SourcifyChina offers buyers a direct link to reliable Chinese manufacturers specializing in plastic parts. With years of experience, they ensure high-quality production that meets international standards, making your sourcing process smoother and more efficient.

Their team provides comprehensive services including product design consultation, quality control, and logistics support, ensuring that every step of the supply chain is streamlined. This results in quicker turnaround times and reduced costs, benefiting your business greatly.

By partnering with SourcifyChina, you gain access to a vast network of vetted factories. This allows for flexible order quantities, whether for small batches or large-scale production, accommodating businesses of all sizes.

Transparency is a core value at SourcifyChina. They provide clear communication and detailed production updates, allowing buyers to make informed decisions. This builds trust and long-lasting business relationships.

Ultimately, choosing SourcifyChina means opting for a hassle-free sourcing experience backed by a team committed to quality and efficiency. With their expertise and extensive factory network, they are your go-to partner for purchasing plastic parts from China.

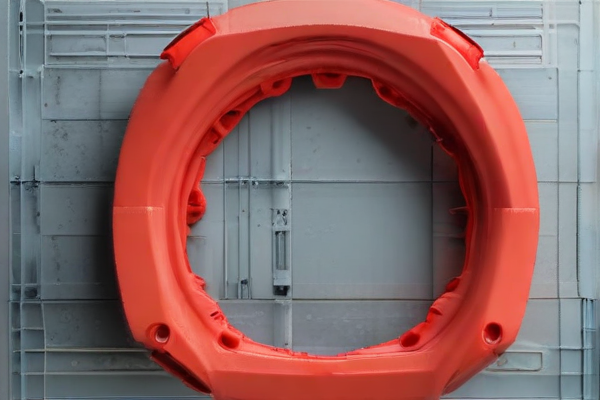

Plastic parts come in various materials and manufacturing techniques, suitable for diverse applications. Understanding the types and options helps in selecting the best plastic parts for specific needs and ensuring optimal performance.

– Injection Molding: Ideal for high-volume production with precise, complex designs.

– Blow Molding: Best for hollow parts like bottles and containers.

– Thermoforming: Used for large-sized parts with lower detail.

– 3D Printing: Suited for rapid prototyping and small-scale custom parts.

– Extrusion: Perfect for continuous lengths of plastic profiles.

– CNC Machining: Provides high precision for custom parts from plastic blocks.

Material Options:

– ABS (Acrylonitrile Butadiene Styrene): Durable and impact-resistant, used in automotive parts and consumer products.

– Polycarbonate: Known for high impact resistance and transparency, ideal for eyewear lenses and safety equipment.

– Nylon: Heat resistant and strong, commonly used in mechanical components.

– Polyethylene: Versatile and cost-effective, used in containers and plastic bags.

– Polypropylene: Chemical resistance and fatigue strength, suitable for living hinges and automotive applications.

– Acrylic (PMMA): Clear and lightweight, often used in displays and signage.

– POM (Polyoxymethylene or Acetal): Known for low friction and high stiffness, used in gears and bearings.

Coatings and Finishes:

– UV Resistant Coating: Protects parts from sun degradation.

– Antimicrobial Treatment: Reduces bacterial growth on surfaces.

– Textured Finishes: Adds grip and aesthetic appeal.

Design Considerations:

– Structural Integrity: Ensuring part strength for intended use.

– Thermal Properties: Matching material with thermal exposure.

– Cost Efficiency: Balancing material and manufacturing costs.

– Chemical Resistance: Important for parts exposed to harsh chemicals.

Selecting the right type and material for plastic parts ensures optimal performance, durability, and cost-effectiveness for any application.

Plastic parts are incredibly versatile and find applications in various industries due to their durability, lightweight, and cost-effectiveness. They are used in:

– Automotive: For interior components, bumpers, and dashboards.

– Electronics: In housings, connectors, and switches.

– Medical: Manufacturing of syringes, prosthetics, and diagnostic devices.

– Packaging: Containers, bottles, and films.

– Construction: Insulation, pipes, and fittings.

– Consumer goods: Toys, kitchenware, and sports equipment.

– Aerospace: Lightweight components and insulation.

Overall, plastic parts play a crucial role in modern manufacturing, offering flexibility and innovation across numerous sectors.

SourcifyChina specializes in providing high-quality plastic parts, ensuring durability and efficiency across various industries. Their materials include ABS, polypropylene, and polycarbonate, known for their strength and resistance to wear and tear.

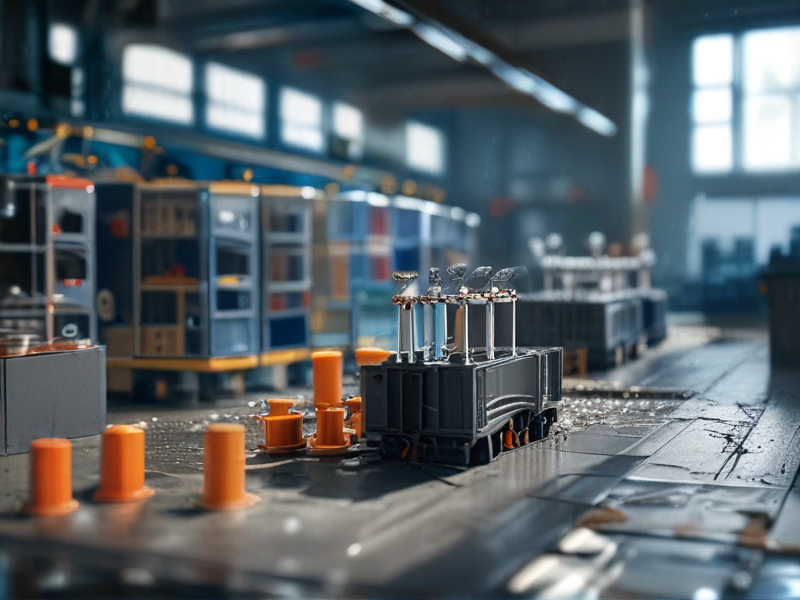

These plastic parts are engineered to meet precise specifications, ensuring compatibility with different manufacturing processes. The use of advanced injection molding techniques guarantees consistency and precision in every part produced.

Furthermore, SourcifyChina places a strong emphasis on sustainability. They utilize eco-friendly materials and processes, minimizing environmental impact without compromising on quality. This commitment to sustainability is pivotal in today’s eco-conscious market.

In addition to robust quality control measures, SourcifyChina offers customization options, allowing clients to tailor plastic parts to their specific needs. This adaptability ensures that the delivered components align perfectly with customer requirements, further enhancing the overall efficiency of their operations.

SourcifyChina’s quality control process for plastic parts begins with meticulous material selection. Only high-grade, reliable raw materials are chosen to ensure the durability and performance of the final products. Each batch undergoes extensive testing for compliance with industry standards.

Next, the manufacturing process is closely monitored. Advanced machinery and cutting-edge techniques are employed, alongside regular inspections to maintain precision. This step-by-step supervision helps to identify and rectify any discrepancies in real-time, ensuring consistency and accuracy.

During post-production, each plastic part undergoes rigorous quality checks. These include stress tests, dimensional assessments, and surface inspections. Any part that does not meet the predefined criteria is promptly discarded. This ensures that only high-quality parts reach the customer.

Finally, SourcifyChina implements a comprehensive feedback loop. Clients are encouraged to provide performance reviews, which are analyzed to make continuous improvements. This commitment to excellence underscores SourcifyChina’s dedication to producing top-tier plastic parts, guaranteeing customer satisfaction and reinforcing their market reputation.

SourcifyChina is a renowned manufacturing service adept at providing high-quality plastic parts. They offer extensive services ensuring top-notch product quality and precise specifications. Their robust capabilities enable them to cater to diverse industry needs effectively.

A standout feature of SourcifyChina is their state-of-the-art technology, which empowers them to produce intricate and durable plastic components. This technological edge facilitates high production standards and consistent quality control, ensuring customer satisfaction.

Another key advantage is their experienced team of engineers and technicians. Their expertise in mold design and production processes ensures that every product meets rigorous quality criteria and functional requirements.

SourcifyChina also prides itself on its efficient project management practices. With a strong focus on timelines, they deliver projects on schedule without compromising on quality, making them a reliable partner in the supply chain.

Additionally, their comprehensive customer support system ensures that all client queries and concerns are addressed promptly and effectively. This dedication to client service underpins their commitment to building sustainable, long-term business relationships.

SourcifyChina’s diverse range of manufacturing capabilities spans various applications, from automotive and electronics to consumer goods and medical devices. This versatility makes them a go-to provider for many industries looking for quality plastic parts.

Ultimately, SourcifyChina combines cutting-edge technology, skilled expertise, and robust customer service to deliver superior plastic parts. Their holistic approach to manufacturing not only meets but often exceeds client expectations, solidifying their reputation as a leader in the industry.

Plastic parts offer numerous advantages across various industries. They are lightweight, cost-effective, and highly versatile, making them ideal for a range of applications.

– Lightweight: Plastic parts significantly reduce the overall weight of products, enhancing portability and ease of handling.

– Cost-Effective: Manufacturing plastic components typically involves lower production and material costs, leading to more affordable end products.

– Durability: Plastics offer high resistance against corrosion, impact, and wear, thereby extending the lifespan of products.

– Versatility: They can be easily molded into complex shapes and designs, allowing for innovative and customized solutions.

– Chemical Resistance: Plastics often withstand exposure to a variety of chemicals, making them suitable for use in harsh environments.

– Thermal Insulation: Certain plastics offer excellent thermal insulation properties, which is beneficial in electronics and construction.

– Electrical Insulation: Many plastics are good electrical insulators, making them ideal for use in electronic and electrical applications.

– Fast Production: Injection molding and other plastic forming techniques allow for rapid production cycles, increasing efficiency.

– Recyclability: Many plastics can be recycled, reducing environmental impact and saving resources.

– Noise Reduction: Some plastic parts can help in damping vibrations and reducing noise, enhancing comfort and quietness in various applications.

– Flexibility: Plastics can be engineered to provide the desired level of flexibility and strength, catering to specific application needs.

– Low Maintenance: Plastic components typically require less maintenance compared to metals and other materials.

These benefits make plastic parts indispensable in industries ranging from automotive and aerospace to consumer products and healthcare.

Plastic parts offer a versatile range of features that make them indispensable in various industries, including automotive, electronics, and consumer goods.

– Durability: Resistant to wear, tear, and corrosion, which extends their lifespan.

– Lightweight: Easier to handle and reduces transportation and installation costs.

– Cost-Effectiveness: Generally cheaper to produce than metal counterparts.

– Flexibility: Can be molded into complex shapes and designs with ease.

– Insulation Properties: Good insulators of heat and electricity, useful in electronics.

– Chemical Resistance: Can withstand exposure to many chemicals and solvents.

– Recyclability: Many types of plastics can be recycled, reducing environmental impact.

– Color Variability: Available in a wide range of colors without significant additional cost.

– Surface Finish: Can be easily textured or polished to achieve desired aesthetic qualities.

– Biocompatibility: Certain plastics are safe for use in medical devices and implants.

– Transparency: Options for clear plastics for applications needing visibility of contents.

– Waterproof: Excellent water resistance, suitable for outdoor and marine environments.

– Sound Dampening: Some plastics can reduce noise and vibration, ideal for use in vehicles and machinery.

– Ease of Assembly: Can often be snapped or clicked together, simplifying assembly processes.

– Temperature Resistance: Special types can withstand high or low temperatures, broadening application range.

These features collectively make plastic parts a highly versatile and essential component in modern applications.

SourcifyChina specializes in creating custom plastic parts tailored to meet the unique needs of various industries. Their commitment to quality ensures that each part meets the highest standards, providing durability and reliability.

From initial design to final production, SourcifyChina offers a comprehensive service that includes prototyping, tooling, and mass production. They employ advanced manufacturing technologies to deliver precise and consistent results every time.

Collaboration is key at SourcifyChina; their team works closely with clients to understand specific requirements and deliver tailored solutions. This emphasis on partnership ensures that every project aligns perfectly with client expectations.

Custom projects at SourcifyChina encompass a wide range of applications, from automotive components to consumer electronics. Their expertise in material selection and engineering allows them to tackle even the most challenging projects.

SourcifyChina also prioritizes sustainability, using eco-friendly materials and practices whenever possible. Their dedication to environmentally conscious manufacturing sets them apart in the industry.

In summary, SourcifyChina is a leader in custom plastic part production, offering end-to-end services that guarantee quality, innovation, and sustainability. Their collaborative approach ensures that each project is a success.

SourcifyChina Plastic Parts is a distinguished company renowned for its precision and versatility in the manufacturing of high-quality plastic components. Located in the heart of China’s dynamic industrial landscape, the company leverages advanced injection molding technology to cater to a wide array of industries, including automotive, consumer electronics, medical devices, and household appliances. With a steadfast commitment to quality, SourcifyChina integrates stringent quality control measures throughout the production process to ensure each part meets precise specifications and industry standards. Their experienced engineering team collaborates closely with clients to offer customized solutions, from initial design to final production, ensuring optimal functionality and cost-efficiency. By harnessing state-of-the-art machinery and adopting sustainable practices, SourcifyChina not only provides exceptional products but also contributes to minimizing environmental impact. The company’s dedication to innovation, client satisfaction, and reliability has made it a trusted partner for businesses seeking top-tier plastic parts in the global market.

The aerospace, defense, and marine sectors have increasingly adopted plastic parts due to their unique properties and benefits. In aerospace applications, the reduction of weight is paramount, as lighter aircraft translate to better fuel efficiency and lower operational costs. Plastics such as PEEK (Polyetheretherketone), polycarbonate, and composites like carbon-fiber reinforced plastic are integral to achieving this. These materials not only provide a significant reduction in weight compared to traditional metals but also exhibit excellent resistance to corrosion and chemicals. They are used in components ranging from interior cabin elements to critical structural parts, ensuring the aircraft remain durable while complying with rigorous safety and performance standards.

In the defense sector, the versatility and high-performance characteristics of plastic parts are highly valued. Plastics are used in applications such as protective gear, weapon systems, and electronic enclosures. They offer vital benefits like impact resistance, thermal stability, and the ability to withstand harsh environmental conditions. Additionally, plastics can be engineered for stealth, reducing the radar signature of military vehicles and equipment. The marine industry similarly benefits from the adoption of plastic components, particularly for their corrosion resistance in saline environments. Parts like bearings, seals, and hull components made from advanced plastics help in minimizing maintenance needs and prolonging the lifespans of marine vessels. Their use not only enhances performance but also ensures compliance with stringent environmental regulations through reduced emissions and operational efficiencies.

Plastic parts have revolutionized the automotive industry by offering a lightweight yet durable alternative to traditional materials like metal. This transition has been driven primarily by the need for enhanced fuel efficiency and design flexibility. Many components, including dashboards, bumpers, fuel tanks, and even structural elements, are now crafted from high-performance plastics. These materials are not only lighter, which helps in reducing the overall weight of vehicles, but also resistant to corrosion and capable of absorbing impact energy, thereby improving safety. Moreover, plastics allow for greater design freedom, enabling manufacturers to produce complex shapes and integrate various functionalities into a single part. Innovations in plastic materials, such as reinforced composites, have further extended their applications in modern vehicles, contributing to performance and sustainability.

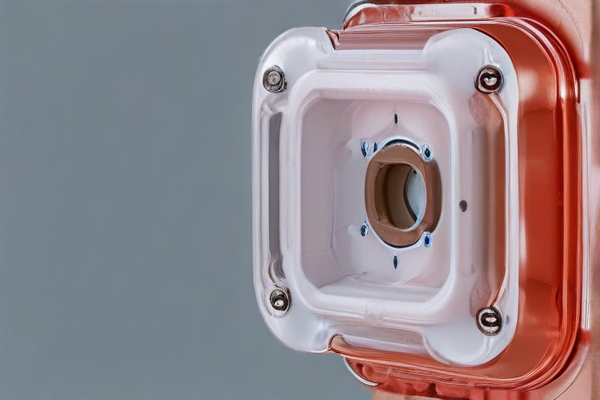

In the realm of electronics, plastic parts are equally transformative, driven by their versatility and insulating properties. From housing components in smartphones and laptops to intricate parts in home appliances and sophisticated medical devices, plastics play a critical role in the functionality and aesthetics of electronic products. Their insulating characteristics make plastics ideal for safely encasing electronic components, thereby preventing short circuits and enhancing user safety. Additionally, the lightweight nature and moldability of plastics allow for the production of compact, ergonomic, and portable electronic devices, essential in today’s technology-driven world. The use of advanced plastics, such as polycarbonates and ABS (Acrylonitrile Butadiene Styrene), has enabled higher resistance to heat and impact, further broadening their application scope. This combination of functionality, safety, and aesthetic appeal propels plastics to remain indispensable in the electronics industry.

Plastic parts have revolutionized the construction industry through their versatility, durability, and cost-effectiveness. Unlike traditional materials such as wood, metal, or concrete, plastics offer a lightweight yet robust alternative that can be engineered to meet specific needs. PVC (Polyvinyl Chloride), for example, is frequently used in piping systems, windows, and doors due to its resistance to corrosion and weathering. Additionally, the ease of installation and maintenance associated with plastic components substantially reduces labor costs and project timelines. Insulating materials, such as polystyrene foams, contribute to energy efficiency in buildings by providing excellent thermal insulation properties. Thus, plastics help meet stringent building regulations and reduce overall energy consumption, significantly influencing green building practices.

In the energy sector, plastic parts play a critical role in enhancing efficiency and sustainability. Photovoltaic solar panels, for instance, often incorporate plastic components in their construction to reduce weight and improve durability under harsh environmental conditions. Plastics are also vital in the manufacturing of wind turbine blades, where their flexibility and strength allow for the design of longer and more efficient blades that can withstand extreme stresses. Even in traditional energy infrastructure, like pipelines and storage tanks, advanced plastic materials such as polyethylene are employed due to their superior chemical resistance and longevity. Furthermore, plastics are integral in the development of emerging energy storage technologies, such as lithium-ion batteries, where they are used as separators and insulators. By contributing to reduced material usage, improved performance, and enhanced sustainability, plastic parts are indispensable in driving the future of both renewable and non-renewable energy applications.

The industrial equipment industry has increasingly integrated plastic parts into its machinery and tools, recognizing the manifold advantages plastics offer over traditional materials like metal and wood. Plastic components are lightweight, which reduces the overall weight of equipment and enhances portability and ease of handling. This translates to lower transportation and installation costs. Furthermore, plastics provide excellent resistance to corrosion and chemicals, a crucial attribute for equipment operating in harsh industrial environments such as chemical plants or mining sites. This resistance ensures longevity and durability, which contributes to lower maintenance costs and extended equipment uptime. Additionally, plastic parts can be manufactured with high precision through various molding techniques, ensuring uniformity and consistency in parts production, thereby improving the reliability and performance of industrial equipment.

Beyond durability and resistance, plastic parts offer superior thermal and electrical insulation properties, making them ideal for applications involving electrical installations and components that require protection against temperature fluctuations. This characteristic is particularly beneficial in the manufacturing of conveyor belts, bearings, gears, and other moving components that may be exposed to high temperatures or require electrical isolation. The versatility of plastics also allows for the incorporation of additives to enhance specific properties, such as UV stabilizers for outdoor equipment or flame retardants for fire-prone environments. This adaptability ensures that plastic parts can meet the varied demands of different industrial sectors. As the industry pushes towards more sustainable practices, the recyclability of certain types of plastics aligns well with environmental objectives, helping companies reduce their carbon footprint while maintaining efficient and high-performing equipment.

Medical devices rely heavily on plastic parts due to their versatility, cost-effectiveness, and ability to meet stringent regulatory standards. Plastics lend themselves to a myriad of applications in the medical field, from single-use syringes and IV tubing to complex diagnostic equipment and prosthetics. Their inherent flexibility allows for the design and production of intricate shapes and features, which is critical for devices that need to be both functional and comfortable for patients. Moreover, plastics can be sterilized through various methods, including autoclaving, gamma irradiation, and ethylene oxide gas, ensuring they meet hygiene and safety requirements essential for medical applications.

Additionally, advancements in polymer science have resulted in the development of biocompatible and bioresorbable plastics that further expand their utility in medical devices. These materials are particularly valuable in applications such as temporary implants or drug delivery systems, where the device needs to safely interact with biological tissues over time. The ability to tailor the mechanical properties of plastic parts to specific medical needs—such as hardness, flexibility, and transparency—enhances the performance and reliability of medical devices. The lightweight nature of plastics also contributes to improved patient comfort and ease of handling by healthcare professionals. Overall, the use of plastic parts in medical devices not only supports innovation in medical technology but also facilitates more personalized and effective patient care.

Plastic parts play an essential role in modern machining and manufacturing due to their versatility, lightweight nature, and cost-effectiveness. In contrast to metals, plastics can be molded into complex shapes with relative ease, offering significant advantages in terms of precision and customization. Techniques such as injection molding, CNC machining, and 3D printing are commonly employed to produce plastic components. Injection molding, in particular, is highly efficient for mass production, enabling the creation of detailed parts with minimal material waste. CNC (Computer Numerical Control) machining, on the other hand, allows for high-precision cutting and shaping, making it ideal for prototypes and small-batch production. Both methods ensure that the resulting plastic parts meet stringent industry standards for quality and durability.

In the context of manufacturing, plastic parts are indispensable across various industries, including automotive, aerospace, consumer electronics, and medical devices. Their inherent properties such as resistance to corrosion, electrical insulation, and flexibility make them suitable for a wide range of applications. For instance, in the automotive industry, plastic components contribute to a reduction in vehicle weight, thereby enhancing fuel efficiency and performance. In the medical field, plastics are used to manufacture disposable syringes, prosthetic devices, and components of medical imaging machines, all of which require stringent hygiene and precision. Moreover, the use of engineering plastics like ABS (Acrylonitrile Butadiene Styrene) and PEEK (Polyether Ether Ketone) adds to the mechanical strength, thermal stability, and chemical resistance needed for high-performance applications. Consequently, the integration of plastic parts in machining and manufacturing continues to drive innovation, efficiency, and sustainability.

Sure! Here is a FAQ list for manufacturing plastic parts with SourcifyChina factory:

—

Q: What types of plastic parts can SourcifyChina manufacture?

A: SourcifyChina specializes in manufacturing a wide range of plastic parts, including injection-molded components, blow-molded parts, thermoformed pieces, and more. We cater to various industries such as automotive, electronics, consumer goods, and medical devices.

Q: What materials does SourcifyChina use for plastic parts manufacturing?

A: We utilize a variety of materials including ABS, Polypropylene (PP), Polyethylene (PE), Polycarbonate (PC), Nylon (PA), and other specialized plastics to meet diverse application requirements.

Q: How does SourcifyChina ensure the quality of plastic parts?

A: Quality is enforced through rigorous processes such as ISO-certified manufacturing practices, continuous in-line inspections, sample testing, and final quality checks. We also offer custom quality control plans tailored to specific client needs.

Q: What is the lead time for manufacturing plastic parts?

A: Typical lead times can vary depending on the complexity of the part and production requirements. Standard lead times range from 4 to 6 weeks after the confirmation of the order and receipt of necessary specifications.

Q: What is the minimum order quantity (MOQ) for plastic parts at SourcifyChina?

A: The MOQ varies by the type of plastic part and the materials used. Generally, our MOQ starts at 1,000 units, but we are open to discussing smaller orders for prototypes or specialized projects.

Q: Does SourcifyChina provide design and prototyping services?

A: Yes, we offer comprehensive design support and prototyping services. Our team can assist with design optimization, material selection, and functional testing to ensure your part meets all required specifications before full-scale production.

Q: Can SourcifyChina handle custom and complex designs?

A: Absolutely. Our experienced engineering team and advanced manufacturing capabilities allow us to handle custom and intricate designs, ensuring high precision and quality.

Q: How do I request a quote from SourcifyChina?

A: Simply send us your part specifications, CAD files, and any other relevant details through our website or contact email. We will provide a detailed quote within 1-2 business days.

—

This FAQ list provides a concise overview of capabilities, processes, and services related to manufacturing plastic parts at SourcifyChina factory.

When considering plastic parts manufacturing from SourcifyChina Factory, focusing on several key aspects can enhance the efficiency and quality of your production process. Here are some tips:

1. Define Requirements Clearly: Provide comprehensive design specifications and material requirements upfront. Clear communication minimizes errors and ensures the final product meets your expectations.

2. Material Selection: Work closely with SourcifyChina to choose the most suitable plastic material for your parts, balancing properties like durability, flexibility, and cost.

3. Prototype Early: Request prototyping services to validate designs before mass production. Early prototypes help identify and correct potential issues, saving time and resources.

4. Quality Assurance: Ensure the factory has robust quality control measures. Inquire about their inspection processes and certifications (e.g., ISO 9001).

5. Mold Design: Discuss mold design with SourcifyChina, considering aspects like mold life, cycle time, and maintenance. Well-designed molds are critical for consistent, high-quality production.

6. Cost Management: Understand the breakdown of costs, including mold creation, labor, and material. Optimize designs to reduce material waste and consider ordering in larger quantities for volume discounts.

7. Lead Times: Clarify expected lead times and plan accordingly. Reliable timelines help in maintaining your supply chain and meeting market demands.

8. Communication: Establish strong communication channels with SourcifyChina’s team. Regular updates and transparency help in addressing issues promptly and ensuring smooth operations.

9. Compliance: Verify that the factory adheres to relevant regulatory standards and environmental guidelines. This ensures your products meet global market requirements.

10. Continuous Improvement: After each production run, analyze performance metrics and feedback to continuously refine and improve processes.

By focusing on these strategies, you can maximize the benefits of partnering with SourcifyChina for your plastic parts manufacturing needs.

Q: What types of plastic parts can SourcifyChina produce?

A: SourcifyChina specializes in a variety of plastic parts including injection-molded components, extruded parts, thermoformed items, and custom plastic products tailored to your specific needs.

Q: How do I submit a request for a quote?

A: To submit a request for a quote, you can either fill out the online form on our website or email your specifications, drawings, and quantity details directly to our sales team at [email protected].

Q: What is the standard lead time for orders?

A: The standard lead time varies depending on the complexity and volume of the order, but it typically ranges from 4 to 8 weeks. Expedited services may be available upon request.

Q: Do you offer prototypes or sample production?

A: Yes, we offer prototype and small-batch production services to help you verify the design, functionality, and quality before committing to mass production.

Q: What quality control measures does SourcifyChina have in place?

A: SourcifyChina employs rigorous quality control measures including material inspection, in-process checks, final product inspection, and adherence to ISO certification standards to ensure consistent quality.

Q: Can SourcifyChina assist with design and development?

A: Absolutely. Our experienced engineering team is available to assist with product design, material selection, and mold development to ensure the best possible outcome for your project.

Q: What are the payment terms for placing an order?

A: Our standard payment terms are 50% deposit upon order confirmation and the remaining 50% upon completion and before shipment. We accept payments through wire transfer, PayPal, and other mutually agreed methods.

Q: How does SourcifyChina handle shipping and logistics?

A: We partner with reputable shipping companies to provide reliable and timely delivery. We offer a variety of shipping options including air, sea, and express courier services, and handle all necessary customs documentation.

Q: What materials can be used for production?

A: SourcifyChina has the capability to work with a wide range of plastic materials including ABS, PVC, PP, PE, nylon, and more, based on the specific requirements of your project.

Q: Is there a minimum order quantity (MOQ) for placing an order?

Sourcing plastic parts from SourcifyChina factory can be efficient and cost-effective if you follow these tips:

1. Clear Specifications: Provide detailed drawings, material specifications, and usage requirements. Clarity reduces misunderstandings and ensures the factory meets your expectations.

2. Supplier Verification: Verify the legitimacy and reliability of SourcifyChina. Check for certifications, quality standards, and customer reviews.

3. Sample Requests: Always request samples before mass production. This helps in assessing the quality and suitability of the plastic parts.

4. Negotiation: Negotiate terms regarding pricing, minimum order quantities (MOQs), lead times, and payment conditions. Aim for a balance between cost and quality.

5. Quality Control Process: Establish a robust quality control (QC) process, including in-line and final inspections, to ensure parts meet your standards.

6. Communication: Maintain open and clear communication. Regular updates help in addressing issues promptly and keeping the project on track.

7. Visit the Factory: If feasible, visit the factory to understand their operations and capabilities. Personal visits can build trust and facilitate smoother transactions.

8. Use a Third-party Agent: Employ a sourcing agent if you’re unfamiliar with Chinese markets. They can handle negotiations, QC, and logistics on your behalf.

9. Logistics Planning: Factor in shipping times and costs. Work with reliable logistics partners to avoid delays and damage.

10. Legal Agreements: Ensure all agreements are documented and legally binding, covering aspects like IP protection, delivery schedules, and dispute resolution mechanisms.

11. Sustainability: Check the factory’s commitment to environmental standards. Sustainable practices can enhance your brand reputation and meet regulatory requirements.

By following these steps, you can efficiently source quality plastic parts from SourcifyChina, ensuring a smooth production cycle and solid business relationship.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.