Reliable Plastic Machining: SourcifyChina Factory Delivers Quality and Precision

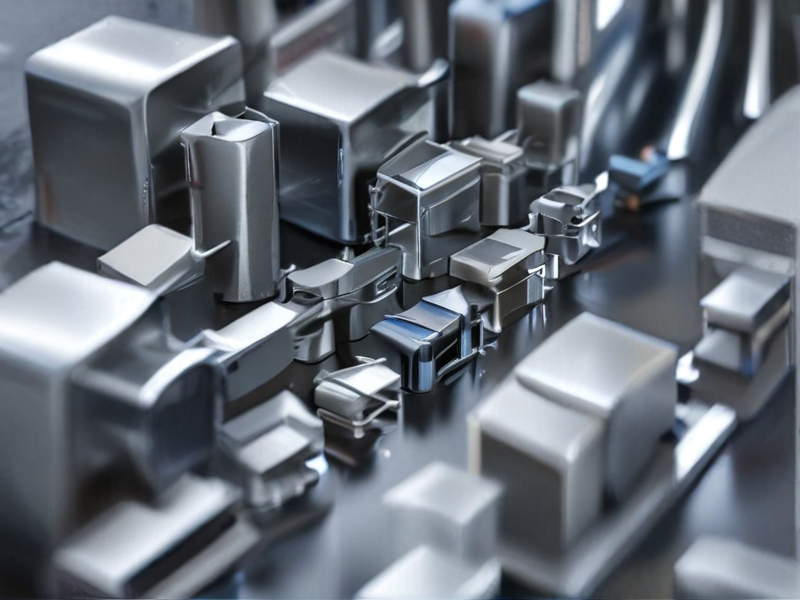

SourcifyChina factory specializes in providing high-quality plastic machining services. With a focus on reliability and precision, they cater to diverse industrial needs, ensuring top-notch products that meet stringent standards.

Choosing SourcifyChina Factory for purchasing plastic for machining offers several advantages. First, their extensive experience in the industry ensures high-quality plastic materials that meet international standards. This expertise gives buyers confidence in the reliability of their products.

Secondly, SourcifyChina prioritizes customer satisfaction by providing personalized, responsive service. They work closely with clients to understand their unique requirements, offering tailored solutions and swift delivery times. This commitment to service excellence sets them apart.

Moreover, competitive pricing at SourcifyChina makes it an attractive option without sacrificing quality. Their well-established supply chain and efficient production methods allow them to offer cost-effective solutions. This pricing benefit helps buyers maximize their budget.

SourcifyChina also emphasizes sustainability by sourcing eco-friendly materials and implementing green manufacturing practices. This focus on environmental responsibility appeals to buyers who value sustainability. It ensures a minimal ecological footprint in your machining projects.

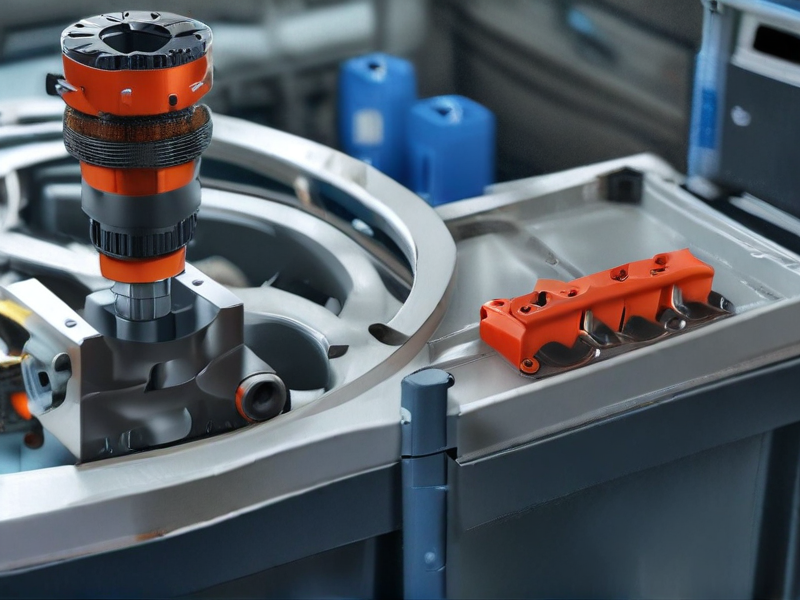

Another key advantage is their advanced technology and equipment. SourcifyChina utilizes state-of-the-art machinery, ensuring precision and consistency in plastic machining. This technological edge translates to higher-quality products and reduced production errors.

Lastly, choosing SourcifyChina Factory means benefiting from their robust quality control measures. Each batch of plastic undergoes rigorous testing to guarantee its durability and performance. This meticulous attention to detail ensures that buyers receive materials they can trust.

Plastic materials for machining offer a diverse range of options, tailored to specific applications based on mechanical properties, thermal resistance, and chemical durability. These materials are widely used in industries such as aerospace, automotive, and medical devices.

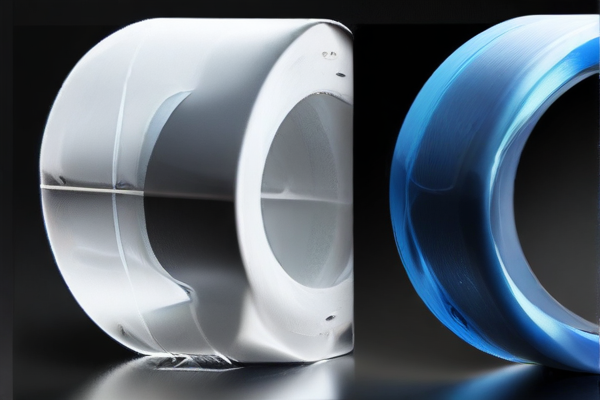

– Acrylic (PMMA): Known for its clarity and resistance to UV radiation, making it suitable for optical applications.

– Nylon (Polyamide): Offers high strength, wear resistance, and excellent chemical stability; ideal for gears, bearings, and bushings.

– Delrin (Acetal): Provides low friction and high dimensional stability, commonly used in high-precision parts and mechanical components.

– Polycarbonate (PC): Highly impact-resistant and transparent, used in safety glazing, electronic components, and lenses.

– PTFE (Teflon): Exceptional chemical resistance and low friction; ideal for seals, gaskets, and applications requiring non-stick properties.

– HDPE (High-Density Polyethylene): Displays excellent impact resistance and moisture resistance, suitable for trays, tanks, and outdoor equipment.

– PEEK (Polyetheretherketone): High-temperature resistance, excellent mechanical strength, and chemical durability; used in aerospace, medical, and automotive parts.

– Polypropylene (PP): Good chemical resistance and fatigue resistance, often used in laboratory equipment and packaging.

– PVC (Polyvinyl Chloride): Versatile and cost-effective with good chemical and moisture resistance; used in plumbing, electrical insulation, and signage.

– ABS (Acrylonitrile Butadiene Styrene): Offers good mechanical properties and ease of processing, commonly used in enclosures, automotive parts, and consumer electronics.

– UHMWPE (Ultra-High Molecular Weight Polyethylene): Extremely wear-resistant and has a low coefficient of friction; used in conveyor belts, liners, and bearings.

Choosing the appropriate plastic material for machining involves considering the specific requirements of the application, including mechanical loads, environmental conditions, and necessary certifications or standards.

Plastics for machining are versatile materials used in various industries due to their lightweight, durability, and ease of forming. They are crucial in applications where high precision and specific properties are required.

– Medical Equipment: Machined plastic components are used in medical devices and diagnostic instruments needing biocompatibility and precision.

– Automotive: Engineered plastics are used for making lightweight yet durable car parts, enhancing performance and fuel efficiency.

– Aerospace: Plastics for machining are used to fabricate critical aerospace components due to their high strength-to-weight ratio.

– Electronics: They are used in manufacturing casings, connectors, and other components that require excellent electrical insulation.

– Industrial Machinery: Custom plastic parts are essential in machinery for low friction, wear resistance, and resistance to chemicals.

– Food Processing: FDA-approved, food-grade plastics are machined for use in food processing equipment to maintain hygiene.

– Construction: Machined plastics are employed for making durable, weather-resistant building materials and components.

– Marine Industry: Utilized for producing corrosion-resistant parts that can withstand harsh marine environments.

– Consumer Goods: Plastics are machined into various household products, from kitchen gadgets to toys, for their durability and versatility.

– Renewable Energy: They are used in wind turbines and solar panels for lightweight, durable parts that can withstand environmental stresses.

By replacing metals in many applications, these machined plastics contribute significantly to innovation across sectors, often providing cost savings and improved performance.

“SourcifyChina” offers a range of plastics for machining applications, each selected for its specific properties and performance characteristics. These materials cater to various industrial needs, ensuring high precision and durability in manufacturing processes.

One commonly used material is Delrin (POM), known for its low friction and high stiffness. It’s ideal for parts requiring tight tolerances and low wear. This makes it a popular choice in the automotive and consumer goods industries.

Another significant material is Nylon, valued for its strength and toughness. Its resistance to wear and chemicals makes it suitable for mechanical and structural applications, including gears and bushings.

Polycarbonate (PC) is also a key plastic used by SourcifyChina, appreciated for its transparency and impact resistance. This material is often utilized in safety equipment, optical devices, and electronics due to its clarity and durability.

Acrylic (PMMA) offers excellent optical properties and weather resistance. It’s often chosen for applications requiring clarity and light transmission, such as display cases, lenses, and signage.

Lastly, SourcifyChina provides PTFE (Teflon), renowned for its non-stick properties and high-temperature resistance. PTFE is crucial in applications involving high heat and chemical exposure, such as seals and gaskets in chemical processing industries.

These materials are selected based on rigorous standards to meet diverse machining needs, ensuring reliable and efficient production outcomes. By leveraging the unique properties of each plastic, SourcifyChina supports a wide array of industries with high-quality, custom-machined components.

SourcifyChina ensures high-quality plastic for machining through stringent quality control measures. The process starts with selecting premium raw materials, ensuring they meet specified standards for durability and consistency.

During production, advanced machinery and techniques are employed to maintain precision and uniformity. This includes rigorous testing for dimensional accuracy and material properties at various stages.

Inspection protocols involve thorough checks, including visual inspections and mechanical testing, to detect any defects or inconsistencies. This proactive approach helps in identifying issues early in the manufacturing process.

SourcifyChina also implements a continuous improvement system, using feedback and data analysis to enhance product quality. By adhering to international standards, they guarantee reliable and high-performance plastic components for various machining applications.

SourcifyChina excels in providing high-quality plastic parts for machining, catering to diverse industries with precision and reliability. Their advanced technology ensures accurate dimensions and superior finishes.

The company offers a wide range of plastic materials, including ABS, PVC, and nylon. These materials are selected for their durability and suitability for various machining processes, ensuring products meet stringent quality standards.

SourcifyChina’s expert team possesses extensive experience in CNC machining, injection molding, and rapid prototyping. Their expertise guarantees that each project is executed with exceptional attention to detail, meeting customer specifications efficiently.

Comprehensive quality control processes are integral to SourcifyChina’s operations. They employ rigorous inspection methods at every stage of production to identify and rectify defects, ensuring products are flawless upon delivery.

What sets SourcifyChina apart is their commitment to customer satisfaction. They offer personalized solutions, working closely with clients to understand their unique requirements and deliver tailored machining services that exceed expectations.

Moreover, SourcifyChina boasts competitive pricing and timely delivery, making them a preferred partner for businesses seeking reliable and cost-effective plastic machining solutions. Their ability to handle both small and large-scale projects demonstrates their versatility.

In conclusion, SourcifyChina’s plastic machining capabilities are characterized by their use of advanced technology, diverse material options, skilled team, stringent quality control, customer-centric approach, competitive pricing, and timely delivery. This combination makes them a trusted provider in the industry.

Plastic for Machining: An Overview

Using plastic for machining offers numerous advantages, making it a popular choice across various industries for creating precise and durable components.

– Cost-Effectiveness: Plastics are generally cheaper than metals, reducing the overall cost of raw materials and manufacturing.

– Lightweight: Plastics are lighter than metals, which is beneficial in applications where weight reduction is critical.

– Corrosion Resistance: Plastics resist corrosion and chemical attacks, ideal for components exposed to harsh environments.

– Ease of Machinability: Plastics are easier to machine, allowing for faster production times and less wear on tools.

– Versatility: A wide range of plastics is available, offering diverse properties to meet various application needs.

– Electrical Insulation: Many plastics offer excellent electrical insulation properties, making them suitable for electrical and electronic applications.

– Thermal Insulation: Plastics can provide good thermal insulation, essential in temperature-sensitive applications.

– Aesthetics: Plastics can be molded into complex shapes, offering more design flexibility and better surface finishes.

– Noise Reduction: Plastic components can help in reducing operational noise, important in moving parts and assemblies.

– Recyclability: Many plastics are recyclable, supporting sustainability and environmental goals.

Plastic is a versatile material widely used in machining due to its lightweight nature, durability, and ease of fabrication. Its features make it suitable for various industrial applications.

– Lightweight: Plastics are much lighter than metals, reducing overall weight and easing handling.

– Durability: Resistant to corrosion, chemicals, and impact, plastics offer long-lasting performance.

– Ease of Machining: Plastics can be easily cut, drilled, and shaped using standard machining tools.

– Cost-Effective: Generally less expensive than metals, plastics can reduce material costs.

– Electrical Insulation: Many plastics provide excellent electrical insulation properties.

– Low Friction: Certain plastics exhibit low friction, suitable for wear-resistant applications.

– Thermal Insulation: Plastics often have low thermal conductivity, useful in insulation.

– Versatility: Available in a wide range of types with varying properties to suit specific needs.

– Surface Finish: Capable of achieving smooth finishes, plastics are ideal for applications requiring aesthetic appeal.

– Moisture Resistance: Many plastics do not absorb moisture, making them suitable for humid environments.

– Biocompatibility: Some plastics are biocompatible, suitable for medical and food-grade applications.

– Recyclability: Many plastics can be recycled, contributing to sustainability efforts.

SourcifyChina specializes in providing high-quality plastic materials for machining custom products. They cater to various industries, ensuring precise, durable, and cost-effective solutions. Their expertise spans across a wide range of plastics including ABS, polycarbonate, and PTFE, tailored to meet specific project requirements.

Their advanced machining capabilities allow for intricate designs and tight tolerances, making them a reliable partner for custom parts. SourcifyChina’s team of skilled engineers collaborates closely with clients to deliver products that meet exact specifications and industry standards.

In addition to machining, they offer value-added services such as prototyping, assembly, and quality control. This comprehensive approach ensures that every project, from concept to completion, receives meticulous attention to detail.

SourcifyChina’s commitment to quality and customer satisfaction is evident in their streamlined production processes and responsive support team. They are dedicated to providing innovative solutions and maintaining long-term partnerships with their clients.

Whether for automotive, aerospace, or medical applications, SourcifyChina’s custom plastic machining services deliver reliability and excellence. Their focus on continuous improvement and technological advancements positions them as a leader in the plastic machining industry.

SourcifyChina’s custom products are designed to meet the highest standards of performance and durability. Their robust quality assurance processes guarantee that each product is manufactured to exact specifications, ensuring client satisfaction.

The company prides itself on its ability to handle complex projects efficiently. With a customer-centric approach, they strive to exceed expectations and provide tailored solutions that address unique challenges.

In summary, SourcifyChina is a trusted provider of custom plastic machining services, offering a complete range of solutions from material selection to final product delivery. Their dedication to quality, precision, and customer satisfaction makes them a preferred choice for industries requiring specialized plastic components.

SourcifyChina is a premier company specializing in high-quality plastic materials tailored for machining applications. Established with a commitment to excellence and innovation, the company has carved a niche for itself by offering an extensive range of plastic products that meet the rigorous demands of various industries such as automotive, aerospace, medical, and electronics. SourcifyChina prides itself on utilizing advanced technology and state-of-the-art manufacturing processes to produce durable, reliable, and precise plastic components. The company’s diverse catalog includes materials like PEEK, PTFE, Nylon, and Delrin, each selected for its unique properties and performance benefits. By prioritizing customer satisfaction, SourcifyChina offers customized solutions, rapid prototyping, and efficient delivery times, ensuring clients receive products that not only meet but exceed their expectations. Their expert team is dedicated to continuous improvement and staying ahead of industry trends, making SourcifyChina a trusted partner for businesses seeking top-tier plastic machining materials.

Plastics for machining have become pivotal in the aerospace, defense, and marine industries due to their lightweight, corrosion-resistant, and high-strength properties. In aerospace, engineered plastics like PEEK (polyetheretherketone) and polyimides are utilized for components such as bushings, seals, and insulators. These materials can withstand extreme temperatures and chemical exposures while maintaining their mechanical integrity, thus enhancing the performance and longevity of aircraft systems. Their reduced weight compared to metals contributes to fuel efficiency and overall operational cost savings, a critical factor in both commercial and military aviation.

In the defense and marine sectors, machined plastics play a crucial role in manufacturing parts that must endure harsh environments and heavy wear. For instance, components made from UHMWPE (ultra-high-molecular-weight polyethylene) are used in ballistic protection and naval applications due to their exceptional impact resistance and low friction properties. Additionally, these plastics are employed in electronic enclosures, antenna systems, and structural elements where durability and resistance to saltwater corrosion are imperative. The versatility of machined plastics, combined with their ability to be precisely fabricated to tight tolerances, ensures they meet the rigorous demands of aerospace, defense, and marine applications effectively.

In the automotive industry, plastic for machining plays a critical role in enhancing performance and reducing weight. Machined plastic components such as gears, bushings, and housings are favored for their durability, resistance to corrosion, and ability to withstand high temperatures and mechanical stress. These properties make plastics ideal for use in engine compartments, fuel systems, and electrical housings. Furthermore, the versatility of plastics allows for complex shapes and designs that improve aerodynamics and overall vehicle efficiency. By replacing traditional metal parts with high-performance plastics, automakers can significantly reduce vehicle weight, leading to improved fuel efficiency and lower emissions.

In the electronics sector, machined plastics are indispensable for producing precision parts used in a wide range of devices, from consumer electronics to industrial machinery. Plastics such as PTFE, PEEK, and ABS are often used for insulating components, connectors, and casings due to their excellent electrical insulating properties, chemical resistance, and durability. These materials can be precisely machined to tight tolerances, ensuring reliability and performance in critical applications. Moreover, the lightweight nature of plastics contributes to the miniaturization of electronic devices, making them more portable and user-friendly. The adaptability of plastic materials also supports rapid prototyping and innovation in electronic product design, enabling manufacturers to quickly develop and refine new technologies.

In the construction industry, the use of plastic for machining has revolutionized the approach to creating complex architectural features and structural components. Machinable plastics like high-density polyethylene (HDPE), polycarbonate, and acrylic are prized for their durability, lightweight nature, and resistance to environmental stressors such as UV rays and moisture. These properties make them ideal for applications ranging from intricate façade elements to mounting brackets and spacers. Machinable plastics can be precisely cut, drilled, and shaped using CNC machines and other equipment, allowing for high tolerances and refined finishes that meet modern construction standards. Additionally, their inherent versatility means they can be adapted to a wide range of specifications, ultimately reducing material waste and production times.

In the energy sector, plastics for machining play a critical role in various applications, particularly in renewable energy systems like wind turbines and solar arrays, as well as in traditional energy setups. Machinable plastics such as PVC, PEEK, and PTFE are often employed in manufacturing components like insulators, gaskets, and seals due to their superior electrical insulating properties and chemical resistance. In renewable energy installations, these materials are used to fabricate lightweight yet robust parts that can withstand harsh environmental conditions, thus improving the lifespan and efficiency of equipment. Moreover, the precise machining capabilities of plastics enable the production of custom-fitted parts that enhance the performance of energy systems, minimizing the risks of leakage, wear, and failure. This adaptability not only contributes to the reliability and sustainability of energy infrastructure but also facilitates advancements in technology through innovative design and engineering solutions.

The industrial equipment industry heavily relies on the use of plastic for machining to improve efficiency, reduce costs, and enhance performance. Unlike metals, plastics are often lighter, more resistant to corrosion, and easier to machine, which makes them highly advantageous in manufacturing processes. Materials such as PEEK, PTFE, and nylon are selected for their durability and versatility. These plastics can withstand high stresses and temperatures, making them suitable for components that need to operate under challenging conditions. For instance, gears, bushings, and seals made from high-performance plastics are commonplace in machinery, as they offer exceptional wear resistance and longevity. Their machinability ensures precise tolerances and intricate designs that meet the rigorous demands of modern industrial applications.

Moreover, plastic for machining offers significant advantages in automation and robotics within the industrial equipment sector. The lightweight nature of plastics reduces the overall weight of components, consequently diminishing energy consumption and enhancing the speed and agility of robotic systems. Custom plastic housings and fixtures are routinely machined for use in automated production lines, providing a high degree of customization and rapid adaptability to changing industrial requirements. Additionally, the inherent electrical insulation properties of certain plastics contribute to safer operation in electrical applications within the industrial setting. Environmental considerations are also addressed, as many engineering plastics are recyclable, thus supporting sustainability initiatives in the industry. Overall, the application of plastic for machining in the industrial equipment industry yields a blend of economic benefits, performance enhancements, and environmental advantages.

Plastic for machining is integral in the medical device industry due to its versatility, biocompatibility, and cost-effectiveness. High-performance plastics such as PEEK, PTFE, and UHMWPE are commonly used for their excellent mechanical properties, chemical resistance, and ability to be sterilized. These materials are machined into a variety of components, including surgical instruments, diagnostic equipment, and implantable devices. Their biocompatibility ensures that they do not induce adverse reactions when used within the human body, making them ideal for applications such as orthopedic implants and dental devices.

Moreover, the machinability of plastics allows for precise and complex shapes to be produced with tight tolerances, which is crucial for the intricate designs required in medical devices. The ability to machine plastics efficiently and economically supports rapid prototyping and small to medium-scale production runs, enabling quicker development cycles and faster time-to-market for new medical technologies. Additionally, the lightweight nature of plastic components enhances the ergonomics of medical instruments, reducing strain for healthcare professionals during lengthy procedures. Overall, the use of machined plastics in medical devices not only enhances performance and reliability but also contributes to the innovation and advancement of healthcare solutions.

Plastic for Machining: In the realm of machining and manufacturing, plastic materials have become indispensable due to their versatility, cost-effectiveness, and unique properties. Plastics such as Delrin, Nylon, and PTFE are commonly used for machining applications because they offer excellent mechanical characteristics like low friction, high wear resistance, and stability under varying temperatures. These properties make them ideal for producing components that require tight tolerances and smooth surfaces, such as gears, bearings, and precision housings. Machinable plastics are also preferred for prototyping and small batch production due to their ease of processing, which reduces both time and tooling costs compared to metals.

Manufacturing Applications: In manufacturing, plastic machining is utilized across various industries, including automotive, aerospace, electronics, and medical devices. For example, in the automotive sector, machined plastic parts are used in fuel systems, braking components, and dashboard elements due to their light weight and corrosion resistance. In electronics, plastics are machined into insulators, connectors, and housings, benefiting from their electrical insulating properties and resistance to environmental factors. The medical industry relies on machined plastics for equipment components and disposable parts, as they can be sterilized and meet stringent regulatory standards. Overall, the use of plastic for machining supports innovation and efficiency in manufacturing by enabling the production of durable, precise, and cost-effective components.

1. What types of plastic does SourcifyChina produce for machining quality work?

SourcifyChina offers a range of high-quality plastics suitable for machining, including ABS, Polycarbonate (PC), Nylon (PA), PEEK, Delrin (POM), and UHMW-PE.

2. What are the key benefits of using SourcifyChina’s plastics for machining?

Our plastics are known for their high durability, precision, and excellent surface finish. They are designed to withstand the rigors of machining processes, providing consistent performance and dimensional stability.

3. How does SourcifyChina ensure the quality of its plastic products?

We implement stringent quality control measures, including material testing, inspection at various production stages, and compliance with international standards. Each batch undergoes thorough testing to ensure it meets the required specifications.

4. Can SourcifyChina provide custom plastic formulations for specific machining needs?

Yes, we offer customized solutions tailored to meet specific requirements. Our team can work with you to develop a plastic formulation that matches your exact machining and performance needs.

5. What machining processes are suitable for SourcifyChina’s plastics?

Our plastics are compatible with a variety of machining processes including CNC milling, turning, drilling, and cutting. They are engineered to perform well under these conditions, providing high precision and reliability.

6. Does SourcifyChina offer assistance with design and prototyping?

Absolutely. We provide comprehensive support for design and prototyping to ensure your project’s success from concept to final product. Our experts are available to offer technical advice and solutions.

7. What is the typical lead time for orders from SourcifyChina?

Lead times vary based on order size and complexity, but typically range from 2 to 4 weeks. We strive to meet your deadlines and can expedite orders when necessary.

8. How can I place an order with SourcifyChina?

You can place an order by contacting our sales team via email or phone. We will guide you through the process and provide a detailed quote based on your specifications.

When considering plastic for machining from SourcifyChina factory, here are key tips to ensure successful manufacturing:

1. Material Selection:

– Choose the right type of plastic based on your product requirements. Common types include ABS, PVC, Nylon, and POM (Delrin). Each has different properties in terms of strength, flexibility, and temperature resistance.

– Ensure that the selected plastic meets industry standards and specifications relevant to your product’s application.

2. Precision and Tolerances:

– Discuss the tolerances and precision levels with SourcifyChina. Different plastics respond differently to machining, so confirm the factory’s capability to meet your design specifications.

– Tight tolerances might require specific machining techniques and more advanced equipment.

3. Machining Techniques:

– Confirm the factory’s expertise with various machining techniques such as CNC milling, turning, and drilling.

– Understand the specific machining processes they employ and how they handle potential issues like thermal expansion or material chipping.

4. Quality Control:

– Ensure the factory has robust quality control processes. This includes regular inspections and testing of the machined parts.

– Request detailed reports and sample parts to verify the quality before full-scale production.

5. Cost and Lead Time:

– Discuss and agree on clear cost estimates and production timelines. Machining plastic can be cost-effective, but prices vary based on complexity and volume.

– Evaluate the lead times for both prototype and full-scale production runs.

6. Communication:

– Maintain clear and regular communication with SourcifyChina’s team. Detailed documentation, including CAD files and material specifications, is crucial.

– Address any potential language barriers to ensure that all technical details are accurately understood and implemented.

7. Post-Machining Services:

– Inquire about any additional services offered, such as finishing, polishing, or assembly, which might be necessary for your final product.

By considering these factors, you can optimize your manufacturing process with SourcifyChina and ensure high-quality, cost-effective plastic parts.

1. What types of plastic materials does SourcifyChina offer for machining?

SourcifyChina provides a wide range of plastic materials suitable for machining, including ABS, PVC, POM (Delrin), PTFE (Teflon), Nylon, and Polycarbonate. Each material has unique properties that cater to various industrial applications.

2. How can I request a quote for my plastic machining project?

To request a quote, visit the SourcifyChina website and fill out the online form with your project specifications, including material type, dimensions, quantity, and any special requirements. You can also contact their sales team directly via email or phone.

3. What is the typical lead time for plastic machining orders?

Lead times vary depending on the complexity and size of the order. Generally, it takes about 2-4 weeks from order confirmation to delivery. For more precise estimates, contact the SourcifyChina team with your project details.

4. Can SourcifyChina handle custom machining projects?

Yes, SourcifyChina specializes in custom machining projects. They can accommodate specific design requirements, tolerances, and finishes. Provide detailed drawings or CAD files when submitting your request.

5. What quality control measures does SourcifyChina implement?

SourcifyChina follows strict quality control procedures, including material inspection, dimensional verification, and surface finish checks. They also adhere to international standards such as ISO 9001 to ensure high-quality outputs.

6. Is there a minimum order quantity (MOQ) for plastic machining services?

The MOQ varies based on the project and material type. For specific information, it’s best to discuss your requirements directly with the SourcifyChina sales team.

7. How does SourcifyChina handle shipping and logistics?

SourcifyChina offers various shipping options, including air freight, sea freight, and express courier services. They handle all logistics, including customs documentation, to ensure smooth delivery to your location.

8. Can I get a sample before placing a full order?

Yes, SourcifyChina can provide samples upon request. This allows you to verify the quality and suitability of the material and machining before committing to a larger order.

Sourcing plastic for machining from a reputable factory like SourcifyChina can streamline your supply chain and ensure quality. Here are succinct tips to help you achieve successful sourcing:

1. Specify Requirements: Clearly define the type of plastic (e.g., ABS, POM, Nylon) and its intended application. Detailed specifications help suppliers understand your needs precisely.

2. Quality Standards: Request material certifications and compliance documents (e.g., ISO, RoHS) to ensure the plastic meets your quality standards and regulatory requirements.

3. Sample Testing: Begin with sample orders to assess material properties such as machinability, durability, and consistency. This will help in verifying that the product meets performance expectations.

4. Factory Evaluation: Conduct a thorough evaluation of SourcifyChina’s facilities. If possible, visit the factory or employ third-party inspectors to review production capabilities, quality control processes, and machinery.

5. Communication: Maintain clear and continuous communication with SourcifyChina. Discuss lead times, production schedules, and potential challenges upfront.

6. Pricing and MOQ: Negotiate pricing based on your volume needs while considering Minimum Order Quantities (MOQs). Establishing these parameters early on can prevent future misunderstandings.

7. Logistics and Shipping: Plan logistics meticulously. Inquire about packaging standards to safeguard your materials during transit, and anticipate potential customs and import regulations.

8. Contracts and Agreements: Draft detailed contracts covering all agreement aspects, including delivery timelines, payment terms, quality assurances, and dispute resolution mechanisms.

9. Sustainability: If environmental sustainability is crucial, ascertain SourcifyChina’s adherence to eco-friendly practices and how they handle waste and recycling.

10. Long-Term Relationship: Build a long-term partnership. Consistent collaboration and feedback can result in better service and potentially more favorable terms over time.

Following these tips will enhance your sourcing strategy, ensuring you receive high-quality plastic materials from SourcifyChina beneficially and efficiently.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.