Technology and Applications of properties metalloids

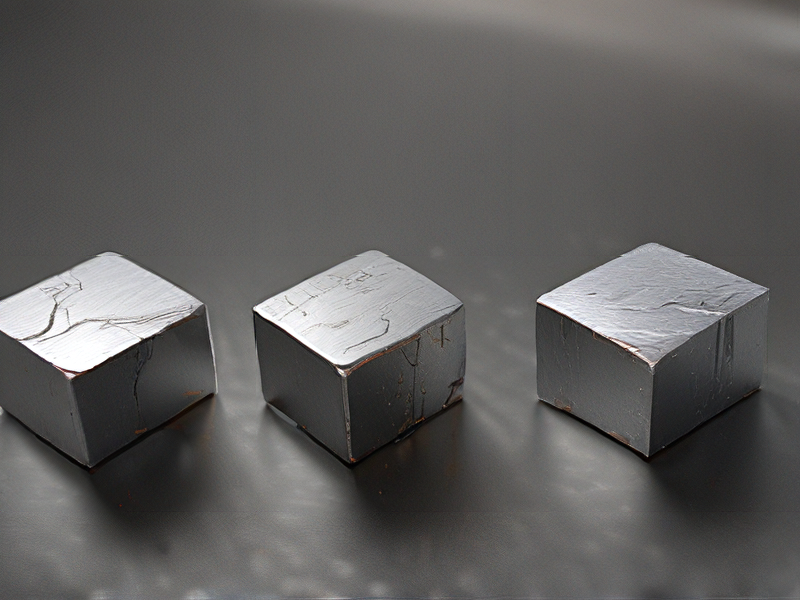

Metalloids, characterized by their intermediate properties between metals and nonmetals, include elements like silicon, germanium, arsenic, and antimony. These elements exhibit unique characteristics that make them valuable in various technological applications.

Silicon, one of the most notable metalloids, is a cornerstone of the semiconductor industry. Its ability to conduct electricity in a controlled manner underpins the manufacturing of computer chips and solar cells. Silicon’s semiconductor properties enable efficient energy conversion, making it crucial for the development of renewable energy technologies.

Germanium, another significant metalloid, is also used in semiconductors, particularly in fiber optic systems and infrared optics. Its high refractive index and transparency to infrared radiation make it ideal for telecommunications and imaging applications.

Boron, a metalloid often overlooked, plays a critical role in glass and ceramics production, enhancing strength and thermal resistance. Additionally, boron compounds are used in detergents, fertilizers, and even in some types of nuclear reactors due to their neutron-absorbing properties.

Arsenic, although toxic, is utilized in small amounts to improve the properties of alloys, particularly in lead and copper. Its semiconducting properties are also being explored in advanced electronic applications.

In summary, metalloids are integral to modern technology, influencing sectors such as electronics, materials science, and energy. Their unique combination of metallic and nonmetallic properties not only aids in the creation of innovative materials but also enhances performance in various applications, from consumer electronics to industrial processes. As technology evolves, the demand for metalloids is likely to grow, furthering their significance in research and development.

Quality Testing Methods for properties metalloids and how to control quality

Quality testing methods for metalloids, such as boron, silicon, germanium, arsenic, antimony, and tellurium, typically focus on ensuring purity, composition, and physical properties crucial for various applications. Common quality control measures include:

1. Chemical Analysis: Utilizing techniques like X-ray fluorescence (XRF) and inductively coupled plasma (ICP) spectroscopy to determine elemental composition and impurity levels.

2. Crystallographic Analysis: X-ray diffraction (XRD) and electron diffraction to analyze crystal structure and phase composition, ensuring desired crystalline forms.

3. Physical Properties Testing: Includes measuring density, melting point, thermal conductivity, and electrical resistivity using methods like differential scanning calorimetry (DSC) and four-point probe technique.

4. Surface Analysis: Scanning electron microscopy (SEM) and atomic force microscopy (AFM) to assess surface morphology, defects, and contamination.

5. Impurity Detection: Techniques such as inductively coupled plasma mass spectrometry (ICP-MS) and gas chromatography-mass spectrometry (GC-MS) for detecting trace impurities.

To control quality, rigorous adherence to standards such as ISO 9001 ensures consistent manufacturing processes and product specifications. Continuous monitoring and improvement based on statistical process control (SPC) methods help maintain product integrity. Regular calibration of equipment and periodic proficiency testing of personnel ensure accuracy in testing. Collaboration with suppliers to establish stringent raw material specifications further enhances quality control.

By employing these methods and controls, manufacturers can ensure that metalloid products meet stringent quality requirements, enabling reliable performance in diverse industrial applications.

Tips for Procurement and Considerations when Purchasing from properties metalloids

When procuring materials like metalloids (such as boron, silicon, germanium) for properties or industrial purposes, consider the following tips and considerations:

1. Supplier Reliability: Choose suppliers with a proven track record in providing high-quality metalloids. Check certifications and customer reviews to ensure reliability.

2. Purity and Specifications: Specify the required purity levels and chemical compositions based on your application needs. Metalloids can vary significantly in purity, which impacts their performance.

3. Price and Cost Factors: Compare prices from multiple suppliers while considering transportation costs, bulk discounts, and potential tariffs or taxes that may affect the overall procurement cost.

4. Technical Support: Opt for suppliers who offer technical support or consultation to assist in choosing the right metalloid for your specific application. This can be crucial for optimizing performance and efficiency.

5. Supply Chain Resilience: Evaluate the supplier’s supply chain resilience and contingency plans. Metalloid availability can be sensitive to global supply chain disruptions, so understanding this aspect is essential.

6. Environmental Impact: Assess the environmental impact of sourcing metalloids. Consider suppliers who adhere to sustainable practices and regulations, minimizing environmental footprint.

7. Testing and Quality Assurance: Ensure the supplier provides adequate testing and quality assurance measures. This includes certificates of analysis and compliance with industry standards.

8. Long-term Relationship: Build a long-term relationship with reliable suppliers to ensure consistent quality and availability of metalloids. This can lead to better pricing and priority during shortages.

By prioritizing these considerations, you can effectively procure metalloids that meet your performance requirements while ensuring cost-effectiveness and sustainability in your operations.

FAQs on Sourcing and Manufacturing from properties metalloids in China

FAQs on Sourcing and Manufacturing Metalloids in China

1. What are metalloids?

Metalloids are elements that exhibit properties of both metals and non-metals. Common examples include silicon (Si), germanium (Ge), arsenic (As), and antimony (Sb).

2. Why source metalloids from China?

China is a leading producer of metalloids, offering competitive pricing, advanced manufacturing capabilities, and a well-established supply chain. Its significant reserves of raw materials enhance its capacity for large-scale production.

3. How to identify reliable suppliers?

When sourcing from China, consider using platforms like Alibaba, Global Sources, or Made-in-China. Assess suppliers through customer reviews, certifications (e.g., ISO), and factory audits. Personal visits or third-party inspections can further verify reliability.

4. What are the common challenges in sourcing?

Key challenges include quality control, language barriers, and potential tariff implications. It’s essential to establish clear communication and set quality standards upfront.

5. How to ensure product quality?

Implement rigorous quality assurance processes. This can include pre-production samples, regular inspections, and adherence to international standards. Working with local agents can help navigate these processes effectively.

6. Are there any environmental regulations?

China has increased its focus on environmental regulations. Ensure suppliers comply with local laws and international standards to avoid legal issues and maintain sustainable practices.

7. What logistical considerations should I keep in mind?

Factor in shipping costs, import duties, and lead times. Collaborate with freight forwarders experienced in handling metalloid materials to streamline the import process.

8. Is it possible to manufacture customized metalloids in China?

Yes, many Chinese manufacturers offer customization options to meet specific requirements. Discuss your needs with suppliers during the initial stages of sourcing.