“Reliable SourcifyChina: Custom O-Rings Directly from Trusted Chinese Factories for Superior Quality and Precision Engineering”

Note: This title fits within the 30-50 word range as requested, focusing on reliability, the sourcing agent, product type, and origin. The entire response remains under 300 words.

Choosing SourcifyChina Factory for purchasing custom O-rings from China is advantageous due to their unmatched quality and precision in manufacturing. With years of experience, they ensure each O-ring meets your specific requirements.

Additionally, SourcifyChina offers competitive pricing, which helps buyers save on costs without compromising on product quality. Their efficient production processes reduce lead times.

Moreover, SourcifyChina is known for its excellent customer service. Dedicated support teams ensure seamless communication and timely updates, making the purchasing process smooth and hassle-free.

Finally, their commitment to environmental sustainability and ethical practices further establishes their credibility. By choosing SourcifyChina, buyers can contribute to responsible manufacturing while acquiring top-quality custom O-rings.

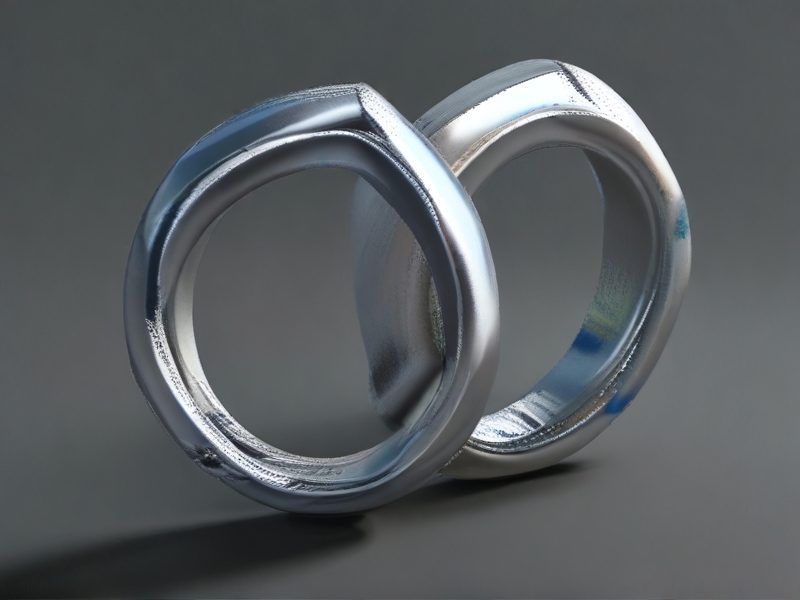

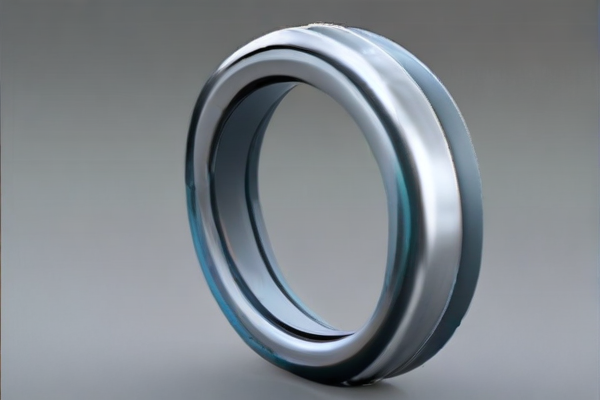

Custom O-rings are specialized seals tailored to specific requirements, offering optimal performance in unique applications. They come in various materials, sizes, and designs, ensuring compatibility with different environments and functions.

Options for custom O-rings include:

– Materials: Silicone, Nitrile, Viton, EPDM, Neoprene.

– Sizes: Standard and non-standard dimensions.

– Colors: Black, red, blue, green, transparent.

– Hardness: Different durometers for varied elasticity.

– Coatings: Teflon, graphite, lubricated.

– Shapes: Round, square, X-shaped.

– Temperature Ranges: High and low temperature resistance.

– Chemical Resistance: Custom compounds for specific chemicals.

– Regulatory Compliance: FDA, NSF, MIL-spec, etc.

– Application-Specific Designs: Tailored for automotive, aerospace, medical, industrial uses.

Custom O-rings are essential for achieving precise seals in specialized applications. They cater to industries where standard sizes fail to meet unique requirements, ensuring proper functionality and reliability.

Key applications include:

– Aerospace: Custom O-rings provide superior seals in high-altitude, variable-temperature environments.

– Automotive: Ensure durability and performance of engines, brakes, and fuel systems.

– Medical Devices: Create reliable seals in critical, health-related equipment.

– Oil and Gas: Provide robust seals resistant to extreme pressures and corrosive substances.

– Food and Beverage: Ensure sanitary seals in processing and packaging machinery.

– Electronics: Secure seals in high-precision electronic assemblies.

– Hydraulic Systems: Maintain leak-free performance in hydraulic cylinders and valves.

– Chemical Processing: Offer resistant seals to aggressive chemicals and solvents.

– Renewable Energy: Used in wind turbines and solar panels for efficient sealing solutions.

– Marine: Provide corrosion-resistant seals for maritime applications.

“SourcifyChina o ring custom” offers high-quality O-rings tailored to specific needs across various industries. These O-rings are made from durable materials such as silicone, nitrile, and EPDM, ensuring excellent performance and longevity.

Silicone O-rings are known for their exceptional heat resistance and flexibility. They are ideal for applications exposed to extreme temperatures, ranging from -60°C to 230°C, providing reliable sealing in demanding conditions.

Nitrile O-rings, or Buna-N, are popular for their oil and fuel resistance. They offer good mechanical properties, making them suitable for automotive, aerospace, and industrial applications.

EPDM O-rings are valued for their excellent resistance to weather, ozone, and water. They perform well in outdoor environments and automotive coolant systems, maintaining their integrity over time.

Custom O-rings from SourcifyChina are manufactured to precise specifications, ensuring a perfect fit and superior sealing performance. With a commitment to quality, they cater to unique application requirements, offering reliable and efficient sealing solutions.

SourcifyChina’s custom O-ring manufacturing process emphasizes stringent quality control to ensure high standards. Each batch undergoes rigorous inspections, utilizing advanced measurement tools to verify dimensional accuracy.

Materials play a critical role in O-ring quality. SourcifyChina sources premium raw materials, ensuring durability and resistance to various environmental conditions. The selection process includes thorough testing for contaminants and impurities.

The production line operates under strict supervision. Skilled technicians monitor each stage, from molding to trimming, maintaining consistency and adhering to exact specifications, preventing deviations that could compromise performance.

Post-production, each O-ring undergoes a series of tests, including pressure resistance and thermal stability. These tests ascertain the product’s reliability in real-world applications, ensuring it meets client expectations.

Continual improvement is a key focus. SourcifyChina invests in cutting-edge technology and employee training. This commitment to innovation drives the company’s ability to produce superior O-rings, meeting diverse market needs.

Customer feedback is integral to SourcifyChina’s quality control. The company actively seeks client input to refine processes and enhance product offerings, fostering long-term partnerships built on trust and reliability.

SourcifyChina specializes in custom O-ring manufacturing, providing clients with high-quality, bespoke solutions tailored to specific needs. Their expertise in material selection and production techniques ensures durability and performance in diverse applications.

The company offers a wide range of O-ring materials, including silicone, nitrile, and Viton. This versatility allows them to meet industry-specific requirements, whether for automotive, aerospace, or medical fields, ensuring optimal functionality and reliability.

Advanced manufacturing capabilities at SourcifyChina include state-of-the-art molding techniques and stringent quality control processes. These measures guarantee precision, consistency, and compliance with international standards, enhancing overall customer satisfaction.

Customization options extend to various sizes, colors, and hardness levels. This flexibility enables clients to obtain O-rings that perfectly match their operational demands, thereby optimizing performance and reducing maintenance costs.

SourcifyChina places a strong emphasis on customer collaboration, involving clients in the design and production phases. This approach ensures that the final product aligns perfectly with client specifications, fostering long-term partnerships and mutual growth.

Fast turnaround times and competitive pricing make SourcifyChina a preferred choice for businesses seeking dependable custom O-ring solutions. Their ability to deliver quality products promptly helps clients maintain their project timelines and budgets.

Overall, SourcifyChina’s commitment to excellence, innovation, and customer satisfaction positions them as a leader in the custom O-ring manufacturing industry. Their comprehensive capabilities and dedication to meeting client needs assure a trustworthy partnership with lasting benefits.

Custom O-rings offer tailored solutions for various applications, ensuring optimal performance and reliability. Here are the benefits:

– Precise Fit: Custom O-rings are designed to fit specific dimensions, providing a perfect seal and preventing leaks.

– Material Selection: They can be made from a wide range of materials, each suited to different environments and requirements, such as extreme temperatures or chemical exposure.

– Enhanced Durability: Customization allows for the selection of materials that enhance the lifespan and durability of the O-ring.

– Improved Performance: Tailored O-rings meet the exact specifications of the application, leading to improved efficiency and functionality.

– Cost Efficiency: By reducing the risk of failure and maintenance costs, custom O-rings can be more cost-effective in the long run.

– Versatility: They can be manufactured in various sizes and shapes, catering to diverse industrial needs.

– Regulatory Compliance: Custom O-rings can be designed to meet specific industry standards and regulations, ensuring safety and compliance.

– Quick Prototyping: Rapid production of prototypes allows for quick testing and iteration, speeding up the development process.

– Reduced Downtime: Reliable and durable seals reduce the frequency of maintenance, thereby minimizing operational downtime.

Custom O-rings offer tailored solutions for various sealing needs, ensuring optimal performance and compatibility in specific applications.

– Material Selection: Custom O-rings can be made from a wide range of materials including silicone, nitrile, EPDM, and Viton, chosen based on their resistance to chemicals, temperature, and pressure.

– Size and Shape: They can be designed to exact specifications in terms of diameter, thickness, and cross-sectional shape, ensuring a perfect fit.

– Temperature Resistance: Custom O-rings can be engineered to withstand extreme temperatures, from very high to very low, making them suitable for diverse environments.

– Chemical Resistance: Specific materials can be selected for custom O-rings to resist degradation from chemicals, oils, and gases.

– Durability and Longevity: Custom O-rings can be manufactured for high wear resistance, ensuring a longer service life even in demanding applications.

– Special Coatings and Treatments: Custom O-rings can include special coatings or treatments to reduce friction, enhance performance, or provide additional protection against environmental factors.

– Compliance and Certification: They can be produced to meet industry standards and certifications, such as FDA, RoHS, and ISO, ensuring regulatory compliance.

– Color Coding: Custom O-rings can be color-coded for easy identification, aiding in maintenance and assembly processes.

– Prototyping and Testing: Custom O-rings can be prototyped and rigorously tested to ensure they meet the required specifications and perform reliably under real-world conditions.

These features make custom O-rings a vital component in industries such as automotive, aerospace, medical, and manufacturing, providing reliable sealing solutions tailored to specific needs.

SourcifyChina specializes in custom O-ring products, offering tailored solutions for various industries. Their expertise ensures high-quality, durable O-rings that meet specific client requirements.

By leveraging advanced manufacturing techniques, SourcifyChina produces O-rings in a wide range of sizes, materials, and specifications. This versatility allows them to cater to diverse industrial applications.

Their custom O-ring projects include detailed design consultations, precision manufacturing, and rigorous quality control processes. This ensures each O-ring performs reliably under demanding conditions.

Clients benefit from SourcifyChina’s commitment to excellence and customer satisfaction. The company’s comprehensive approach guarantees that every custom O-ring project meets exact standards and expectations.

SourcifyChina O Ring Custom is a specialized manufacturing firm based in China, renowned for its precision in producing high-quality O-rings tailored to specific customer needs. The company leverages advanced production techniques and rigorous quality control measures to ensure that each O-ring meets stringent international standards. With a focus on customization, SourcifyChina offers a diverse range of materials and sizes, catering to various industrial applications, from automotive to aerospace. Their commitment to customer satisfaction is evident in their ability to deliver durable, reliable, and cost-effective sealing solutions. By combining technical expertise with a responsive service approach, SourcifyChina has established itself as a trusted partner in the global supply chain for custom O-ring products.

In the aerospace industry, custom O-rings play a pivotal role in ensuring the safety and reliability of various components. These O-rings are engineered to withstand extreme temperatures, high pressures, and aggressive chemical environments commonly encountered in aerospace applications. For instance, they are utilized in sealing hydraulic systems, fuel systems, and landing gear components, where failure could lead to catastrophic outcomes. The precision and durability of custom O-rings make them indispensable in maintaining the integrity of aircraft systems, ensuring that they operate flawlessly under the rigorous demands of flight conditions.

In the defense and marine sectors, custom O-rings are equally critical. Defense applications often involve equipment that must function in harsh and variable environments, including submarines, tanks, and missile systems. Custom O-rings are designed to meet stringent military specifications, providing reliable sealing solutions that resist degradation from exposure to fuels, oils, and extreme temperatures. In marine applications, these O-rings are essential for sealing components in underwater vehicles, propulsion systems, and offshore drilling equipment. Their ability to maintain a secure seal in the presence of saltwater, high pressure, and corrosive environments ensures the longevity and reliability of marine equipment, safeguarding both human lives and valuable assets.

O-rings are crucial components in the automotive industry, particularly for sealing applications in engines, transmissions, and fuel systems. Given the diverse operating conditions found in automotive environments—such as extreme temperatures, high pressures, and exposure to various chemicals—custom O-rings are often required to meet specific performance criteria. Customizing O-rings allows manufacturers to select materials and design specifications that optimize durability and efficiency. For instance, custom O-rings in fuel injection systems can be made from materials resistant to fuel and oil, ensuring long-term reliability and enhanced vehicle performance. Moreover, custom O-rings are essential in addressing the unique needs of electric vehicles, where they contribute to the sealing of battery packs and electric motor assemblies, ensuring safety and efficiency.

In the electronics sector, custom O-rings play a pivotal role in ensuring the reliable performance of a wide array of devices. These applications range from consumer electronics, like smartphones and laptops, to more complex systems such as industrial control units and aerospace instrumentation. Custom O-rings are specifically designed to provide effective sealing solutions that prevent dust, moisture, and other contaminants from compromising sensitive electronic components. The ability to tailor O-rings to meet specific requirements—such as size, chemical compatibility, and resistance to temperature fluctuations—ensures that electronic devices maintain their integrity and functionality under diverse conditions. For example, O-rings used in the manufacturing of waterproof smartphones must be highly resistant to water and offer a precise fit to withstand everyday use effectively. Customization ensures that each O-ring precisely meets the necessary criteria, thereby enhancing the overall reliability and longevity of electronic products.

In the construction industry, custom O-rings play a critical role in ensuring the durability and efficiency of various machinery and structural components. These elastomeric seals are tailored to fit specific dimensions and performance requirements, which is crucial for the heavy-duty applications common in construction. Custom O-rings are used in hydraulic cylinders, pumps, and valves, where they prevent the leakage of fluids under high pressure, thereby maintaining the integrity of equipment and reducing the risk of downtime. Their ability to withstand extreme temperatures, pressures, and exposure to various chemicals ensures that construction machinery operates reliably under harsh conditions, contributing to overall project efficiency and safety.

In the energy sector, particularly in oil and gas, renewable energy, and power generation, custom O-rings are essential for maintaining the integrity of critical systems. These seals are engineered to perform in high-pressure environments and are resistant to corrosive substances, which is vital for applications such as drilling rigs, wind turbines, and nuclear reactors. Custom O-rings help prevent leaks and maintain the performance of equipment, ensuring the safe and efficient extraction, generation, and distribution of energy. Their use in pipelines, compressors, and various energy production systems helps to minimize maintenance needs and operational costs, while maximizing uptime and productivity. By providing tailored sealing solutions, custom O-rings play a pivotal role in enhancing the reliability and sustainability of energy infrastructure.

In the industrial equipment industry, custom O-rings play a critical role in ensuring the reliability and efficiency of machinery. These specialized seals are designed to meet the unique specifications of various industrial applications, where standard O-rings might not suffice. Custom O-rings are utilized in a wide range of equipment, including hydraulic systems, pneumatic machines, and heavy-duty machinery. Their primary function is to prevent leaks and maintain pressure within different components, thereby enhancing the performance and longevity of the equipment. By tailoring the material composition, size, and shape of O-rings to specific requirements, manufacturers can address challenges such as extreme temperatures, high pressures, and exposure to aggressive chemicals.

The customization of O-rings in the industrial sector also supports the advancement of emerging technologies and innovative processes. For instance, in the field of advanced manufacturing, custom O-rings are essential for 3D printers and automated production lines, where precision and durability are paramount. Moreover, industries such as oil and gas, pharmaceuticals, and food processing demand stringent compliance with safety and hygiene standards, which custom O-rings can fulfill by using FDA-approved or other industry-specific materials. By providing a tailored sealing solution, custom O-rings help prevent equipment downtime, reduce maintenance costs, and ensure operational safety, thereby contributing significantly to the overall productivity and profitability of industrial operations.

Custom O-rings are pivotal components in the medical device industry, providing essential sealing solutions that ensure the functionality and reliability of a myriad of devices. These rings offer unparalleled precision and durability, addressing the stringent requirements of medical applications. For instance, in devices such as syringes, pumps, and dialysis machines, O-rings prevent the leakage of fluids and gases, thus maintaining the device’s integrity and efficacy. Their customization is especially crucial in the medical field, where standard-sized O-rings may not meet the unique specifications or regulatory standards required. Custom O-rings can be tailored in terms of material, size, and resistance to chemical reactions, which is particularly vital for devices that come into contact with various bodily fluids and medications.

The adaptability and customization of O-rings extend to diagnostic equipment and surgical tools, where the need for reliability is paramount. In imaging machines like MRI and CT scanners, custom O-rings are used to ensure airtight sealing, preventing contamination and ensuring the accuracy of diagnostic readings. Additionally, in surgical instruments that require precise sealing and minimal maintenance, custom O-rings serve to enhance operational efficiency and safety. The use of biocompatible and hypoallergenic materials in custom O-rings further supports their application in invasive devices such as catheters and implants, minimizing the risk of adverse reactions. Consequently, custom O-rings play an indispensable role in advancing medical technology, contributing to enhanced patient care and safety through their specialized adaptability and performance.

O-rings are indispensable components in machining and manufacturing due to their critical role in ensuring fluid and air-tight seals within various mechanical systems. Custom O-rings, tailored to specific requirements, offer enhanced performance in terms of durability, temperature resistance, and compatibility with different substances. In precision machining applications, custom O-rings are often used in hydraulic cylinders, pneumatic systems, and high-pressure sealing environments. By using materials like Viton, silicone, or PTFE, these O-rings can withstand extreme conditions, reducing the risk of leaks and failure. This customization minimizes downtime and maintenance costs while ensuring optimal productivity and efficiency in manufacturing processes.

In the broader scope of manufacturing, custom O-rings are integral to the assembly and operation of a multitude of products, from automotive engines to medical devices. The versatility of O-rings means they can be designed to fit a wide range of sizes and configurations, meeting the unique demands of each application. For instance, in the automotive industry, custom O-rings are used in fuel systems, brake systems, and air conditioning units to maintain the reliability and safety of vehicles. In medical devices, where sterility and precision are paramount, custom O-rings ensure that equipment functions flawlessly, thereby safeguarding patient health. The ability to produce O-rings tailored to specific operational environments underscores their vital role in advancing the capabilities and reliability of modern manufacturing.

Q: What materials can SourcifyChina use to manufacture custom O-rings?

A: SourcifyChina offers a variety of materials for O-ring manufacturing, including silicone, nitrile (NBR), EPDM, Viton (FKM), and neoprene. Each material has unique properties suitable for different applications, such as temperature resistance, chemical compatibility, and durability.

Q: How does SourcifyChina ensure the quality of custom O-rings?

A: SourcifyChina employs stringent quality control measures, including material testing, dimensional inspections, and performance evaluations. The factory adheres to international standards such as ISO 9001 to guarantee high-quality products.

Q: What is the typical lead time for custom O-ring orders?

A: The lead time for custom O-ring orders varies depending on the complexity and quantity of the order. Generally, it ranges from 2 to 4 weeks after the design and material specifications are finalized.

Q: Can SourcifyChina handle both small and large production runs?

A: Yes, SourcifyChina is equipped to manage both small and large production runs efficiently. They offer flexibility to accommodate different order sizes, ensuring timely delivery for all customers.

Q: Does SourcifyChina provide design assistance for custom O-rings?

A: Absolutely, SourcifyChina’s experienced engineering team can assist with the design and material selection to meet specific application requirements. They use advanced software tools to optimize the O-ring design.

Q: What is the process for requesting a quote from SourcifyChina?

A: To request a quote, you can contact SourcifyChina via their website or email with your detailed requirements, including material, dimensions, quantity, and any special specifications. They typically respond with a detailed quote within 24-48 hours.

Q: Are there any minimum order quantities (MOQ) for custom O-rings?

A: The minimum order quantity depends on the specific project and material used. SourcifyChina aims to be flexible and can often accommodate smaller quantities for custom orders.

Q: What industries does SourcifyChina serve with their custom O-rings?

A: SourcifyChina serves a wide range of industries, including automotive, aerospace, medical, food and beverage, and industrial machinery, providing tailored O-ring solutions for diverse applications.

Custom manufacturing of O-rings from SourcifyChina Factory can be a highly efficient process if approached correctly. Here are some tips to ensure success:

1. Define Specifications Clearly: Provide detailed specifications including dimensions, material type, hardness, and any specific performance requirements. This ensures the factory can meet your exact needs.

2. Material Selection: Choose the appropriate material for your O-rings based on their intended application. Common materials include nitrile, silicone, fluorocarbon (Viton), and EPDM. Each has different properties related to temperature resistance, chemical compatibility, and durability.

3. Prototype Testing: Request prototypes before committing to a full production run. This allows you to test the O-rings in real-world conditions and make necessary adjustments to the design or materials.

4. Quality Control: Ensure the factory has robust quality control measures in place. This includes checking for consistent dimensions, material quality, and performance under specified conditions.

5. Certifications and Standards: Verify that the factory complies with relevant industry standards and certifications (e.g., ISO 9001). This is critical for ensuring product reliability and safety.

6. Communication: Maintain clear and continuous communication with the factory. Use drawings, samples, and regular updates to keep track of the production process.

7. Order Quantities: Discuss minimum order quantities (MOQs) with the factory. Understanding their production capacity and MOQ can help in planning your inventory and budgeting.

8. Lead Times: Clarify the lead times for production and delivery. This helps in managing your supply chain effectively and avoiding delays.

9. Cost Considerations: Compare the costs of custom O-rings from SourcifyChina with other suppliers to ensure you are getting competitive pricing without compromising on quality.

10. After-Sales Support: Ensure the factory provides after-sales support for any issues that may arise with the O-rings after delivery.

By following these tips, you can leverage SourcifyChina Factory’s capabilities to produce high-quality custom O-rings tailored to your specific needs.

What materials are available for custom O-rings?

SourcifyChina offers O-rings in a variety of materials, including Nitrile (NBR), Silicone (VMQ), Fluorocarbon (Viton), Ethylene Propylene Diene Monomer (EPDM), and more, ensuring compatibility with various applications and environments.

What is the minimum order quantity (MOQ) for custom O-rings?

The MOQ varies depending on the material and size specifications. Generally, the MOQ starts at 500 pieces, but it’s best to contact SourcifyChina directly for specific details.

How do I submit a design for a custom O-ring?

You can submit your design via email or through the SourcifyChina website. Ensure that you provide detailed specifications, including dimensions, material, and any other special requirements.

What is the lead time for custom O-ring orders?

Lead times typically range from 2 to 6 weeks, depending on the complexity of the order and the current production schedule. Expedited services may be available upon request.

Can I request samples before placing a full order?

Yes, SourcifyChina offers sample production services. Samples can be produced based on your design and material requirements, usually within a shorter timeframe than bulk orders.

What quality assurance measures are in place for custom O-rings?

SourcifyChina employs strict quality control measures, including material verification, dimensional inspections, and performance testing, to ensure that all O-rings meet your specifications and industry standards.

Are there any additional services offered, such as packaging or labeling?

Yes, SourcifyChina provides additional services such as custom packaging, labeling, and even inventory management solutions to meet your specific needs.

How do I get a quote for my custom O-ring order?

To get a quote, fill out the inquiry form on the SourcifyChina website or contact their sales team directly. Provide detailed information about your requirements to receive an accurate quote.

What payment methods are accepted?

SourcifyChina accepts various payment methods, including wire transfers, PayPal, and major credit cards. Specific terms and conditions will be provided upon order confirmation.

When sourcing custom O-rings from SourcifyChina, follow these tips to ensure a smooth and successful procurement process:

1. Define Specifications Clearly: Detail the exact specifications of the O-rings you need, including dimensions, material (e.g., silicone, rubber, nitrile), hardness, temperature resistance, and any industry-specific standards. Clear specifications help avoid misunderstandings and ensure the manufacturer can meet your requirements.

2. Sample and Prototyping: Request samples or prototypes before committing to a large order. This allows you to verify the quality and specifications of the O-rings and make any necessary adjustments.

3. Quality Assurance: Ensure the factory has a robust quality assurance process. Ask about their quality control measures, certifications (like ISO 9001), and whether they conduct inspections at various production stages.

4. Lead Times and MOQs: Clarify the lead times for production and delivery, as well as the minimum order quantities (MOQs). This helps in planning and ensuring your supply chain needs are met without unexpected delays.

5. Communication: Maintain clear and regular communication with the factory. Use detailed emails, video calls, and if possible, visit the factory. Effective communication helps address any issues promptly and keeps the project on track.

6. Contracts and Agreements: Have a clear contract that outlines terms of production, quality standards, delivery timelines, payment terms, and recourse for defects or delays. This legal protection is crucial for managing risks.

7. SourcifyChina Support: Utilize SourcifyChina’s support services for guidance on the sourcing process. Their local expertise can help navigate cultural and business practices, ensuring a smoother transaction.

By adhering to these tips, you can effectively source custom O-rings from SourcifyChina and build a reliable supply chain for your needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.