Description

titanium steel vs stainless steel Safety Certifications

Titanium steel and stainless steel are both widely used in various industries due to their durability and resistance to corrosion. However, when it comes to safety certifications, they have distinct characteristics and compliance standards.

Titanium Steel:

Certifications:

1. ISO 5832: This standard specifies the requirements for unalloyed titanium for surgical implants. It’s crucial for medical applications to ensure biocompatibility.

2. ASTM F136: A standard specification for wrought titanium-6 aluminum-4 vanadium ELI (extra-low interstitial) alloy for surgical implant applications, ensuring material quality and safety.

3. AMS 4911: This specification covers titanium alloy sheet, strip, and plate, ensuring high strength and corrosion resistance, critical for aerospace applications.

4. FDA Approval: For titanium used in medical devices, FDA approval is often necessary to ensure the material meets biocompatibility and safety standards.

Stainless Steel:

Certifications:

1. ISO 5832-1: This standard pertains to stainless steel for surgical implants, ensuring material is suitable for medical use.

2. ASTM F138/F139: These standards specify the requirements for stainless steel bars and wires for surgical implants, focusing on material strength and biocompatibility.

3. SAE J405: Provides standards for the chemical composition of stainless steels used in automotive and other engineering applications.

4. EN 10088-1: A European standard that specifies stainless steel grades and the general requirements for resistance to corrosion and mechanical properties.

5. FDA Approval: Stainless steel used in medical devices must also be FDA-approved, ensuring it meets necessary safety and efficacy standards.

Both materials have stringent certification requirements, especially for medical and aerospace applications. Titanium steel is often preferred in medical fields for its superior biocompatibility, while stainless steel is widely used in various industries due to its cost-effectiveness and robust mechanical properties. Ensuring these materials meet the relevant safety certifications is crucial for their application in sensitive and high-stress environments.

List Reference Technical Parameters of “titanium steel vs stainless steel”

Titanium Steel vs. Stainless Steel: Reference Technical Parameters

#### Composition

– Titanium Steel: Primarily composed of titanium alloyed with other elements like aluminum and vanadium.

– Stainless Steel: An alloy of iron with a minimum of 10.5% chromium, often containing nickel, molybdenum, and carbon.

#### Density

– Titanium Steel: Approximately 4.5 g/cm³.

– Stainless Steel: Approximately 7.8 g/cm³.

#### Strength

– Titanium Steel: Tensile strength ranges from 480 to 620 MPa, depending on the alloy.

– Stainless Steel: Tensile strength varies widely; for example, austenitic grades like 304 have around 505 MPa, while martensitic grades like 410 can reach up to 750 MPa.

#### Corrosion Resistance

– Titanium Steel: Excellent corrosion resistance in various environments, particularly seawater and chlorides.

– Stainless Steel: Good to excellent corrosion resistance depending on the grade; austenitic grades are generally the most resistant.

#### Temperature Resistance

– Titanium Steel: High melting point around 1668°C; maintains strength at elevated temperatures.

– Stainless Steel: Melting point varies; for example, 304 stainless steel melts around 1400-1450°C.

#### Weight

– Titanium Steel: Lightweight, roughly 45% lighter than stainless steel.

– Stainless Steel: Heavier, providing more density and sturdiness.

#### Applications

– Titanium Steel: Used in aerospace, military, medical devices, and high-performance automotive parts.

– Stainless Steel: Widely used in kitchenware, construction, automotive, medical instruments, and industrial equipment.

#### Machinability

– Titanium Steel: More challenging to machine due to its hardness and heat retention.

– Stainless Steel: Easier to machine but varies by grade; austenitic steels are the most machinable.

#### Cost

– Titanium Steel: Generally more expensive due to complex processing and raw material costs.

– Stainless Steel: Less expensive, with a broader range of prices depending on the grade and application.

By comparing these parameters, one can better understand the differences and appropriate applications of titanium steel and stainless steel.

List Product features of “titanium steel vs stainless steel”

Titanium Steel vs. Stainless Steel: Product Features

#### Titanium Steel

1. Strength and Durability:

– Extremely strong and resistant to wear and tear.

– Higher strength-to-weight ratio compared to stainless steel.

2. Weight:

– Significantly lighter than stainless steel, making it ideal for applications where weight is a critical factor.

3. Corrosion Resistance:

– Highly resistant to corrosion, including saltwater and chlorine, making it suitable for marine and chemical environments.

4. Biocompatibility:

– Non-reactive with human tissues, often used in medical implants and body jewelry.

5. Aesthetics:

– Typically has a matte, grayish appearance.

– Can be anodized to produce various colors.

6. Cost:

– Generally more expensive than stainless steel due to the complexity of extraction and manufacturing.

#### Stainless Steel

1. Strength and Durability:

– Strong and durable, though generally not as strong as titanium steel in terms of strength-to-weight ratio.

– Good impact resistance.

2. Weight:

– Heavier than titanium steel, which can be a disadvantage in weight-sensitive applications.

3. Corrosion Resistance:

– Excellent resistance to rust and corrosion, especially with high chromium content (e.g., 304 and 316 grades).

– Suitable for a wide range of environments, including kitchens and bathrooms.

4. Versatility:

– Available in a variety of finishes and grades, suitable for diverse applications from kitchenware to industrial uses.

5. Aesthetics:

– Often polished to a shiny, mirror-like finish, but also available in matte and brushed finishes.

– Maintains appearance over time with minimal maintenance.

6. Cost:

– Generally less expensive than titanium steel, making it a more economical choice for many applications.

Both titanium steel and stainless steel offer unique advantages, making them suitable for different applications based on specific needs for strength, weight, corrosion resistance, and cost.

List Application of “titanium steel vs stainless steel”

Applications of Titanium Steel vs. Stainless Steel

#### Titanium Steel

1. Aerospace Industry: Titanium steel is prized for its high strength-to-weight ratio and resistance to corrosion, making it ideal for aircraft frames, engines, and spacecraft components.

2. Medical Implants: Due to its biocompatibility and resistance to body fluids, titanium steel is used in prosthetics, dental implants, and surgical instruments.

3. Sports Equipment: Its lightweight and durable nature makes titanium steel a popular choice for bicycles, golf clubs, and other high-performance sports gear.

4. Automotive Industry: High-end and racing cars utilize titanium steel for parts like exhaust systems, valves, and suspension components due to its strength and lightness.

5. Marine Applications: Titanium steel’s corrosion resistance is beneficial in saltwater environments, making it suitable for submarines, ship hulls, and offshore drilling rigs.

#### Stainless Steel

1. Construction: Stainless steel is widely used in building materials, architectural structures, and bridges due to its strength and aesthetic appeal.

2. Kitchenware: Its resistance to rust and staining makes stainless steel a preferred material for cookware, cutlery, and appliances.

3. Medical Equipment: Stainless steel is also used in medical instruments and devices because it can be easily sterilized and offers good biocompatibility.

4. Food and Beverage Industry: Tanks, pipelines, and equipment in food processing are often made from stainless steel to maintain hygiene and prevent contamination.

5. Energy Sector: Stainless steel is utilized in the construction of power plants, especially in nuclear reactors and components exposed to high temperatures and corrosive environments.

Both titanium steel and stainless steel offer unique advantages, with titanium steel excelling in lightweight, high-strength applications and stainless steel being favored for its durability, cost-effectiveness, and versatility across various industries.

List Various Types of “titanium steel vs stainless steel”

Titanium Steel vs. Stainless Steel: Types and Comparisons

1. Material Composition:

– Titanium Steel: Primarily titanium alloyed with other metals like aluminum or vanadium. Lightweight, strong, and highly resistant to corrosion.

– Stainless Steel: Iron-based alloy containing chromium (at least 10.5%), nickel, and other elements. Known for its strength, durability, and corrosion resistance.

2. Types of Titanium Steel:

– Grade 1 Titanium: Pure titanium, known for excellent corrosion resistance and formability but lower strength.

– Grade 2 Titanium: Commercially pure titanium, offering a balance of strength and corrosion resistance.

– Grade 5 Titanium (Ti-6Al-4V): Alloyed with aluminum and vanadium, offering high strength and corrosion resistance. Widely used in aerospace and medical applications.

3. Types of Stainless Steel:

– Austenitic Stainless Steel (300 Series): Contains high chromium and nickel content. Highly resistant to corrosion and non-magnetic. Example: 304 and 316 stainless steel.

– Ferritic Stainless Steel (400 Series): Contains chromium and is magnetic. Less corrosion-resistant compared to austenitic. Example: 430 stainless steel.

– Martensitic Stainless Steel: Contains higher carbon and chromium. Known for hardness and strength but lower corrosion resistance. Example: 410 and 420 stainless steel.

– Duplex Stainless Steel: Combines austenitic and ferritic properties, offering high strength and excellent resistance to stress corrosion cracking. Example: 2205 stainless steel.

4. Properties and Applications:

– Strength: Titanium alloys (like Grade 5) are stronger than most stainless steels.

– Weight: Titanium is about 45% lighter than stainless steel, making it ideal for weight-sensitive applications.

– Corrosion Resistance: Both materials offer excellent corrosion resistance, but titanium is superior in harsh environments, including marine and chemical applications.

– Cost: Titanium is generally more expensive due to its processing and material costs.

– Applications:

– Titanium: Aerospace, medical implants, high-performance automotive parts.

– Stainless Steel: Construction, kitchenware, medical instruments, automotive parts.

Understanding these differences helps in selecting the appropriate material for specific applications based on the required properties.

titanium steel vs stainless steel Accessories Upgrades and Custom Manufacturing Options

Titanium Steel vs. Stainless Steel: Accessories Upgrades and Custom Manufacturing Options

Titanium Steel:

1. Durability and Strength: Titanium steel is renowned for its exceptional strength-to-weight ratio, making it a top choice for high-performance accessories. It’s highly resistant to corrosion, ensuring longevity even in harsh environments.

2. Customization: Titanium’s versatility allows for a variety of finishes and treatments, including anodizing, which can produce a range of colors. Custom shapes and intricate designs are possible through advanced CNC machining.

3. Hypoallergenic Properties: Titanium is biocompatible, making it an ideal option for accessories that will be in contact with the skin, reducing the risk of allergic reactions.

4. Weight: Despite its strength, titanium is lightweight, making it comfortable for wearables such as watches and jewelry.

Stainless Steel:

1. Durability and Versatility: Stainless steel is known for its strength and resistance to rust and tarnish. It is highly durable and suitable for a wide range of applications, from kitchenware to industrial components.

2. Customization: Stainless steel can be polished to a high shine or given a matte finish. It supports various manufacturing techniques, including casting, forging, and welding, enabling complex and customized designs.

3. Cost-Effectiveness: Generally more affordable than titanium, stainless steel offers a cost-effective solution without compromising on quality.

4. Availability: Due to its popularity, stainless steel is readily available in various grades and finishes, making it a versatile choice for many applications.

Comparison and Considerations:

– Weight: Titanium steel is lighter than stainless steel, which can be a deciding factor for wearable accessories.

– Strength and Durability: Both materials offer high durability, but titanium’s superior strength makes it preferable for high-stress applications.

– Aesthetic and Customization: Both materials can be customized, but titanium offers more unique color options through anodizing.

– Cost: Stainless steel is generally less expensive than titanium, making it more accessible for mass production.

In summary, the choice between titanium steel and stainless steel for accessories and custom manufacturing largely depends on the specific requirements of strength, weight, customization, and budget.

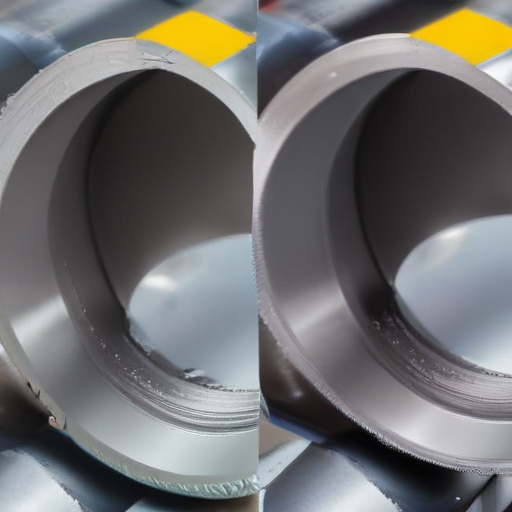

List Quality Control and The Manufacturing Process of “titanium steel vs stainless steel”

Quality Control and Manufacturing Process of Titanium Steel vs. Stainless Steel

#### Titanium Steel

Manufacturing Process:

1. Ore Extraction: Titanium is extracted from minerals like ilmenite and rutile.

2. Refining: The Kroll process is used to produce titanium sponge, which involves reducing titanium tetrachloride (TiCl₄) with magnesium.

3. Melting: The sponge is melted in a vacuum arc remelting furnace to produce ingots.

4. Forming: Ingots are processed through forging, rolling, or extrusion to create desired shapes.

5. Heat Treatment: This improves the mechanical properties and microstructure.

Quality Control:

1. Chemical Composition Analysis: Ensures purity and correct alloying elements.

2. Mechanical Testing: Tensile strength, hardness, and impact resistance tests.

3. Non-destructive Testing: Ultrasonic and radiographic tests for internal defects.

4. Surface Inspection: Checking for surface defects and finishing quality.

5. Dimensional Checks: Ensuring products meet specified dimensions and tolerances.

#### Stainless Steel

Manufacturing Process:

1. Raw Material Preparation: Iron ore, chromium, nickel, and other alloying elements are prepared.

2. Melting: The raw materials are melted in an electric arc furnace.

3. Refining: Oxygen is blown through the molten steel to remove impurities.

4. Casting: The refined steel is cast into slabs, billets, or blooms.

5. Forming: These are hot rolled or cold rolled into desired forms like sheets, bars, or wires.

6. Annealing and Pickling: Heat treatment to remove internal stresses and surface scaling.

Quality Control:

1. Chemical Composition Analysis: Ensures the correct alloying elements and purity.

2. Mechanical Testing: Tests for tensile strength, hardness, and toughness.

3. Non-destructive Testing: Methods like X-ray, ultrasonic, and magnetic particle inspection.

4. Corrosion Resistance Testing: Salt spray tests to check for corrosion resistance.

5. Surface Inspection and Finishing: Ensuring surface quality and proper finishing treatments.

Both materials undergo stringent quality control to ensure their performance and reliability in various applications, from aerospace to medical devices for titanium steel, and construction to household items for stainless steel.

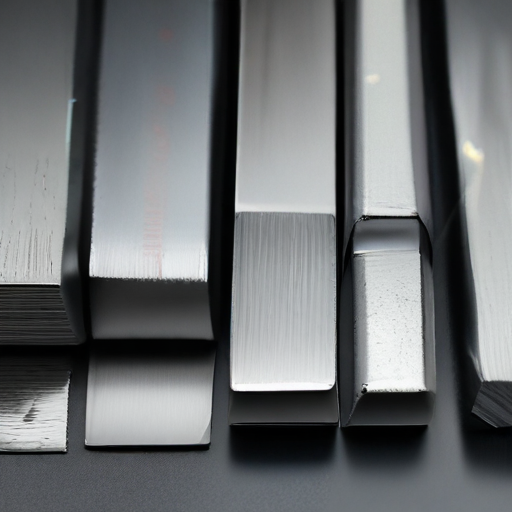

Materials of “titanium steel vs stainless steel”

Titanium Steel vs. Stainless Steel

Composition and Structure:

– Titanium Steel: Composed primarily of titanium, often alloyed with small amounts of aluminum and vanadium. Titanium is notable for its high strength-to-weight ratio.

– Stainless Steel: Composed of iron, carbon, and chromium (minimum 10.5%). The addition of chromium forms a thin layer of oxide on the steel’s surface, providing corrosion resistance.

Strength and Weight:

– Titanium Steel: Offers superior strength while being significantly lighter than stainless steel. This makes it ideal for applications where weight reduction is crucial without compromising strength, such as in aerospace and high-performance sports equipment.

– Stainless Steel: Generally heavier but also very strong. It is widely used in construction, kitchenware, and medical devices due to its durability and resistance to wear and tear.

Corrosion Resistance:

– Titanium Steel: Exhibits excellent corrosion resistance, particularly against seawater and chlorine. This makes it suitable for marine environments and chemical processing.

– Stainless Steel: Also highly resistant to corrosion, especially types 304 and 316, which are common in food processing and medical implants. However, it can be susceptible to corrosion in highly saline or chlorinated environments over time.

Applications:

– Titanium Steel: Used in aerospace, military, biomedical implants, and high-performance sporting goods. Its biocompatibility makes it ideal for medical implants.

– Stainless Steel: Common in construction, automotive, appliances, surgical instruments, and food processing equipment. Its ease of sterilization and strength make it a staple in kitchens and hospitals.

Cost:

– Titanium Steel: More expensive due to the complex extraction and processing methods. The high cost is justified by its performance in specialized applications.

– Stainless Steel: More affordable and widely available, making it the preferred choice for many general-purpose applications.

Conclusion:

While titanium steel offers unmatched strength-to-weight ratio and corrosion resistance, stainless steel remains a versatile, cost-effective choice for many industries. The selection between the two depends on the specific requirements of strength, weight, corrosion resistance, and budget.

“titanium steel vs stainless steel” Comparative Analysis

Titanium Steel vs. Stainless Steel: Comparative Analysis

1. Composition and Weight:

– Titanium Steel: An alloy primarily composed of titanium, known for its high strength-to-weight ratio. It is lightweight, roughly 45% lighter than stainless steel.

– Stainless Steel: Composed mainly of iron, chromium (at least 10.5%), and nickel, making it heavier than titanium steel but still relatively light compared to other metals.

2. Strength and Durability:

– Titanium Steel: Extremely strong and durable, with excellent resistance to corrosion, making it suitable for aerospace, medical implants, and high-performance applications. Its high tensile strength allows it to withstand extreme conditions.

– Stainless Steel: Also very strong and durable, with good resistance to corrosion and oxidation. It is commonly used in kitchenware, construction, and medical instruments. While strong, it is generally less strong than titanium steel on a per-weight basis.

3. Corrosion Resistance:

– Titanium Steel: Superior corrosion resistance, especially in environments exposed to saltwater or chemicals. This makes it ideal for marine and medical applications.

– Stainless Steel: Highly resistant to rust and corrosion due to its chromium content. It performs well in many environments but can corrode under extreme conditions.

4. Cost:

– Titanium Steel: More expensive due to its processing complexity and raw material costs. The price reflects its superior properties in terms of strength and weight.

– Stainless Steel: More affordable and widely available. Its cost-efficiency makes it a popular choice for a variety of applications.

5. Applications:

– Titanium Steel: Preferred in aerospace, medical implants, military equipment, and high-performance sports gear where strength, weight, and corrosion resistance are critical.

– Stainless Steel: Used in household items (cutlery, cookware), construction (structural components, cladding), automotive parts, and surgical instruments due to its durability and resistance to everyday wear and tear.

Conclusion:

Titanium steel excels in applications requiring high strength, light weight, and superior corrosion resistance but comes at a higher cost. Stainless steel offers a good balance of strength, durability, and affordability, making it suitable for a broad range of everyday and industrial applications.

“titanium steel vs stainless steel” Warranty and Support

When comparing titanium steel and stainless steel, both materials have distinct properties that influence their warranty and support aspects.

Titanium Steel:

Warranty:

– Durability: Titanium steel is highly durable and resistant to corrosion, often resulting in longer warranties. Manufacturers may offer extended warranties due to the material’s longevity and robustness.

– Specialized Use: Because titanium is often used in high-stress applications (like aerospace and medical implants), warranties might cover specific use cases and conditions, reflecting the material’s premium status.

Support:

– Specialized Knowledge: Support for titanium steel products typically requires specialized knowledge due to the material’s unique properties. This can lead to more specialized, but potentially slower, support.

– Availability of Parts: Replacement parts or services for titanium steel items might be less readily available than for more common materials, potentially affecting support response times.

Stainless Steel:

Warranty:

– Common Use: Stainless steel is widely used in various applications, from household items to industrial equipment. This ubiquity often leads to more standardized and shorter warranties compared to titanium.

– Corrosion Resistance: While stainless steel is corrosion-resistant, it is not as impervious as titanium, sometimes resulting in shorter warranty periods, especially for products exposed to harsh environments.

Support:

– Ease of Access: Support for stainless steel products is generally more accessible due to its widespread use. Technicians and support staff are usually well-versed in handling stainless steel products.

– Readily Available Parts: Replacement parts and maintenance services for stainless steel items are typically easier to find, ensuring quicker and more efficient support.

In summary, titanium steel often comes with longer and more specific warranties due to its superior properties, but may have more specialized support requirements. Stainless steel, while offering more readily accessible support and parts, usually has shorter and more standardized warranties due to its common use and slightly lower resistance to corrosion.

List “titanium steel vs stainless steel” FAQ

Titanium Steel vs. Stainless Steel: FAQs

1. What are the main differences between titanium steel and stainless steel?

Titanium steel is lighter and more corrosion-resistant than stainless steel. It has a higher strength-to-weight ratio but is more expensive. Stainless steel is heavier, less expensive, and easier to machine.

2. Which is more durable, titanium steel or stainless steel?

Titanium steel is more durable due to its superior corrosion resistance and strength. However, stainless steel is also highly durable and is more resistant to scratches.

3. How do the weights of titanium steel and stainless steel compare?

Titanium steel is significantly lighter than stainless steel. This makes it ideal for applications where weight is a concern, such as in aerospace and sports equipment.

4. Which material is more cost-effective?

Stainless steel is generally more cost-effective than titanium steel. Titanium steel’s higher cost is due to its superior properties and the difficulty in processing it.

5. What are common uses for titanium steel?

Titanium steel is used in aerospace, medical implants, high-end sports equipment, and luxury goods due to its light weight and high strength.

6. What are common uses for stainless steel?

Stainless steel is widely used in kitchen appliances, cutlery, surgical instruments, construction materials, and industrial equipment due to its corrosion resistance and affordability.

7. Can titanium steel be easily welded and machined?

Titanium steel is more challenging to weld and machine than stainless steel due to its properties. Specialized techniques and equipment are required.

8. Which is more suitable for medical implants, titanium steel or stainless steel?

Titanium steel is more suitable for medical implants due to its biocompatibility, corrosion resistance, and lightweight nature.

9. How do the aesthetics of titanium steel and stainless steel differ?

Titanium steel often has a more modern, matte finish, while stainless steel typically has a bright, polished look. Both can be finished in various ways to suit different aesthetic preferences.

10. Is titanium steel hypoallergenic?

Yes, titanium steel is hypoallergenic, making it ideal for people with metal allergies. Stainless steel can also be hypoallergenic but may cause reactions in some individuals.

Top 10 FAQ with answer about titanium steel vs stainless steel for Buyer Sourcing from China

Sure, here are the top 10 FAQs about sourcing titanium steel vs stainless steel from China, with concise answers:

1. What is the main difference between titanium steel and stainless steel?

– Titanium steel is known for its superior strength-to-weight ratio and corrosion resistance, while stainless steel is more affordable and widely used for its durability and aesthetic appeal.

2. Which is more expensive, titanium steel or stainless steel?

– Titanium steel is generally more expensive due to its complex extraction and processing methods.

3. What are the common applications of titanium steel and stainless steel?

– Titanium steel is often used in aerospace, medical devices, and high-performance sporting goods. Stainless steel is widely used in kitchenware, construction, automotive, and industrial equipment.

4. How do the corrosion resistance properties compare?

– Titanium steel offers excellent corrosion resistance, even in harsh environments, while stainless steel is highly resistant but can still corrode under certain conditions.

5. Which material is easier to work with in manufacturing?

– Stainless steel is easier to machine and weld compared to titanium steel, which requires specialized equipment and expertise.

6. What are the weight differences between titanium steel and stainless steel?

– Titanium steel is significantly lighter than stainless steel, which is beneficial for applications where weight reduction is crucial.

7. How do their thermal properties compare?

– Titanium steel has lower thermal conductivity and can withstand higher temperatures compared to stainless steel.

8. What should I consider when sourcing from China?

– Ensure the supplier has a good reputation, check certifications, request material samples, and consider logistics and import regulations.

9. Are there any notable Chinese suppliers for these materials?

– China has several reputable suppliers; it’s advisable to conduct thorough research or use platforms like Alibaba to find verified manufacturers.

10. How can I verify the quality of the materials?

– Request detailed material specifications, certifications (such as ISO or ASTM), and consider third-party inspections before finalizing the purchase.