Choosing SourcifyChina Factory ensures top-tier precision machining products due to its state-of-the-art technology and rigorous quality control measures. This guarantees products meet exact specifications with high consistency. Additionally, SourcifyChina has extensive industry expertise, allowing it to cater to diverse and complex client requirements efficiently.

Furthermore, the factory offers competitive pricing without compromising on quality, making it an attractive option for cost-conscious buyers. SourcifyChina’s robust supply chain network ensures timely delivery and reduces lead times, enhancing overall customer satisfaction. Their transparent and responsive customer service supports smooth communication, fostering trust and reliability.

With a dedicated team of skilled professionals, SourcifyChina continually innovates and adopts best practices to stay ahead in the precision machining industry. Their commitment to continuous improvement and adherence to international standards ensure products of the highest quality. Choosing SourcifyChina Factory means investing in reliability, excellence, and exceptional value.

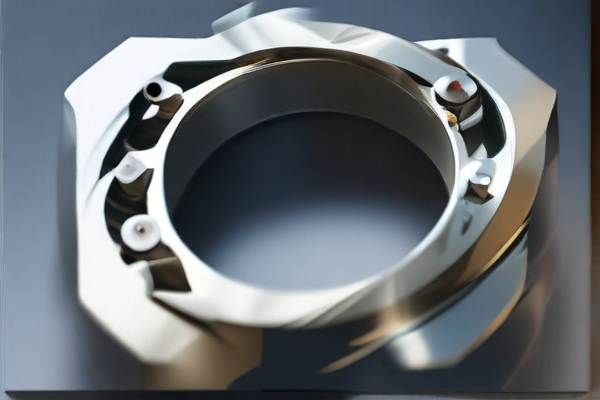

Precision machining products encompass a wide range of items crafted with high accuracy and tight tolerances. These products are essential in various industries, ensuring reliability and optimal performance.

Types and options for precision machining products include:

– CNC Machined Parts: High precision, customizable components made using computer numerical control machines.

– Turned Components: Cylindrical parts produced by lathes, essential for automotive and aerospace applications.

– Milled Parts: Complex shapes achieved through multi-axis milling machines, used in electronics and medical devices.

– EDM Parts: Electrical Discharge Machining components, ideal for hard materials and intricate designs.

– Injection Mold Tooling: Precision molds for plastic components, crucial in consumer goods and medical devices.

– Grinding Products: Super-finished parts with extremely tight tolerances, often used in the automotive and aerospace sectors.

– Laser Cut Parts: High-precision parts made with laser cutting, suitable for intricate designs and rapid prototyping.

– Micro Machining Components: Tiny, precise parts for electronics, medical devices, and micro-mechanical systems.

– Prototyping Services: Custom, precision prototypes for product development and testing.

– Swiss Machined Parts: Highly accurate and small parts produced by Swiss-type lathes, used in watchmaking and medical instruments.

Precision machining products find applications across various industries due to their high accuracy and reliability. These products enable the creation of complex parts and components essential for modern technology and engineering.

– Aerospace: Precision machining products are crucial for manufacturing aircraft components such as turbine blades, engine parts, and structural elements.

– Medical Devices: High-precision machining is used to produce surgical instruments, implants, and diagnostic equipment that require exact specifications.

– Automotive: Machined parts are essential for engines, transmissions, and safety systems, ensuring performance and safety.

– Electronics: Precision machining is used to create housings, connectors, and micro-components for smartphones, computers, and other electronic devices.

– Defense: Components for weapons systems, vehicles, and communication equipment rely on precision machining for durability and performance.

– Robotics: Custom-machined parts are vital for building robots with precise movements and functionalities.

– Energy: Precision components are required in oil and gas exploration, renewable energy systems, and power generation equipment.

– Industrial Machinery: High-precision parts ensure the efficiency and longevity of machinery in manufacturing processes.

– Optics: Machining of lenses, mirrors, and other optical components demands extremely high precision.

– Jewelry and Fashion: Precision machining provides detailed designs and intricate patterns for high-end jewelry and fashion accessories.

In summary, precision machining products are indispensable across a wide range of industries, improving efficiency, performance, and innovation in technology and manufacturing.

SourcifyChina specializes in precision machining products crafted from high-quality materials. Their primary materials include stainless steel, aluminum, and titanium, chosen for their durability, corrosion resistance, and excellent mechanical properties.

Stainless steel is favored for its strength and resistance to rust, making it ideal for medical, automotive, and aerospace applications. The material ensures long-lasting performance in demanding environments.

Aluminum is lightweight yet strong, providing excellent thermal conductivity and resistance to corrosion. It is extensively used in industries such as aerospace, automotive, and electronics, where weight reduction is crucial.

Titanium, known for its superior strength-to-weight ratio and biocompatibility, is essential in medical implants, aerospace, and high-performance engineering applications. Its resistance to extreme temperatures and chemicals adds to its versatility.

In summary, SourcifyChina’s use of these materials ensures their precision machining products meet the rigorous standards required by various high-tech industries, offering reliability, longevity, and optimal performance.

SourcifyChina excels in precision machining products through a rigorous quality control manufacturing process. The journey begins with raw material inspection to ensure all materials meet stringent standards before production.

State-of-the-art CNC machines are used to achieve exact specifications. Each stage of the machining process is meticulously monitored by skilled technicians to maintain high accuracy and consistency.

After machining, products undergo thorough inspections, including dimensional checks and surface quality assessments, using advanced measurement tools. This ensures each piece meets the precise requirements.

Finally, products are subjected to rigorous functional tests under various conditions. This comprehensive quality control process guarantees that SourcifyChina delivers precision machining products of the highest quality and reliability to its customers.

SourcifyChina offers top-tier precision machining products, catering to diverse industries such as aerospace, automotive, and medical. Their state-of-the-art facilities ensure high-quality and accurate manufacturing.

Utilizing advanced CNC machines, SourcifyChina delivers components with tight tolerances and complex geometries. This ensures consistency and reliability across all production batches.

Their team of skilled engineers collaborates closely with clients, providing custom solutions tailored to specific requirements. This client-focused approach enhances product development and innovation.

SourcifyChina’s rigorous quality control measures include thorough inspections and testing. These practices guarantee that each product meets stringent industry standards and customer expectations.

With a commitment to continuous improvement and cutting-edge technology, SourcifyChina consistently provides superior precision machining solutions, ensuring client satisfaction and long-term partnerships.

Precision machining products offer unparalleled accuracy and efficiency, making them essential in various high-tech industries like aerospace, medical, and automotive.

– High Accuracy: Ensures components meet exact specifications, reducing error margins.

– Consistency: Produces identical parts with minimal variation, vital for mass production.

– Efficiency: Reduces material waste and minimizes the need for additional processing.

– Cost-Effectiveness: Lowers production costs over time by maximizing raw material usage.

– Quality: Delivers high-quality finishes that enhance the longevity and reliability of the final product.

– Versatility: Can work with various materials, including metals, plastics, and composites.

– Speed: Accelerates production timelines while maintaining high standards.

– Innovation: Facilitates the development of complex, cutting-edge designs.

Precision machining is a cornerstone for industries looking to achieve excellence and innovation.

Precision machining products boast exceptional accuracy and high-quality finishes, critical for industries such as aerospace, medical, and automotive.

– Tight Tolerances: Precision machined parts offer extremely tight tolerances, ensuring components fit together perfectly and function seamlessly.

– Surface Finish: Achieve superior surface finishes that meet stringent specifications and enhance the overall performance and appearance of the components.

– Material Versatility: Capable of working with a wide range of materials, including metals, plastics, ceramics, and composites, to meet diverse industry needs.

– Complex Geometries: Ability to create intricate and complex shapes that would be difficult or impossible with conventional machining techniques.

– Repeatability and Consistency: Ensures that every part produced matches the exact specifications, essential for mass production and high-reliability applications.

– Efficiency: High-speed and efficient production processes reduce cycle times and increase throughput, making it cost-effective for large and small-scale production runs.

– Customization: Facilitates highly customized solutions tailored to specific application requirements, providing versatility for unique designs.

– Advanced Technology: Utilization of state-of-the-art machinery and computer-aided design (CAD) for enhanced precision and innovation.

– Quality Assurance: Rigorous quality control measures and inspections ensure that all parts meet or exceed industry standards and customer expectations.

– Cost-Effective: While initial setup may be expensive, the long-term benefits of precision, reduced waste, and lower rejection rates contribute to overall cost savings.

– Durability: Produces highly durable and reliable parts that can withstand demanding conditions and prolonged use.

– Scalability: Flexibility to scale up production efficiently as demand grows without compromising on quality.

The combination of these features makes precision machining indispensable for high-precision applications, offering unparalleled performance, reliability, and quality.

SourcifyChina specializes in precision machining products, delivering custom components with high accuracy and reliability. Their state-of-the-art facilities ensure top-notch quality and adherence to exact specifications.

Their custom products range from intricate parts for aerospace to robust components for automotive industries. SourcifyChina meets diverse industry needs with precision engineering and superior materials.

SourcifyChina takes on complex projects, from initial design to final production, providing comprehensive support throughout the process. Their experienced team ensures timely delivery and optimal performance.

By leveraging advanced technology and skilled craftsmanship, SourcifyChina maintains a reputation for excellence in custom precision machining. Their commitment to quality and customer satisfaction sets them apart in the market.

SourcifyChina Precision Machining Products is a leading manufacturer specializing in high-quality, custom precision machining solutions. With a reputation for excellence, the company offers a comprehensive range of services, including CNC milling, turning, and assembly. Their state-of-the-art facilities are equipped with advanced machinery and staffed by skilled technicians, ensuring the production of components that meet stringent tolerances and complex specifications. SourcifyChina caters to diverse industries such as aerospace, automotive, medical, and electronics, providing tailored solutions that enhance performance and reliability. Committed to quality and customer satisfaction, the company adheres to strict quality control processes and international standards. Through innovation and continuous improvement, SourcifyChina remains at the forefront of the precision machining industry, delivering exceptional products and services that drive success for their clients worldwide.

In aerospace, defense, and marine industries, precision machining products are critical for achieving the exceptional levels of accuracy and performance these sectors demand. In aerospace, components such as turbine blades, landing gear, and structural frames must meet stringent tolerances to ensure safety and optimal performance under extreme conditions. Precision machining allows for the meticulous production of these complex components, with CNC (computer numerical control) technology enabling highly repeatable and consistent manufacturing processes. This precision is essential not only for the mechanical fit but also for the aerodynamic efficiency and longevity of aircraft parts, which operate under high stress and require materials that can withstand significant thermal and mechanical loads.

In the defense sector, precision machining products play a vital role in the development and maintenance of advanced weaponry, surveillance systems, and armored vehicles. High-precision parts are needed for missile guidance systems, radar components, and communication devices, ensuring reliable functionality and interoperability in critical mission scenarios. Similarly, in the marine industry, precision-machined parts are indispensable for the manufacture of propellers, engine components, and underwater exploration equipment. The rigorous environments encountered at sea, including high pressure and corrosive conditions, necessitate components of exceptional accuracy and durability. Using precision machining, manufacturers can produce intricate parts that contribute to the overall safety, reliability, and efficiency of naval and marine equipment, making it an indispensable technology in these high-stakes fields.

Precision machining products play an integral role in the automotive industry, where the demand for highly accurate and reliable components is ever-growing. From engine blocks and transmission parts to intricate components of fuel injection systems and turbochargers, precision machining ensures each part meets stringent specifications and tolerances. This level of exactitude is crucial not only for optimal performance but also for the safety and longevity of vehicles. In electric vehicles (EVs), precision machining is even more critical, given the complexity and compactness of electric drivetrains and battery systems. Advanced techniques such as computer numerical control (CNC) machining enable manufacturers to produce complex geometries with minimal waste, pushing the boundaries of automotive innovation while ensuring cost-effectiveness and sustainability.

In the realm of electronics, precision machining products are indispensable for manufacturing the minuscule and intricate components that define modern electronic devices. Printed circuit boards (PCBs), semiconductor components, and microelectromechanical systems (MEMS) all require the exactitude that precision machining provides. With the ongoing miniaturization in technology, even small deviations can lead to significant performance issues or failures. High-precision machining allows for the production of components with micron-level tolerances, essential for the function and reliability of smartphones, laptops, and various other consumer and industrial electronics. Moreover, cutting-edge techniques like 5-axis machining make it possible to produce more complex components with fewer setups, enhancing manufacturing efficiency and reducing lead times. This capability is vital in a market where the pace of technological advancement and consumer demand for new products is relentless.

Precision machining products play a crucial role in the construction industry by providing highly accurate and reliable components essential for various building and infrastructure projects. These products, such as custom-made bolts, brackets, and joints, ensure that structures are assembled with exact specifications, which enhances their stability and longevity. The precision in these components minimizes the risk of structural failures, which is vital for both safety and performance. Additionally, precision-machined tools and parts are integral in the manufacturing of heavy machinery used in construction, such as cranes and excavators, enabling them to operate smoothly and efficiently under rigorous conditions.

In the energy sector, precision machining products are indispensable for the development and maintenance of energy generation and distribution systems. Components like turbine blades, pump housings, and valve parts require high precision to ensure optimal performance and efficiency in power plants, whether they are fossil fuel, nuclear, or renewable energy facilities. The accuracy and reliability of these machined parts are critical in maintaining the integrity of systems operating under extreme pressures and temperatures. Furthermore, in the renewable energy industry, precision machining aids in the creation of components for wind turbines, solar panels, and other sustainable energy technologies, thereby contributing to more efficient and sustainable energy production solutions.

The industrial equipment industry extensively utilizes precision machining products to enhance the performance and reliability of various machinery and components. Precision machining allows for the fabrication of parts with extremely tight tolerances and intricate designs, which are essential for ensuring the smooth operation of complex machinery. For example, in the production of turbines, gears, and hydraulic components, precision machining ensures that each part fits perfectly and operates efficiently under high stress and demanding conditions. This level of accuracy minimizes wear and tear, reduces maintenance costs, and extends the lifespan of the equipment, making it a critical aspect of the manufacturing process for industrial equipment.

Moreover, precision machining is pivotal in the customization and innovation within the industrial equipment sector. It enables manufacturers to produce bespoke components tailored to specific applications, thereby improving the functionality and adaptability of the equipment. With advancements in CNC (Computer Numerical Control) technology, precision machining can achieve complex geometries and fine details that were previously unattainable. This capability is crucial for industries such as aerospace, automotive, and medical devices, where even the slightest deviation can significantly impact performance and safety. By leveraging precision machining, the industrial equipment industry can maintain high standards of quality, push the boundaries of engineering possibilities, and meet the stringent requirements of modern applications.

Precision machining products have become a cornerstone in the medical devices industry, enabling the creation of highly intricate and reliable components that are vital for patient care. These products are manufactured using advanced techniques like CNC (Computer Numerical Control) machining, laser cutting, and micro-machining, ensuring an extraordinary level of accuracy and consistency. Precision machining allows for the production of complex geometries and extremely tight tolerances, essential for devices such as surgical instruments, implantable devices like hip and knee joints, and intricate components of diagnostic equipment. The stringent requirements of the medical sector for biocompatibility and sterilization also highlight the need for high-quality materials and finishes that precision machining can consistently deliver.

Furthermore, the precision machining process enhances the customization and personalization of medical devices to better meet the unique needs of individual patients. For example, custom prosthetics and dental implants can be precision-machined to fit perfectly, providing superior comfort and functionality. Additionally, precision machining aids in the rapid prototyping and iterative design processes crucial for innovation in the medical field, enabling the swift transition from concept to production. This accelerates the development of new and improved medical devices, which can significantly enhance treatment outcomes and the quality of life for patients. Overall, the application of precision machining products in medical devices not only supports the creation of highly reliable and effective medical solutions but also fosters advancements that drive the industry forward.

Precision machining products are pivotal in the realm of machining and manufacturing, providing high accuracy and efficiency in creating components that meet stringent specifications. Utilizing advanced technologies such as computer numerical control (CNC) machining, these products ensure that each part produced is consistent and meets the exact dimensions required by various industries. This precision is essential in sectors like aerospace, automotive, and medical devices, where even the slightest deviation can lead to significant operational issues or safety concerns. The use of precision machining products also enhances production speed, reduces material waste, and minimizes the need for manual adjustments, thereby streamlining manufacturing processes and improving overall productivity.

In manufacturing, precision machining products enable the production of complex geometries and intricate designs that would be challenging or impossible to achieve with traditional machining methods. These products support a wide range of applications, from creating prototypes to mass-producing parts with exceptional repeatability. For example, in the automotive industry, precision machining is used to produce engine components, transmission parts, and various other critical assemblies with tight tolerances. In the medical field, it allows for the fabrication of surgical instruments, implants, and prosthetics that require exceptional precision to ensure patient safety and efficacy. The adaptability and precision of these machining products make them indispensable in modern manufacturing, driving innovation and ensuring the high-quality output necessary for today’s advanced technological applications.

What types of precision machining services do you offer?

We offer a wide range of precision machining services, including CNC milling, CNC turning, grinding, and EDM (Electrical Discharge Machining). Our capabilities also extend to complex component manufacturing, prototype production, and high-volume production runs.

What materials can you machine?

Our factory is equipped to machine various materials, including stainless steel, aluminum, titanium, brass, copper, and various plastics. We ensure material quality to meet your specific requirements and standards.

What quality control measures are in place?

We implement stringent quality control measures, including in-process inspections, final inspections, and the use of advanced measurement tools like CMM (Coordinate Measuring Machines). Our quality management system is ISO 9001 certified, ensuring consistent and reliable quality.

Can you provide custom machining solutions?

Yes, we specialize in custom machining solutions tailored to your unique specifications. Our team works closely with clients to understand their needs and provide bespoke machining services that meet exacting standards.

What is your turnaround time for orders?

Turnaround times vary depending on the complexity and quantity of the order. Typically, prototype orders take 1-2 weeks, while larger production runs may take 4-6 weeks. We strive to meet your deadlines and offer expedited services if required.

Do you offer prototyping services?

Yes, we provide prototyping services to help you validate designs and functionality before full-scale production. Our prototyping services ensure that you can make necessary adjustments early in the development process.

How do you handle shipping and logistics?

We manage shipping and logistics to ensure timely delivery of your products. We partner with reputable shipping companies and provide comprehensive documentation and tracking information to ensure smooth and efficient delivery.

Can you handle high-volume production?

Yes, our facility is equipped to handle high-volume production runs while maintaining the highest quality standards. We utilize advanced machinery and efficient production processes to meet large-scale demands.

What industries do you serve?

We serve a wide range of industries, including aerospace, automotive, medical, electronics, and industrial equipment. Our diverse experience allows us to cater to the specific needs of each industry.

How can I request a quote?

You can request a quote by contacting us through our website or emailing our sales team. Please provide detailed information about your project, including drawings, material specifications, and quantities required. Our team will respond promptly with a detailed quotation.

When it comes to precision machining products manufacturing from SourcifyChina factory, leveraging these tips can ensure you get high-quality components efficiently:

– Clearly outline your product requirements including dimensions, tolerances, materials, and finishes. Precision machining relies on exact details.

– Choose appropriate materials for your application, considering factors like strength, durability, and cost. SourcifyChina typically offers a range of materials including metals and plastics.

– Start with a prototype to verify the design and machining process. This helps catch potential issues early, ensuring the final product meets your specifications.

– Specify the tolerances you require. SourcifyChina can adhere to tight tolerances, but clear communication is vital to avoid misunderstandings.

– Inquire about the factory’s machinery and technology. Advanced CNC machines and CAD/CAM software can significantly impact the precision and efficiency of the manufacturing process.

– Maintain regular communication with the factory. Use video calls, emails, and drawings to ensure both parties are aligned. Effective collaboration can prevent costly errors.

– Ensure robust quality control measures are in place, including rigorous inspection processes. Request a detailed quality report with each batch.

– Discuss lead times upfront to plan your production schedule better. Efficient logistics and timely deliveries are crucial to maintaining your supply chain.

– While aiming for cost savings, do not compromise on quality. SourcifyChina can offer competitive pricing, but balance it with the precision and quality requirements of your project.

– Leverage the factory’s experience by asking for case studies or references from similar projects. An experienced manufacturer will be well-versed in handling complex precision machining tasks.

By following these tips, you can optimize your precision machining needs with SourcifyChina, ensuring high-quality production that meets your exact specifications.

FAQ for Sourcing Precision Machining Products from SourcifyChina Factory

Q: What types of precision machining products does SourcifyChina factory offer?

A: SourcifyChina factory offers a wide range of precision machining products, including CNC machined parts, turned parts, milled components, and custom machined components for various industries such as automotive, aerospace, medical, and electronics.

Q: How can I request a quote for precision machining products?

A: To request a quote, visit the SourcifyChina website and fill out the quote request form. Provide detailed information about your requirements, including material specifications, dimensions, tolerances, and quantity.

Q: What is the lead time for orders?

A: The lead time for orders varies depending on the complexity and quantity of the products. Generally, it ranges from 2 to 4 weeks. For urgent orders, expedited services are available upon request.

Q: Does SourcifyChina provide samples before production?

A: Yes, SourcifyChina offers prototype and sample production services. Samples can be provided for approval before commencing full-scale production to ensure the product meets your specifications.

Q: What quality control measures are in place at SourcifyChina?

A: SourcifyChina employs rigorous quality control measures, including ISO certification, in-process inspections, and final inspections. They use advanced measurement tools and equipment to ensure all products meet the highest quality standards.

Q: Can SourcifyChina handle custom designs?

A: Absolutely. SourcifyChina specializes in custom precision machining and can work with your design team to produce parts according to your exact specifications.

Q: What materials can SourcifyChina work with?

A: SourcifyChina can machine a variety of materials including aluminum, steel, stainless steel, brass, titanium, plastics, and more, depending on your project requirements.

Q: How does SourcifyChina ensure competitive pricing?

A: SourcifyChina leverages advanced manufacturing technologies and efficient production processes to offer competitive pricing without compromising on quality.

Q: What are the payment terms for placing an order?

A: Payment terms are typically 30% deposit upon order confirmation and 70% balance before shipment. SourcifyChina accepts various payment methods, including bank transfer and PayPal.

Q: How can I contact SourcifyChina for further inquiries?

A: You can contact SourcifyChina via email, phone, or through the contact form on their website. Their customer service team is available to assist with any inquiries you may have.

Sourcing precision machining products from a factory like SourcifyChina requires a systematic approach to ensure quality and reliability. Here are some tips to guide you:

1. Research and Verify Credentials:

– Certifications: Check for ISO and other relevant certifications to ensure quality standards.

– Reputation: Look for factory reviews and testimonials. Use platforms like Alibaba, Global Sources, or Made-in-China for additional insights.

2. Detailed Specifications:

– Provide detailed product specifications and tolerances. Precision machining demands exacting standards.

– Share any CAD drawings or prototypes to avoid misunderstandings.

3. Request for Samples:

– Ask for samples to assess quality before committing to large orders.

– Evaluate samples for precision, finish, and conformity to specifications.

4. Quality Control:

– Establish clear quality control measures and acceptable quality limits.

– Consider third-party inspections for added assurance.

5. Communication:

– Maintain clear and consistent communication. Language barriers can be mitigated by detailed, unambiguous instructions.

– Use video calls to discuss specifications, expectations, and progress.

6. Lead Times and MOQs:

– Clarify lead times and Minimum Order Quantities (MOQs) upfront to avoid delays and misunderstandings.

– Factor in time for potential rework or adjustments.

7. Logistics and Shipping:

– Discuss logistics early on, including packaging standards and shipping methods.

– Consider using freight forwarders experienced in handling precision equipment.

8. Costing and Payment Terms:

– Get detailed quotes that outline material, machining, and additional costs.

– Agree on favorable payment terms, balancing upfront deposits with final payments upon delivery.

9. After-Sales Support:

– Ensure there is a clear process for handling any issues post-delivery.

– Discuss warranty and return policies upfront.

By following these steps, you can effectively source high-quality precision machining products from SourcifyChina, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.