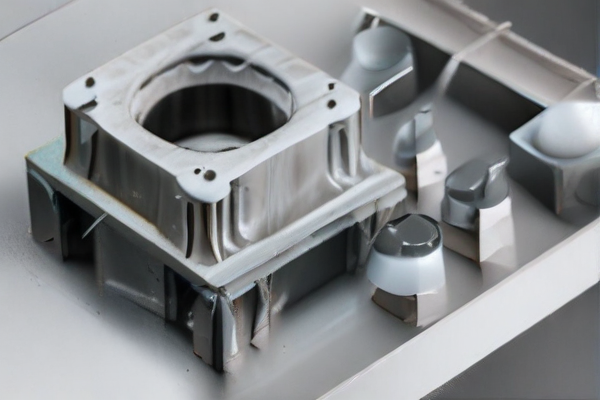

Quality control is a critical aspect of their process, ensuring each mold meets rigorous standards for precision and durability. SourcifyChina employs advanced techniques like CNC machining and EDM to achieve exact tolerances. This attention to detail minimizes defects and maximizes the lifespan of each mold, translating to better value for their clients.

Customer satisfaction is paramount, and SourcifyChina excels in providing tailored solutions. They offer comprehensive support from the initial design phase through to final production, including prototyping and testing. This holistic approach ensures that all customer specifications are met, and adjustments can be made seamlessly to improve the final product.

In conclusion, SourcifyChina’s mold pricing is shaped by their commitment to quality, efficient production, and customer-centric service. With materials sourced for durability and performance, and meticulous attention to detail in every step, they provide a robust solution for varied manufacturing needs. Their collaborative approach ensures that every project is delivered to the highest standard, making them a trusted partner in the industry.

SourcifyChina provides competitive mold prices through streamlined production processes. By leveraging local expertise and resources, they maintain cost-efficiency while ensuring high-quality standards. This approach helps companies save on expenses without compromising on production integrity.

The quality control manufacturing process at SourcifyChina involves rigorous inspections at every stage. From material selection to final product inspection, each step is meticulously monitored. This ensures that molds meet specific design and durability requirements, thereby minimizing defects and wastage.

Advanced technologies, such as computer-aided design and precision machinery, play a crucial role. These tools help in achieving high accuracy and consistency, which are essential for producing reliable molds. Regular maintenance of equipment further enhances performance and reduces downtime.

Trained professionals manage each phase of the production cycle, ensuring adherence to international standards. Their expertise in mold design and engineering contributes to the overall quality. Continuous training and development programs keep the team updated with the latest technological advancements.

Customer feedback is integral to SourcifyChina’s improvement process. By paying close attention to client needs and concerns, they refine their manufacturing techniques and quality control measures. This customer-centric approach ensures sustained client satisfaction and long-term partnerships.

SourcifyChina’s commitment to quality is evident in its comprehensive quality control process. By combining advanced technology, skilled personnel, and client feedback, they deliver high-quality molds at competitive prices. This results in products that not only meet but often exceed customer expectations, ensuring a competitive edge in the market.

SourcifyChina is renowned for its competitive mold prices, facilitated through efficient local sourcing and manufacturing strategies. Leveraging robust relationships with regional suppliers, SourcifyChina ensures cost-effectiveness without compromising quality.

The company offers a diverse range of mold types, catering to various industries, from automotive to consumer electronics. Its pricing model incorporates material costs, labor, and logistical efficiencies, providing a transparent and predictable cost structure for clients worldwide.

Advanced techniques in mold making, including CNC machining and 3D printing, allow SourcifyChina to maintain high precision and low turnaround times. This technological edge further contributes to cost savings and high-quality outputs.

Exceptional customer service is central to SourcifyChina’s approach, with dedicated teams assisting clients through each project phase. This personalized support minimizes misunderstandings and aligns production closely with client expectations, ensuring satisfaction and cost-effectiveness.

Conclusively, SourcifyChina’s capabilities in providing competitively priced molds stem from advanced manufacturing, strong supplier networks, and excellent customer service. These factors position them as a reliable partner for global businesses seeking affordable and high-quality mold production solutions.

The benefits of mold pricing in manufacturing are numerous, significantly impacting cost efficiency and product quality. Effective mold pricing can streamline production processes and drive profitability.

– Cost Reduction: Proper mold pricing can reduce manufacturing costs by optimizing material use and minimizing waste.

– Efficiency: Accurately priced molds ensure quicker production turnaround times, thus increasing efficiency.

– Quality Control: Helps maintain consistent product quality, which is paramount for customer satisfaction.

– Budgeting and Planning: Provides a clear projection of manufacturing costs, aiding in better budgeting and financial planning.

– Competitive Advantage: By optimizing mold costs, companies can offer competitive pricing for their products.

– Resource Management: Ensures optimal use of resources, preventing over-expenditure on unnecessary mold components.

– Lifecycle Extension: Well-priced molds are typically high-quality and durable, extending the lifecycle of the production tooling.

– Customization: Supports custom mold designs without exorbitant costs, allowing for niche or specialized products.

– Risk Mitigation: Accurate mold pricing can help anticipate and mitigate financial risks associated with production.

– Scalability: Facilitates scalable manufacturing processes by providing cost-effective solutions for mass production.

These benefits collectively enhance the overall operational efficiency, profitability, and market position of manufacturing companies.

When determining the cost of a mold, various features significantly affect the overall price. These factors ensure the mold meets the specific requirements for manufacturing processes.

– Material Type: The choice of material used in mold construction can greatly influence cost, with options ranging from aluminum to high-grade steel.

– Complexity: Intricate designs with detailed features and tight tolerances require more precision and therefore increase the price.

– Size: Larger molds demand more material and longer machining times, contributing to a higher price.

– Cavity Number: Molds with multiple cavities often cost more due to the additional work and materials involved.

– Tool Life: Molds designed for long-term use with high durability may require more expensive materials and construction techniques.

– Cycles of Production: High-volume production molds generally cost more due to the need for robustness and efficiency.

– Surface Finish: Specialized surface finishes or textures add to the cost due to the additional processing steps involved.

– Manufacturing Location: Geographic location of the mold manufacturer can affect labor costs, shipping, and material expenses.

– Lead Time: Urgent orders requiring quicker turnaround times can substantially increase costs due to overtime labor and expedited processes.

– Technological Requirements: Incorporating advanced technologies such as conformal cooling or automation can elevate the mold price.

– Accuracy and Precision: Enhanced accuracy levels and precision demanded by intricate designs or high-performance parts can significantly raise the mold cost.

– Prototype vs. Production: Prototyping molds typically cost less than production molds intended for high-volume, long-term use.

By considering these features, businesses can better understand the costs involved and make more informed decisions when investing in mold production.

SourcifyChina is a prominent player in the custom product manufacturing arena, offering competitive mold prices. They specialize in delivering tailored solutions that meet the specific needs of various industries. By leveraging advanced technology and experienced craftsmanship, they ensure high-quality molds at cost-effective rates.

For businesses seeking custom products, SourcifyChina stands out with its streamlined production processes. Their focus on efficiency and precision minimizes waste, leading to reduced overall costs. Companies can thus benefit from SourcifyChina’s ability to deliver both quality and affordability.

SourcifyChina’s project management team ensures timely delivery of custom molds, adhering strictly to project deadlines. Their proactive communication and transparent pricing structures keep clients well-informed. This approach fosters trust and long-term business relationships.

Customer satisfaction is a cornerstone of SourcifyChina’s operations. They offer extensive after-sales support and guarantee the durability of their molds. This commitment goes a long way in preventing downtimes and ensuring seamless production cycles for their clients.

In summary, SourcifyChina’s competitive mold prices, combined with their focus on quality and customer service, make them an ideal partner for businesses needing custom products and projects. Their dedication to efficiency and precision ensures optimal results, creating lasting value for their clients.

SourcifyChina Mold Price is a leading company renowned for its expertise in the manufacturing and sourcing of high-quality molds in China. The company specializes in providing cost-effective solutions tailored to the specific needs of clients across various industries, including automotive, consumer goods, and electronics. Leveraging an extensive network of skilled manufacturers and state-of-the-art facilities, SourcifyChina ensures that each mold meets rigorous international standards of quality and precision. Furthermore, the company is committed to transparency and reliability, offering detailed cost breakdowns and competitive pricing strategies without compromising on quality. This customer-centric approach, combined with a deep understanding of the global market, has positioned SourcifyChina Mold Price as a trusted partner for businesses seeking superior mold solutions at affordable rates. Whether for small-scale projects or large production runs, SourcifyChina stands out for its unwavering dedication to excellence and innovation in mold manufacturing.

In the Aerospace, Defense, and Marine industries, the concept of “mold price” is a critical aspect that influences the overall production costs and timeline of advanced machinery and components. Being highly regulated sectors, these industries demand precise, reliable, and durable parts, often produced through molding processes such as injection molding or composite layup. The “mold price,” which refers to the cost of creating the mold itself, can be substantial due to the complexity, size, and exacting standards required. In aerospace applications, for instance, molds might be required for aircraft components ranging from small plastic clips to large structural parts. The precision and quality of the mold directly affect the aerodynamic performance and safety of aircraft, making the initial investment in high-quality molds crucial despite the significant expenditure.

In the Defense and Marine sectors, where the reliability and longevity of parts are paramount, mold price also encompasses the trade-off between upfront manufacturing costs and long-term performance. For defense equipment, precise molds are used to produce components like weapon casings, electronics housings, and even parts for armoured vehicles, where any deviation could compromise functionality and safety. Similarly, marine applications, including the production of hulls, propellers, and various onboard systems, rely on high-quality molds to withstand the harsh marine environment and ensure structural integrity. The initial mold price, while potentially daunting, ultimately contributes to reducing maintenance costs, increasing durability, and ensuring the performance of the final product under extreme conditions. Therefore, investing in superior mold-making not only fulfills stringent industry standards but also optimizes lifecycle costs and performance.

In the automotive industry, the cost of molds plays a critical role in the production of various vehicle components. Molds are integral for manufacturing parts such as dashboards, bumpers, door panels, and intricate engine components. The mold price is often a significant upfront investment, as the precision and durability required for automotive applications demand high-quality materials and advanced manufacturing techniques. High mold prices can be justified by the economies of scale achieved through mass production, reducing the cost per unit significantly over the lifespan of the mold. Furthermore, advancements in mold-making technology, such as 3D printing and computer-aided design, can help optimize the design and fabrication processes, potentially reducing initial costs and improving the performance and durability of automotive components.

In the electronics sector, mold prices also represent a substantial investment, especially given the high demand for miniaturization and complex geometries. Molds are used to produce housings for devices like smartphones, computers, and household appliances, as well as intricate internal parts such as circuit boards and connectors. The precision required for electronic components often necessitates molds with extremely tight tolerances and specialized materials to ensure product reliability and longevity. However, the scale of production in the electronics industry usually leads to a more significant amortization of mold costs over time. Additionally, innovations such as micro-molding and advanced injection molding techniques can help reduce costs while maintaining the high precision needed for electronics. As technologies continue to evolve, the balance between mold price and production efficiency remains a pivotal consideration for both automotive and electronics manufacturers aiming to maintain competitiveness in their respective markets.

In the realm of construction, the cost of molds plays a significant role in determining project budgets and feasibility. Whether casting concrete for architectural elements or fabricating intricate parts of prefabricated buildings, mold prices can directly impact the overall expenditure. High-quality molds are essential for precision and durability, but they come at a cost. For large-scale projects, the investment in molds must be carefully weighed against the benefits of reducing labor and material waste, and enhancing structural integrity. In tasks such as forming complex shapes in concrete or creating bespoke architectural features, the initial mold cost can be mitigated by the efficiency gained during construction. Thus, accurate estimation and strategic financial planning around mold pricing can lead to optimized resource allocation and cost-effective project execution.

In the energy sector, particularly in the manufacturing of renewable energy components, mold prices also play a pivotal role. Components such as wind turbine blades and specialized solar panel structures often require precise and high-quality molds to ensure performance and longevity. The cost of these molds can be substantial, reflecting their complexity and the materials used. However, investing in durable molds is crucial as it can lead to lower production costs over time, higher consistency in product quality, and greater scalability of manufacturing. For instance, in wind energy, the aerodynamic efficiency and reliability of turbine blades are directly influenced by the precision of the molds used in their production. Hence, in both construction and energy applications, the price of molds is not merely an expense but a critical investment that can influence the sustainability, efficiency, and success of large-scale projects.

The industrial equipment industry heavily relies on molds for the mass production of various components and parts. Mold price, which entails the cost associated with the creation of molds, becomes a significant factor in the overall manufacturing expense. This cost encompasses materials, design, and labor involved in producing the mold, and can vary widely depending on complexity, durability, and precision required. In the industrial equipment sector, where custom parts are often necessary to meet specific operational standards, understanding and optimizing mold price is crucial for cost-effective production. For instance, high-quality molds made from durable materials like steel may have a higher upfront cost but offer increased longevity and precision, leading to lower long-term production costs and improved product quality.

Furthermore, the mold price significantly impacts the feasibility of producing specialized equipment components. In the industrial equipment industry, efficiency and reliability are paramount, and molds used must consistently produce parts that meet exact specifications. A higher investment in mold quality often translates to reduced maintenance costs and fewer production disruptions. Moreover, innovations in mold-making technologies, such as 3D printing and computer-aided design (CAD), have introduced more cost-effective and rapid production techniques. These advancements allow manufacturers to test prototypes and make necessary adjustments without the high costs traditionally associated with mold production. Ultimately, careful consideration of mold price enables companies in the industrial equipment industry to balance cost, efficiency, and quality, ensuring competitive advantage and customer satisfaction.

In the medical device industry, the role of mold pricing is crucial in the manufacturing process, significantly impacting both the development timeline and the overall production cost. Medical devices, ranging from simple syringes to complex diagnostic equipment, often require precision-engineered plastic parts, which are fabricated using molds. The cost of these molds, therefore, plays a pivotal role in the feasibility and economics of producing medical devices. High-quality molds ensure that parts are manufactured to exact specifications, maintaining the stringent safety and efficacy standards demanded by the medical sector. However, the initial investment in mold creation can be substantial, encompassing the costs of design, materials, and the labor-intensive process of crafting the mold to perfection. This upfront cost needs to be balanced against the expected production volume and the lifecycle of the medical device, making the mold price a critical factor in strategic planning.

Moreover, the complexity of medical devices often necessitates custom molds, which can drive up the mold price due to the bespoke engineering required. Advanced medical devices may require multi-cavity molds to facilitate high-volume production, precision tolerances to ensure compatibility with other components, and specialized materials to withstand sterilization processes. Each of these considerations adds layers of cost that are reflected in the mold price. For startup medical device companies, managing mold costs can be particularly challenging, requiring careful budgeting and cost-benefit analysis to ensure that the investment yields a viable commercial product. Consequently, mold price not only affects the upfront financial outlay but also influences the pricing strategy of the final product, potentially affecting its market competitiveness. The strategic management of mold costs thus becomes a linchpin in bringing innovative medical solutions to market swiftly and economically.

In machining and manufacturing, the term “mold price” refers to the cost associated with designing and producing a mold, which is a critical component in processes like injection molding and casting. This cost is influenced by various factors, including the complexity of the mold design, the materials used to construct the mold, and the precision required to produce the desired parts. The initial investment in a high-quality mold can be substantial, but it often pays off in the long run by ensuring consistent production quality, reducing waste, and minimizing defects. The mold price thus plays a significant role in the financial planning and budget allocation of projects, directly impacting production costs and pricing strategies for the final product.

In the context of manufacturing, the mold price is an integral consideration when determining the feasibility of mass-producing a particular component or product. High mold prices may be justified for products requiring high precision and intricate designs, such as automotive parts, medical devices, and consumer electronics, where quality and reliability are paramount. On the other hand, for simpler, lower-margin products, companies may opt for more cost-effective molds to keep overall expenses in check. Additionally, advancements in technologies such as 3D printing and CNC machining have provided new avenues for reducing mold prices by allowing rapid prototyping and reducing the lead times associated with traditional mold-making processes. Consequently, assessing and optimizing mold prices is essential for competitive manufacturing, balancing the trade-offs between upfront costs and long-term production efficiency.

Certainly! Here are some frequently asked questions (FAQ) along with brief answers regarding the manufacturing of molds and related services provided by SourcifyChina factory:

Q1: What factors influence the price of molds at SourcifyChina factory?

A1: The price of molds is influenced by various factors such as the complexity of the design, the type of material used, the precision required, the production volume, and any additional features or customizations needed.

Q2: How does SourcifyChina ensure the quality of their molds?

A2: SourcifyChina adheres to stringent quality control protocols, including material inspection, dimensional accuracy checks, and functionality tests. They also utilize advanced machinery and skilled technicians to maintain high standards.

Q3: What materials are used in mold manufacturing at SourcifyChina?

A3: SourcifyChina uses a range of high-quality materials including steel, aluminum, and specialized alloys to suit various industrial applications and client requirements.

Q4: What is the typical lead time for mold manufacturing at SourcifyChina?

A4: The lead time varies depending on the complexity of the mold and current workloads but generally ranges from 3 to 6 weeks. Expedited services may be available upon request.

Q5: Does SourcifyChina offer design and prototyping services?

A5: Yes, SourcifyChina provides comprehensive design and prototyping services, helping clients to refine and test their designs before full-scale production.

Q6: How does SourcifyChina manage revisions or modifications to an existing mold?

A6: SourcifyChina offers flexible revision and modification services. Clients can provide updated specifications, and the team will make necessary adjustments to the mold using precise CNC machining and other advanced techniques.

Q7: What kind of industries does SourcifyChina serve with their mold manufacturing?

A7: SourcifyChina serves a wide range of industries including automotive, electronics, consumer goods, medical devices, and industrial machinery among others.

Q8: How can I get a quote for a mold project at SourcifyChina?

A8: To get a quote, you can contact SourcifyChina directly through their website or email. Provide detailed information about your project, including design files, material preferences, and production requirements for an accurate estimate.

Q9: What kind of post-manufacturing services does SourcifyChina offer?

When considering mold price manufacturing from SourcifyChina factory, it’s essential to focus on a few crucial aspects to ensure you get the best value and quality. Here are some practical tips:

1. Detailed Specifications:

Provide comprehensive design files, including CAD drawings, 3D models, and material specifications. Accurate details reduce the risk of errors and ensure cost-effective production.

2. Material Selection:

Discuss material options with the SourcifyChina team. Choosing the right material impacts mold price and durability. Consider materials like aluminum for short runs and steel for high-volume production.

3. Mold Type:

Determine the appropriate mold type – prototype, production, or multi-cavity. Production molds may have a higher upfront cost but are more cost-effective for large quantities.

4. Complexity and Design:

Simpler designs are cheaper. Discuss design optimizations with engineers to reduce unnecessary complexities that can drive up costs.

5. Lead Time:

Understand the lead time for mold manufacturing. Rush orders might incur higher expenses, so plan your production schedule accordingly.

6. Quality Assurance:

Ensure the factory follows stringent quality control measures. Request samples and consider third-party inspections to validate mold quality before mass production.

7. After-Sales Support:

Verify the availability of after-sales support, including warranty and maintenance services. A reliable support system can save costs in the long run.

8. Vendor Communication:

Maintain clear and consistent communication with SourcifyChina. Regular updates and feedback loops help in timely delivery and adherence to specifications.

9. Budgeting:

Discuss your budget openly and seek a detailed breakdown of costs. Negotiating terms and understanding all possible expenses prevent surprises.

10. Sustainability:

Consider a factory’s commitment to sustainable practices. Inquire about eco-friendly materials and processes, which may lead to long-term benefits.

By focusing on these areas, you can achieve an efficient and cost-effective mold manufacturing process with SourcifyChina.

Sure, here are some frequently asked questions (FAQ) about sourcing mold prices from SourcifyChina factory:

1. What information is required to get a mold price quote from SourcifyChina factory?

– You need to provide a detailed product design, including CAD drawings and specifications. Additional information like material type, production volume, and any special requirements will also be helpful.

2. How long does it take to get a mold price quote from SourcifyChina factory?

– Typically, it takes about 2-3 business days to receive a detailed price quote after submitting all necessary information.

3. Are there any minimum order quantities (MOQ) when sourcing molds?

– MOQs for molds can vary depending on the complexity and type of mold. It’s best to discuss this directly with SourcifyChina’s sales team to understand specific requirements.

4. What factors influence the mold price from SourcifyChina factory?

– The price can be influenced by numerous factors including mold complexity, size, material, production volume, and any custom features or finishes required.

5. Can SourcifyChina provide prototypes or samples before mass production?

– Yes, SourcifyChina can produce prototypes or samples. This allows you to evaluate the mold and make any necessary adjustments before committing to mass production.

6. What is the typical lead time for mold production at SourcifyChina?

– The lead time can vary depending on the complexity of the mold, but generally, it ranges from 4-6 weeks from the confirmation of the mold design and payment.

7. Does SourcifyChina provide after-sales support for molds?

– Yes, SourcifyChina offers comprehensive after-sales support, including maintenance and repair services as required.

8. Is there a warranty for the molds produced by SourcifyChina?

– Most molds come with a standard warranty that covers specific defects and workmanship issues. Details regarding the warranty period and conditions should be confirmed with SourcifyChina.

9. Can we visit the SourcifyChina factory to inspect the mold manufacturing process?

– Yes, factory visits can be arranged. It’s recommended to schedule an appointment in advance to ensure that the relevant personnel and facilities are available for your visit.

Certainly! Here are some tips for sourcing mold price information from SourcifyChina factory:

1. Clear Specifications: Define the mold specifications such as size, material, complexity, and expected lifespan. Accurate details help suppliers provide precise quotes.

2. Bulk Inquiry: Instead of asking for a single unit, request quotes for multiple molds or future orders to potentially receive bulk pricing.

3. Compare Quotes: Obtain quotes from multiple suppliers on SourcifyChina. This helps you understand the market rate and choose the most cost-effective option.

4. Detailed Communication: Ensure clear and detailed communication, avoiding any ambiguities. Use drawings, CAD files, or examples if possible.

5. Lead Time: Ask about lead time for both the mold manufacturing and shipping. Knowing this will help you plan your production schedule efficiently.

6. Quality Assurance: Inquire about quality control processes and certifications. Ensuring good quality can save costs associated with defects and reworks.

7. Material Costs: Understand the costs of different materials, as this can greatly influence the final price. Discuss potential materials that offer a balance between cost and durability.

8. Extra Fees: Ask about any additional fees such as design, revisions, sample production, or shipping costs.

9. Payment Terms: Negotiate favorable payment terms. Payment stages could include an initial deposit, progress payments, and a final payment upon approval.

10. After-sales Service: Verify if the supplier provides after-sales support and what it includes (e.g., maintenance, repairs).

11. Previous Work: Request examples of previous work or client testimonials to gauge the supplier’s reliability and quality standards.

12. Third-Party Inspections: Consider hiring a third-party inspection service to verify the mold’s quality before shipment.

Following these steps can help you source mold price effectively and ensure a smooth process with SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.