SourcifyChina Factory stands out as a premier choice for buyers sourcing phenolic sheet material from China. Their stringent quality control ensures the highest standards, providing durable and reliable products that meet international specifications.

Exceptional customer service sets SourcifyChina apart. Their dedicated team prioritizes client satisfaction through tailored solutions, consistent communication, and timely responses, providing a seamless purchasing experience that builds long-term relationships.

Competitive pricing is another advantage of selecting SourcifyChina Factory. They leverage strong, direct relationships with manufacturers to offer cost-effective rates without compromising on quality, making it easier for buyers to stay within budget and maximize value.

Quick and efficient delivery processes are a hallmark of SourcifyChina. They streamline logistics with well-established networks, ensuring that phenolic sheet materials are delivered promptly and reliably to clients worldwide, thus minimizing downtime and enhancing productivity.

In summary, SourcifyChina Factory is the ideal partner for purchasing phenolic sheet material. Their commitment to quality, exceptional customer service, competitive pricing, and efficient delivery processes make them a trustworthy and reliable choice in the international market.

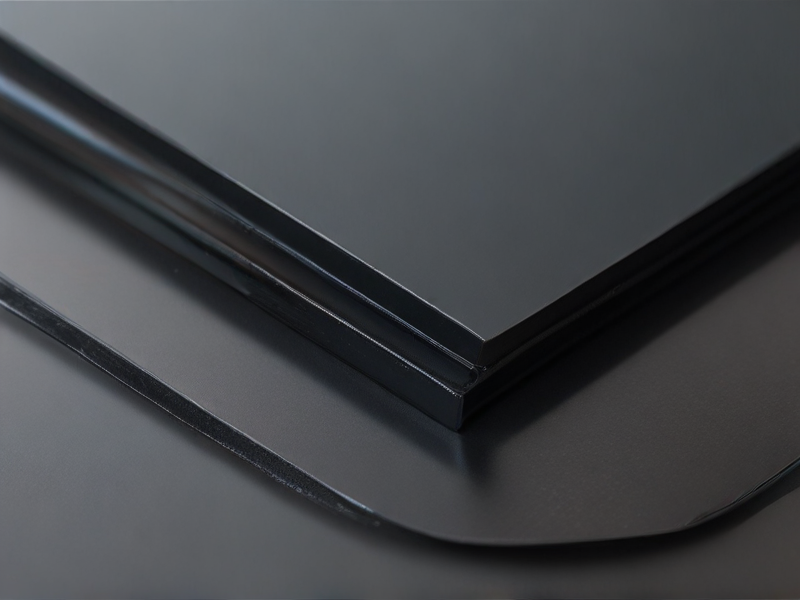

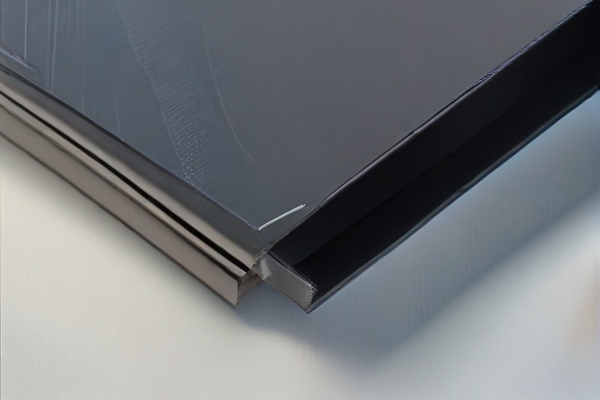

Phenolic sheet material is a versatile, durable, and heat-resistant composite used in various industries. It is made by impregnating layers of paper or fabric with phenolic resin and then applying heat and pressure to form rigid sheets.

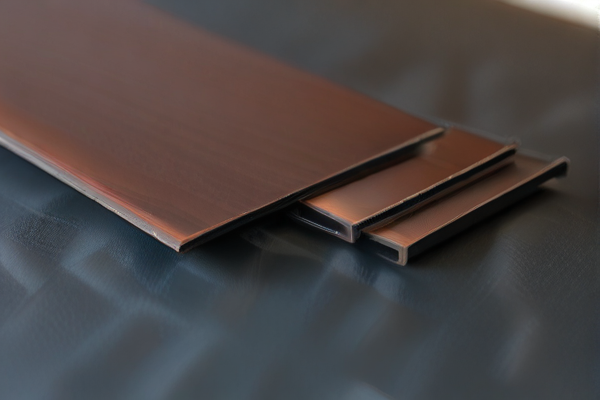

Options for phenolic sheet material include:

– Paper-based phenolic sheets: Lightweight and cost-effective options primarily used in electrical insulation and structural components.

– Fabric-based phenolic sheets: Enhanced mechanical strength and toughness, suitable for wear-resistant parts and mechanical components.

– Carbon-filled phenolic sheets: Increased rigidity and thermal properties, ideal for high-performance applications.

– Glass cloth-based phenolic sheets: Excellent dielectric properties and dimensional stability, used in electrical and high-temperature environments.

– High-pressure laminate (HPL) phenolic sheets: Decorative and robust surfaces for furniture, wall panels, and worktops.

– Low smoke emission phenolic sheets: Suitable for transport and public spaces due to safety and fire resistance.

These options cater to applications requiring specific mechanical, thermal, and electrical properties in industries like aerospace, automotive, marine, and construction, ensuring optimal performance and longevity.

Phenolic sheet material is invaluable in various industries due to its robustness, thermal resistance, and electrical insulating properties. Here are some applications:

– Electrical Insulation: Excellent for insulating electrical components and preventing short circuits.

– Construction: Used in countertops, laminates, and flooring due to its durability.

– Automotive: Utilized for gaskets, brake pads, and clutches for heat resistance.

– Aerospace: Suitable for aircraft interiors and structural components.

– Marine: Ideal for boat parts, thanks to its moisture resistance.

– Industrial Machinery: Applied in machine parts and gears for its wear resistance.

– Medical Equipment: Serves as a stable and sterilizable base for medical devices.

– Signage: Used in durable outdoor signs and display boards.

– Railway: Employed in train interiors and electrical insulators.

– Furniture: Forms robust, attractive surfaces for tables and cabinetry.

By leveraging the unique properties of phenolic sheet material, industries can enhance the durability, safety, and performance of a wide array of products.

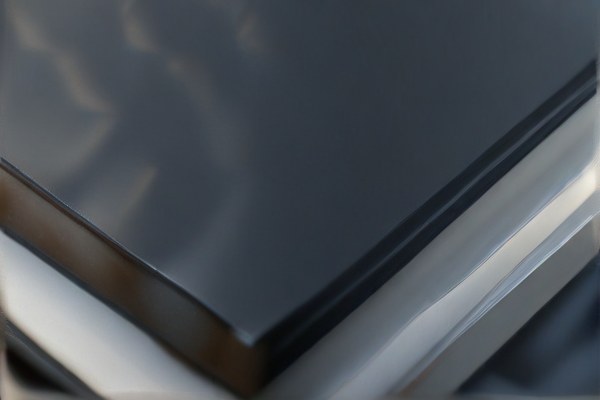

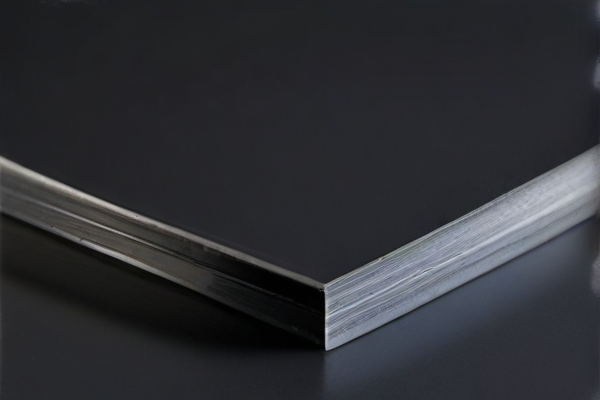

SourcifyChina offers high-quality phenolic sheet material renowned for its durability and reliability. These sheets are made from phenolic resin and reinforced with layers of fiberglass, providing exceptional strength and stiffness. Phenolic sheets are widely used in various industries due to their excellent mechanical properties and resistance to chemicals, heat, and abrasion.

The outstanding features of phenolic sheets include their lightweight nature, which simplifies handling and installation. Moreover, these sheets exhibit high dielectric strength, making them suitable for electrical insulation applications. They are also flame retardant, ensuring safety in demanding environments.

Additionally, phenolic sheet material from SourcifyChina promises good machinability, allowing for easy cutting, drilling, and shaping to meet specific needs. Its smooth surface finish not only adds to its aesthetic appeal but also contributes to its resistance to moisture and corrosion. This versatility enables its application in aerospace, automotive, and electronic industries, among others.

Overall, SourcifyChina’s phenolic sheet material stands out due to its blend of strength, durability, and adaptability, catering to a wide range of industrial requirements. With its consistent quality and superior performance, it remains a preferred choice for engineers and manufacturers seeking reliable material solutions.

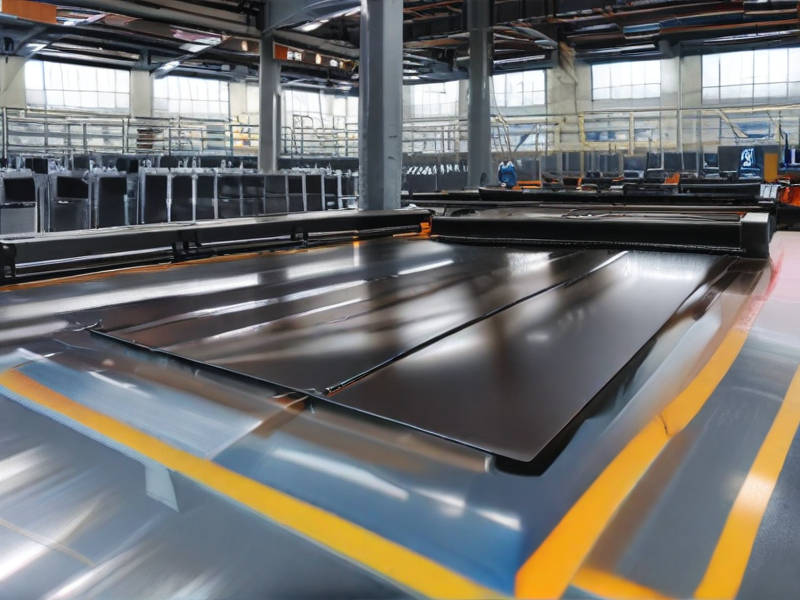

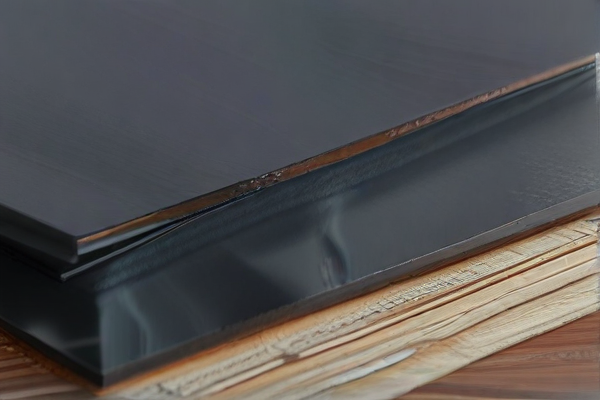

SourcifyChina’s phenolic sheet material undergoes stringent quality control measures to ensure top-notch quality and consistency. Advanced technology and strict protocols guide every step, from raw material inspection to final product packaging.

Raw materials are sourced from certified suppliers and rigorously inspected before production. Only materials meeting SourcifyChina’s stringent standards proceed to the next stage, ensuring integrity and performance.

During the manufacturing process, state-of-the-art machinery and precision techniques produce the phenolic sheets. Continuous monitoring ensures uniformity and adherence to design specifications, minimizing defects and errors.

Post-production, each phenolic sheet undergoes comprehensive testing. Mechanical strength, thermal resistance, and dimensional accuracy are scrutinized to meet industry benchmarks and client requirements.

The final inspection phase focuses on appearance and packaging integrity. Each sheet is carefully examined, and defective units are discarded. Packaging is designed to protect during transportation and storage, ensuring customers receive flawless products. By implementing meticulous quality control measures, SourcifyChina guarantees that their phenolic sheet materials are reliable and high-performing.

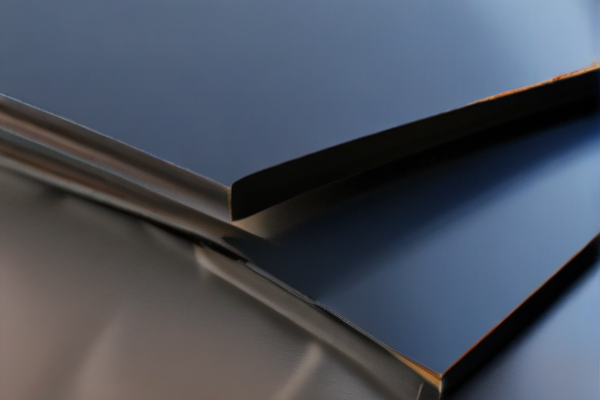

SourcifyChina’s phenolic sheet material stands out due to its exceptional durability and resistance to heat and chemicals. These properties make it ideal for demanding industrial environments.

Moreover, SourcifyChina ensures their phenolic sheets offer superior electrical insulation. This makes them perfect for applications in the electronics and electrical industries, delivering reliable performance consistently.

Their phenolic sheet material also boasts great mechanical strength, ensuring long-term stability and reducing maintenance costs. This ensures dependable performance even in the most challenging situations.

Another advantage of SourcifyChina’s phenolic sheets is their versatility. Available in various sizes and thicknesses, these sheets can be customized to meet specific project requirements.

Beyond functional benefits, these phenolic sheets adhere to high safety and environmental standards. SourcifyChina takes pride in providing materials that are not only effective but also environmentally responsible.

In summary, SourcifyChina’s phenolic sheet material exhibits exceptional heat and chemical resistance, superior electrical insulation, and remarkable mechanical strength. Their customizable options and commitment to safety and sustainability make them a reliable choice for various industrial applications.

Phenolic sheet material offers a multitude of benefits, making it a preferred choice in various industries due to its superior performance and versatility.

– High Strength and Durability: Phenolic sheets are known for their exceptional mechanical strength and long-lasting durability, making them suitable for heavy-duty applications.

– Thermal Resistance: These sheets can withstand extreme temperatures, both high and low, making them ideal for environments with harsh thermal conditions.

– Chemical Resistance: Phenolic sheets show excellent resistance to chemicals, oils, and solvents, ensuring longevity even in chemically aggressive environments.

– Electrical Insulation: With superb electrical insulating properties, phenolic sheets are widely used in the electrical and electronics industries.

– Low Moisture Absorption: Their low moisture absorption helps in maintaining structural integrity even in damp or wet conditions.

– Cost-Effective: Phenolic sheets offer a cost-effective solution by reducing maintenance costs and extending the life of the product.

– Lightweight: Despite their strength, these sheets are relatively lightweight, offering ease of handling and installation.

– Versatility: Phenolic sheets can be easily machined into various shapes and sizes, providing flexibility for different industrial applications.

– Flame Resistance: High flame resistance makes phenolic sheets safe for use in applications where fire hazards are a concern.

– Low Friction Surface: The smooth, low friction surface of phenolic sheets is beneficial in applications that require wear resistance and lower friction coefficients.

Phenolic sheet material’s combination of mechanical resilience, thermal and chemical stability, and versatile applicability positions it as an outstanding option for numerous industrial needs.

Phenolic sheet material, also known as phenolic laminate, is a versatile and robust composite engineered to meet various industrial needs.

Key features of phenolic sheet material:

– High Strength and Rigidity: Offers excellent mechanical properties, making it suitable for heavy-duty applications.

– Heat Resistance: Can withstand high temperatures without losing structural integrity, ideal for environments with thermal challenges.

– Electrical Insulation: Provides good electrical insulation, which is essential for electrical and electronic applications.

– Chemical Resistance: Resistant to a wide range of chemicals, ensuring durability in corrosive environments.

– Moisture Resistance: Minimizes absorption, making it suitable for humid or wet conditions.

– Dimensional Stability: Maintains shape and size under varying conditions.

– Flame Retardant: Some grades offer fire resistance, enhancing safety in critical applications.

– Easily Machinable: Can be easily cut, drilled, and shaped to meet specific design requirements.

– Good Surface Finish: Provides a smooth surface that can be enhanced with various coatings or finishes.

– Cost-Effective: Offers a balance of performance and cost, making it an economical choice for many industries.

Phenolic sheets are primarily used in electrical, automotive, aerospace, and construction sectors due to their multifunctional capabilities. They are essential materials for insulating electrical components, fabricating machine parts, and creating durable surfaces.

SourcifyChina offers an exceptional range of custom phenolic sheet material products, designed to meet the diverse needs of various industries. These sheets are known for their superior mechanical strength and outstanding chemical resistance, making them ideal for high-performance applications.

Their phenolic materials cater to industries like automotive, electrical, and aerospace, ensuring optimal performance under extreme conditions. Custom fabrication options guarantee a perfect fit for any project, delivering precision and reliability.

SourcifyChina’s expertise simplifies the procurement process. From prototype to mass production, their skilled team works closely with clients, ensuring projects are completed on time and within budget.

For businesses seeking durable and versatile materials, SourcifyChina’s phenolic sheets provide quality and customization. Their commitment to excellence ensures that every project meets exacting standards, fulfilling and exceeding expectations.

SourcifyChina, renowned for its innovative materials, specializes in phenolic sheet material, a staple in various industrial applications due to its exceptional mechanical properties and versatility. Headquartered in China, the company has established a robust supply chain and cutting-edge manufacturing facilities, ensuring that its phenolic sheets meet stringent quality standards. These sheets, known for their high heat resistance, excellent electrical insulating properties, and impressive dimensional stability, serve an array of sectors including aerospace, automotive, and electrical engineering. SourcifyChina’s commitment to sustainability and technological advancement is evident in their continuous investment in eco-friendly production processes and research and development. With a customer-centric approach, they offer tailored solutions to meet specific client needs, solidifying their reputation as a trustworthy partner in the global market. Their seamless blend of quality, innovation, and reliability underscores their position as a leader in the phenolic sheet material industry.

Phenolic sheet material, known for its exceptional mechanical strength, heat resistance, and electrical insulating properties, finds extensive applications in the aerospace, defense, and marine industries. In the aerospace sector, phenolic sheets are widely used for insulation and structural components within aircraft and spacecraft. They provide critical flame retardancy and thermal insulation, which are paramount in ensuring passenger safety and protecting sensitive equipment from extreme temperatures and potential fire hazards. Additionally, their lightweight nature contributes to overall weight reduction in aircraft, enhancing fuel efficiency and performance. The material’s robustness in harsh environments ensures longevity and reliability, making it indispensable for mission-critical aerospace applications.

In the defense sector, phenolic sheets are utilized in a variety of applications due to their superior mechanical properties and resistance to impact, heat, and chemicals. These attributes make them suitable for use in ballistic panels, protective gear, and vehicle armor, where they offer a lightweight yet formidable barrier against projectiles and shrapnel. Moreover, phenolic sheets serve as essential components in electronic enclosures and circuit boards, providing necessary insulation and ensuring the integrity of sensitive military electronics in combat situations. In marine applications, phenolic sheets are employed in the construction of submarines, boats, and other aquatic vessels. Their high resistance to moisture, saltwater, and corrosion makes them ideal for marine environments, where they are used for bulkheads, decks, and engine room components. The material’s durability ensures that it can withstand the rigors of prolonged exposure to harsh marine conditions, thus contributing to the vessel’s operational efficacy and lifespan.

Phenolic sheet materials, renowned for their high mechanical strength and excellent thermal and electrical insulating properties, find significant applications in the automotive industry. In automotive systems, these materials are integral components in the manufacturing of interior structures, engine parts, and electrical systems. Notably, phenolic sheets are used to produce brake pads, clutch discs, and transmission components due to their excellent wear resistance and ability to withstand high temperatures. Additionally, they are utilized in various insulating components within the vehicle’s electrical system, aiding in noise reduction and vibration damping. This enhances the overall durability and performance of the automotive systems, contributing to vehicle safety and longevity.

In the realm of electronics, phenolic sheet materials are equally valuable due to their robust insulating properties and resistance to moisture and chemicals. They serve as the base material for printed circuit boards (PCBs), which are foundational to almost all electronic devices. Phenolic sheets’ high dielectric strength ensures the reliable performance of electronic circuits, reducing the risk of short circuits and other electrical failures. Moreover, their fire-retardant properties make them ideal for use in consumer electronics and industrial applications where safety is a priority. These materials are also used in transformers, switches, and various other electronic components, underscoring their versatility and crucial role in the efficient functioning of modern electronic devices.

Phenolic sheet material, also known as phenolic laminate, is widely acclaimed in the construction industry for its exceptional properties. Engineered from layers of paper or fabric impregnated with phenolic resin, this composite offers unparalleled durability, high strength-to-weight ratio, and resistance to moisture and chemicals. Its non-conductive nature makes it particularly suitable for electrical insulation applications in building projects. Architects and builders frequently use phenolic sheets to construct wall panels, countertops, and flooring, as they are not only aesthetically pleasing but also meet stringent safety standards. The material’s inherent flame-retardant characteristics make it a preferred choice for ensuring fire safety in residential and commercial structures.

In the realm of energy applications, phenolic sheet material excels due to its thermal stability and insulating properties. It is extensively used in the manufacturing of components for wind turbines, transformers, and switchgear, where high mechanical strength coupled with electrical insulation is paramount. Moreover, the resistance to extreme temperatures and minimal thermal expansion of phenolic sheets make them ideal for solar panel mounting systems and other renewable energy technologies. By incorporating phenolic materials, energy systems not only enhance performance and durability but also achieve significant cost efficiency and longevity. This combination of robustness and multifunctional properties positions phenolic sheet material as a critical component in advancing modern construction and energy solutions.

Phenolic sheet material, known for its high strength, heat resistance, and excellent electrical insulation properties, is extensively used in the industrial equipment industry. These sheets are made from layers of paper or fabric impregnated with phenolic resin, cured under heat and pressure. This composition endows the material with durability and stability, making it ideal for demanding applications such as electrical insulators, gaskets, and high-wear components in machinery. Their ability to withstand harsh environments and maintain performance under high stress and temperature conditions ensures that phenolic sheets are reliable in heavy-duty industrial settings, reducing maintenance and downtime.

In addition to mechanical robustness, phenolic sheets offer significant advantages in terms of machinability and ease of fabrication. They can be precisely cut, drilled, and shaped to fit specific industrial requirements, enabling custom solutions for various equipment needs. This versatility allows for the creation of complex parts and assemblies, enhancing the efficiency and functionality of industrial machines. Furthermore, phenolic sheets are often used in the production of work surfaces and protective barriers due to their resistance to chemicals and abrasion. By integrating phenolic sheet materials, the industrial equipment industry benefits from increased operational efficiency, improved safety, and extended lifespan of machinery components.

Phenolic sheet material, known for its exceptional durability, thermal resistance, and low moisture absorption, plays a critical role in the manufacturing of various medical devices. Its inherent properties make it an ideal choice for equipment that requires precise, robust, and reliable performance under prolonged use. In medical environments, phenolic sheets are frequently used for fabricating surgical instrument trays, diagnostic equipment housings, and laboratory work surfaces. The material’s resistance to chemicals and easy-to-clean surface ensure that sterile conditions are maintained, which is crucial for patient safety and the prevention of infections.

Moreover, phenolic sheet material is utilized in the production of prosthetics and orthopedic supports due to its robust mechanical strength and lightweight nature. These characteristics facilitate the creation of comfortable, yet durable, components that can withstand significant wear and tear without compromising on patient comfort. Additionally, phenolic materials possess high dielectric strength, making them suitable for use in electrical insulation for diagnostic devices and machines, ensuring that precise and accurate readings are maintained. These versatile applications underscore the significant contribution of phenolic sheet materials to the advancement of modern medical technology and the enhancement of healthcare outcomes.

Phenolic sheet materials, also known as phenolic laminates, are widely utilized in machining and manufacturing applications due to their exceptional mechanical and electrical properties. These materials are fabricated by impregnating layers of paper, cotton fabric, or other substrates with phenolic resin, then applying heat and pressure to cure the resin into a dense, durable composite. In machining, phenolic sheets are prized for their excellent stability, low moisture absorption, and resistance to a wide range of chemicals and temperatures. These properties make them suitable for producing precision components such as electrical insulators, structural supports, and gears. The machinability of phenolic sheets allows for precise cutting, drilling, milling, and turning operations, enabling the creation of complex shapes and intricate parts without compromising material integrity or performance.

In the realm of manufacturing, phenolic sheet materials find applications across various industries including aerospace, automotive, and electronics due to their lightweight nature combined with high tensile strength. Their outstanding insulating properties make them indispensable in electrical and electronic manufacturing, where they are used to produce circuit boards, switchgear panels, and transformer components. Additionally, phenolic sheets serve as a reliable alternative to metal components in situations where reducing weight is crucial, helping to improve fuel efficiency in automotive and aerospace designs. Their resistance to wear and environmental degradation also makes them ideal for manufacturing jigs, fixtures, and assembly line components that undergo frequent use and exposure to harsh conditions. Overall, phenolic sheet materials stand out for their versatility, reliability, and performance, securing their place as essential materials in advanced manufacturing processes.

FAQ for Manufacturing Phenolic Sheet Material Quality Work from SourcifyChina Factory

1. What is phenolic sheet material?

Phenolic sheet material is a high-strength, heat-resistant laminate made by impregnating layers of paper or fabric with phenolic resin. It is widely used in electrical, mechanical, and industrial applications due to its durability and insulating properties.

2. Why choose SourcifyChina for phenolic sheet material?

SourcifyChina offers high-quality phenolic sheet materials with consistent quality control, competitive pricing, and timely delivery. Our state-of-the-art manufacturing processes ensure superior performance and reliability.

3. What quality standards do SourcifyChina’s phenolic sheets adhere to?

Our phenolic sheets meet international standards such as ISO, ASTM, and NEMA. We ensure that each product undergoes rigorous testing for mechanical strength, thermal resistance, and electrical insulation properties.

4. What are the typical applications of phenolic sheets?

Phenolic sheets are used in electrical insulation, aerospace, automotive, marine, and industrial machinery. They serve as insulators, structural components, and wear-resistant surfaces.

5. Can SourcifyChina customize phenolic sheets to specific requirements?

Yes, we offer customization services to meet specific dimensions, thicknesses, and other technical specifications. We work closely with clients to provide tailored solutions for their unique needs.

6. How does SourcifyChina ensure consistent quality?

We implement strict quality control measures throughout the manufacturing process, from raw material selection to final inspection. Our advanced testing equipment ensures each batch meets the highest standards.

7. What is the lead time for orders?

Lead times vary based on order size and customization requirements. Typically, standard orders are fulfilled within 2-4 weeks. We strive to accommodate urgent requests as well.

8. What is the minimum order quantity (MOQ) for phenolic sheets?

The MOQ depends on the specific product and customization needs. Generally, it ranges from 100 to 500 sheets. Contact us for detailed information on your specific requirements.

9. How can I place an order with SourcifyChina?

You can place an order by contacting our sales team through our website, email, or phone. Provide your specifications, and we will assist you with the ordering process and provide a detailed quote.

10. What after-sales support does SourcifyChina provide?

We offer comprehensive after-sales support, including technical assistance, product warranty, and prompt resolution of any issues. Our goal is to ensure complete customer satisfaction.

When considering phenolic sheet material manufacturing from SourcifyChina factory, here are some efficient tips to ensure a smooth and effective process:

1. Quality Assurance:

– Request detailed material specifications and certifications to ensure that the phenolic sheets meet international standards. Reliable factories like SourcifyChina should provide test reports, including mechanical properties and compliance with fire retardancy standards.

2. Customization Options:

– Ensure that SourcifyChina can accommodate customization needs, whether it’s specific sizes, thicknesses, or color requirements. Customization might also include surface finishes or added features like anti-static properties.

3. Sample Orders:

– Place a small sample order before committing to larger quantities. This allows you to assess the product’s quality firsthand and make any necessary adjustments to your specifications.

4. Lead Times and Production Capacity:

– Clarify lead times upfront to ensure they align with your project timelines. Discuss production capacity to confirm that SourcifyChina can handle your order volume within your needed time frame.

5. Communication:

– Maintain clear and consistent communication with SourcifyChina’s representatives. This helps in resolving any potential issues quickly and ensures that your specifications are well understood and implemented.

6. Packaging and Shipping:

– Discuss packaging options to protect the phenolic sheets during transit. Ensure that the materials are packed securely to prevent damage. Inquire about shipping methods and costs to select the most efficient and economical option.

7. Cost Management:

– Negotiate pricing terms directly, considering volume discounts and potential long-term partnership benefits. Factor in shipping costs and any import duties or taxes applicable to your region.

8. Sustainable Practices:

– Inquire about SourcifyChina’s sustainability practices. Ensure that the phenolic sheets are produced using environmentally friendly methods, which can be a significant selling point for your customers.

By focusing on these key areas, you can effectively manage the procurement of phenolic sheet materials from SourcifyChina factory, ensuring high-quality products and a streamlined supply chain.

FAQ for Sourcing Phenolic Sheet Material from SourcifyChina Factory

Q: What types of phenolic sheet materials does SourcifyChina offer?

A: SourcifyChina provides a variety of phenolic sheet materials including paper-based, fabric-based, and glass cloth-based phenolic laminates. Each type is designed for specific applications and performance requirements.

Q: Can SourcifyChina customize phenolic sheets according to specific requirements?

A: Yes, SourcifyChina offers customization options including different sizes, thicknesses, and properties to meet specific needs. Custom colors and finishes are also available upon request.

Q: What are the typical applications of phenolic sheet materials?

A: Phenolic sheets are widely used in electrical insulation, mechanical parts, and industrial applications due to their excellent thermal, mechanical, and electrical properties.

Q: What is the minimum order quantity (MOQ) for phenolic sheets from SourcifyChina?

A: The MOQ varies depending on the type and specifications of the phenolic sheet. It’s best to contact SourcifyChina directly for detailed information regarding order quantities.

Q: How long does it take to process and deliver an order?

A: Lead times depend on the order size and customization requirements. Generally, it takes about 2-4 weeks to process and deliver standard orders. Custom orders might take longer.

Q: What quality assurance measures does SourcifyChina implement?

A: SourcifyChina follows stringent quality control protocols, including ISO certification, to ensure all products meet international standards. Each batch undergoes rigorous testing for consistency and performance.

Q: Does SourcifyChina provide samples of phenolic sheet materials?

A: Yes, samples are available upon request. This allows customers to evaluate the material before making a bulk purchase.

Q: How can I get a quote for phenolic sheet materials?

A: To get a quote, contact SourcifyChina with your specific requirements including type, size, quantity, and any customization needs. They will provide a detailed quote based on your specifications.

Q: Are there any shipping options available for international orders?

A: SourcifyChina offers various shipping options, including air and sea freight, to accommodate international orders. Shipping costs and delivery times will depend on the destination and order size.

Sourcing phenolic sheet material from SourcifyChina factory can be streamlined with the following tips:

1. Define Specifications: Clearly outline the specific requirements for the phenolic sheet material, including dimensions, thickness, density, and any other relevant physical and chemical properties.

2. Quality Standards: Ensure that the material meets international standards such as ISO, ASTM, or any industry-specific requirements. Request quality certifications and test reports.

3. Supplier Verification: Conduct a thorough background check on SourcifyChina factory. Verify their manufacturing capabilities, previous client feedback, and industry reputation. Utilize platforms like Alibaba or Global Sources for additional reviews.

4. Samples and Prototyping: Request samples to evaluate the quality firsthand. This helps in confirming that the material meets your requirements before placing a large order.

5. Communication: Maintain clear and consistent communication with the supplier. Discuss all technical details, lead times, and delivery schedules to avoid any misunderstandings.

6. Negotiation: Negotiate terms including pricing, minimum order quantities, payment terms, and delivery schedules. Ensure that all agreements are documented.

7. Logistics and Shipping: Plan the logistics carefully. Choose reliable shipping methods and consider any customs regulations or import duties that may apply. Work with a freight forwarder if necessary.

8. Contractual Agreement: Draft a detailed contract outlining all terms and conditions, including quality control measures, payment terms, delivery timelines, and penalties for non-compliance.

9. Continuous Monitoring: Once the order is placed, continuously monitor the production process through regular updates from the supplier. Consider conducting factory visits or third-party inspections to ensure compliance with agreed standards.

10. After-Sales Support: Ensure there is a clear after-sales support plan in case of any issues with the material upon receipt.

Following these steps can help ensure a smooth and successful sourcing experience from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.