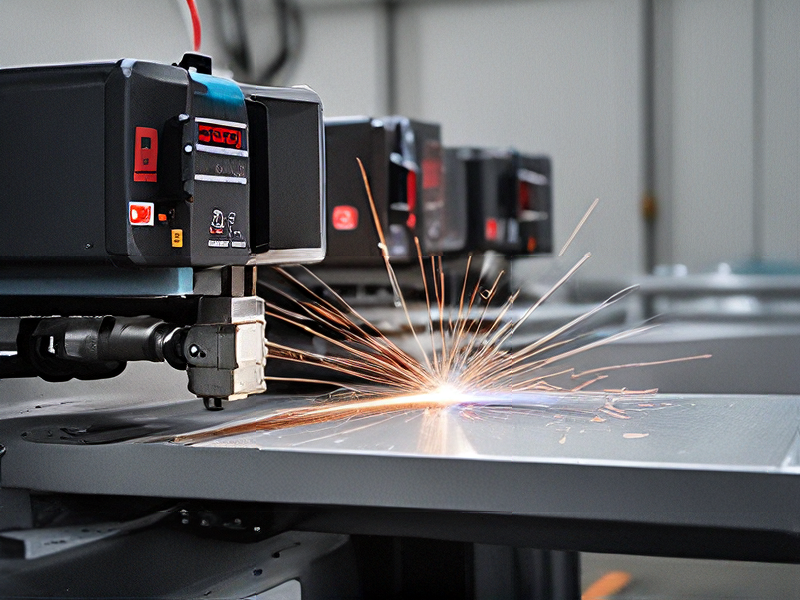

Technology and Applications of price of laser welding machine

Laser welding machines are advanced tools used across various industries for precision welding tasks. Their price varies widely based on several factors. Entry-level models, suitable for small businesses or hobbyists, can range from $10,000 to $50,000. These machines typically offer basic functionalities and lower power outputs.

Mid-range laser welders, priced between $50,000 and $200,000, cater to medium-sized enterprises requiring higher precision and reliability. They often feature more advanced controls, improved energy efficiency, and enhanced safety measures.

High-end laser welding machines, costing upwards of $200,000, are designed for industrial applications demanding utmost accuracy and speed. These models offer superior power levels, sophisticated automation options, and integration capabilities with robotic systems.

Applications of laser welding machines span diverse sectors such as automotive, aerospace, electronics, and medical devices. In automotive manufacturing, they enable precise joining of components, reducing weight and improving structural integrity. In electronics, micro-welding capabilities are crucial for assembling miniature components. Aerospace industries utilize laser welding for critical components that require high strength and durability.

Overall, the price of a laser welding machine reflects its technological sophistication, power output, precision, and automation capabilities, aligning with specific industry needs for high-quality welding solutions.

Quality Testing Methods for price of laser welding machine and how to control quality

To ensure the quality of a laser welding machine and control costs effectively, several methods can be employed:

1. Performance Testing: Conduct comprehensive testing of the machine’s welding capabilities under various conditions. This includes evaluating weld strength, precision, and durability.

2. Material Inspection: Verify that the materials used in construction meet specified standards. This ensures longevity and reliability of the machine.

3. Component Testing: Test individual components such as laser source, optics, and cooling systems to guarantee they meet performance benchmarks.

4. Quality Assurance Protocols: Implement stringent quality checks at every stage of production, from assembly to final inspection. This minimizes defects and ensures consistency.

5. Cost Control Measures: Optimize production processes to reduce manufacturing costs without compromising on quality. This includes efficient sourcing, streamlined assembly, and waste reduction strategies.

6. Customer Feedback Loop: Gather feedback from customers to continuously improve product design and functionality. This enhances customer satisfaction and product reliability.

7. Supplier Collaboration: Collaborate closely with suppliers to ensure timely delivery of high-quality components at competitive prices.

By implementing these methods, manufacturers can maintain high standards of quality while effectively managing costs in the production of laser welding machines.

Tips for Procurement and Considerations when Purchasing from price of laser welding machine

Tips for Procurement and Considerations when Purchasing a Laser Welding Machine

1. Understand Your Needs:

– Determine the specific applications and materials you will be working with. This will influence the type of laser (e.g., fiber, CO2, or Nd:YAG) and power requirements.

2. Budget:

– Set a clear budget. Laser welding machines can range from $10,000 to over $200,000. Consider not just the initial purchase price but also the cost of maintenance, consumables, and potential downtime.

3. Supplier Reputation:

– Choose reputable suppliers known for quality and support. Research customer reviews and ask for references to gauge reliability and service quality.

4. Technical Support and Training:

– Ensure the supplier offers robust technical support and training. Proper training can maximize the machine’s capabilities and minimize operational issues.

5. Service and Maintenance:

– Inquire about service agreements and the availability of spare parts. Regular maintenance is crucial for the longevity and performance of the machine.

6. Performance Specifications:

– Compare the specifications such as welding speed, precision, and depth of penetration. Ensure the machine meets your performance requirements.

7. Flexibility and Upgradability:

– Consider machines that offer flexibility in terms of future upgrades or modifications. This can be cost-effective as your business needs evolve.

8. Energy Efficiency:

– Evaluate the energy consumption of the machine. Energy-efficient models can reduce operational costs in the long run.

9. Safety Features:

– Ensure the machine has adequate safety features to protect operators and comply with workplace safety regulations.

10. Warranty and After-Sales Service:

– Look for a comprehensive warranty and reliable after-sales service. This provides peace of mind and ensures quick resolution of any issues.

By following these tips, you can make an informed decision when purchasing a laser welding machine, balancing cost with performance, reliability, and long-term value.

FAQs on Sourcing and Manufacturing from price of laser welding machine in China

FAQs on Sourcing and Manufacturing Laser Welding Machines in China

1. What is the price range of laser welding machines in China?

The price of laser welding machines in China varies widely depending on specifications, such as power output, brand, and additional features. Typically, prices range from $1,000 to $30,000. Basic models start around $1,000-$5,000, while high-end industrial machines can exceed $30,000.

2. How do I find reliable manufacturers?

Start with online platforms like Alibaba, Made-in-China, and Global Sources. Look for manufacturers with high ratings, verified status, and positive reviews. Additionally, attending trade shows like the China International Industry Fair can provide direct contact with reputable suppliers.

3. What factors should I consider when choosing a supplier?

Consider the supplier’s experience, certification (ISO, CE), production capacity, and after-sales support. It’s also crucial to assess their communication skills and willingness to provide product samples or factory visits.

4. Are there quality concerns with Chinese laser welding machines?

Quality varies among manufacturers. To mitigate risks, opt for suppliers with a proven track record, request product samples, and ensure compliance with international standards. Conducting factory audits or hiring third-party inspection services can also ensure product quality.

5. What are the shipping and import duties involved?

Shipping costs depend on the machine’s size, weight, and destination. Common shipping methods include sea and air freight. Import duties vary by country, so check with your local customs authority for specific rates. Typically, duties range from 0-10% of the machine’s value.

6. How long does it take to receive the machine after ordering?

Lead times can vary but generally range from 20-60 days, depending on the order’s complexity and the manufacturer’s schedule. Shipping time adds another 7-30 days, depending on the chosen shipping method.

7. What after-sales services are available?

Reputable manufacturers offer warranties ranging from 1-2 years, technical support, and spare parts availability. Ensure the supplier provides clear warranty terms and reliable customer service.

By considering these factors and conducting thorough research, you can effectively source and manufacture laser welding machines from China.