Sure, here’s a precise and informative title for you:

Choosing SourcifyChina Factory for purchasing DC motor parts offers expertise, reliability, affordability, customization, and streamlined logistics. Located strategically, the factory promises quick turnarounds, quality assurance, and personalized service. Here’s why:

Expertise and Reliability: SourcifyChina boasts extensive experience in manufacturing DC motor parts. Their commitment to quality and reliability ensures you receive top-notch components that meet stringent standards.

Affordability with Quality: The factory provides competitively priced parts without compromising quality. Their optimized production processes and economies of scale allow for cost-effective solutions tailored to your budget.

Customization and Flexibility: No two projects are the same. SourcifyChina understands this and offers customization options to meet your specific requirements, ensuring each part fits seamlessly into your assembly.

Streamlined Logistics: SourcifyChina’s strategic location ensures expedited shipping and efficient logistics management. This minimizes lead times, ensuring your parts arrive when you need them, keeping your project on schedule.

Top-Notch Customer Service: With a dedicated support team, SourcifyChina offers exceptional customer service. From consultation to post-purchase support, they guide you through every step, ensuring a smooth purchasing experience.

Quality Assurance: Rigorous quality control processes are in place at SourcifyChina. Each component undergoes stringent testing to meet international standards, providing peace of mind and reliable performance.

In conclusion, choosing SourcifyChina Factory means opting for a blend of expert craftsmanship, affordability, and exceptional service. Their commitment to quality, customization, and timely delivery makes them an ideal partner for sourcing DC motor parts from China. With SourcifyChina, you can be assured of receiving excellent products tailored to your needs, supported by comprehensive customer service and efficient logistics.

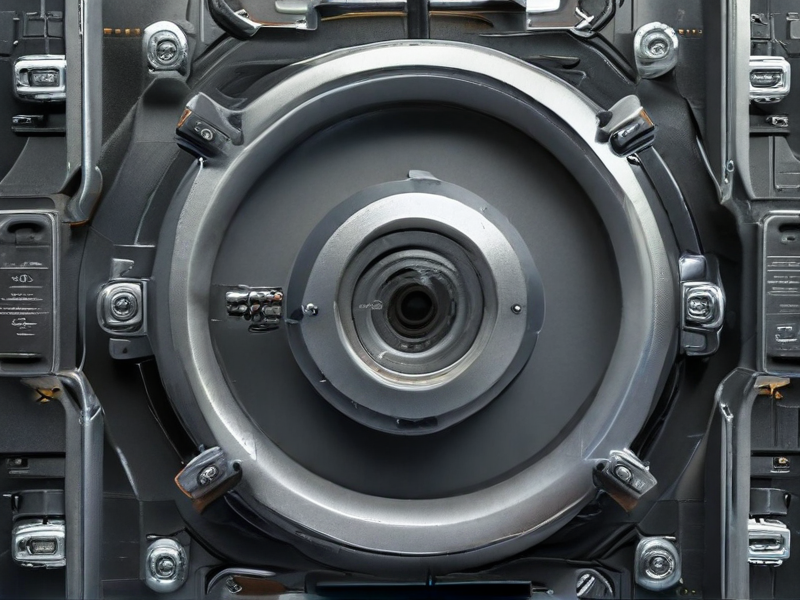

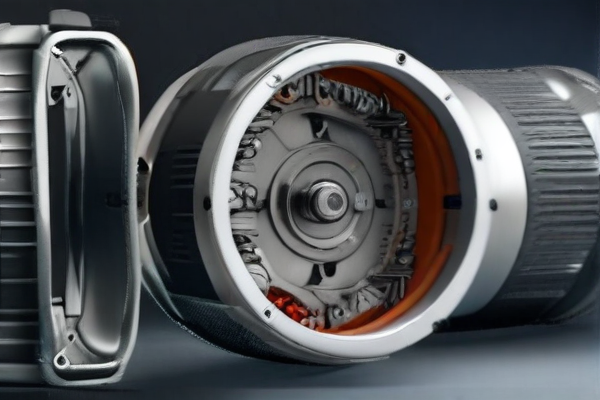

DC motors consist of several key components, each playing a crucial role in their function. The main parts include the stator, rotor, brushes, commutator, and bearings. These parts work together to convert electrical energy into mechanical motion.

– Stator: The stationary part providing magnetic field.

– Rotor (Armature): The rotating part that carries current.

– Brushes: Conduct electricity between stationary and rotating parts.

– Commutator: A switch that reverses current direction in the rotor.

– Bearings: Support the rotor and reduce friction.

– Shaft: Transfers mechanical power from the motor.

– Field Windings: Electromagnets that create a magnetic field in the stator.

– End Bells: Support the bearings and maintain motor alignment.

– Windings: Coils of wire that create a magnetic field when energized.

– Housing: Protects internal components and provides structure.

DC motors are integral in numerous applications, from household appliances to industrial machinery. Each part, such as the rotor, stator, commutator, and brushes, plays a critical role in ensuring efficient performance.

– Rotor: Essential for rotational motion, found in devices like power tools and fans.

– Stator: Provides magnetic fields, used in electric vehicles and robotics.

– Commutator: Facilitates current direction change, employed in cranes and vacuum cleaners.

– Brushes: Ensure electrical contact, crucial for mixers and sewing machines.

– Bearings: Reduce friction, utilized in conveyor belts and elevators.

– Shaft: Transfers mechanical power, used in pumps and winches.

– Armature: Core component for electromagnetism, found in electric bicycles and drones.

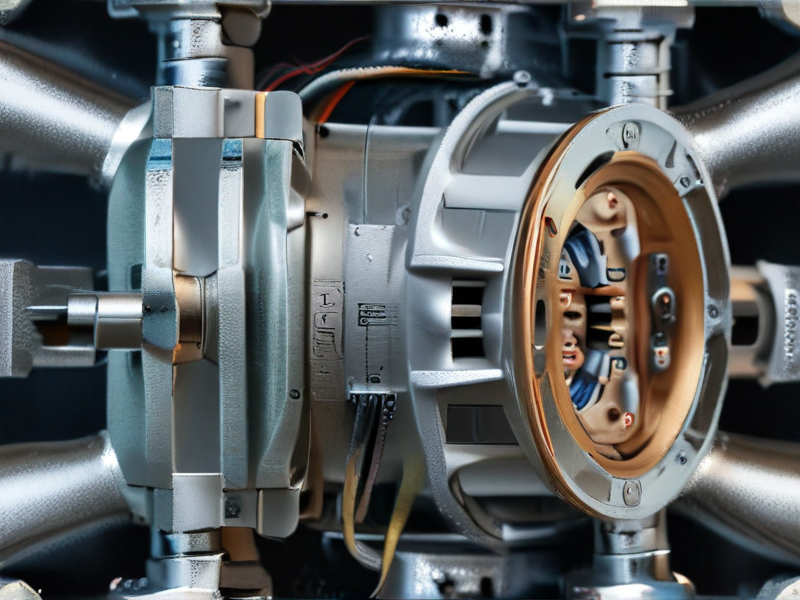

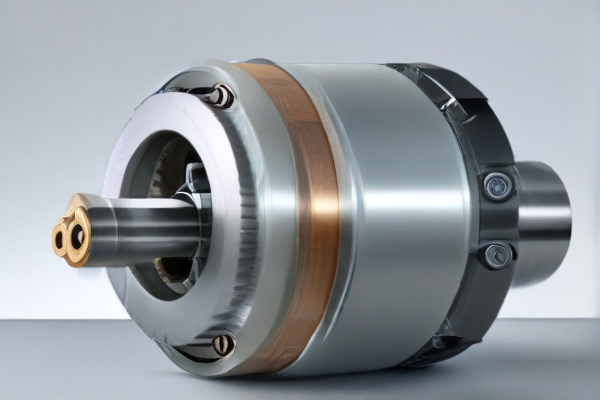

SourcifyChina provides a variety of materials for the parts of a DC motor, ensuring high quality and durability. The components include copper for windings, due to its excellent electrical conductivity. Steel or laminated silicon steel is often used for the stator and rotor cores, offering optimal magnetic performance.

The commutator is typically crafted from high-conductivity copper or brass, ensuring efficient current transfer. Insulation materials, such as mica or thermoplastic, are crucial for preventing electrical faults. The brushes, usually made of carbon or graphite, are designed for minimal wear and tear.

Bearings, often made of steel, ensure smooth rotational motion. Housing materials vary from high-strength aluminum alloys to thermoplastics, providing stable support and protection. Specialty coatings may be applied to enhance corrosion resistance and durability.

Maintaining consistent material quality across these components is vital for efficient motor performance. SourcifyChina’s rigorous material selection and quality control processes ensure that each part meets the necessary specifications. This leads to motors that are both reliable and long-lasting, a critical factor for various industrial applications.

SourcifyChina adopts a rigorous quality control manufacturing process for DC motor parts. Every component undergoes meticulous inspection to ensure compliance with industry standards and customer specifications. This begins with raw material verification to confirm their suitability and consistency.

Production stages are carefully monitored, with precision measurements taken at each step to maintain dimensional accuracy. Assembling the parts involves advanced machinery and skilled technicians, guaranteeing a high level of craftsmanship. Continuous training programs are in place to keep the workforce updated on the latest quality assurance practices.

Post-assembly, each DC motor is subjected to functional testing to verify performance metrics such as torque, speed, and efficiency. Any deviations from quality benchmarks trigger immediate corrective actions. Environmental tests simulate real-world conditions to validate the durability and reliability of the motors under various operating scenarios.

The final stage includes a thorough visual inspection and documentation review. Products that pass this rigorous screening are packaged under controlled conditions to prevent contamination and damage. This comprehensive approach ensures that SourcifyChina consistently delivers high-quality DC motor parts, meeting the stringent demands of a global clientele.

In addition to these processes, customer feedback is actively sought and analyzed for continuous improvement. This proactive approach allows SourcifyChina to identify potential quality issues and innovate to enhance product reliability. Ensuring customer satisfaction remains at the core of their quality control strategy.

SourcifyChina excels in producing high-precision core components for DC motors, such as rotors and stators. The company employs state-of-the-art manufacturing techniques to ensure peak reliability and performance.

For commutators and brushes, SourcifyChina uses top-grade materials to minimize electrical noise and optimize lifespan. Their stringent quality control ensures durability and consistent function under various operating conditions.

Bearings and shafts from SourcifyChina are crafted with precision to reduce friction and wear. This promotes efficiency and longevity, essential for high-performance applications where reliability is critical.

The company’s embedded sensors are engineered for accuracy, allowing for precise speed and torque control. These sensors are pivotal in advanced DC motor applications requiring exact measurements and adjustments.

In summary, SourcifyChina produces essential DC motor components that meet demanding performance and quality standards. Their expertise in materials and precision engineering ensures these parts contribute to the optimal functionality and longevity of DC motors.

A DC motor consists of several key parts, each contributing to its efficient operation and control. These components provide various benefits, enhancing the motor’s performance, durability, and reliability.

– Armature: Converts electrical energy into mechanical energy, ensuring smooth rotation and torque production.

– Commutator: Facilitates the switching of current direction, enabling continuous rotation and improved efficiency.

– Brushes: Conduct electrical current between the stationary and rotating parts, ensuring consistent energy transfer.

– Field Windings: Generate a magnetic field, which is crucial for motor operation and control.

– Shaft: Transfers mechanical power to the external load, maintaining smooth and stable motion.

– Bearings: Reduce friction between moving parts, extending motor lifespan and enhancing performance.

A DC motor converts electrical energy into mechanical motion using various integral components working harmoniously. Key parts include the stator, rotor, commutator, brushes, windings, and bearings.

– Stator: The stationary part that provides a constant magnetic field.

– Rotor (Armature): The rotating component that interacts with the stator’s magnetic field to produce motion.

– Commutator: Mounted on the rotor, it switches the direction of current to maintain rotation.

– Brushes: Conduct electric current between the stationary wires and the rotating armature.

– Windings: Coils of wire that generate a magnetic field when energized.

– Bearings: Facilitate the smooth rotation of the rotor by reducing friction.

These components collaboratively ensure efficient operation and direction of the motor’s movement.

SourcifyChina specializes in sourcing high-quality parts for DC motors, ensuring reliable performance for various industrial applications. Our extensive network of suppliers allows us to provide customized solutions tailored to your specific needs.

From armatures to brushes, each component is rigorously tested to meet stringent quality standards. Our focus is on delivering products that enhance the efficiency and longevity of your DC motors.

Whether you need a complete motor assembly or individual parts, SourcifyChina offers flexible options. We work closely with clients to understand their requirements and deliver solutions that meet or exceed expectations.

Custom projects are a significant part of our service offering. We collaborate with engineers and designers to create bespoke solutions that address unique challenges and specifications. Our expertise in DC motor parts ensures that every project we undertake is completed with precision and professionalism.

In summary, SourcifyChina is committed to providing top-notch DC motor parts and custom solutions. Partner with us for quality components and exceptional service, tailored to your specific project needs.

SourcifyChina is a prominent company specializing in the sourcing and supply of DC motor parts, catering primarily to a diverse array of industries requiring high-performance and reliable components. With its roots in the heart of China’s bustling manufacturing sector, SourcifyChina has established itself as a bridge between cutting-edge technology and practical engineering solutions. The company’s extensive catalog includes components like armatures, stators, brushes, and commutators, each meticulously tested to ensure adherence to rigorous quality standards. Leveraging strong relationships with top-tier manufacturers, SourcifyChina not only provides superior products but also offers customized solutions to meet the specific needs of its clients. Their dedication to quality is matched by a commitment to competitive pricing and timely delivery, making them a trusted partner in the global supply chain. Continuous innovation, comprehensive technical support, and an unwavering focus on customer satisfaction have propelled SourcifyChina to the forefront of the DC motor parts industry, ensuring that businesses worldwide can rely on them for efficiency and excellence in their motor applications.

Aerospace, Defense, and Marine sectors heavily rely on the components of DC motors to enhance the efficiency, reliability, and precision of various systems and machinery. In aerospace applications, DC motors are integral in actuating flight control surfaces, landing gear systems, and thrust vector control mechanisms. The importance of brushed or brushless DC motors in ensuring smooth and responsive control over aircraft actuators cannot be overstated. Their rotor and stator, commutator, brushes, and windings collectively enable precise manipulation of control surfaces, thereby contributing to the overall stability and maneuverability of an aircraft. Similarly, in the defense sector, DC motor components are employed in weapon systems, radar units, and unmanned vehicles. The compact size, reliability, and high torque-to-weight ratio offered by these motors make them ideal for the demanding and precise operation required in defense applications.

In marine environments, DC motors and their constituent parts are pivotal in the function and control of propulsion systems, winches, and automated navigation aids. The flexibility and durability of these motors allow ships and submarines to achieve meticulous control over speed and direction, even under the most challenging sea conditions. Additionally, the corrosion-resistant materials used in the brushes, armatures, and housings are tailored to withstand the harsh marine atmosphere. For example, in underwater drones or Remote Operated Vehicles (ROVs), DC motors provide the needed propulsion and control systems, enabling them to perform underwater exploration and maintenance tasks efficiently. Thus, the meticulous engineering of DC motor components ensures operational excellence across these high-stakes sectors, significantly contributing to advancements in technology and reliability.

DC motors play a crucial role in the automotive industry, particularly in applications requiring precise control of speed and torque. In electric and hybrid vehicles, DC motors drive propulsion systems, ensuring smooth acceleration and deceleration. Components such as the armature, commutator, and brushes are essential for converting electrical energy into mechanical energy efficiently. The armature, which rotates, interacts with the magnetic field generated by the stator to produce motion. The commutator and brushes work together to switch the current direction in the armature windings, maintaining continuous rotation. This precise control of motion is also utilized in automotive applications like power windows, windshield wipers, and seat adjustments, where reliable and consistent performance is paramount.

In the electronics sector, DC motors are integral to the operation of various devices, from household appliances to sophisticated industrial machinery. The versatility of DC motors allows them to be used in everything from small gadgets like electric toothbrushes and toys to more complex systems like computer fans and robotics. The stator’s permanent magnets or electromagnets create a magnetic field that interacts with the armature to produce rotational motion, which is critical for these applications. The commutator and brushes ensure the motor runs smoothly by continually reversing the current, providing the necessary torque and speed control. This functionality is essential for precise applications, such as in hard drives and optical drives, where the accurate positioning of components is crucial for performance and reliability. The robustness and efficiency of DC motors make them indispensable in both automotive and electronics applications, driving innovation and enhancing functionality across various devices and systems.

A DC motor, fundamental in many construction applications, is composed of essential parts such as the stator, rotor, commutator, brushes, and armature. In construction, particularly in power tools and machinery like drills, saws, and cranes, these components work synergistically to convert electrical energy into mechanical motion. The stator provides a stationary magnetic field, while the rotor rotates within it, attached to the output shaft of the motor. Brushes and commutator ensure current flows through the armature windings, creating a consistent, controllable torque which is vital for the varying demands of construction tasks. This reliable power conversion allows for precision and efficiency in cutting, drilling, lifting, and other operations critical to modern construction projects.

In energy applications, the functionality of DC motor components is harnessed in renewable energy technologies, such as wind and solar power systems. Within wind turbines, DC motors can act as generators; as the turbine blades rotate from wind energy, the rotor turns, and the commutator and brushes direct the electrical current generated. Similarly, in solar panels, DC motors help track the sun’s position to maximize energy capture by adjusting the panel angles. The efficiency of the DC motor’s design allows for optimal energy conversion and distribution, ensuring that generated power is effectively utilized or stored. These components’ seamless operation in energy applications underscores their versatility and critical role in advancing sustainable energy solutions.

The industrial equipment industry heavily relies on the functionality of DC motors due to their simplicity, efficiency, and precision control. DC motors are composed of various critical parts such as the stator, rotor (or armature), commutator, brushes, and field windings, each playing a pivotal role in converting electrical energy into mechanical motion. In applications like conveyor belts, cranes, and machining tools, the stator and field windings generate a steady magnetic field, while the rotor’s interaction with this magnetic field produces rotational motion. The brushes and commutator are essential for maintaining electrical contact with the rotating armature, ensuring consistent current flow and torque generation. This particular setup allows DC motors to offer variable speed control and high starting torque, making them indispensable in applications requiring precise motion control and heavy load handling.

Additionally, the reliability and maintenance simplicity of DC motors contribute significantly to their widespread use in industrial equipment. The commutator, though subject to wear and tear, is relatively easy to replace, ensuring minimal downtime during maintenance. Furthermore, the modular nature of DC motor components allows for straightforward customization and scalability, which is crucial for industrial machinery that must often be adapted to specific operational needs. For instance, in robotic arms used in assembly lines, the ability to finely tune the motor’s speed and torque is vital for maintaining production efficiency and precision. Also, industries like mining and steel production benefit from the robustness of DC motors, where harsh operational environments demand durable and reliable motor performance. Overall, the intricate design and dependable operation of DC motor parts make them a cornerstone of the industrial equipment sector.

Medical devices often incorporate parts of direct current (DC) motors due to their precision, reliability, and versatility. DC motors are critical in a variety of medical applications, particularly where exact movements and controlled speed are essential. For example, infusion pumps, which deliver precise amounts of medications to patients, frequently utilize DC motors. The rotor, stator, commutator, and brushes of the DC motor work in unison to ensure that the pump operates consistently, delivering medication at the required rate. This precision is indispensable in critical care scenarios, where misdosage can have severe consequences.

Additionally, components of DC motors are integral to the functioning of medical imaging devices, such as MRI and CT scanners, which demand meticulous control over movement to capture high-resolution images. The armature and electromagnets in DC motors contribute to the rapid and precise adjustments necessary for positioning imaging plates and scanning components. Moreover, surgical robots, which assist in minimally invasive procedures, rely on finely-tuned DC motors to perform accurate and delicate maneuvers. The continuous, smooth motion of these motors reduces the risk of tissue damage during surgery. Thus, DC motor parts are not just vital for ensuring the functioning of complex medical devices but are also integral to improving patient outcomes through enhanced precision and reliability.

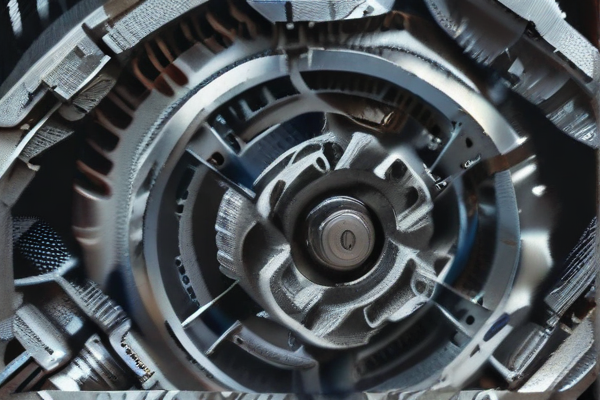

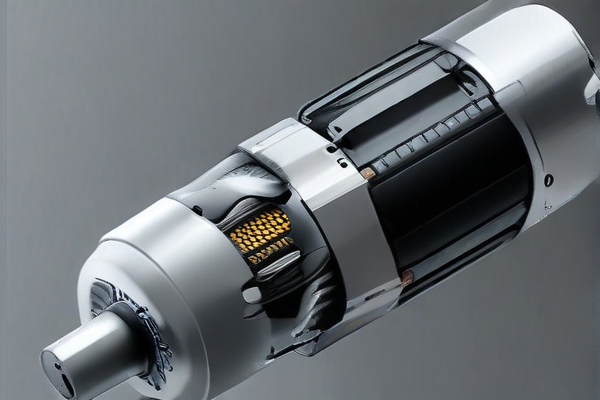

Machining and manufacturing of DC motor parts involve precision engineering to ensure the performance and longevity of the motor. Key components such as the armature, commutator, brushes, and bearings are meticulously crafted using advanced machining techniques. The armature, a rotating component, is typically made of laminated iron cores with precisely wound copper wire, requiring high accuracy to maintain balance and reduce energy loss. The commutator, which facilitates current flow to the armature, is manufactured with copper segments separated by insulation, demanding exact spacing and alignment to prevent short circuits and ensure smooth operation. Modern CNC (Computer Numerical Control) machines are often employed to achieve the tight tolerances required in these parts.

In the broader manufacturing process, the integration of these machined components into a functional DC motor involves assembly procedures that ensure proper alignment and fit. Quality control is critical, with each part undergoing rigorous testing to meet industry standards. The brushes, made from carbon or graphite, must maintain consistent contact with the commutator without causing excessive wear, highlighting the need for precise material selection and machining. Bearings, essential for reducing friction and wear on the rotating shaft, are machined to exact dimensions to support smooth and quiet motor operation. The entire process, from raw material to final assembly, leverages advancements in machining technology to produce efficient, reliable DC motors used in various applications, from household appliances to industrial machinery.

Sure, here is a concise FAQ tailored to the manufacturing of DC motor parts with quality work from SourcifyChina factory:

1. What types of DC motor parts do you manufacture?

We manufacture a wide range of DC motor parts including armatures, commutators, brushes, end caps, and permanent magnets.

2. What materials are used in the DC motor parts?

We use high-quality materials such as copper, steel, aluminum, and various alloys to ensure durability and reliability in the motor parts.

3. How do you ensure the quality of your motor parts?

We adhere to strict quality control processes, which include material inspection, dimensional checks, and performance testing to meet international standards.

4. Can you provide custom DC motor parts?

Yes, we offer customization services to meet specific requirements. Our engineering team can design and produce parts according to your specifications.

5. What is the lead time for producing custom parts?

Lead times vary depending on the complexity and quantity of the order but typically range from 4 to 8 weeks.

6. What quality certifications does SourcifyChina factory hold?

We are ISO 9001 certified, and all our manufacturing processes comply with international quality standards.

7. Do you provide prototypes before mass production?

Yes, we can provide prototypes for testing and validation before proceeding with mass production.

8. Can you supply documentation and compliance certificates for the motor parts?

Yes, we can supply the necessary documentation and compliance certificates upon request to meet your regulatory requirements.

9. What are the minimum order quantities (MOQ) for DC motor parts?

MOQ varies depending on the part, but we are flexible and can discuss terms to suit your needs.

10. How do you handle shipping and logistics?

We offer comprehensive shipping and logistics support, including international shipping options. Our goal is to ensure timely and safe delivery of your order.

This FAQ is structured to help you get a quick overview while remaining under 300 words.

When it comes to manufacturing parts of a DC motor, SourcifyChina Factory offers several advantages due to their advanced technology and expertise. Here are some useful tips for optimizing your experience with them:

1. Material Quality: Ensure that the factory uses high-quality materials such as copper for windings and durable magnets. Ask for material certifications to verify their standards.

2. Design Customization: Take advantage of SourcifyChina’s customization options. Provide precise specifications and CAD drawings to ensure parts meet your project requirements.

3. Sample Prototyping: Request samples before committing to large orders. This helps in verifying the quality and specifications of motor parts like armatures, commutators, and stators.

4. Communication: Maintain clear and regular communication. Use platforms like WeChat or email to discuss your needs in detail and ensure alignment.

5. Quality Control: Inquire about their quality control processes. Ensure they perform thorough testing on parts, including electrical and mechanical stress tests.

6. Lead Time: Understand their production lead times and plan accordingly. Factor in time for potential revisions if the initial samples need adjustments.

7. MOQ Negotiation: Discuss minimum order quantities (MOQs) and negotiate if necessary. This can be particularly important for startups or smaller businesses.

8. Logistics and Shipping: Work out logistics in advance. SourcifyChina can handle shipping, but confirm shipping costs, expected delivery times, and customs considerations.

9. Cost Efficiency: Compare prices without compromising on quality. Ask for a detailed breakdown to understand the cost structure.

10. Sustainability: If eco-friendliness is important to your company, inquire about their sustainable practices and whether they can provide RoHS-compliant materials.

By following these tips and leveraging SourcifyChina Factory’s strengths, you can achieve high-quality, cost-effective DC motor parts that are tailored to your specific needs.

Sure, here’s a list of frequently asked questions (FAQ) about sourcing parts of a DC motor from SourcifyChina factory:

Q: What types of DC motor parts can I source from SourcifyChina factory?

A: SourcifyChina offers a wide range of DC motor parts including armatures, brushes, commutators, bearings, end shields, and more. They can also customize parts based on specific requirements.

Q: How do I place an order for DC motor parts?

A: To place an order, you can contact their sales team via email or through their website’s contact form. Provide details such as part specifications, quantity, and any customization requests.

Q: What is the minimum order quantity (MOQ) for DC motor parts?

A: The MOQ varies depending on the part and its specifications. It’s best to contact SourcifyChina directly to get precise information for your specific order.

Q: Can I request samples before placing a bulk order?

A: Yes, SourcifyChina can provide samples. You can request a sample and will need to cover the sample cost and shipping charges.

Q: What is the lead time for manufacturing and delivery?

A: Lead times depend on the complexity of the parts and the order size. Typically, it ranges from 2 to 6 weeks for manufacturing, plus shipping time. For accurate lead times, it’s advisable to consult with their sales team.

Q: What are the payment terms available?

A: SourcifyChina usually offers multiple payment terms including T/T (bank transfer), L/C (letter of credit), and PayPal, depending on the order size and negotiation.

Q: Do you provide quality assurance and what is your return policy?

A: Yes, SourcifyChina provides a quality assurance guarantee. If parts are found to be defective, they offer returns or replacements based on their return policy, which can be discussed during order placement.

Q: Can I get custom packaging for my order?

A: Yes, custom packaging is available upon request. You can specify your packaging requirements when placing your order.

Q: What shipping methods are available for delivering the parts?

A: They offer various shipping methods including air freight, sea freight, and express delivery via DHL, FedEx, or UPS. The method depends on your preference and urgency.

Q: How can I track my order once it’s shipped?

When sourcing parts of a DC motor from SourcifyChina factory, follow these tips to ensure a smooth and efficient process:

1. Research and Verify Supplier: Start by researching SourcifyChina factory. Verify their credibility through reviews, references, and certifications such as ISO. A trustworthy supplier is crucial for quality parts.

2. Detailed Specifications: Clearly specify the parts needed, including dimensions, materials, tolerances, and performance requirements. Provide detailed drawings and technical data to avoid any ambiguity.

3. Request Samples: Before placing a large order, request samples of the parts. This helps in assessing the quality and compatibility with your requirements.

4. Communicate Clearly: Maintain clear and frequent communication with the supplier. Use diagrams and images to ensure both parties have a mutual understanding of the requirements.

5. Negotiate Terms: Negotiate payment terms, delivery schedules, and warranty conditions. Ensure all terms are documented in a contract to avoid misunderstandings.

6. Quality Assurance: Inquire about the supplier’s quality control processes. Consider third-party inspections to verify the quality of the parts before they are shipped.

7. Understand Logistics: Familiarize yourself with the logistics involved, including shipping methods, customs regulations, and potential import duties. Choose a reliable shipping partner to handle transportation.

8. Build a Relationship: Develop a good relationship with the supplier. This can lead to better communication, discounts, and priority treatment in future orders.

9. Risk Management: Have a contingency plan in case of delays or issues with the order. Diversify your supplier base to mitigate risks associated with relying on a single supplier.

10. After-Sales Support: Ensure the supplier offers after-sales support for issues like defects or part failures. This adds a layer of security and reliability to your sourcing process.

By following these steps, you can efficiently source high-quality DC motor parts from SourcifyChina factory, ensuring your projects are successful and your supply chain is reliable.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.