Choosing SourcifyChina Factory allows buyers to access high-quality plating metals directly from China’s top manufacturers. Known for rigorous quality control, this factory ensures reliable and durable products, meeting international standards.

SourcifyChina Factory streamlines the purchasing process with an efficient supply chain network. This ensures timely deliveries and minimizes downtime, giving buyers a competitive edge in their market.

Their extensive experience in metal plating industries offers expert guidance. Clients benefit from customized solutions, catering to specific requirements, leading to enhanced productivity and cost-efficiency.

Furthermore, SourcifyChina Factory prioritizes customer satisfaction. Their dedicated support team assists in addressing queries and issues promptly, fostering smooth business operations and long-term partnerships.

Choose SourcifyChina Factory for a seamless, reliable, and cost-effective solution to your plating metal needs. Experience unparalleled quality, timely delivery, and exceptional customer service with each order, ensuring your manufacturing excellence.

There are various types of metal plating, each offering unique benefits. Common methods include electroplating, electroless plating, and galvanizing, catering to industries requiring durability, corrosion resistance, and aesthetics.

– Electroplating: Utilizes an electric current to reduce metal cations, coating the workpiece with a thin layer of material.

– Options: Chrome, nickel, gold, silver, copper.

– Applications: Automotive parts, electronics, jewelry.

– Electroless Plating: Uses a chemical reduction process to deposit metals on a substrate without electrical energy.

– Options: Nickel-phosphorus, nickel-boron.

– Applications: Complex geometries, hard disks, fuel injectors.

– Galvanizing: Applies a protective layer of zinc to steel or iron to prevent rusting.

– Options: Hot-dip galvanizing, electro-galvanizing.

– Applications: Structural steel, roofing, outdoor pipes.

– Anodizing: Electrochemical process that converts the metal surface into a decorative, durable, and corrosion-resistant oxide finish.

– Options: Sulfuric acid anodizing, hard anodizing.

– Applications: Aerospace parts, consumer electronics, architectural elements.

– Powder Coating: Involves applying a dry powder, then curing it under heat to form a protective layer.

– Options: Thermoplastics, thermosetting polymers.

– Applications: Appliances, automotive parts, construction materials.

– Hot-dip Coating: Immerses the metal in molten zinc, aluminum, or other alloys for corrosion resistance.

– Options: Galv-annealing, aluminizing.

– Applications: Metal roofing, automotive parts, electrical enclosures.

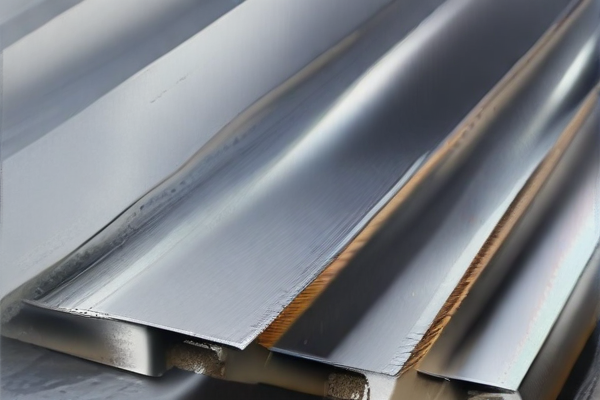

– Cladding: Bonding a layer of one metal to another to improve strength and resistance.

– Options: Stainless steel cladding, copper cladding.

– Applications: Cookware, electrical industry, construction.

Each plating technique serves specific needs, with options chosen based on the desired aesthetic, mechanical properties, and environmental resistance. The right plating method ensures optimal performance for diverse industrial applications.

Plating metals involves coating a metal surface with a thin layer of another metal to enhance its properties. This process has numerous applications across various industries due to the benefits it provides.

– Corrosion Resistance: Extends the life of base metals by preventing oxidation and rust.

– Aesthetics: Offers a decorative finish, used in jewelry, watches, and home décor.

– Electrical Conductivity: Improves conductivity, essential in electronics and connectors.

– Wear Resistance: Increases surface hardness, making components more durable.

– Reflectivity: Enhances light reflection in mirrors and optical devices.

– Cost Efficiency: Provides a cheaper alternative to solid precious metals.

– Medical Devices: Creates biocompatible surfaces for implants and tools.

– Automotive Industry: Protects vehicle parts from harsh environmental conditions.

– Aerospace Applications: Ensures components withstand extreme temperatures and pressures.

– Food Industry: Coats surfaces in processing equipment for hygiene and durability.

– Tool Manufacturing: Adds toughness to cutting tools and machine parts.

– Plumbing Fixtures: Prevents corrosion on pipes and fixtures in humid environments.

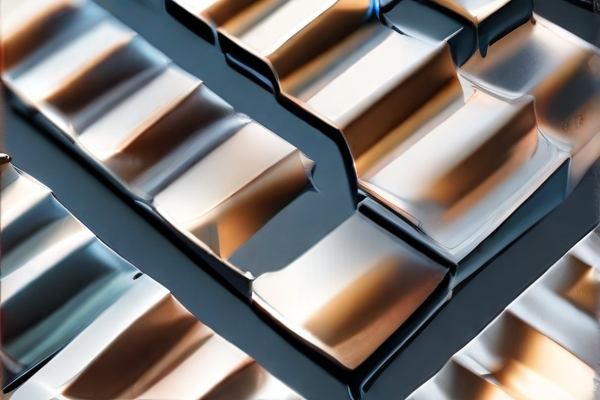

SourcifyChina specializes in the high-quality plating of various metals to meet industrial or aesthetic requirements. The company’s portfolio includes a wide range of metals like zinc, nickel, chromium, and precious metals such as gold and silver.

Their zinc plating offers excellent corrosion resistance and is usually employed to protect steel surfaces. Nickel plating also serves as a protective layer and adds a high-lustre finish, ideal for both decorative and functional applications.

Chromium plating excels in creating a durable, mirror-like finish and is frequently used in automotive parts and household fixtures. Gold and silver plating services are often pursued for their superior conductivity and high-end appearance.

Quality control is a cornerstone of SourcifyChina’s operations. They employ cutting-edge technologies to ensure that every piece meets rigorous industry standards. Customer satisfaction remains paramount, driving continuous innovation and improvement in their plating services.

SourcifyChina places a strong emphasis on quality control throughout the plating metals manufacturing process. Experts meticulously test raw materials for composition and purity before they proceed to production, ensuring the end products meet stringent standards.

The manufacturing environment is rigorously controlled to maintain ideal conditions for plating. Parameters such as temperature, humidity, and solution concentration are constantly monitored and adjusted to ensure uniform coating and finish on the metal surfaces.

Quality checks occur at multiple stages of production. Intermediate products undergo regular inspections using advanced measurement tools to detect any deviations from specifications, allowing for immediate corrective actions.

Post-production, every piece undergoes an extensive final inspection. This includes both visual examinations and precision testing to measure coating thickness, adhesion strength, and other critical attributes. Only flawless products are approved for dispatch.

Continuous improvement practices underscore SourcifyChina’s commitment to excellence. Feedback from the inspection process is analyzed to refine methodologies and prevent future defects, embodying a relentless pursuit of quality.

SourcifyChina specializes in high-quality metal plating services, catering to a diverse range of industries. Their state-of-the-art facilities ensure precise and uniform coatings, enhancing durability and aesthetic appeal of metal parts.

Their capabilities span various types of plating, including gold, silver, copper, and nickel, tailored to meet specific client requirements. Advanced technology and stringent quality control processes guarantee exceptional results, from single prototypes to high-volume production runs.

Clients benefit from SourcifyChina’s expertise in electroplating, electroless plating, and anodizing, which improve corrosion resistance, electrical conductivity, and wear properties. Their skilled technicians optimize solutions for automotive, aerospace, electronics, and consumer goods sectors.

The company’s commitment to sustainability is evident in their environmentally-friendly processes, minimizing waste and reducing energy consumption. Continuous innovation and investment in research ensure they stay ahead of industry trends and maintain competitiveness.

In conclusion, SourcifyChina’s plating metal capabilities make them a reliable partner for businesses seeking top-tier finishing services. Their dedication to quality, versatility, and sustainability positions them as a leader in the metal plating industry.

Plating metals offers numerous advantages, enhancing both functionality and aesthetic appeal across various industries.

– Corrosion Resistance: Plating provides a protective barrier against rust and corrosion, significantly extending the life of metal components.

– Enhanced Durability: Metal plating increases the hardness and strength of materials, making them more resistant to wear and tear.

– Aesthetic Improvement: Plated metals often have a superior finish and appearance, which can be crucial for consumer products.

– Electrical Conductivity: Certain metal plating, such as gold or silver, improves the electrical conductivity of components, essential for electronic devices.

– Reduced Friction: Plated surfaces can have lower friction, which is beneficial for moving parts in machinery.

– Heat Resistance: Plating can improve the heat resistance of metals, making them suitable for high-temperature applications.

– Improved Solderability: Some plating materials make metals easier to solder, which is important for manufacturing electronic components.

– Biocompatibility: Metal plating is essential in medical devices and implants, ensuring they are compatible with the human body.

– Cost-Effective: Plating can be a more economical solution compared to manufacturing components entirely out of precious or corrosion-resistant metals.

– Environmental Protection: Modern plating techniques often focus on reducing the environmental impact by using safer materials and processes.

In summarizing, metal plating is a versatile and valuable process that significantly enhances the performance and aesthetics of metal components, proving indispensable across numerous fields.

Plating metals is a crucial technique in various industries, offering enhanced durability, aesthetic appeal, and resistance to corrosion. This method involves coating one metal with a thin layer of another metal.

– Corrosion Resistance: Metal plating provides a protective layer that shields the base metal from oxidation and corrosive environments.

– Enhanced Durability: The plated surface becomes harder and more wear-resistant, extending the lifespan of components.

– Improved Aesthetic Appeal: Metal plating can give products a shiny, polished appearance, which is often desirable in consumer goods.

– Electrical Conductivity: Plating with metals like gold or silver enhances the conductivity of electronic components.

– Friction Reduction: Plating metals can reduce friction between moving parts, which is particularly beneficial in mechanical applications.

– Heat Resistance: Certain plating materials offer superior thermal management, making them suitable for high-temperature environments.

– Chemical Resistance: Some plated metals can resist chemical reactions, protecting the base material in harsh chemical settings.

– Magnetic Properties: Plating with certain metals can enhance the magnetic properties of the base material.

– Customizability: Various metals and alloys can be chosen for plating, providing flexibility based on specific application needs.

– Cost-Effective: Metal plating can be a cost-effective solution to enhance cheaper base materials, providing premium qualities at a lower cost.

– Biocompatibility: Plating metals such as titanium and chromium can make medical devices safe for use inside the human body.

– Layer Uniformity: Precision in the plating process ensures a uniform layer, essential for specific engineering requirements.

– Regulatory Compliance: Plated metals often meet industry standards and regulations essential for safety and performance.

– Recyclability: Plated components can be recycled, contributing to sustainability and reducing environmental impact.

– Ease of Maintenance: Plated surfaces often require less maintenance due to their enhanced properties, saving time and resources.

Overall, metal plating significantly improves the properties and performance of materials, making it indispensable across numerous applications.

SourcifyChina is a leading provider of custom plating metal products, catering to a diverse range of industries. They specialize in high-quality metal plating solutions, ensuring durability and aesthetic appeal for their clients’ specific needs.

From automotive to electronics, their custom projects are tailored to meet unique specifications. SourcifyChina’s expertise includes various plating techniques such as gold, silver, zinc, and nickel plating, delivering exceptional results every time.

Their team works closely with clients to develop innovative solutions. They prioritize customer satisfaction and quality control, making them a trusted partner in metal plating. With state-of-the-art facilities, they handle both small-scale and large-scale orders efficiently.

SourcifyChina also emphasizes sustainability in their processes, using eco-friendly methods whenever possible. This commitment to the environment sets them apart from competitors, reflecting their dedication to responsible manufacturing practices.

In conclusion, SourcifyChina stands out for its customized, high-quality metal plating services. Their focus on detail and customer satisfaction, along with sustainable practices, ensures they meet and exceed client expectations.

SourcifyChina Plating Metals is an industry leader renowned for providing high-quality metal plating services across a broad spectrum of industries. Specializing in a variety of plating techniques, including but not limited to zinc, chrome, nickel, and gold, the company prides itself on its precision, durability, and adherence to stringent international standards. With a focus on innovation and environmental sustainability, SourcifyChina employs state-of-the-art technology and eco-friendly practices to ensure minimal ecological footprint. Their expertise extends to servicing automotive, electronics, aerospace, and luxury goods sectors, offering customized solutions to meet the specific needs of each client. Backed by a team of experienced professionals and engineers, the company is committed to continuous improvement, ensuring their plating solutions are both cutting-edge and economically viable. Customers around the globe trust SourcifyChina Plating Metals for its unwavering commitment to quality, timely delivery, and exceptional customer service, making it a cornerstone in the metal plating industry.

Plating metals is a crucial process in the aerospace, defense, and marine industries, providing essential protection and enhancing the performance of critical components. In aerospace applications, plating metals like chromium, nickel, and cadmium ensures that parts such as landing gear, engine components, and exhaust systems can withstand extreme temperatures, friction, and environmental exposure. The enhanced wear resistance and corrosion protection offered by metal plating are vital for maintaining the integrity and reliability of aircraft systems, ultimately contributing to the safety and longevity of the aircraft. Additionally, the reduction in friction through lubricative coatings can lead to better fuel efficiency and performance, which are critical parameters in the highly competitive aerospace sector.

In the defense industry, metal plating serves a multifaceted role, from improving the durability of weapons systems to providing essential resistance against harsh operational environments. Commonly used in the plating of firearms, military vehicles, and electronic equipment, metals like gold, silver, and zinc are employed to ensure electrical conductivity, enhance corrosion resistance, and increase overall robustness. In marine applications, the constant exposure to saltwater poses a significant threat to metal components. Plating metals such as zinc and copper-nickel alloys are extensively engineered to protect ship hulls, propellers, and underwater structures against corrosion and biofouling. This prolongs the service life of marine vessels and reduces maintenance costs, while also ensuring safe and efficient operation in demanding maritime environments.

Automotive Application of Plating Metals:

In the automotive industry, metal plating is a crucial process for enhancing the durability, performance, and aesthetic appeal of various vehicle components. For example, chrome plating is extensively used on car parts such as bumpers, grilles, and trim to provide a reflective, mirror-like finish that is not only visually appealing but also resistant to corrosion and wear. Similarly, the undercarriage parts are often plated with zinc or cadmium to offer superior protection against harsh environmental conditions, including salt and moisture, which can lead to rust and deterioration. Plated metals also exhibit improved hardness and wear resistance, ensuring that engine components and other mechanical parts such as gears and shafts maintain their integrity and functionality over prolonged periods of usage. This results in lower maintenance costs and extended lifespans of automotive components, thereby adding value and reliability to vehicles.

Electronics Application of Plating Metals:

In the electronics sector, metal plating is integral in the manufacturing of circuit boards, connectors, and various electronic components. Gold plating, for instance, is widely utilized for coating connectors and contacts due to its excellent electrical conductivity and resistance to tarnishing and corrosion. This ensures reliable and efficient signal transmission, critical for the performance of electronic devices. Additionally, tin and nickel plating are common in the production of printed circuit boards (PCBs), providing solderability and protection against oxidation, which can impair the functionality of the circuits. The precise application of metal plating in microelectronics helps in achieving fine detailing and uniform distribution of conductive materials, essential for the miniaturization and efficiency of modern electronic gadgets. As electronic devices become more complex and compact, metal plating continues to be an indispensable technique that supports innovation and technological advancement in the industry.

Plating metals plays a significant role in construction due to its ability to enhance the durability and appearance of building materials. By coating metals like steel or aluminum with layers of zinc, chrome, or nickel, the construction industry can effectively protect these materials from corrosion and wear. In environments where metallic structures are exposed to harsh weather conditions, moisture, or chemicals, such as bridges, pipelines, and skyscrapers, metal plating extends the lifespan of the components, thereby reducing maintenance costs and improving safety. Additionally, the aesthetic appeal of plated metals contributes to architectural designs, offering sleek finishes and varied appearances that meet both structural and visual demands.

In the realm of energy, metal plating is indispensable in improving the efficiency and longevity of components used in power generation and distribution. For instance, the internal surfaces of turbines and engines in power plants are often plated with alloys like chromium or platinum to withstand high temperatures and reduce friction, thereby enhancing operational efficiency. In renewable energy sectors, such as solar and wind power, connectors and electrical components benefit from silver or gold plating to ensure excellent conductivity and resistance to corrosion, which is crucial for reliable energy transmission. Moreover, in battery technology, particularly in advanced lithium-ion batteries, metal plating is employed on electrodes to enhance charge capacity and cycle stability, thus pushing forward the performance of energy storage systems. By leveraging plating technologies, the energy sector can achieve more reliable, efficient, and sustainable operations.

The industrial equipment industry heavily relies on the application of metal plating to enhance the durability, functionality, and aesthetics of various components. Metal plating is the process of depositing a thin layer of metal onto the surface of a substrate, which is often composed of a different metal. This technique is quintessential in improving resistance to corrosion, wear, and friction, thus significantly extending the lifespan and reliability of industrial machinery. Commonly used metals for plating include nickel, chromium, zinc, and gold. Nickel plating, for instance, is particularly favoured for its remarkable ability to provide a uniform coating and enhance the surface hardness of machine parts, making it invaluable for components exposed to rigorous operational environments.

Another significant application of metal plating in the industrial equipment sector is in improving the electrical conductivity and solderability of components, which is crucial for the production of high-performance electrical and electronic equipment. Copper plating, for example, is widely utilized for its excellent conductive properties, making it suitable for enhancing connectors, switches, and other integral parts of electrical machinery. Additionally, the aesthetic appeal provided by metal plating cannot be understated, as parts can be plated with precious metals such as gold and silver to prevent tarnish and provide a high-gloss finish, which is essential for equipment exposed to public or customer-facing environments. Overall, metal plating is a multifaceted process that brings critical enhancements across various dimensions of industrial equipment, underscoring its indispensable role in the sector.

Plating metals in the realm of medical devices is a critical technology that enhances the biocompatibility, durability, and functionality of various implants and instruments. Medical devices such as stents, orthopedic implants, pacemakers, and surgical instruments often require specialized coatings to ensure they are both safe and effective when used within the human body. Plating with biocompatible metals like titanium, gold, and platinum is particularly beneficial as these metals are less likely to cause allergic reactions or adverse tissue responses. These coatings can also improve the corrosion resistance and mechanical strength of the underlying materials, making the devices more reliable and longer-lasting. For example, the gold plating often used in pacemaker electrodes enhances electrical conductivity while minimizing the risk of immune reactions, thus ensuring the seamless performance of the device over long periods.

Additionally, the application of antimicrobial metal coatings, such as silver, is gaining traction for its ability to reduce the risk of infections associated with medical devices. Silver-plated catheters and wound dressings, for instance, have demonstrated significant antibacterial properties, which help to prevent bacterial colonization and biofilm formation that could lead to infections. Furthermore, plating processes such as electroplating or physical vapor deposition can be precisely controlled to create uniform and adherent coatings, which are crucial for maintaining device performance without compromising structural integrity. The innovation in plating technologies, including the development of nano-coatings, is paving the way for next-generation medical devices that offer superior performance and patient outcomes. By enhancing the surface properties of medical devices, metal plating plays a vital role in advancing healthcare technology and improving the quality of life for patients.

Plating metals is a fundamental application in both machining and manufacturing, aimed at enhancing the performance, durability, and aesthetic appeal of various components. In machining, metal plating is often applied to tools and machine parts to extend their lifespan and improve their resistance to corrosion and wear. For instance, cutting tools coated with titanium nitride or chromium last significantly longer and maintain sharpness better than uncoated tools. This process not only reduces the frequency of tool replacement but also enhances the precision and efficiency of machining operations, ultimately resulting in cost and time savings for manufacturers.

In broader manufacturing contexts, metal plating serves multiple strategic purposes. One common application is in the automotive industry, where chrome plating is used to provide a shiny, corrosion-resistant surface on parts like bumpers and exhaust systems. Electroplating with nickel or gold is prevalent in electronics manufacturing to ensure superior conductivity and protect sensitive components from oxidation. Additionally, metal plating is used in aerospace and medical device manufacturing to meet stringent regulatory and performance standards. Overall, the application of plating metals in manufacturing processes is pivotal for improving product quality, ensuring compliance with industry requirements, and maximizing the functional life of various products.

Here is a list of frequently asked questions (FAQs) along with their answers regarding manufacturing “plating metals quality work” from the SourcifyChina factory:

Q: What types of metal plating services do you offer?

A: SourcifyChina provides a wide range of metal plating services including nickel plating, chrome plating, zinc plating, gold plating, and more. Each type is suitable for different applications, ensuring high-quality finishes for various industrial needs.

Q: What industries can benefit from your metal plating services?

A: Our metal plating services cater to multiple industries such as automotive, electronics, aerospace, and consumer goods. We tailor our solutions to meet the specific requirements of each sector.

Q: How do you ensure the quality of your plating work?

A: Quality is our top priority. We use state-of-the-art equipment, employ skilled technicians, and follow strict industry standards. Our in-house quality control team conducts rigorous inspections throughout the plating process to ensure consistency and durability.

Q: What certifications does SourcifyChina hold?

A: SourcifyChina is ISO 9001:2015 certified, ensuring that our processes meet international quality management standards. We also comply with RoHS and REACH regulations to maintain environmental and safety standards.

Q: Can you handle high-volume orders?

A: Yes, SourcifyChina is equipped to handle both small batch and high-volume orders. Our flexible manufacturing capabilities allow us to scale production based on your needs without compromising on quality.

Q: Do you offer customization services?

A: Absolutely! We provide customized plating solutions tailored to your specifications. Our engineering team works closely with clients to deliver bespoke finishes that meet their unique requirements.

Q: What is the typical lead time for a project?

A: Lead times vary depending on the project size and complexity. On average, it takes about 2-4 weeks from order confirmation to delivery. We strive to meet your deadlines without sacrificing quality.

Q: How can I get a quote for my project?

A: You can request a quote by visiting our website and filling out the request form, or you can contact our customer service team directly via email or phone. Please provide detailed information about your project for an accurate estimate.

Q: Do you provide samples before mass production?

A: Yes, we offer sample production to ensure that the quality and finish meet your expectations before proceeding with mass production. This helps in making any necessary adjustments early in the process.

Plating metals is a crucial process in various industries, and selecting a reliable partner like SourcifyChina factory can significantly impact your project’s success. Here are essential tips for effective metal plating manufacturing:

1. Material Compatibility: Ensure the base metal is compatible with the plating material. SourcifyChina can provide expert advice on optimal combinations for durability and performance.

2. Quality Control: Prioritize a factory with stringent quality control measures. SourcifyChina employs advanced testing protocols to ensure defect-free plating, enhancing the final product’s longevity and functionality.

3. Advanced Technology: Leverage a factory equipped with modern plating technologies. SourcifyChina utilizes state-of-the-art machinery, which ensures uniform coating thickness and superior adhesion.

4. Customization Capabilities: Choose a manufacturer that offers customization to meet specific requirements. SourcifyChina can tailor plating thickness, finish, and other parameters to suit your exact needs.

5. Eco-Friendly Practices: Opt for a factory that adheres to environmental regulations. SourcifyChina implements eco-friendly practices, including waste reduction and recycling, to minimize environmental impact.

6. Expert Workforce: Skilled labor ensures precision and quality. SourcifyChina’s team of experienced professionals guarantees meticulous attention to detail in every plating project.

7. Timely Delivery: Timeliness is critical in manufacturing. SourcifyChina is known for its efficient processes and reliable delivery schedules, helping you meet tight deadlines without compromising quality.

8. Transparent Communication: Establish clear communication channels for regular updates. SourcifyChina provides detailed progress reports to keep you informed throughout the production process.

9. Cost-effectiveness: Evaluate the pricing structure to ensure it aligns with your budget without sacrificing quality. SourcifyChina offers competitive rates while maintaining high standards.

By considering these tips, you can maximize the benefits of working with SourcifyChina for your metal plating needs, ensuring superior quality, efficiency, and cost-effectiveness.

1. What types of plating metals does SourcifyChina factory offer?

SourcifyChina factory provides a wide range of plating metals, including but not limited to gold, silver, nickel, copper, and chrome. They can accommodate specific requirements based on your project needs.

2. What is the minimum order quantity (MOQ) for plating metals?

The MOQ at SourcifyChina factory typically varies depending on the type of metal and the complexity of the project. Generally, the MOQ starts from 50 pieces but can be adjusted for bulk orders.

3. Can SourcifyChina factory handle custom plating projects?

Yes, SourcifyChina factory specializes in custom plating projects. Clients are encouraged to provide detailed specifications, and the factory’s skilled team will work to meet your custom needs.

4. How long does it take to complete a plating order?

Lead times can vary depending on the volume and complexity of the order. Standard lead times range from 2 to 4 weeks. Expedited services might be available upon request.

5. What quality assurance measures are in place?

SourcifyChina factory adheres to stringent quality control standards, including ISO certifications and rigorous in-house testing. They ensure every product meets the client’s requirements before shipping.

6. Are samples available before placing a bulk order?

Yes, samples are available and can be provided to ensure the quality and suitability of the plating metals. Sample fees may apply and can often be deducted from the bulk order cost.

7. What kind of customer support is available?

SourcifyChina factory offers comprehensive customer support, including pre-sale consultations, production updates, and post-sale assistance. They can be contacted via email, phone, or through their website.

8. How are the plated products packaged for shipping?

Plated products are carefully packaged using materials that prevent damage during transit, such as bubble wrap, foam inserts, and sturdy boxes. Custom packaging solutions are also available if required.

9. What payment methods are accepted?

SourcifyChina factory accepts various payment methods, including bank transfers, PayPal, and major credit cards. Terms can be discussed during the order process.

10. Are there any environmental considerations in the plating process?

The factory employs eco-friendly plating processes and complies with relevant environmental regulations to minimize ecological impact. They use non-toxic chemicals and recycle waste materials whenever possible.

When sourcing plating metals from SourcifyChina factory, follow these tips to ensure a smooth and efficient process:

1. Research and Due Diligence:

– Verify the reputation of SourcifyChina through reviews and testimonials.

– Check their compliance with international standards and certifications for metal plating.

– Assess their production capabilities and quality control measures.

2. Define Requirements Clearly:

– Clearly outline the type of plating metal (e.g., gold, silver, nickel) and specific grade or quality.

– Provide detailed specifications regarding thickness, finish, and any other technical requirements.

3. Request Samples:

– Ask for sample products to evaluate quality firsthand before committing to a large order.

– Ensure samples match your specifications exactly.

4. Negotiate Terms:

– Discuss and agree on pricing, minimum order quantities, lead times, and payment terms.

– Clarify any additional costs like shipping, duties, or taxes.

5. Quality Assurance:

– Implement a robust quality assurance process, including third-party inspections if necessary.

– Arrange periodic inspections during production and pre-shipment to ensure compliance with your standards.

6. Communication:

– Maintain clear and consistent communication with the factory.

– Use detailed purchase orders and contracts that specify every agreed term, including packaging and labeling requirements.

7. Intellectual Property Protection:

– Protect your designs and specifications through NDAs and other legal agreements.

– Ensure that all intellectual property aspects are covered to avoid potential infringements.

8. Logistics and Shipping:

– Plan logistics carefully, considering factors like shipping methods and timelines.

– Choose a reliable shipping partner familiar with international freight and customs procedures.

9. Sustainable Practices:

– Inquire about the factory’s environmental and social responsibility practices.

– Favor suppliers that demonstrate sustainability and ethical production processes.

By following these steps, you can effectively source plating metals from SourcifyChina, ensuring quality, cost-efficiency, and timely delivery.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.