“Reliable SourcifyChina: High-Quality Factory Parts for Vertical Mills – A Comprehensive Resource Guide”

Our guide focuses on the most reliable parts for vertical mills, sourced through SourcifyChina, ensuring superior quality and performance for your industrial needs. Highlighting expert recommendations and sourcing tips for optimal operational efficiency.

Choosing “SourcifyChina” Factory for purchasing parts of a vertical mill from China offers several significant advantages. Firstly, they ensure the highest quality standards, employing rigorous quality control measures to meet international standards.

Secondly, SourcifyChina provides competitive pricing, capitalizing on China’s cost-effective manufacturing environment without compromising on quality, ensuring outstanding value for money.

Thirdly, they maintain efficient communication channels, offering excellent customer service with multilingual support, which helps in clear and precise transactions.

Additionally, the factory has a robust logistics network, guaranteeing timely delivery and minimizing disruptions in the supply chain.

Furthermore, their experienced team can offer expert advice on parts selection, ensuring optimal performance and compatibility with your vertical mill.

SourcifyChina offers customization options, allowing buyers to acquire parts tailored to specific requirements, enhancing the flexibility and efficiency of their machinery.

Their extensive industry experience positions them as a reliable partner, providing buyers with the confidence needed for international transactions.

Moreover, they maintain compliance with environmental and safety standards, contributing to sustainable and responsible sourcing practices.

In summary, choosing SourcifyChina Factory for purchasing vertical mill parts ensures high-quality products, competitive pricing, efficient communication, timely delivery, expert advice, customization options, industry reliability, and adherence to environmental standards. This makes them a superior choice for your manufacturing needs.

A vertical mill uses moving cutters to remove material from a workpiece, featuring components like the spindle, table, and motor. Various parts and options tailor the mill’s functionality for different tasks and materials.

– Spindle: Rotating axis for cutting tools.

– Table: Platform that holds the workpiece.

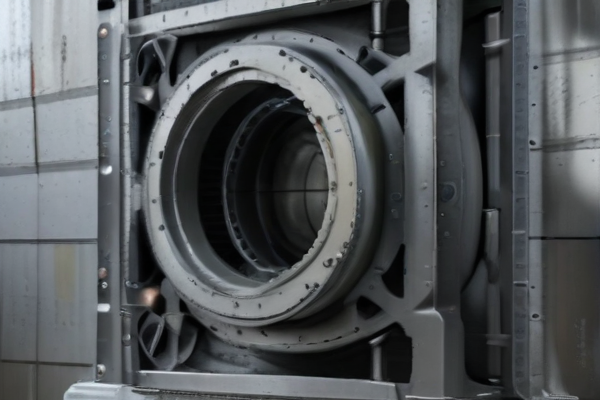

– Quill: Allows vertical movement of the spindle.

– Motor: Provides power to the spindle.

– Column: Vertical support holding the machine’s parts.

– Knee: Allows vertical adjustment of the table.

– Base: Foundation providing stability.

– Head: Houses the spindle, motor, and other components.

– Control Panel: Manages machine settings and operations.

– Coolant System: Keeps the cutting area cool.

– Power Feed: Automates table movement.

– Digital Readout (DRO): Displays precise measurements.

– Tool Changer: Automatically switches cutting tools.

– Lights: Enhances workspace visibility.

– Chip Shields: Protects operators from debris.

Parts of a vertical mill are crucial for various industrial applications, including metalworking and manufacturing. These components ensure precision, efficiency, and versatility in machining operations.

– Spindle: Holds and rotates cutting tools for precision machining.

– Table: Provides a platform for securing workpieces during machining.

– Column: Supports the spindle and table, maintaining rigidity.

– Quill: Allows vertical movement of the spindle for depth control.

– Knee: Adjusts vertically to change the table height and accommodate different workpiece sizes.

– Saddle: Provides horizontal adjustment of the table for transverse movements.

– Base: Ensures machine stability by supporting all other components.

– Head: Houses the spindle and quill, offering control over rotation speed.

– Tool holders: Secure cutting tools in the spindle for various operations.

– X-axis handwheel: Manually adjusts the table for precise horizontal positioning.

– Y-axis handwheel: Controls the saddle’s transverse movement for accuracy.

– Z-axis handwheel: Adjusts the quill’s vertical position for depth regulation.

– Power feed: Automates table movement for consistent machining.

– Coolant system: Manages heat and lubrication to prolong tool life and improve cut quality.

– Digital readout (DRO): Provides real-time position feedback for precise machining.

Each part of a vertical mill works harmoniously to perform complex tasks like drilling, cutting, and shaping materials, critical for manufacturing and production industries.

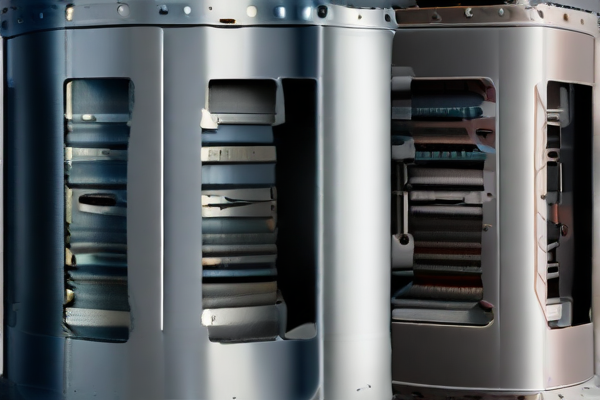

SourcifyChina supplies various components crucial for the efficient operation of vertical mills. Their offerings include high-quality wear-resistant plates, essential for extending the lifespan of the mill. These plates are crafted from hardened steel or advanced composites, providing durability against constant grinding forces.

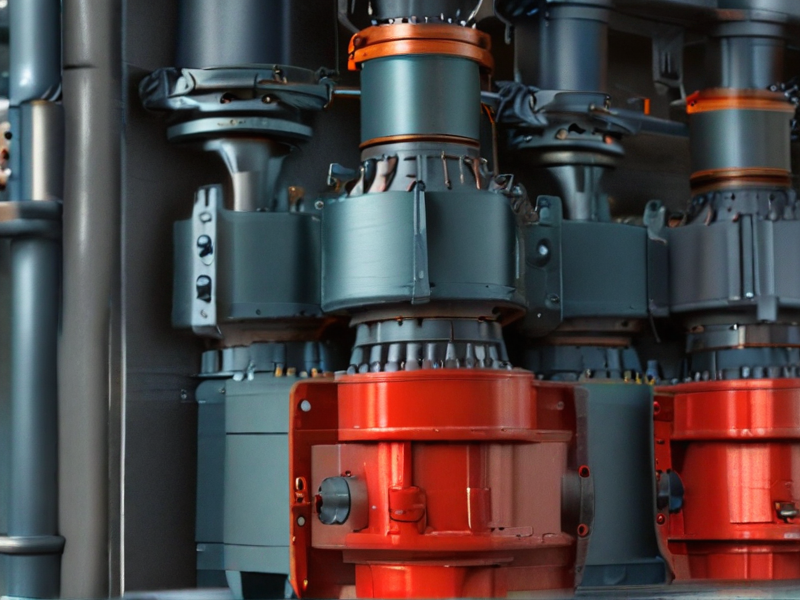

Another essential part is the grinding roller, made from heat-treated alloy steel. This material ensures the necessary hardness and toughness to endure the milling process, delivering consistent and reliable performance. The roller’s design also helps in the uniform distribution of grinding pressures, enhancing overall efficiency.

The separator blades form an equally important component, typically manufactured from ceramic or alloy steel. These blades play a pivotal role in separating fines from coarse particles during processing. Their high resistance to abrasion ensures longer operational life and minimal maintenance.

SourcifyChina also supplies mill liners made from rubber or composite materials. Liners protect the mill’s internal parts from wear and tear, adding to the equipment’s overall longevity. Their tailored fit ensures optimal performance and easy installation, reducing downtime.

In conclusion, SourcifyChina’s selection of vertical mill parts crafted from advanced materials ensures durability, efficiency, and cost-effectiveness. From wear plates to grinding rollers and separators, each component is designed to provide superior performance while minimizing maintenance and operational costs.

SourcifyChina adheres to stringent quality control standards in its vertical mill parts manufacturing process. Each component undergoes thorough inspection throughout production to ensure compliance with exact specifications and superior performance.

Raw materials procurement is a crucial stage where only certified suppliers are engaged. These materials undergo rigorous testing to verify their chemical and mechanical properties before they are approved for production, ensuring the foundation of high-quality components.

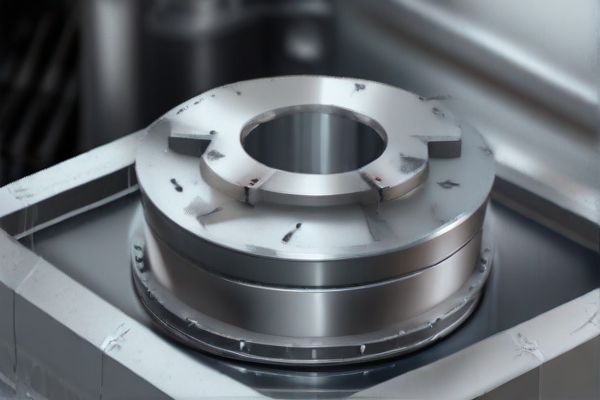

During machining, advanced CNC equipment is utilized to achieve high precision and consistency. Each machined part is meticulously measured and inspected using state-of-the-art metrology tools to ensure dimensional accuracy and tolerance adherence.

In the assembly phase, only parts that have passed previous inspections are put together. This assembly process is monitored by skilled technicians who follow standardized procedures to maintain alignment, fit, and function precision.

Final inspection encompasses comprehensive functional and performance tests for each assembled vertical mill. This includes load testing and operational simulation under real-world conditions to verify reliability and durability before the product is cleared for shipping.

The quality control does not end at production. SourcifyChina implements a feedback loop with their clients to continually monitor the performance of their vertical mill parts. This data is analyzed for continuous improvement in both product and process standards, ensuring they always meet or exceed client expectations.

SourcifyChina is a trusted supplier specializing in the components of vertical mills, delivering unmatched quality and reliability. Their product range includes everything from grinding rollers to gearing systems, ensuring seamless operations in a variety of industrial applications.

Their grinding rollers are designed for durability and precision, providing consistent performance under high-pressure conditions. This results in efficient material processing and reduced maintenance costs.

Moreover, SourcifyChina offers state-of-the-art hydraulic systems that enhance the overall efficiency of vertical mills. These hydraulic systems are engineered for optimal force distribution, thus improving operational stability and longevity.

Additionally, SourcifyChina provides robust gearing systems tailored to the specific needs of vertical mills. These gears are crafted from high-quality materials, ensuring they withstand heavy loads and extreme conditions.

Another noteworthy aspect is their customizable wear parts, which cater to the unique demands of different milling processes. This flexibility allows for longer service life and minimized operational downtimes.

SourcifyChina’s commitment extends beyond just supplying parts; they also offer comprehensive after-sales services. Their expert team is dedicated to providing prompt support and maintenance, assuring peak performance and satisfaction.

In summary, SourcifyChina excels in providing high-quality components for vertical mills, including durable grinding rollers, advanced hydraulic systems, robust gears, and customizable wear parts. Their comprehensive after-sales support further solidifies their position as a dependable partner in the industry.

Vertical mills offer numerous benefits in various industrial applications due to their structural design and component functionalities. They provide efficient material removal and precision.

Key

Benefits of Vertical Mill Parts:

– Spindle and Cutting Tools:

– Achieve high precision and fine surface finishes.

– Enable complex cutting and shaping.

– Support versatile tooling options.

– Motor Drive System:

– High torque output ensures efficient cutting.

– Variable speed control improves adaptability.

– Enhanced energy efficiency reduces operational costs.

– Column and Base:

– Provide stability and ensure accuracy.

– Support heavy loads and maintain alignment.

– Vibration dampening minimizes machining errors.

– Table:

– Adjustable for multi-directional movement.

– Facilitates machining of large and irregular pieces.

– Integrated with coolant systems for improved tool longevity.

– Control System:

– Automation and CNC capabilities enhance productivity.

– User-friendly interfaces simplify operations.

– Real-time monitoring improves quality control.

– Coolant System:

– Reduces heat generation during cutting.

– Prolongs tool lifespan and maintains workpiece quality.

– Minimizes wear and tear on machine parts.

By utilizing these parts, vertical mills enhance operational efficiency and provide precise, reliable performance across various machining tasks.

A vertical mill is an essential machine tool in modern machining, used for precise cutting, drilling, and shaping of materials. Key features and components include:

– Spindle: The rotating axis that holds and drives the cutting tool.

– Table: The surface where the workpiece is clamped, adjustable in X and Y directions.

– Knee: Supports the table and allows vertical movement.

– Column: The mainframe, providing structural stability and rigidity.

– Power Feed: Automates table movements for consistent cutting.

– Quill: Vertical spindle movement mechanism for drilling and boring.

– Base: Foundation of the mill, ensuring overall stability.

– Coolant System: Provides lubrication and cooling to the cutting area.

SourcifyChina specializes in custom parts for vertical mills, ensuring top-notch quality and precision. Our offerings include various components such as grinding rollers, tables, and liners, tailored to meet specific industry requirements. Each part undergoes rigorous testing to guarantee durability and performance.

Our custom products are designed to enhance the operational efficiency of vertical mills. Whether you need replacement parts or specialized components, our expertly crafted solutions minimize downtime and maximize productivity. Every piece is engineered with precision, reflecting our commitment to excellence in the manufacturing sector.

For unique projects, SourcifyChina partners closely with clients, understanding their precise needs. This collaboration results in bespoke vertical mill components that fit seamlessly into existing setups. Our ability to adapt to diverse project requirements makes us a go-to provider for specialized manufacturing solutions.

In addition to quality, we emphasize sustainability and innovation in our production processes. Our advanced technology ensures that each product not only meets but exceeds industry standards. Clients can rely on us for environmentally friendly solutions, which also contribute to longer equipment life and reduced operational costs.

Ultimately, SourcifyChina is dedicated to delivering excellence in custom vertical mill components. We combine quality, precision, and customer-focused service to meet and exceed expectations. Partner with us for reliable, efficient, and tailored solutions for all your vertical milling needs.

SourcifyChina is a dynamic and industry-leading company dedicated to the supply and sourcing of high-quality parts for vertical mills, which are integral to the manufacturing and heavy industries. Leveraging its extensive network of reliable suppliers across China, the company ensures that every component, from grinding rollers to gearboxes, meets stringent quality standards and client specifications. SourcifyChina’s commitment to excellence is reflected in its meticulous quality control processes and its ability to provide bespoke solutions tailored to the unique needs of each client. With a reputation built on reliability, cost-efficiency, and unparalleled customer service, SourcifyChina has become the go-to partner for businesses seeking dependable parts for vertical mills. The company’s deep understanding of the manufacturing landscape, combined with its innovative approach to supply chain management, positions it at the forefront of the industry, ensuring that clients receive not only the best products but also the best value.

The Aerospace, Defense, and Marine industries rely heavily on the precision and versatility of vertical milling machines to fabricate critical components. In aerospace applications, vertical mills are essential for creating complex parts like turbine blades, engine components, and structural frameworks. These machines offer unparalleled precision, essential for meeting the stringent tolerances and safety standards required in the aerospace sector. The ability to machine various materials, from aluminum to high-strength alloys, makes vertical milling indispensable in the production of lightweight yet robust aerospace parts. Additionally, vertical mills’ adaptability allows for rapid prototyping and customization, which is vital for the iterative design processes common in aerospace engineering.

In the Defense and Marine sectors, vertical milling machines are equally crucial. Defense applications benefit from the vertical mill’s ability to produce intricate parts for weapons systems, armored vehicles, and communication equipment. The high precision of vertical mills is vital for ensuring the reliability and durability of defense components, which often operate in extreme environments and under severe stress. For marine applications, vertical mills facilitate the fabrication of critical components such as propeller shafts, engine parts, and various fittings exposed to harsh marine conditions. The robust design and precision machining of these mills ensure the longevity and performance of marine vessels, contributing significantly to safety and operational efficiency. The versatility of vertical milling machines thus makes them indispensable across these high-stakes industries, where precise, reliable, and durable components are paramount.

Parts of a vertical mill, such as the spindle, bed, and cutting tools, play a crucial role in automotive manufacturing. The spindle, driven by a powerful motor, rotates the cutting tool with high precision, enabling the creation of intricate engine components, transmission parts, and chassis elements. This precision is paramount in the automotive industry, where even minor deviations can affect vehicle performance and safety. The bed or table provides a stable surface for securing workpieces, facilitating consistent and accurate material removal. Cutting tools, which can be customized to handle different materials and geometries, ensure the efficient machining of metals and alloys used in producing robust and reliable automotive parts. Vertical mills enhance production speed and maintain tight tolerances, contributing to the high standards required in modern automotive manufacturing.

In the electronics industry, vertical mills are instrumental in fabricating enclosures and housings for various devices, including smartphones, laptops, and other consumer electronics. The precise nature of milling allows for the creation of complex features such as heatsinks, ports, and mounting points that are integral to the functionality and durability of electronic devices. The spindle’s excellent control over cutting actions ensures clean edges and precise dimensions, crucial for fitting electronic components snugly. The stable bed allows for accurate positioning of workpieces, critical for producing parts that fit well and perform reliably. Additionally, customized cutting tools cater to the diverse materials used in electronics, from lightweight aluminum to robust plastics, ensuring optimal material handling and finish quality. This precision manufacturing capability supports the constantly evolving demands of the electronics industry, which requires smaller, more efficient, and ever more sophisticated components.

Vertical mills are essential in the construction industry for processing raw materials used in building infrastructure. These mills break down large chunks of materials such as limestone, granite, and other aggregates into finer particles, which can then be used to produce concrete, asphalt, and other construction materials. Key components of a vertical mill include the grinding rollers, grinding table, and hydraulic system. The grinding rollers, which are mounted on a spinning vertical axis, work in conjunction with the grinding table to pulverize materials. The hydraulic system ensures consistent pressure and controls the movement of the rollers, optimizing the efficiency and output of the milling process. By producing fine, consistent material particles, vertical mills contribute significantly to creating high-quality construction products, ensuring the durability and longevity of buildings and infrastructure.

In the energy sector, vertical mills play a crucial role in processing materials for power generation, especially in coal-fired and biomass power plants. Within these settings, parts of a vertical mill such as the classifier, separator, and grinding rollers are pivotal. Coal or biomass is fed into the mill where the grinding rollers and table pulverize it into a fine powder. The classifier and separator then ensure that only the finest particles pass through to the burners, enhancing combustion efficiency and reducing emissions. Additionally, the control systems of vertical mills enable precise adjustments to the milling process, optimizing fuel usage and minimizing waste. This efficiency not only improves the overall performance of the power plant but also supports efforts toward cleaner energy production. As energy needs continue to rise, the role of vertical mills in transforming raw, combustible materials into efficient energy sources becomes increasingly significant.

The industrial equipment industry leverages the parts of a vertical mill to enhance the efficiency, precision, and durability of various manufacturing processes. A vertical mill, comprising components such as the spindle, bed, column, and the cutting tools, is pivotal for machining tasks that require exceptional accuracy and consistency. The spindle, which holds and rotates the cutting tool, enables intricate cutting, drilling, and milling operations. The bed and column provide the necessary stability and support to withstand high operational loads and vibrations, ensuring that parts are machined to exact specifications. By utilizing these components, manufacturers in industries such as aerospace, automotive, and heavy machinery achieve finer tolerances and smoother surface finishes, ultimately improving product quality and performance.

In addition, the versatility of a vertical mill’s parts allows for a wide array of applications in the industrial sector, from prototyping to large-scale production runs. The interchangeable cutting tools affixed to the spindle can be adapted to handle diverse materials, including metals, plastics, and composites. The precision control offered by components such as the digital readout systems and programmable logic controllers (PLCs) enable automated and repeatable operations, reducing human error and downtime. This adaptability and reliability make vertical mills essential for industries aiming to optimize their fabrication processes, enhance operational efficiency, and stay competitive in an increasingly demanding market. The deployment of vertical mill parts in the production line, therefore, acts as a catalyst for innovation and productivity in various facets of industrial manufacturing.

Vertical mills, widely recognized in industrial manufacturing for their efficiency and precision, offer significant utility in the medical devices sector through their diverse applications. The spindle, one of the key parts of a vertical mill, provides the power and motion necessary for precise cutting, grinding, and shaping of medical device components. This precision is critical when producing complex, high-quality parts such as orthopedic implants, dental prosthetics, and surgical instruments. The spindle’s ability to operate at varying speeds ensures that different materials, including biocompatible metals and polymers, can be processed with high accuracy and minimal risk of defects, thus ensuring the reliability and safety required in medical applications.

Another crucial component, the bed of the vertical mill, provides the stability and support necessary for achieving high levels of precision during the manufacturing process. It allows for secure clamping of workpieces, reducing vibrations and ensuring consistent results. For instance, in the fabrication of delicate cardiac stents, the bed facilitates meticulous tolerances and surface finishes essential for the device’s performance and patient safety. Moreover, the versatility and adaptability of vertical mills allow for rapid prototyping and customization, critical in developing tailor-made medical solutions for individual patients. Overall, the integration of vertical milling technology in the production of medical devices enhances the quality, precision, and reliability of medical products, contributing to better patient outcomes and advancing the field of medical technology.

A vertical mill, an indispensable tool in machining and manufacturing, boasts a spindle that is vertically oriented, allowing for precision in milling applications. Key components of a vertical mill include the table, spindle, column, base, knee, and quill. These components facilitate the accurate cutting, drilling, and shaping of materials such as metal and plastic. The table, which moves both horizontally and vertically, provides a stable platform to secure workpieces using various fixturing methods. The spindle, housing the cutting tool, ensures that the cutter is held tightly and rotated accurately to perform the necessary operations. The quill allows for vertical movements of the spindle, providing the depth control needed for detailed work.

In manufacturing, vertical mills are celebrated for their versatility and precision, making them essential for creating complex parts in industries ranging from aerospace to automotive. For instance, the milling process can produce parts like gears, brackets, and engine components, all requiring tight tolerances and intricate designs. Operators can utilize the knee’s vertical adjustment to position the table at precise heights, aligning the workpiece correctly relative to the cutting tool. The vertical mill’s ability to execute a variety of cuts—face milling, slotting, and drilling—enhances its functionality, making it a cost-effective solution for both prototyping and production-level machining. The interplay of the column and base adds to the machine’s rigidity, ensuring stability even during high-intensity operations, thereby maintaining the integrity of the manufactured parts.

FAQ for Manufacturing Parts of a Vertical Mill Quality Work from SourcifyChina Factory

1. What types of vertical mill parts do you manufacture?

We specialize in producing high-quality components for vertical mills, including grinding rollers, crusher hammers, wear-resistant liners, roller tires, grinding tables, and other key elements essential for mill operation.

2. How do you ensure the quality of vertical mill parts?

We adhere to rigorous quality control protocols at every stage of production. Our process includes material selection, precision machining, heat treatment, and thorough inspection. We are ISO 9001 certified, which guarantees our commitment to quality standards.

3. Can you provide custom parts based on specific requirements?

Yes, SourcifyChina is fully equipped to design and manufacture custom parts that meet your specific requirements. Our engineering team works closely with clients to create bespoke solutions that ensure optimal performance and longevity.

4. What materials do you use to manufacture vertical mill parts?

We work with a range of high-grade materials, including alloy steel, manganese steel, and high-chromium iron, tailored to ensure durability and resistance to wear and tear, depending on the application.

5. What is your typical production timeline?

Production timelines can vary based on the complexity and volume of the order. Typically, our lead time ranges from 4 to 8 weeks. We strive to provide realistic delivery schedules and keep clients informed throughout the production process.

6. Do you offer after-sales support?

Absolutely. SourcifyChina provides comprehensive after-sales support, including part installation guidance, troubleshooting, and maintenance advice to ensure your mill runs efficiently for years to come.

7. How do you handle international shipping and logistics?

We have extensive experience in international logistics and can manage the entire supply chain, from production to delivery. We collaborate with reputable shipping companies to ensure parts reach you safely and on time.

8. Can I get a sample before placing a bulk order?

Yes, we can provide samples for your evaluation. This allows you to inspect the quality and compatibility of our parts with your equipment before committing to a larger order.

9. What are your payment terms?

We offer flexible payment options, including T/T, L/C, and other arrangements that best suit your needs. Specific terms will be discussed and agreed upon during the quotation process.

10. How do I get a quote for my order?

When sourcing parts of a vertical mill from SourcifyChina factory, here are key tips to ensure successful procurement:

1. Research Thoroughly: Understand the specific parts you need (e.g., spindle, column, knee, saddle, table, ram). This clarity helps in accurate communication with the factory.

2. Quality Assurance: Verify the factory’s quality management systems. Ensure they have certifications like ISO 9001, which signals commitment to quality standards.

3. Samples and Prototypes: Request samples or prototypes before full-scale production. This will help you assess the quality and suitability of the parts.

4. Material Specifications: Clearly outline the materials needed for the parts. This includes grades of metal or other materials, as the right material is crucial for the durability and performance of mill parts.

5. Customization and Tolerance: Confirm the factory’s capability to meet your customization needs and tight tolerances. Detailed engineering drawings should be provided to avoid any miscommunication.

6. Production Capacity and Lead Time: Ensure the factory can handle your order volume within required timelines. This is particularly important if you’re working with specific project deadlines.

7. Factory Visits: If possible, visit the factory. This helps build a rapport and enables firsthand verification of their capabilities and facilities.

8. Communication: Maintain clear and consistent communication. Use precise technical language and, if necessary, employ translators to bridge any language barriers.

9. Pricing and Payment Terms: Discuss and negotiate pricing, but don’t compromise on quality. Clarify payment terms and be wary of terms that seem too good to be true.

10. Logistics and Shipping: Plan for logistics including packaging, shipping, and import regulations. Discuss these details with the factory to ensure smooth delivery.

By following these tips, you can improve the efficiency and reliability of sourcing vertical mill parts from SourcifyChina factory.

Sure, here are some FAQs with answers for sourcing parts of a vertical mill from SourcifyChina factory:

1. What parts can SourcifyChina provide for a vertical mill?

SourcifyChina offers a comprehensive range of parts for vertical mills, including spindle heads, gearboxes, pulleys, motors, control panels, bearings, and bed plates. They also supply custom-machined components tailored to specific requirements.

2. How can I place an order with SourcifyChina for vertical mill parts?

You can place an order by contacting SourcifyChina through their official website, email, or phone. A sales representative will assist you in submitting your order requirements, providing specifications, and completing the purchasing process.

3. What is the lead time for receiving parts from SourcifyChina?

The lead time for delivery depends on the complexity and quantity of the order. Typically, standard parts may take 4-6 weeks, while custom parts could take 8-12 weeks to manufacture and deliver.

4. Does SourcifyChina provide quality assurance for the parts?

Yes, SourcifyChina follows strict quality control processes, including material inspection, precision testing, and final inspections, to ensure that all parts meet industry standards and customer specifications.

5. Are there any minimum order quantities (MOQ) for vertical mill parts?

The MOQ varies depending on the part and material. It’s best to consult with a SourcifyChina representative to understand the specific MOQ for your desired items.

6. Can SourcifyChina assist with the design and engineering of custom parts?

Absolutely. SourcifyChina has a skilled engineering team that can collaborate with you on the design, prototyping, and manufacturing of custom vertical mill parts to ensure they fit your exact needs.

7. What payment methods does SourcifyChina accept?

SourcifyChina accepts various payment methods, including bank transfers (T/T), Letters of Credit (L/C), and sometimes PayPal or credit card payments, depending on the order size and customer agreement.

8. Does SourcifyChina offer shipping and logistics services?

Yes, SourcifyChina provides comprehensive shipping and logistics services, including options for sea freight, air freight, and express courier services, ensuring timely and secure delivery of your parts.

9. How can I track my order once it’s shipped?

When sourcing parts of a vertical mill from SourcifyChina factory, consider the following tips to ensure a seamless and efficient process:

1. Clearly Define Requirements: Specify the exact parts needed, including material specifications, dimensions, tolerances, and any quality standards (e.g., ISO, ASTM).

2. Research the Factory: Check the factory’s credentials, production capabilities, and track record. Look for reviews and ratings from other buyers and request samples to assess quality.

3. Use Detailed RFQs: Draft detailed Request for Quotations (RFQs) outlining all technical requirements, quantities, lead times, and preferred pricing structures to ensure accurate quotations.

4. Communication: Establish clear and consistent communication. Utilize platforms like Alibaba’s Trade Assurance or Made-in-China’s Inquiries System to protect transactions and maintain a communication log.

5. Request Certifications: Ask for necessary certifications and quality assurance documents such as ISO 9001, material test reports, and inspection certificates.

6. Factory Audits: If possible, conduct on-site or third-party factory audits to verify production facilities, quality control processes, and worker conditions.

7. Samples and Prototyping: Request samples or prototype parts before placing a mass order to verify the product’s quality and conformity to specifications.

8. Negotiate Terms: Negotiate favorable terms including payment, delivery schedules, and incoterms (e.g., FOB, CIF). Consider paying through secure methods like TT (Telegraphic Transfer) or LC (Letter of Credit).

9. Quality Control: Develop and share a quality control checklist. Consider third-party inspection services to perform pre-shipment inspections and ensure parts meet all specified criteria.

10. Logistics Planning: Coordinate with reliable shipping agencies and plan for customs clearance to avoid delays. Understand and plan for potential risks like tariffs and import regulations.

By adhering to these tips, you can effectively source high-quality vertical mill parts from SourcifyChina, ensuring a smooth procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.