Technology and Applications of paint of metal

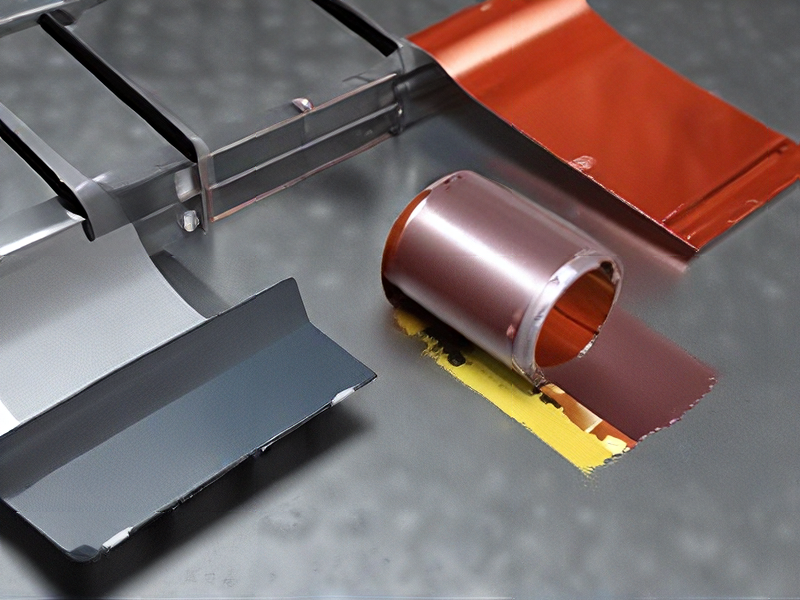

The technology of paint for metal has evolved significantly, enhancing both aesthetic appeal and protective functions. Modern metal paints comprise various formulations, including enamels, epoxies, polyurethanes, and alkyds. Each type caters to specific applications based on their properties like durability, UV resistance, and chemical compatibility.

Applications of Metal Paints:

1. Protective Coatings: Metal surfaces, such as steel and aluminum, are susceptible to corrosion. Protective paints form a barrier against moisture, air, and chemicals, extending the lifespan of structures like bridges, pipelines, and industrial equipment.

2. Aesthetic Finishes: Paints enhance the visual appeal of metal objects such as vehicles, furniture, and decorative elements. The use of vibrant colors and finishes, including matte, gloss, and metallic, allows for creative expression in design.

3. Heat Resistance: Specialized high-temperature paints are formulated for metal surfaces exposed to extreme heat, commonly used in automotive, aerospace, and industrial applications.

4. Industrial Uses: Metal paints are vital in manufacturing settings, where they are used to coat machinery, tools, and equipment, often providing slip-resistant properties and enhancing safety.

5. DIY and Home Improvement: Products designed for consumer use make it easy for individuals to transform metal objects, such as garden furniture or appliances, offering a durable and protective finish.

In recent years, advancements like the development of eco-friendly, low-VOC (volatile organic compounds) paints have gained traction, aligning with sustainability goals. Innovations in application techniques, such as spray, brush, or electrostatic painting, have also improved efficiency and finish quality.

In summary, metal paint technology plays a crucial role in protecting, enhancing, and preserving metal surfaces across diverse sectors while adapting to evolving environmental standards and consumer needs.

Quality Testing Methods for paint of metal and how to control quality

Quality testing for paint on metal is crucial for ensuring durability, aesthetics, and corrosion resistance. Here are some common methods:

Visual Inspection:

* Examine the paint surface for defects like cracks, bubbles, runs, or unevenness.

* Check color consistency and adherence to the substrate.

Film Thickness Measurement:

* Use a micrometer or a specialized gauge to measure the paint thickness.

* Ensure the film thickness meets the manufacturer’s specifications.

Adhesion Testing:

* Apply a cross-hatch or scribe pattern on the painted surface.

* Pull a tape across the pattern; good adhesion means minimal paint removal.

Impact Resistance:

* Drop a weighted object onto the paint film to assess its ability to withstand impact.

* Measure the amount of damage or paint chipping.

Corrosion Resistance:

* Expose the painted metal to a controlled corrosive environment (e.g., salt spray chamber).

* Observe the extent of corrosion after a specified period.

Quality Control:

* Standardization: Define clear quality standards and specifications for paint thickness, color, adhesion, and other relevant properties.

* Process Monitoring: Implement regular checks and measurements throughout the painting process to identify potential issues early on.

* Training: Ensure painters are adequately trained in proper application techniques and quality control procedures.

* Documentation: Maintain detailed records of paint batches, application methods, and testing results.

Tips for Procurement and Considerations when Purchasing from paint of metal

When procuring paint for metal surfaces, several key considerations can ensure optimal results and cost-effectiveness:

1. Surface Preparation: Before purchasing, assess the condition of the metal surface. Proper surface preparation (cleaning, rust removal, and priming) is crucial for paint adhesion and longevity.

2. Type of Paint: Choose the right type of paint for metal. Options include oil-based, water-based, and specialized metal coatings. Oil-based paints often provide durability, while water-based options are easier to clean and safer.

3. Weather Resistance: If the metal will be exposed outdoors, select a paint that offers UV and moisture resistance to prevent fading and corrosion.

4. Finish: Decide on the desired finish (gloss, semi-gloss, or matte). Glossy finishes offer increased protection and ease of cleaning, while matte finishes can hide imperfections.

5. Color and Aesthetics: Consider the color scheme and visibility requirements. Dark colors may absorb more heat and could affect the metal’s integrity; lighter shades reflect light and help keep surfaces cooler.

6. Application Method: Evaluate the application method—brush, roller, or spray. This will affect your paint choice since some paints are more suited for certain methods.

7. Safety and Environmental Compliance: Ensure the paint complies with local regulations regarding VOC (volatile organic compounds) emissions. Look for eco-friendly options if sustainability is a concern.

8. Budget and Quantity: Calculate the total area to be painted to estimate the amount of paint needed. Factor in costs for primer and additional supplies.

By considering these tips, you can make informed procurement decisions that enhance the durability and appearance of metal surfaces while optimizing your budget.

FAQs on Sourcing and Manufacturing from paint of metal in China

FAQs on Sourcing and Manufacturing Metal Paint in China

1. What types of metal paint are available in China?

China offers a wide variety of metal paints, including enamel, acrylic, epoxy, and polyurethane coatings. These paints cater to diverse applications, from industrial uses to decorative finishes.

2. How do I find reliable manufacturers?

Research potential manufacturers through platforms like Alibaba, Made-in-China, and Global Sources. Look for verified suppliers with positive reviews, certifications, and a strong export history. Request samples to assess quality.

3. What are the typical MOQ (Minimum Order Quantities)?

MOQs can vary depending on the manufacturer and product type but generally range from 500 to 2000 liters for paint. Always confirm with the supplier for specific requirements.

4. How can I ensure product quality?

Implement quality control measures such as third-party inspections during the production process. Ask suppliers for product certifications and test reports to guarantee compliance with international standards.

5. What is the lead time for production?

Lead times typically range from 15 to 45 days, depending on the order size and complexity. Discuss and confirm timelines with the manufacturer upfront.

6. Are there regulations I need to be aware of?

Yes, familiarize yourself with International Organization for Standardization (ISO) regulations and local environmental regulations related to VOC (Volatile Organic Compounds) emissions in paint.

7. Can I customize packaging?

Most manufacturers offer customization options for packaging, including labeling and sizes. Discuss your requirements to ensure they can accommodate your needs.

8. What payment options are available?

Common payment methods include T/T (bank transfer), PayPal, and L/C (letter of credit). Negotiate terms that work for both parties.