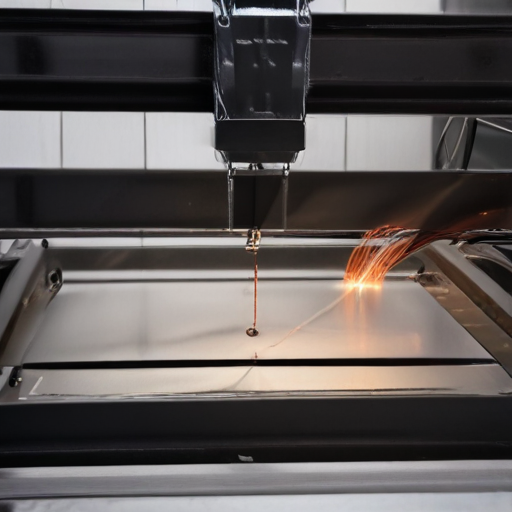

Description

laser cutter for metal Safety Certifications

When selecting a laser cutter for metal, ensuring it has the appropriate safety certifications is crucial for both regulatory compliance and operational safety. Here are some key certifications to look for:

1. CE Marking:

– This certification indicates that the product complies with the European Union’s health, safety, and environmental protection standards. CE marking is essential for products sold within the European Economic Area (EEA).

2. FDA Compliance:

– In the United States, the Food and Drug Administration (FDA) regulates laser products. Laser cutters must comply with FDA regulations (21 CFR 1040.10 and 1040.11) to ensure they are safe for use.

3. ISO 11553:

– This International Organization for Standardization (ISO) standard specifies safety requirements for laser processing machines. ISO 11553-1 focuses on general safety requirements, while ISO 11553-2 addresses the hazards associated with the human eye.

4. IEC 60825:

– The International Electrotechnical Commission (IEC) 60825 standard provides guidelines for the safety of laser products, including laser cutters. It covers classification, labeling, and user information to ensure safe operation and prevent laser-related hazards.

5. OSHA Compliance:

– In the U.S., the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including laser use. Compliance with OSHA standards ensures a safe working environment and minimizes the risk of accidents.

6. UL Certification:

– Underwriters Laboratories (UL) certification indicates that the product has been tested for safety and meets the necessary standards. UL certification is recognized in North America and provides assurance of the laser cutter’s safety.

7. RoHS Compliance:

– The Restriction of Hazardous Substances (RoHS) directive ensures that electronic equipment does not contain harmful substances such as lead, mercury, and cadmium. RoHS compliance is essential for environmental and health safety.

When purchasing a laser cutter for metal, verifying these certifications ensures the equipment meets stringent safety standards, reducing risks associated with laser operation and promoting a safe working environment.

List Reference Technical Parameters of “laser cutter for metal”

Reference Technical Parameters for Laser Cutters for Metal

1. Laser Power

– Range: Typically between 500W to 12kW.

– Impact: Higher power allows cutting thicker metals and increases cutting speed.

2. Wavelength

– Common Types: CO2 lasers (10.6 µm), Fiber lasers (1.06 µm).

– Impact: Different wavelengths are more effective for various types of metals.

3. Cutting Speed

– Range: Depends on laser power and material thickness, e.g., 1m/min to 50m/min.

– Impact: Higher speeds improve productivity but may affect cut quality.

4. Material Thickness Capability

– Range: Up to 30 mm for steel, 20 mm for aluminum, and 15 mm for stainless steel.

– Impact: Thicker materials require more powerful lasers.

5. Accuracy and Precision

– Typical Tolerance: ±0.1 mm.

– Impact: Higher precision is critical for detailed and intricate designs.

6. Beam Quality (BPP)

– Range: 1.0 to 4.0 mm·mrad for fiber lasers.

– Impact: Better beam quality results in finer cuts and higher efficiency.

7. Cutting Area

– Common Sizes: 1000 x 1000 mm, 1500 x 3000 mm, 2000 x 6000 mm.

– Impact: Larger areas accommodate bigger workpieces.

8. Assist Gas Requirements

– Types: Oxygen, nitrogen, and air.

– Impact: Different gases affect the cutting quality and speed; for instance, oxygen is used for mild steel, nitrogen for stainless steel.

9. Cooling System

– Types: Water-cooled or air-cooled.

– Impact: Efficient cooling maintains performance and extends laser life.

10. Control System

– Features: CNC controls with advanced software for precision and repeatability.

– Impact: Advanced controls facilitate complex cutting tasks and improve efficiency.

11. Power Consumption

– Range: Depends on laser power, typically between 5 kW to 30 kW.

– Impact: Higher consumption requires robust electrical infrastructure.

12. Footprint

– Range: Varies, from compact tabletop models to large industrial setups.

– Impact: Determines the space requirements and suitability for different work environments.

These parameters provide a comprehensive overview of the capabilities and requirements for metal laser cutters, ensuring you choose the right equipment for your needs.

List Product features of “laser cutter for metal”

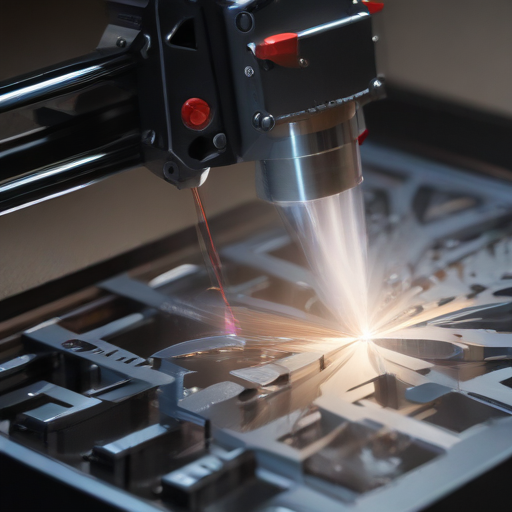

A laser cutter for metal is a specialized device designed for precision cutting and engraving of various metal types. Key features of a metal laser cutter include:

1. Laser Type: Typically uses fiber lasers, CO2 lasers, or crystal lasers, each suited for different types of metals and cutting needs.

2. Power Output: Available in a range of power outputs, from 500W to over 10kW, determining the thickness and speed of cutting.

3. Cutting Speed: High-speed capabilities for efficient processing, often adjustable to suit different materials and thicknesses.

4. Cutting Area: Varies in size, typically from small desktop units to large industrial machines, accommodating different sheet sizes and production volumes.

5. Material Compatibility: Capable of cutting various metals, including stainless steel, carbon steel, aluminum, brass, and copper.

6. Precision and Accuracy: High precision with minimal tolerances, ensuring intricate designs and detailed work.

7. Cooling System: Integrated water or air cooling systems to manage the heat generated during cutting, ensuring continuous operation and longevity.

8. Software Integration: Comes with advanced software for design input, often supporting popular CAD formats and offering features like nesting for material optimization.

9. Automation Features: Options for automated loading and unloading, conveyor systems, and robotic arms for increased efficiency and reduced manual labor.

10. Safety Features: Includes protective enclosures, safety interlocks, and emergency stop functions to ensure operator safety.

11. Maintenance and Support: Easy maintenance with accessible parts, regular software updates, and manufacturer support for troubleshooting and repairs.

12. Versatility: Besides cutting, many models can also engrave and mark metals, adding to their functionality.

13. Energy Efficiency: Designed to minimize energy consumption while maximizing cutting power and efficiency.

14. User Interface: Intuitive touchscreens and user-friendly controls for ease of operation, even for beginners.

15. Customizability: Options for customization to meet specific industrial needs or personal preferences, including different bed sizes and power configurations.

These features make metal laser cutters versatile tools suitable for industries ranging from automotive and aerospace to jewelry making and custom metal fabrication.

List Application of “laser cutter for metal”

Laser cutters for metal have revolutionized manufacturing and fabrication across various industries. Here are key applications:

1. Automotive Industry: Laser cutters are used to manufacture precise components, including intricate parts for engines, transmissions, and body panels. This ensures high accuracy and reduced material wastage.

2. Aerospace: Precision and reliability are critical in aerospace. Laser cutting is employed to create complex, high-precision components for aircraft, including structural parts and intricate engine components.

3. Medical Devices: The medical industry relies on laser cutting for manufacturing surgical instruments, implants, and medical devices. The precision of laser cutting ensures components meet strict hygiene and quality standards.

4. Jewelry Making: Laser cutters allow jewelers to create intricate designs with fine details. They are used for cutting metals like gold, silver, and platinum, enabling custom and mass-produced pieces.

5. Electronics: Laser cutters are used to produce components for electronic devices, including circuit boards, enclosures, and heat sinks. The precision of lasers allows for intricate designs and high-quality finishes.

6. Construction: In the construction industry, laser cutters are utilized to fabricate metal parts for buildings, bridges, and infrastructure projects. This includes cutting steel beams and other structural components.

7. Signage and Advertising: Metal signage and displays benefit from laser cutting for precise and intricate designs. This application ensures high-quality finishes and the ability to produce custom signage quickly.

8. Custom Metal Fabrication: Metalworking shops use laser cutters to produce custom parts and prototypes for various applications, from artistic sculptures to industrial machinery components.

9. Renewable Energy: Laser cutting is vital in manufacturing components for renewable energy systems, such as solar panels and wind turbines, ensuring precision and efficiency in production.

10. Defense and Military: Laser cutters are used to produce components for military equipment, including armored vehicles, aircraft, and weapons. The accuracy and strength of laser-cut parts are crucial for these applications.

These applications demonstrate the versatility and precision of laser cutters in metalworking, making them indispensable in modern manufacturing and fabrication.

List Various Types of “laser cutter for metal”

Types of Laser Cutters for Metal

1. Fiber Laser Cutters

– Principle: Uses a solid-state laser generated by a fiber optic cable.

– Advantages: High efficiency, excellent beam quality, low maintenance, long lifespan.

– Applications: Cutting stainless steel, aluminum, brass, copper, and other reflective metals.

2. CO2 Laser Cutters

– Principle: Utilizes a gas mixture (mainly CO2) to produce a laser beam.

– Advantages: Versatile, can cut non-metal materials like wood and acrylic in addition to metals.

– Applications: Thicker metals like mild steel, also used for engraving.

3. Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) Laser Cutters

– Principle: A solid-state laser that uses Nd:YAG crystals.

– Advantages: High peak power, can work with thin and thick metals.

– Applications: Cutting, welding, drilling, and marking metals like steel and titanium.

4. Disk Laser Cutters

– Principle: A type of solid-state laser similar to fiber lasers, using a thin disk of Yb:YAG crystal.

– Advantages: High beam quality, efficient energy usage, and reliable performance.

– Applications: Precision cutting of metals, suitable for automotive and aerospace industries.

5. Crystal Laser Cutters

– Principle: Uses a crystal as the gain medium, typically Nd:YVO (Neodymium-doped Yttrium Orthovanadate).

– Advantages: High energy density, capable of cutting thick metals with precision.

– Applications: Industrial applications requiring high precision, such as electronics and medical device manufacturing.

6. Hybrid Laser Cutters

– Principle: Combines the advantages of fiber and CO2 lasers.

– Advantages: Versatile cutting capabilities, able to handle a wide range of materials.

– Applications: Industries needing flexibility in material processing, like metal fabrication and construction.

Summary

Different laser cutters are suited for various metal cutting applications, depending on factors like efficiency, beam quality, material type, and thickness. Fiber lasers are popular for their efficiency and quality, while CO2 lasers are versatile. Nd:YAG, disk, and crystal lasers offer high precision for specialized applications, and hybrid lasers provide flexibility across diverse material types.

laser cutter for metal Accessories Upgrades and Custom Manufacturing Options

When upgrading a laser cutter for metal, several accessories and custom manufacturing options can enhance its performance, precision, and versatility.

Accessories and Upgrades:

1. Rotary Attachments:

– Enable engraving and cutting on cylindrical objects like pipes and tubes.

2. Auto-Focus Systems:

– Automatically adjust the focal distance to ensure consistent cuts and engravings, improving accuracy and reducing setup time.

3. High-Pressure Assist Gas Kits:

– Enhance cutting speed and quality by using gases like oxygen, nitrogen, or air to blow away molten material and prevent oxidation.

4. Fume Extractors:

– Essential for maintaining a clean and safe working environment by removing harmful fumes and particles generated during the cutting process.

5. Advanced Cooling Systems:

– Improve machine longevity and performance by preventing overheating, especially crucial for high-power lasers.

6. Software Upgrades:

– Enhanced software can provide better control over cutting parameters, more advanced design options, and integration with CAD/CAM systems.

Custom Manufacturing Options:

1. Bespoke Laser Cutters:

– Tailored machines designed to meet specific production requirements, including custom bed sizes, power levels, and configurations.

2. Customized Laser Heads:

– Different laser heads optimized for various tasks such as fine engraving, deep cutting, or high-speed marking.

3. Modular Designs:

– Machines designed with interchangeable modules, allowing easy upgrades and customization without replacing the entire system.

4. Specialized Fixtures and Jigs:

– Custom fixtures designed to hold unique workpieces securely, ensuring precision and repeatability in production runs.

5. Integrated Automation Systems:

– Incorporating robotic arms or conveyor systems for automated loading and unloading, enhancing production efficiency and reducing labor costs.

Upgrading and customizing a laser cutter for metal can significantly expand its capabilities, making it suitable for a wider range of applications and improving overall productivity. Consider these options to tailor the machine to your specific needs and maximize its performance.

List Quality Control and The Manufacturing Process of “laser cutter for metal”

Quality Control in Laser Cutter Manufacturing

1. Material Selection: Quality control begins with selecting high-grade materials for components such as the laser source, optics, and mechanical parts. Suppliers are vetted, and materials are inspected upon arrival.

2. Precision Manufacturing: Parts are manufactured using precision machining and advanced fabrication techniques to ensure they meet strict dimensional tolerances.

3. Component Testing: Key components like laser sources and optics undergo rigorous testing to verify performance characteristics such as power output, beam quality, and durability.

4. Assembly Inspection: During assembly, each subassembly is inspected for proper fit, alignment, and function. Critical alignments, such as the laser path, are carefully calibrated.

5. System Testing: Fully assembled units undergo comprehensive testing, including operational tests at various power levels and cutting speeds, to ensure performance meets specifications.

6. Calibration and Adjustment: Final calibration ensures the laser cutter operates within specified parameters. Adjustments are made for optimal performance.

7. Burn-In Testing: Extended operational testing (burn-in) is conducted to identify any potential issues that may arise during prolonged use.

8. Final Inspection: A thorough final inspection covers all aspects, including safety features, software functionality, and overall build quality.

Manufacturing Process of Laser Cutters for Metal

1. Design and Engineering: Engineers design the laser cutter, specifying materials, components, and performance criteria. CAD software is used to create detailed plans.

2. Procurement: Raw materials and components are sourced from approved suppliers. Quality control checks ensure compliance with specifications.

3. Fabrication: Key components are fabricated using CNC machining, welding, and other precision manufacturing techniques. Optics are specially crafted and coated.

4. Subassembly Construction: Major components such as the laser source, gantry, and cutting bed are assembled into subassemblies. Each is tested individually.

5. Main Assembly: Subassemblies are brought together in a controlled environment. Precision alignment is crucial, particularly for the laser optics and mechanical systems.

6. Integration and Calibration: The system is integrated, connecting mechanical, electrical, and optical systems. Calibration ensures all parts work harmoniously.

7. Software Installation: Control software is installed and configured to manage the laser cutter’s operations, including cutting parameters and safety protocols.

8. Testing and Quality Assurance: The complete system undergoes rigorous testing, including cutting various metal types to verify performance.

9. Packaging and Shipping: After passing all tests, the laser cutter is carefully packaged to prevent damage during shipping and sent to the customer.

These processes ensure that the laser cutters for metal are reliable, precise, and meet stringent quality standards.

Materials of “laser cutter for metal”

A laser cutter for metal is a precision tool used in various industries to cut and engrave metal materials. The primary components of a laser cutter for metal include:

1. Laser Source:

– Fiber Laser: Uses optical fibers doped with rare-earth elements. It is highly efficient for cutting metals like steel, aluminum, and brass due to its high power density and excellent beam quality.

– CO2 Laser: Utilizes carbon dioxide gas as the laser medium. While effective for cutting non-metal materials, it can also cut metals, though generally less efficiently than fiber lasers.

2. Optics:

– Lenses: Focus the laser beam onto the metal surface, typically made from zinc selenide (ZnSe) for CO2 lasers or fused silica for fiber lasers.

– Mirrors: Direct and focus the laser beam. High-reflectivity mirrors are often coated with gold or dielectric materials.

3. Cutting Head:

– Nozzle: Directs assist gases (like oxygen, nitrogen, or air) onto the cutting area to remove molten material and improve cut quality.

– Height Sensor: Maintains the optimal distance between the nozzle and the metal surface.

4. Assist Gas System:

– Oxygen: Enhances cutting speed for thicker materials by creating an exothermic reaction.

– Nitrogen: Produces cleaner cuts without oxidation, ideal for stainless steel and aluminum.

– Air: Cost-effective alternative, suitable for thinner materials and less critical applications.

5. Cooling System:

– Water Chiller: Maintains the laser source and optics at stable operating temperatures to prevent overheating.

6. Control System:

– CNC (Computer Numerical Control): Guides the laser head movement based on programmed designs, ensuring precise and repeatable cuts.

7. Machine Frame and Enclosure:

– Frame: Provides a stable base, often made from steel or aluminum.

– Enclosure: Protects operators from laser radiation and contains fumes and debris.

Together, these materials and components enable laser cutters to precisely cut and engrave various metals, supporting industries like automotive, aerospace, and manufacturing.

“laser cutter for metal” Comparative Analysis

When comparing laser cutters for metal, several factors such as power, precision, speed, and versatility are crucial. Here’s a brief analysis of some top models available in 2024:

1. Triumph Fiber Laser Cutting Machine: This fiber laser is ideal for metalwork, featuring a 200 x 200 mm work area and compatibility with design software like CorelDraw and AutoCAD. It’s highly praised for its precision and ease of use, making it suitable for detailed metal cutting and engraving tasks. It is priced around $5,799, positioning it as a professional-grade option【6†source】.

2. xTool P2: A desktop CO2 laser engraver, the xTool P2 stands out for its speed (600mm/s) and dual auto-focus cameras that enhance precision, especially on uneven surfaces. With a 55W laser, it is ideal for small businesses needing efficient batch processing for metal objects like jewelry. It also supports rotary engraving for cylindrical items, adding to its versatility【7†source】.

3. xTool F1: Known for its portability, the xTool F1 combines a diode and infrared laser, making it capable of engraving a variety of materials, including metals. Its compact size and safety features, such as an enclosure that makes it safe for use around people, make it suitable for on-the-go engraving, particularly at craft fairs. It’s priced around $1,599【9†source】.

4. xTool D1 Pro: This diode laser cutter, available in 10W and 20W versions, is praised for its high precision and robust build quality. While not as powerful as fiber lasers, it can effectively mark coated metals like anodized aluminum. It’s an affordable option for hobbyists and small businesses, with prices starting at $629.99【7†source】.

5. Ten-High Upgraded Version CO2 Laser: This machine is considered the best overall for versatility. It comes in various power options (50W, 60W, 80W, 100W) and is suitable for a wide range of materials, including metals when coated. Its large working area (400 x 600 mm) and reasonable speed (3600mm/min) make it a strong contender for comprehensive use cases【6†source】.

These models cover a range of needs from high-precision professional work to portable, budget-friendly options for small businesses and hobbyists. The right choice will depend on your specific requirements, including the types of metals you plan to work with, desired precision, and budget constraints.

“laser cutter for metal” Warranty and Support

When considering a laser cutter for metal, it is crucial to examine the warranty and support options provided by the manufacturer. Here are key aspects to consider:

Warranty Coverage:

1. Duration: Most laser cutters come with a warranty ranging from one to three years. This typically covers parts and labor but may vary by manufacturer.

2. Inclusions: The warranty should cover key components such as the laser tube, power supply, motors, and control systems. Some warranties may also include software and firmware updates.

3. Exclusions: Consumables like lenses, mirrors, and filters are often excluded from standard warranties. Ensure you understand what is and isn’t covered to avoid unexpected costs.

Support Services:

1. Technical Support: Reliable technical support is crucial. Look for companies that offer 24/7 support, either via phone, email, or live chat. Immediate assistance can minimize downtime in case of malfunctions.

2. Training and Resources: Many manufacturers provide training sessions, either on-site or online, to help you get the most out of your laser cutter. Additionally, check for available manuals, tutorials, and user forums.

3. Repair Services: Assess the availability and efficiency of repair services. Some manufacturers offer on-site repairs, while others may require shipping the machine to a service center. Quick turnaround times are essential for minimizing production delays.

4. Software Support: Laser cutters often come with proprietary software. Ensure that software support, including updates and troubleshooting, is included.

Extended Warranties and Service Plans:

Consider extended warranty options or service plans for long-term peace of mind. These plans can offer additional years of coverage and may include periodic maintenance checks.

Customer Reviews and Reputation:

Research customer reviews and testimonials regarding the manufacturer’s warranty and support services. A company’s reputation in honoring warranties and providing robust support is a strong indicator of the quality and reliability of their service.

By thoroughly evaluating these factors, you can ensure that your investment in a laser cutter for metal is backed by solid warranty and support, providing you with the necessary assurance and assistance for seamless operation.

List “laser cutter for metal” FAQ

Laser Cutter for Metal FAQ

1. What is a laser cutter for metal?

A laser cutter for metal uses a high-powered laser beam to cut and engrave various types of metals, providing precise and intricate designs.

2. How does a laser cutter for metal work?

The laser cutter directs a concentrated laser beam onto the metal surface, which melts, burns, or vaporizes the material. The process is controlled by computer software for accurate cuts.

3. What types of metals can be cut with a laser cutter?

Common metals include stainless steel, carbon steel, aluminum, brass, and copper. The laser’s power and type determine the range of metals it can handle.

4. What are the benefits of using a laser cutter for metal?

Laser cutters offer high precision, speed, and the ability to cut complex shapes with minimal waste. They also produce clean edges and require less post-processing.

5. What are the different types of laser cutters for metal?

The main types include CO2 lasers, fiber lasers, and Nd:YAG lasers. Fiber lasers are typically preferred for cutting metals due to their efficiency and effectiveness.

6. What safety precautions should be taken when using a laser cutter for metal?

Operators should wear appropriate safety gear, such as goggles, and ensure proper ventilation. Following manufacturer guidelines and having fire safety measures in place are crucial.

7. How thick can a laser cutter cut metal?

The thickness depends on the laser cutter’s power. High-powered industrial lasers can cut through metals up to several inches thick, while lower-powered models are suitable for thinner sheets.

8. What are common applications for laser-cut metal?

Applications include manufacturing, automotive, aerospace, jewelry making, and creating intricate designs in metalworking projects.

9. How do you maintain a laser cutter for metal?

Regular maintenance includes cleaning the lenses and mirrors, checking the cooling system, ensuring proper alignment, and replacing worn parts as needed.

10. How much does a laser cutter for metal cost?

Prices vary widely based on power, size, and features. Entry-level models start around a few thousand dollars, while high-end industrial machines can cost upwards of $100,000.

Top 10 FAQ with answer about laser cutter for metal for Buyer Sourcing from China

Top 10 FAQ for Sourcing Laser Cutters for Metal from China

1. What types of metal can Chinese laser cutters handle?

– Chinese laser cutters can typically cut various metals, including steel, stainless steel, aluminum, brass, and copper. Ensure the machine’s specifications match your material requirements.

2. What is the cutting thickness capacity?

– The cutting thickness depends on the laser power. For instance, a 1000W laser cutter can handle up to 12mm of carbon steel and 5mm of stainless steel. Higher power lasers can cut thicker materials.

3. What is the average cost of a laser cutter from China?

– Prices vary based on power and features but generally range from $10,000 to $100,000. Request detailed quotes from multiple suppliers for comparison.

4. Are Chinese laser cutters reliable?

– Many Chinese manufacturers offer reliable and high-quality laser cutters. Look for ISO-certified companies and read reviews or ask for customer references.

5. What about after-sales service and support?

– Confirm that the manufacturer provides comprehensive after-sales support, including installation, training, maintenance, and troubleshooting services.

6. What is the delivery time for a laser cutter from China?

– Delivery times vary but typically range from 30 to 60 days, depending on customization and shipping logistics. Confirm this with the supplier.

7. Are there any certifications required for importing laser cutters?

– Check for necessary certifications like CE (for Europe), FDA (for the USA), and other relevant safety and quality standards for your region.

8. How can I ensure the quality of the laser cutter?

– Request a factory visit, video inspections, or third-party inspections to verify the machine’s quality before shipping.

9. What about the warranty period?

– Most Chinese laser cutters come with a 1-2 year warranty on the machine and 6 months on consumables. Clarify warranty terms with the supplier.

10. What are the shipping costs and methods?

– Shipping costs vary based on the machine size and destination. Suppliers typically use sea freight for large machines, but air freight is also an option for faster delivery.

Ensure clear communication with suppliers to address these FAQs and secure a reliable laser cutter for your needs.