Description

metal cutter laser machine Safety Certifications

When dealing with metal cutter laser machines, safety is paramount. These machines pose significant hazards, including high-powered laser beams, electrical risks, and mechanical dangers. To ensure safe operation, adherence to various safety certifications and standards is crucial. Here are key certifications and standards relevant to metal cutter laser machines:

1. ISO 11553-1 and ISO 11553-2: These standards specifically address the safety of laser processing machines. ISO 11553-1 focuses on safety requirements for laser processing equipment, while ISO 11553-2 deals with the safety aspects of laser processing installations.

2. IEC 60825-1: This international standard pertains to the safety of laser products. It classifies lasers into different categories based on their potential to cause harm and outlines requirements for labeling, user information, and safety features.

3. ANSI Z136.1: This American National Standard provides guidelines for the safe use of lasers. It includes recommendations for hazard evaluation, control measures, training, and medical surveillance.

4. CE Marking: In Europe, laser cutting machines must comply with the Machinery Directive 2006/42/EC. The CE marking indicates that the machine meets EU safety, health, and environmental protection requirements.

5. EN 60825-1: Similar to IEC 60825-1, this European standard addresses laser safety, including classification, labeling, and user instructions to ensure safe operation.

6. OSHA Standards: In the United States, the Occupational Safety and Health Administration (OSHA) provides regulations and guidelines for the safe use of laser equipment in the workplace, such as 29 CFR 1910.213 for machine guarding and 29 CFR 1910.132 for personal protective equipment (PPE).

7. NFPA 79: The National Fire Protection Association’s standard for industrial machinery, which includes guidelines for electrical equipment used in industrial machines to ensure fire safety.

8. CSA Z386: This Canadian standard offers comprehensive guidelines for laser safety, including control measures, training, and safety management programs.

Adherence to these certifications and standards helps ensure the safe operation of metal cutter laser machines, protecting operators and minimizing risks associated with laser processing activities.

List Reference Technical Parameters of “metal cutter laser machine”

Technical Parameters of a Metal Cutter Laser Machine

1. Laser Type

– Fiber Laser

– CO2 Laser

– Nd:YAG Laser

2. Laser Power

– Typically ranges from 500W to 10,000W or more.

– Higher power allows cutting thicker materials.

3. Cutting Thickness

– Varies with laser power.

– Common range: 1mm to 30mm for steel; 1mm to 15mm for aluminum.

4. Cutting Speed

– Dependent on material type and thickness.

– For example, a 1mm stainless steel can be cut at speeds up to 20m/min.

5. Working Area

– Common sizes include 1500x3000mm, 2000x4000mm.

– Larger machines available for industrial applications.

6. Positioning Accuracy

– Typically ±0.03mm to ±0.1mm.

– Crucial for precision cutting.

7. Repeatability

– Usually within ±0.03mm.

– Ensures consistent quality over multiple cuts.

8. Cooling System

– Water-cooled systems are common.

– Necessary to maintain laser and component temperatures.

9. Control System

– CNC (Computer Numerical Control) systems.

– Often feature user-friendly interfaces for programming and operation.

10. Support Gas

– Oxygen, nitrogen, or compressed air.

– Choice of gas affects cut quality and speed.

11. Power Supply

– Voltage requirements typically 380V, 50Hz for industrial machines.

– Power consumption varies with machine size and laser power.

12. Machine Dimensions

– Depends on working area and design.

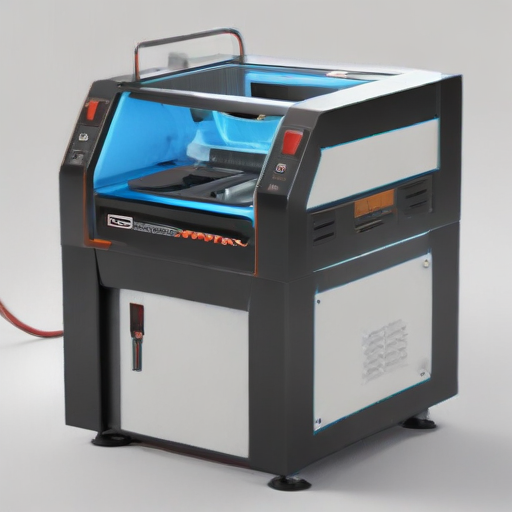

– Compact models available for smaller workshops.

13. Weight

– Ranges from a few hundred kilograms to several tons.

– Heavier machines usually offer greater stability.

14. Software Compatibility

– Supports common file formats (DXF, DWG, etc.).

– May include proprietary software for enhanced functionality.

15. Auxiliary Features

– Automatic loading and unloading systems.

– Dust and fume extraction systems for cleaner operation.

Understanding these parameters is essential for selecting the right metal cutter laser machine for specific applications, ensuring efficiency, precision, and cost-effectiveness.

List Product features of “metal cutter laser machine”

A “metal cutter laser machine” typically boasts the following features:

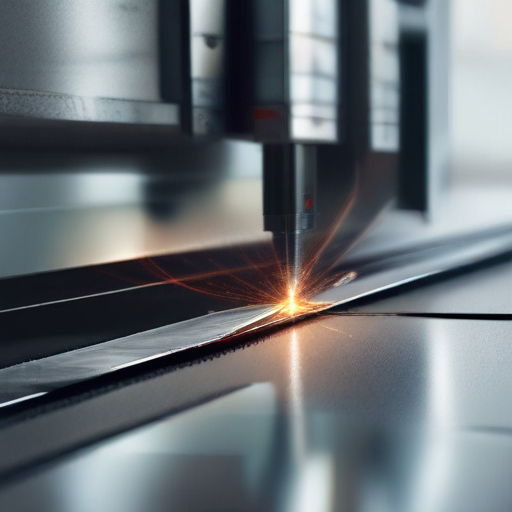

1. High Precision Cutting: Capable of intricate and detailed cuts with minimal tolerance, ensuring clean edges and accurate dimensions.

2. Versatile Material Compatibility: Can cut various metals such as steel, aluminum, brass, and titanium, accommodating diverse industrial needs.

3. Powerful Laser Source: Equipped with high-wattage laser sources (CO2, fiber, or diode lasers) for efficient and fast cutting.

4. Automated Operation: Integration with CNC (Computer Numerical Control) systems for automated control, enhancing precision and reducing manual intervention.

5. Adjustable Cutting Speed: Variable speed settings to optimize cutting performance for different thicknesses and materials.

6. Efficient Cooling Systems: Incorporates cooling mechanisms (air or water-cooled) to prevent overheating and maintain laser performance.

7. User-Friendly Interface: Intuitive software interface for easy programming, operation, and monitoring of the cutting process.

8. High Cutting Capacity: Can handle thick metal sheets and large workpieces, suitable for industrial-scale operations.

9. Minimal Waste Production: Produces low kerf width (cutting width), reducing material waste and maximizing resource utilization.

10. Safety Features: Equipped with safety measures such as enclosed cutting areas, emergency stop buttons, and laser safety glasses to protect operators.

11. Low Maintenance: Designed for durability with minimal maintenance requirements, ensuring long-term reliability and uptime.

12. Energy Efficiency: Optimized for low energy consumption, reducing operational costs and environmental impact.

13. Dust and Fume Extraction: Integrated systems for extracting and filtering dust and fumes generated during cutting, maintaining a clean working environment.

14. Customizable Settings: Allows for customization of laser intensity, focus, and cutting parameters to suit specific project requirements.

15. Remote Monitoring and Diagnostics: Advanced models may include remote monitoring and diagnostic capabilities for real-time performance tracking and troubleshooting.

These features make metal cutter laser machines essential tools in manufacturing, automotive, aerospace, and other industries requiring precise metal fabrication.

List Application of “metal cutter laser machine”

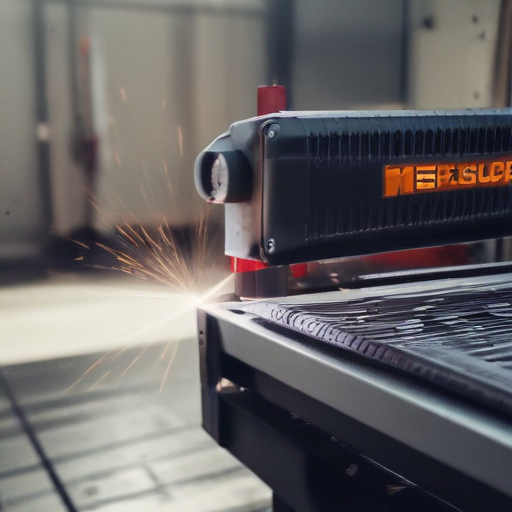

A metal cutter laser machine has diverse applications across various industries due to its precision, speed, and versatility. Here are some key applications:

1. Manufacturing and Fabrication: Used extensively in cutting, engraving, and shaping metal components, it enhances the efficiency of producing parts for machinery, automotive, and aerospace industries.

2. Automotive Industry: Critical in manufacturing car parts, such as gears, body panels, and intricate components, ensuring high precision and minimal waste.

3. Aerospace: Essential for cutting and shaping parts that require high accuracy and durability, like turbine blades and structural components.

4. Construction: Utilized in creating metal frameworks, structural beams, and intricate decorative elements for buildings and infrastructure projects.

5. Medical Devices: Important in manufacturing surgical instruments, implants, and medical device components, demanding high precision and hygiene standards.

6. Electronics: Used to create precise and small components, such as circuit boards and microchips, which require meticulous detailing and minimal thermal distortion.

7. Jewelry Making: Allows for intricate designs and detailed engraving on precious metals, enhancing creativity and quality in jewelry production.

8. Signage and Advertising: Enables the production of detailed metal signs, logos, and decorative elements, offering high customization and durability.

9. Art and Sculpture: Artists use laser cutters to craft intricate metal artworks and sculptures, pushing creative boundaries with precision cutting.

10. Tool and Die Making: Integral in producing precise molds and dies used in various manufacturing processes, ensuring consistent quality and fit.

11. Energy Sector: Used in cutting and shaping components for renewable energy systems, such as wind turbines and solar panels, requiring high accuracy.

These applications demonstrate the metal cutter laser machine’s capability to enhance productivity, precision, and innovation across multiple fields, making it a valuable tool in modern industry.

List Various Types of “metal cutter laser machine”

Various types of metal cutter laser machines cater to different industrial needs, primarily distinguished by their laser source, power, and specific application. Here are the main types:

1. CO2 Laser Cutters:

– Technology: Uses a gas mixture (primarily CO2) excited by an electrical discharge to produce the laser beam.

– Applications: Suitable for cutting, engraving, and marking a wide range of materials including metal, wood, acrylic, and fabric.

– Advantages: High precision and smooth cut quality.

2. Fiber Laser Cutters:

– Technology: Utilizes optical fibers doped with rare earth elements to generate the laser beam.

– Applications: Ideal for cutting various metals, including steel, aluminum, brass, and copper.

– Advantages: High efficiency, lower operating costs, faster cutting speeds, and excellent beam quality.

3. Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) Laser Cutters:

– Technology: Uses a crystal as the laser medium, excited by a flashlamp or laser diode.

– Applications: Used for cutting, drilling, and engraving metals and some plastics.

– Advantages: High peak power, good for thick and reflective materials.

4. Disk Laser Cutters:

– Technology: Employs a disk-shaped gain medium for the laser, offering a high beam quality and power density.

– Applications: Suitable for high-precision cutting of metals and other materials.

– Advantages: High power output, excellent beam quality, and robust design.

5. Pulsed Laser Cutters:

– Technology: Delivers the laser energy in pulses rather than a continuous beam.

– Applications: Best for precise cutting and drilling of small holes in metal sheets and intricate designs.

– Advantages: Reduces heat-affected zones, suitable for delicate materials.

6. Continuous Wave (CW) Laser Cutters:

– Technology: Provides a constant laser beam output for continuous cutting.

– Applications: Ideal for cutting thicker metals and materials that require prolonged exposure.

– Advantages: Consistent energy output, efficient for thicker cuts.

These laser cutting machines offer various advantages depending on the specific requirements, such as material type, thickness, precision, and production speed.

metal cutter laser machine Accessories Upgrades and Custom Manufacturing Options

Metal Cutter Laser Machine Accessories, Upgrades, and Custom Manufacturing Options

#### Accessories

1. Nozzles and Lenses: High-quality nozzles and lenses improve precision and cutting speed. Different materials and shapes are available for various cutting needs.

2. Air Compressors: Essential for blowing away debris, cooling the cutting area, and preventing material warping.

3. Exhaust Systems: Proper ventilation systems remove fumes and particles, ensuring a clean and safe working environment.

4. Rotary Attachments: Enable cutting and engraving on cylindrical objects, expanding the machine’s versatility.

5. Laser Power Supply: Upgrading the power supply can enhance cutting capabilities for thicker materials.

#### Upgrades

1. Software Upgrades: Advanced software can provide better control, more cutting options, and improved efficiency.

2. Cooling Systems: Enhanced cooling systems prevent overheating, allowing for longer and more intensive cutting sessions.

3. Motor and Drive System: Upgrading to a higher quality motor and drive system can result in smoother and faster operations.

4. Automatic Focus: Automatic focusing mechanisms adjust the laser for different material thicknesses, improving precision and reducing manual adjustments.

5. Dual Laser Heads: Adding a second laser head can double productivity, enabling simultaneous cutting of identical or different designs.

#### Custom Manufacturing Options

1. Tailored Bed Sizes: Custom bed sizes can accommodate larger or unusually shaped materials, providing greater flexibility for diverse projects.

2. Specialized Fixtures: Custom fixtures hold unique or irregular materials securely, ensuring accurate cuts.

3. Integrated Automation: Full automation systems, including material loading and unloading, can streamline production and reduce manual labor.

4. Custom Software Solutions: Bespoke software tailored to specific industry needs can optimize workflow and enhance functionality.

5. Enhanced Safety Features: Custom safety enclosures, emergency stop systems, and advanced monitoring technologies ensure compliance with safety standards and protect operators.

Investing in these accessories, upgrades, and custom manufacturing options can significantly enhance the performance, efficiency, and versatility of metal cutter laser machines.

List Quality Control and The Manufacturing Process of “metal cutter laser machine”

Quality Control in Metal Cutter Laser Machine Manufacturing

Quality control in the manufacturing of metal cutter laser machines ensures high precision, reliability, and safety. Key aspects include:

1. Material Inspection: Raw materials like steel, aluminum, and electronic components are rigorously tested for defects and compliance with specifications.

2. Component Testing: Critical components, such as laser sources, mirrors, and lenses, are checked for performance and alignment accuracy.

3. Assembly Inspection: Each assembly stage undergoes inspection to ensure correct assembly and functioning of parts.

4. Calibration: Machines are calibrated to ensure lasers emit the correct power and wavelength, and that cutting precision meets design standards.

5. Performance Testing: Completed machines are tested under various conditions to ensure they meet cutting speed, accuracy, and quality standards.

6. Safety Checks: Machines are evaluated for safety compliance, ensuring they meet industry standards to protect operators.

7. Final Inspection: A comprehensive final inspection includes functional tests, quality audits, and customer requirement verifications.

Manufacturing Process of Metal Cutter Laser Machine

1. Design and Engineering: Engineers design the machine, focusing on precision, durability, and ease of use. CAD software is used for detailed schematics.

2. Material Procurement: High-quality materials and components are sourced from reliable suppliers to ensure durability and performance.

3. Component Manufacturing: Parts like frames, laser sources, control systems, and cooling units are manufactured. Precision machining is essential for parts like laser heads and optical components.

4. Assembly: Components are assembled in a step-by-step process. This includes mounting the laser source, installing optical systems, and integrating control units.

5. Calibration and Alignment: The laser system is calibrated and aligned to ensure the beam’s precision and focus. This step is crucial for cutting accuracy.

6. Software Installation: Control software is installed, which includes user interfaces, CNC controls, and safety protocols.

7. Testing: The assembled machine undergoes rigorous testing to ensure it meets operational and safety standards. This includes test cuts on various materials.

8. Quality Control: A thorough quality control process is conducted to identify any defects or issues.

9. Packaging and Shipping: Once the machine passes all tests, it is securely packaged and shipped to customers.

This streamlined process ensures the production of high-quality metal cutter laser machines capable of delivering precise and efficient cutting solutions.

Materials of “metal cutter laser machine”

A “metal cutter laser machine” typically involves various materials to ensure precision, durability, and functionality. Here’s a breakdown of the primary materials used:

1. Laser Source

– Fiber Lasers: Use optical fibers doped with rare-earth elements (e.g., ytterbium) to generate high-powered beams.

– CO2 Lasers: Utilize a gas mixture of carbon dioxide, nitrogen, and helium to produce infrared beams.

2. Machine Frame

– Steel: Provides rigidity and stability, ensuring minimal vibrations during cutting operations.

– Aluminum: Often used for components requiring lightweight and corrosion resistance.

3. Optics and Lenses

– Fused Silica: High purity and low thermal expansion, ideal for high-power laser systems.

– ZnSe (Zinc Selenide): Commonly used for CO2 laser systems due to its transparency in the infrared spectrum.

4. Cooling System

– Water Chillers: Typically constructed with stainless steel and copper components to prevent corrosion and ensure efficient heat dissipation.

5. Electrical Components

– Copper: Used extensively for wiring and electrical connections due to its excellent conductivity.

– Plastic Insulation: Ensures safety and protection for electrical components.

6. Guide Rails and Motors

– Hardened Steel or Stainless Steel Rails: Provide smooth and precise movement.

– Stepper or Servo Motors: Usually encased in aluminum housings for lightweight and efficient heat dissipation.

7. Protective Housing and Panels

– Acrylic or Polycarbonate: Transparent panels allow operators to monitor the cutting process while providing protection.

– Steel or Aluminum Panels: Ensure the machine’s structural integrity and safety.

8. Control System

– Circuit Boards: Made from fiberglass-reinforced epoxy laminates (FR4) for durability and stability.

– Plastic Housings: Provide protection and insulation for control units and interfaces.

These materials collectively contribute to the efficiency, precision, and longevity of metal cutter laser machines, making them vital tools in various industrial applications.

“metal cutter laser machine” Comparative Analysis

When comparing metal cutter laser machines in 2024, several key models stand out based on their capabilities, precision, and application suitability. Here’s a comparative analysis of some prominent options:

1. Triumph Fiber Laser Cutting Machine:

– Type: Fiber Laser

– Work Area: 200 x 200 mm

– Applications: Ideal for precision metal cutting, compatible with software like CorelDraw, AutoCAD, and Photoshop.

– Cost: Approximately $5,799

– Features: High precision, ease of use, and robust software compatibility make it a top choice for detailed metalwork.

2. xTool D1 Pro:

– Type: Diode Laser

– Power Options: 5W, 10W, 20W, 40W

– Work Area: Extendable to 936 x 432 mm

– Applications: Suitable for marking coated metals like stainless steel and anodized aluminum; can engrave cylindrical objects with additional accessories.

– Features: High accuracy, user-friendly interface, and modular design for enhanced versatility.

3. Baison High Power Sheet Metal Laser Cutting Machine:

– Type: Fiber Laser

– Power: 4000W (with options up to 20000W)

– Applications: Best for industrial-grade sheet metal cutting, capable of handling materials like stainless steel, carbon steel, and aluminum.

– Features: Advanced cutting features, automatic nesting, and high-speed operation make it ideal for large-scale manufacturing.

4. ELECNC-1530 Fiber Laser Cutting Machine:

– Type: Fiber Laser

– Work Area: 1500 x 3000 mm

– Applications: Dual-use for cutting metal sheets and tubes, suitable for various metals including brass and aluminum.

– Features: High efficiency, dual-platform for sheet and tube cutting, and robust build quality for long-term durability.

5. Full Spectrum Laser Muse:

– Type: CO2 Laser

– Applications: Versatile for both professional and hobbyist use, capable of high precision engraving and cutting.

– Features: Compact design, user-friendly, compatible with various file formats, making it a flexible option for diverse projects.

Each of these machines offers distinct advantages depending on specific needs, such as power requirements, material compatibility, and intended applications. The Triumph Fiber Laser and xTool D1 Pro are excellent for detailed and precision work, while the Baison and ELECNC models cater to heavy-duty industrial applications. For users needing versatility and ease of use, the Full Spectrum Laser Muse is a strong contender.

“metal cutter laser machine” Warranty and Support

When considering the warranty and support for a metal cutter laser machine, it is crucial to ensure comprehensive coverage to protect your investment and ensure uninterrupted operation.

Warranty

1. Duration: Standard warranties typically range from one to three years. Verify if the warranty covers both parts and labor.

2. Coverage: The warranty should cover essential components such as the laser source, control systems, motors, and optical elements. Consumables like lenses and mirrors might be excluded.

3. Extended Warranty Options: Check if the manufacturer offers extended warranty plans beyond the standard period for added peace of mind.

Support

1. Technical Support: Ensure 24/7 access to technical support via phone, email, or live chat. This is crucial for quick resolution of any issues that might disrupt your operations.

2. On-Site Service: Look for on-site support services where technicians can visit your facility to perform repairs or maintenance. Some manufacturers offer this service within a certain radius or for an additional fee.

3. Training: Comprehensive training programs for operators and maintenance personnel can significantly reduce downtime and improve efficiency. This may include initial training sessions and ongoing education opportunities.

4. Spare Parts Availability: Ensure that spare parts are readily available and can be delivered quickly. Some manufacturers provide guaranteed parts availability within a specific timeframe.

5. Software Updates: Regular updates to the machine’s control software can enhance performance and introduce new features. Verify if these updates are included in the support plan.

6. Documentation: Detailed user manuals, troubleshooting guides, and maintenance schedules should be provided. These resources are invaluable for day-to-day operations and minor troubleshooting.

By ensuring robust warranty and support provisions, you can maintain optimal performance of your metal cutter laser machine, minimize downtime, and extend the machine’s lifespan. Always read the terms carefully and consider the reputation of the manufacturer and their after-sales service capabilities.

List “metal cutter laser machine” FAQ

Metal Cutter Laser Machine FAQ

1. What is a metal cutter laser machine?

– A metal cutter laser machine uses a concentrated beam of light (laser) to cut through various types of metal with high precision and speed.

2. How does a laser cutter work?

– The laser generates a high-intensity light beam that melts, burns, or vaporizes the metal, following a computer-controlled pattern to achieve the desired cut.

3. What types of metals can be cut with a laser cutter?

– Commonly cut metals include stainless steel, carbon steel, aluminum, copper, and brass.

4. What are the advantages of using a laser cutter?

– High precision, fast cutting speeds, smooth edges, minimal waste, and the ability to cut complex shapes without needing additional tooling.

5. What are the power requirements for a metal cutter laser machine?

– Power requirements vary depending on the machine, ranging from 1 kW to over 10 kW, with higher power machines capable of cutting thicker materials.

6. What thickness of metal can a laser cutter handle?

– Depending on the machine’s power, laser cutters can handle metal thicknesses from thin sheets up to 25mm or more for high-power industrial models.

7. Is laser cutting suitable for all types of metalwork?

– While highly versatile, laser cutting is not always suitable for reflective metals like copper and brass without specialized equipment.

8. What safety measures are needed when operating a laser cutter?

– Proper ventilation, protective eyewear, machine enclosures, and adherence to manufacturer safety guidelines are essential.

9. How much maintenance does a laser cutter require?

– Regular maintenance includes cleaning lenses and mirrors, checking and replacing filters, and ensuring proper alignment and calibration.

10. What software is needed to operate a laser cutter?

– Laser cutters typically use CAD (Computer-Aided Design) software for creating design files and CAM (Computer-Aided Manufacturing) software to control the cutting process.

11. What is the cost of a metal cutter laser machine?

– Prices vary widely based on machine size, power, and features, ranging from a few thousand dollars for small desktop models to several hundred thousand dollars for industrial machines.

12. Can laser cutting cause material deformation?

– With proper settings, laser cutting minimizes material deformation, but incorrect settings can cause warping or burning.

Top 10 FAQ with answer about metal cutter laser machine for Buyer Sourcing from China

Top 10 FAQs About Metal Cutter Laser Machines for Buyer Sourcing from China

1. What are the main types of metal cutter laser machines available?

– The main types include CO2 laser cutters, fiber laser cutters, and crystal laser cutters. Fiber lasers are most popular for metal cutting due to their efficiency and precision.

2. What materials can metal laser cutters handle?

– Metal laser cutters can process various metals like stainless steel, carbon steel, aluminum, copper, and brass. Some machines can also cut non-metal materials.

3. What is the cutting thickness range?

– The cutting thickness depends on the laser power. Typically, fiber lasers can cut up to 20mm in stainless steel and up to 25mm in carbon steel.

4. How to ensure the quality of the machine?

– Ensure the machine meets international standards (e.g., CE, ISO) and request test cuts. Reputable suppliers often provide sample cutting services.

5. What is the expected lifespan of a laser cutter?

– The lifespan varies, but generally, a well-maintained machine can last 10-15 years. The fiber laser source typically lasts around 100,000 hours.

6. What is the typical lead time for delivery?

– Lead times can range from 30 to 60 days depending on customization and production schedules.

7. How much does a metal cutter laser machine cost?

– Prices vary widely based on power, size, and features. Entry-level machines can start at $30,000, while high-end models can exceed $200,000.

8. What are the maintenance requirements?

– Regular maintenance includes cleaning lenses, checking optics, and servicing moving parts. Most suppliers provide a maintenance schedule.

9. What about after-sales support and training?

– Reputable suppliers offer comprehensive after-sales support, including training, installation, troubleshooting, and spare parts availability.

10. How to choose the right supplier?

– Evaluate the supplier’s reputation, customer reviews, after-sales service, and their ability to provide training and technical support. Visiting the supplier’s factory can also provide valuable insights.

By considering these factors, buyers can make informed decisions when sourcing metal cutter laser machines from China.