“Reliable Rapid Manufacturing Solutions with SourcifyChina Factory: Your Trusted Partner in High-Quality Production”

Discover the benefits of partnering with SourcifyChina Factory Rapid Manufacturing Group for unparalleled reliability and efficiency in high-quality production solutions tailored to meet your specific needs.

By choosing SourcifyChina, buyers gain access to a vast network of pre-vetted factories specializing in rapid manufacturing. This ensures high-quality production and adherence to timelines, minimizing risks associated with outsourcing.

SourcifyChina offers end-to-end support including negotiation, quality assurance, and logistics management. This comprehensive service reduces the complexity of the manufacturing process for buyers.

With expertise in navigating China’s manufacturing landscape, SourcifyChina effectively bridges cultural and communication gaps, ensuring clear and efficient interactions between buyers and factory partners.

Their robust vetting process ensures that only reliable factories are recommended, safeguarding buyers from potential pitfalls like substandard quality or delays. This reliability is crucial for maintaining brand reputation.

Cost-effectiveness is another advantage. SourcifyChina leverages its industry knowledge and relationships to secure competitive pricing, providing buyers with affordability without compromising on quality.

In summary, SourcifyChina stands out as a dependable partner for buyers seeking rapid manufacturing solutions in China. Their extensive support, expertise, and commitment to quality and cost-efficiency make them an ideal choice for seamless international manufacturing.

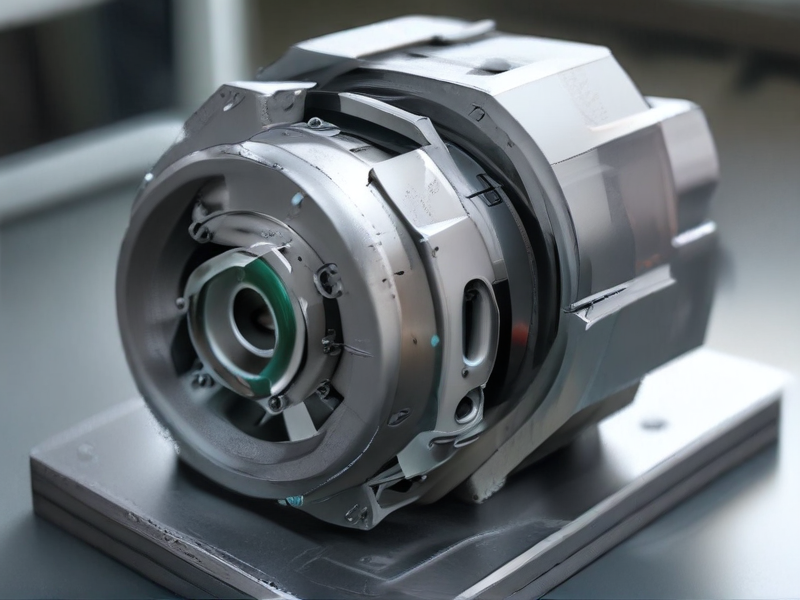

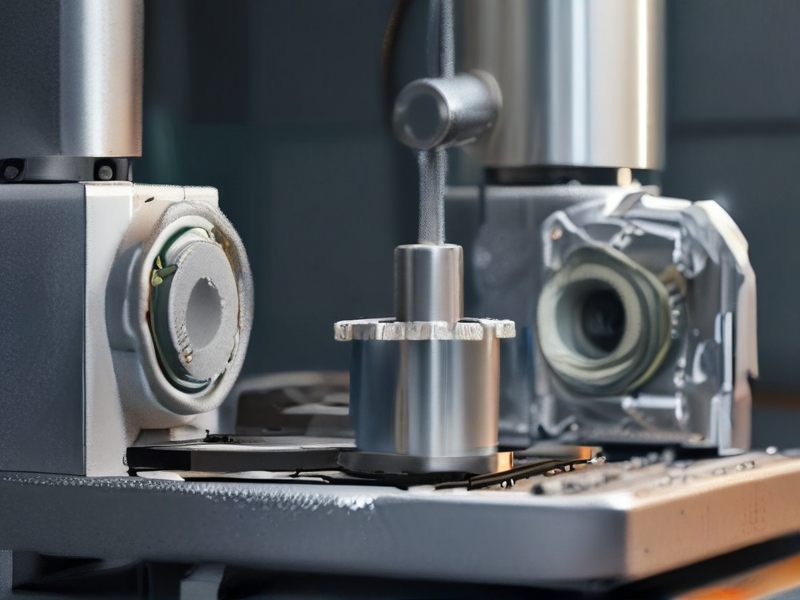

Rapid manufacturing groups specialize in swiftly producing parts or products using advanced technologies. Options include 3D printing, CNC machining, injection molding, and laser cutting. These methods offer quick turnaround, customization, and cost-efficiency for various industries.

– 3D Printing (Additive Manufacturing)

– Uses materials like plastics, metals, and ceramics.

– Ideal for prototypes and complex geometries.

– Benefits: Speed, customization, reduced waste.

– CNC Machining

– Subtractive process; cuts material from a solid block.

– Suitable for metals, plastics, and composites.

– Benefits: Precision, versatility, high-quality finishes.

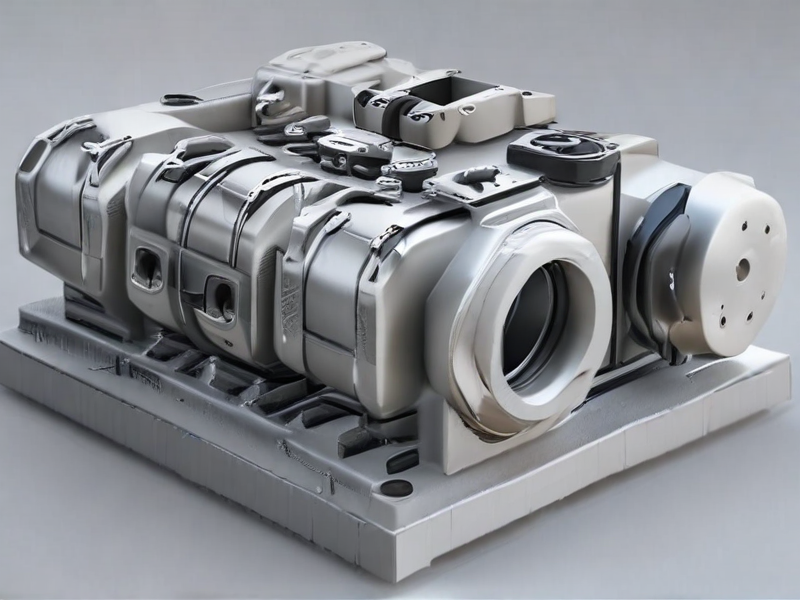

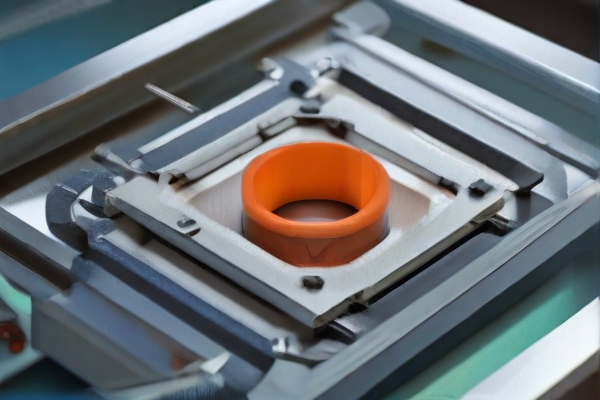

– Injection Molding

– Involves injecting molten material into molds.

– Best for high-volume production of plastic parts.

– Benefits: Consistent quality, efficiency, scalability.

– Laser Cutting

– Uses high-powered lasers to cut or engrave materials.

– Works on metals, plastics, wood, and more.

– Benefits: Accuracy, speed, minimal material deformation.

– Sheet Metal Fabrication

– Involves cutting, bending, and assembling metal sheets.

– Suitable for creating enclosures, brackets, and chassis.

– Benefits: Durability, high strength, cost-effective for medium to large quantities.

– Urethane Casting

– Uses silicone molds to produce parts from urethane.

– Good for low-volume or prototype production.

– Benefits: Flexibility, reduced lead times, and cost savings compared to injection molding.

These rapid manufacturing options cater to diverse industry needs, providing efficient solutions from prototyping to full-scale production.

Rapid Manufacturing Group specializes in fast-track production solutions, enabling businesses to accelerate their product development and market release. Their applications span various industries and include:

– Prototyping: Quick creation of prototypes for design validation and iterative testing.

– Custom Components: Manufacturing tailored parts for specific needs.

– Medical Devices: Production of precise, FDA-compliant health care gadgets.

– Automotive Parts: Rapid production of vehicle components for testing and small-scale manufacturing.

– Consumer Goods: Accelerating the launch of new products with quick-turnaround manufacturing.

– Aerospace Components: Precision parts for aviation and space exploration.

– Tooling: Fast production of manufacturing tools and molds.

– Electronics: Quick fabrication of electronic components and housings.

– Military and Defense: Rapid development of mission-critical parts and equipment.

– Architecture: Custom-designed components for architectural models and final structures.

– Renewable Energy: Quick production of components for solar, wind, and other renewable technologies.

– Sports Equipment: Rapid development of custom and performance-enhancing sports gear.

– Education and R&D: Speedy manufacturing of educational kits and research prototypes.

– Fashion: Creation of custom accessories and fast deployment of sample pieces.

– Home Appliances: Accelerated manufacturing processes for household gadget prototypes.

– Art and Design: Fast production of custom art pieces and decorative designs.

– Packaging: Quick turnaround for custom packaging solutions.

– Robotics: Rapid creation of robotic parts and mechanisms.

– Agriculture: Production of specialized parts for agricultural machinery.

– Marine: Fast-track development of maritime equipment and components.

By leveraging advanced manufacturing technologies, Rapid Manufacturing Group provides essential solutions that meet the dynamic demands of modern industries, ensuring efficiency and high quality.

SourcifyChina Rapid Manufacturing Group specializes in providing a wide array of materials for rapid prototyping and manufacturing. They offer metals, plastics, and composites, ensuring high versatility for various industries.

Their metal options include aluminum, stainless steel, and titanium, chosen for their strength, durability, and suitability for diverse applications. These metals are ideal for automotive parts, aerospace components, and industrial machinery.

In terms of plastics, SourcifyChina offers ABS, polycarbonate, and nylon, among others. These materials are lightweight, cost-effective, and excellent for creating prototypes, consumer products, and medical devices.

Composites like carbon fiber and fiberglass are also available, providing enhanced strength and reduced weight. These are perfect for high-performance applications in sports equipment, aerospace, and marine engineering.

With their extensive material options, SourcifyChina ensures that clients can select the best possible resources for their specific needs, leading to efficient and high-quality manufacturing solutions. This commitment to material diversity and quality underlines their prominence in the rapid manufacturing industry.

SourcifyChina Rapid Manufacturing Group employs a meticulous quality control process. Their first step is rigorous raw material inspection. Ensuring top-grade materials form the foundation of their production emphasizes precision and reliability.

Post-material inspection, they implement in-process quality checks. This stage involves continuous monitoring and evaluation during production. Technicians utilize advanced technologies to detect and rectify defects promptly.

Next, the final product undergoes comprehensive testing. Products are scrutinized for dimensional accuracy, performance, and durability. Such inter-stage assessments guarantee adherence to stringent quality standards.

Additionally, the company uses statistical process control methods. These techniques analyze production data to identify variations and reduce inconsistencies, aiming for uniformity.

Feedback from clients is also integral. The Group maintains an open channel for customer reviews, using this input to refine processes and increase satisfaction continually.

The ultimate goal is to deliver flawless products. By integrating quality control at every production phase, SourcifyChina stands out as a leader in reliable, high-standard manufacturing. Their dedication to quality ensures customer trust and long-term success.

SourcifyChina Rapid Manufacturing Group specializes in providing high-quality, custom manufacturing solutions. Their capabilities span a variety of services including CNC machining, 3D printing, and injection molding, enabling the production of complex parts with precision.

With state-of-the-art equipment and advanced technologies, SourcifyChina ensures rapid prototyping and scalable production for industries such as automotive, aerospace, and consumer electronics. They emphasize speed without compromising on quality, meeting tight deadlines efficiently.

The company’s commitment to quality is reinforced through rigorous quality control processes. Each product undergoes meticulous inspection to ensure it meets exact specifications and industry standards, giving clients confidence in their final product.

SourcifyChina also excels in material versatility, offering an extensive range of materials from metals to plastics. This allows clients to choose the best materials suited to their application, achieving optimal performance and durability.

Customer satisfaction is at the core of SourcifyChina’s operations. They focus on personalized service, working closely with clients from initial design to final delivery, ensuring each project’s unique requirements are met.

Overall, SourcifyChina’s rapid manufacturing capabilities provide comprehensive, reliable, and innovative solutions, making them a trusted partner for companies seeking to accelerate their product development and manufacturing processes. Their dedication to quality, speed, and customer service sets them apart in the manufacturing landscape, ensuring products are brought to market efficiently and effectively.

Rapid Manufacturing Group brings numerous advantages through its advanced manufacturing techniques, delivering efficient, customized, and cost-effective solutions across various industries. Streamlining production, reducing time-to-market, and enhancing product quality are just a few of its many benefits.

– Speed and Efficiency: Accelerates production cycles, reducing time-to-market for new products.

– Customization: Allows for highly customized designs without the long lead times of traditional manufacturing processes.

– Cost-Effective: Minimizes waste and reduces costs by optimizing resource usage and automating processes.

– Prototyping: Facilitates rapid prototyping, enabling swift design iterations and improvements.

– Flexibility: Adaptable to changes in design and production needs without major disruptions or additional costs.

– High-Quality Outputs: Utilizes advanced technology to ensure high precision and superior product quality.

– Sustainability: Often employs eco-friendly practices and materials, reducing environmental impact.

– Complex Geometries: Capable of producing intricate and complex geometries that are difficult or impossible with traditional methods.

– Scalability: Easily scalable from small batch to large volume production to meet varying demands.

– Market Competitiveness: Helps businesses stay competitive by enabling quicker response to market changes and consumer demands.

– Reduced Tooling Costs: Often requires less or no specialized tooling, which reduces setup costs and lead times.

– Resource Efficiency: Maximizes the use of materials, contributing to lower overhead costs and improved profitability.

– Innovation Encouragement: Fosters innovation through the ability to experiment with new designs and materials easily.

– Remote Manufacturing: Enables production in remote locations, reducing dependency on centralized manufacturing hubs.

In summary, Rapid Manufacturing Group revolutionizes traditional production methods, providing unparalleled advantages in efficiency, cost-saving, and product innovation, ultimately driving better competitiveness in the market.

Rapid Manufacturing Group excels in delivering high-quality, swift production solutions using cutting-edge technology. Their services are pivotal for industries needing quick turnarounds.

– Advanced 3D Printing: Utilizes state-of-the-art 3D printing technologies to produce complex geometries and intricate designs with precision.

– Custom Prototyping: Offers rapid prototyping services to quickly iterate designs, enabling faster product development cycles.

– CNC Machining: Provides high-accuracy CNC machining services for producing detailed parts with tight tolerances.

– Injection Molding: Capable of rapid injection molding processes to produce plastic parts in large volumes efficiently.

– Material Versatility: Works with a wide range of materials, including metals, plastics, and composites, to meet various manufacturing needs.

– Quality Control: Implements rigorous quality assurance protocols to ensure product accuracy and reliability.

– Scalability: Offers scalable solutions from prototyping to full-scale production, adapting to the client’s manufacturing demands.

– Reduced Lead Times: Minimized production lead times through streamlined processes and efficient workflow management.

– Cost-Effectiveness: Competitive pricing models that ensure cost savings without compromising on quality.

– Expert Consultation: Provides expert advice and design optimization tips to improve manufacturability and reduce costs.

– Sustainability Initiatives: Focuses on eco-friendly practices and sustainable materials to reduce environmental impact.

– Global Reach: Extensive network and facilities enable them to serve clients worldwide with consistent service and support.

– Customer Support: Dedicated customer service team to provide ongoing support and address any manufacturing challenges.

These features make Rapid Manufacturing Group a leader in the industry, enabling businesses to bring their products to market faster and more efficiently.

SourcifyChina Rapid Manufacturing Group specializes in producing high-quality custom products tailored to meet diverse client requirements. Utilizing state-of-the-art technology and a skilled workforce, they offer precision manufacturing for various industries.

From prototyping to full-scale production, SourcifyChina provides end-to-end solutions. Their services include CNC machining, 3D printing, injection molding, and more. This flexibility ensures that customers receive products that meet their exact specifications and standards.

The company excels in rapid turnaround times, maintaining rigorous quality control throughout the manufacturing process. This commitment to excellence makes them a preferred choice for both startups and established corporations.

Projects range from automotive components to medical devices, demonstrating their versatility and expertise in handling diverse materials and complex designs. SourcifyChina’s ability to adapt to shifting market demands sets them apart.

Client collaboration is a cornerstone of their operational philosophy. They work closely with each client, offering technical support and consultation to optimize the design and manufacturing process, ensuring project success and customer satisfaction.

As an industry leader, SourcifyChina continues to innovate, incorporating the latest advancements in manufacturing technology. Their commitment to sustainability and efficiency not only reduces costs but also minimizes environmental impact.

Overall, SourcifyChina Rapid Manufacturing Group is dedicated to delivering custom, high-quality products that exceed client expectations. Whether you need a single prototype or millions of production units, their expertise and dedication ensure timely and cost-effective solutions.

SourcifyChina Rapid Manufacturing Group is a dynamic and innovative company specializing in delivering efficient, high-quality manufacturing solutions from China to clients worldwide. Established with the vision of bridging the gap between rapid prototyping and full-scale production, the company leverages advanced technologies and an extensive network of skilled manufacturers to deliver precision-crafted products tailored to specific client requirements. Combining expertise in CNC machining, injection molding, 3D printing, and sheet metal fabrication, SourcifyChina excels in producing highly accurate and complex components quickly and cost-effectively. The group’s commitment to excellence is evident in its stringent quality control measures, ensuring every product meets international standards and client specifications. Furthermore, SourcifyChina prides itself on its customer-centric approach, providing end-to-end support that includes design consultation, material selection, and efficient logistics. This seamless integration of services empowers businesses to accelerate their product development cycles, reduce costs, and achieve faster time-to-market. Whether for startups needing rapid prototyping or established companies seeking reliable mass production solutions, SourcifyChina stands out as a trusted partner in the global manufacturing landscape.

The Aerospace, Defense, and Marine sectors have increasingly integrated the capabilities of the Rapid Manufacturing Group to enhance their production efficiencies and deliver superior components. Rapid manufacturing, which encompasses advanced techniques like additive manufacturing (3D printing) and automated machining processes, enables these industries to significantly reduce production times and costs. In aerospace, the ability to swiftly create lightweight, high-strength parts that can withstand extreme conditions is crucial. With rapid manufacturing, custom aerodynamic components can be developed and tested in a fraction of the time compared to traditional methods. Defense applications benefit similarly, where the demand for rugged, precise, and reliable parts dictates the need for robust manufacturing processes. The ability to quickly prototype and produce components enhances the readiness and adaptability of defense systems to evolving threats.

In the Marine industry, rapid manufacturing offers the ability to produce corrosion-resistant parts crucial for marine environments. The flexibility of rapid manufacturing allows for the efficient production of complex geometries and bespoke components tailored to specific vessels, enhancing performance and operational capabilities. Furthermore, the capacity to produce on-demand spare parts alleviates supply chain bottlenecks, ensuring timely maintenance and reducing downtime. The integration of rapid manufacturing techniques also opens new avenues for design innovation, permitting more efficient and eco-friendly marine architectures. By leveraging the capabilities of the Rapid Manufacturing Group, the Aerospace, Defense, and Marine sectors can maintain a competitive edge, meeting stringent performance standards while embracing advancements in technology and production methodologies.

Rapid Manufacturing Group has significantly transformed the automotive industry by providing unparalleled speed and precision in the manufacturing process. Their advanced techniques, including 3D printing, CNC machining, and laser cutting, allow for the rapid prototyping and production of complex parts and components. This accelerates the product development cycle, enabling automotive manufacturers to bring innovations to market faster than ever before. By minimizing lead times and reducing the dependency on traditional, labor-intensive manufacturing methods, Rapid Manufacturing Group helps companies improve overall efficiency and cost-effectiveness. Additionally, the customization capabilities offered by their technologies mean that unique, high-performance components can be tailored to meet specific vehicle requirements, thereby enhancing vehicle performance, safety, and consumer satisfaction.

In the realm of electronics, Rapid Manufacturing Group’s cutting-edge solutions have revolutionized the way electronic devices are designed and produced. Leveraging advanced additive manufacturing techniques, they facilitate the creation of intricate circuit boards, housings, and other electronic components with a high degree of precision and reliability. This not only speeds up the prototyping phase but also allows for quick iterations and modifications, which are crucial in the fast-paced electronics industry. The ability to produce small to medium-sized batches efficiently supports the demands of limited-run or bespoke devices. Furthermore, the materials used in rapid manufacturing processes can include specialized conductive and insulative properties, ensuring the electronic components meet the stringent performance standards required in today’s high-tech landscape. By integrating these advanced manufacturing solutions, electronics companies can innovate more rapidly and respond to market needs with greater agility.

The Rapid Manufacturing Group (RMG) has revolutionized the construction industry by employing cutting-edge additive manufacturing and advanced material technologies. In the construction domain, RMG leverages 3D printing to create complex architectural designs and structural components with unparalleled precision and efficiency. This not only minimizes waste but also significantly accelerates project timelines. For instance, RMG’s ability to produce on-site customized building materials and prefabricated modules drastically reduces labor costs and logistical challenges. Furthermore, the utilization of sustainable materials in their processes aligns with the global drive toward greener construction practices, enabling the realization of eco-friendly structures that meet stringent regulatory standards.

In the realm of energy applications, the Rapid Manufacturing Group enhances the production and optimization of various energy systems. By integrating rapid manufacturing techniques, RMG can develop bespoke components for renewable energy solutions such as wind turbines, solar panels, and energy storage systems with improved performance and longevity. These advancements are pivotal in reducing the overall cost of renewable energy projects and accelerating the transition to sustainable energy sources. Additionally, RMG’s innovative approaches in producing lightweight, high-strength materials facilitate the construction of more efficient and durable components for traditional energy infrastructure. This dual focus on both renewable and conventional energy systems underscores RMG’s commitment to driving technological progress while supporting a diverse energy landscape.

The industrial equipment industry has witnessed a significant transformation with the advent of rapid manufacturing technologies, driven by entities such as the “Rapid Manufacturing Group.” These advanced manufacturing techniques, which include 3D printing, additive manufacturing, and rapid prototyping, enable companies to produce complex machine components with unprecedented speed and precision. The integration of these technologies allows for shorter production cycles, decreased lead times, and the ability to quickly iterate on design processes. As a result, industrial equipment manufacturers can meet the diverse and evolving needs of their clients more efficiently. This agility is particularly beneficial for projects requiring customized machinery or parts, as it allows for rapid adaptations and modifications without incurring the high costs traditionally associated with such changes.

Moreover, the “Rapid Manufacturing Group” enhances sustainability within the industrial equipment sector by optimizing material usage and reducing waste. Traditional manufacturing methods often involve significant material wastage due to subtractive processes like cutting and machining. In contrast, additive manufacturing constructs components layer by layer, utilizing only the necessary materials and thereby minimizing excess. Additionally, rapid manufacturing supports the decentralization of production, enabling localized manufacturing hubs that can produce parts on-demand. This not only lowers transportation costs and emissions but also enhances supply chain resilience by reducing dependence on distant suppliers. Consequently, the application of rapid manufacturing within the industrial equipment industry stands as a pivotal advancement, promoting efficiency, cost-effectiveness, and sustainability in the production of diverse machinery and components.

The “rapid manufacturing group” pertains to the advanced methods of producing medical devices swiftly and efficiently, leveraging cutting-edge technologies such as 3D printing, CNC machining, and additive manufacturing. This group is instrumental in revolutionizing the healthcare sector by enabling the production of custom, patient-specific devices including prosthetics, implants, and surgical instruments in significantly reduced timeframes. By employing digital models and rapid prototyping, manufacturers can quickly iterate designs and bring innovative solutions to market, thereby enhancing patient outcomes and streamlining medical processes. These technologies also facilitate the creation of complex geometries and structures that are often challenging to produce with traditional manufacturing techniques.

Moreover, the rapid manufacturing group aids in reducing costs and minimizing waste, which is critical in the highly-regulated medical device industry. The ability to produce small batches or even single-unit runs without the need for extensive tooling or setup processes is economically advantageous, particularly for bespoke medical devices tailored to individual patient needs. Additionally, by integrating these rapid manufacturing processes with advanced materials like biocompatible polymers and metals, the group ensures that the resulting medical devices are not only precisely engineered but also meet stringent safety and efficacy standards. Consequently, the rapid manufacturing group holds promise for driving the next wave of medical innovation, delivering timely and personalized healthcare solutions that are both high in quality and accessibility.

The Rapid Manufacturing Group specializes in delivering agile and innovative machining solutions that significantly reduce production time while maintaining high standards of quality and precision. By incorporating advanced CNC (Computer Numerical Control) machining technologies, the group can create complex parts with intricate details that are essential for various industries, including aerospace, automotive, and medical devices. Their approach leverages high-speed machining centers and state-of-the-art software to streamline the design-to-production pipeline, allowing for rapid prototyping and small-batch production without the need for extensive setup times or tooling costs.

In the realm of manufacturing, the Rapid Manufacturing Group excels in providing customized solutions tailored to specific client needs. Utilizing additive manufacturing techniques such as 3D printing along with traditional subtractive methods, they offer a hybrid approach that maximizes material efficiency and reduces waste. This combination of methods not only speeds up the production cycle but also facilitates flexibility and scalability in manufacturing. Clients benefit from reduced lead times, cost-effective production runs, and the ability to quickly iterate and refine their product designs. As a result, the Rapid Manufacturing Group stands at the forefront of modern manufacturing practices, driving innovation and efficiency across multiple sectors.

Sure, here is a list of FAQs with concise answers for the context of manufacturing “rapid manufacturing group quality work from SourcifyChina factory”:

Q1: What is rapid manufacturing?

A1: Rapid manufacturing refers to the fast production of high-quality components using advanced techniques such as 3D printing, CNC machining, and injection molding.

Q2: How does SourcifyChina ensure high-quality work?

A2: SourcifyChina ensures high quality through stringent quality control processes, certified materials, and state-of-the-art manufacturing technologies.

Q3: What types of materials can SourcifyChina work with for rapid manufacturing?

A3: SourcifyChina can handle a variety of materials including plastics, metals, and composites to meet different industrial requirements.

Q4: What are the typical lead times for rapid manufacturing projects?

A4: Lead times can vary based on the complexity and volume of the order, but SourcifyChina aims to deliver within 1 to 4 weeks for most projects.

Q5: How does SourcifyChina handle design and prototyping?

A5: SourcifyChina offers comprehensive design and prototyping services, including CAD design, to provide a clear visualization before production.

Q6: What industries does SourcifyChina serve?

A6: SourcifyChina serves a wide range of industries including automotive, aerospace, consumer electronics, healthcare, and industrial machinery.

Q7: Can SourcifyChina accommodate custom manufacturing requests?

A7: Yes, SourcifyChina specializes in customized manufacturing solutions tailored to meet unique client specifications and requirements.

Q8: How does SourcifyChina manage intellectual property protection?

A8: SourcifyChina takes intellectual property (IP) protection seriously by implementing confidentiality agreements and secure data management protocols.

Q9: Is there a minimum order quantity (MOQ) for rapid manufacturing projects at SourcifyChina?

A9: MOQ requirements depend on the specific project, but SourcifyChina offers flexible options to cater to both small and large production runs.

Q10: How can I request a quote for my rapid manufacturing project?

A10: You can request a quote by visiting the SourcifyChina website and submitting your project details, or contacting their customer service team directly.

Navigating the landscape of rapid manufacturing and group manufacturing with a company like SourcifyChina can significantly boost efficiency and reduce time-to-market. Here are some concise tips for maximizing your collaboration:

1. Detailed Specifications: Provide thorough and detailed specifications for your product. Clear CAD designs, material requirements, and functional descriptions help avoid misunderstandings and ensure accurate production.

2. Prototyping Speed: Leverage SourcifyChina’s rapid prototyping capabilities to quickly iterate on designs. Use 3D printing, CNC machining, or rapid tooling to develop prototypes and validate designs before committing to mass production.

3. Batch Production: Utilize the group manufacturing strategy by combining smaller orders to take advantage of bulk production economies of scale. This minimizes costs and resources while maintaining high-quality standards.

4. Material Selection: Discuss material options early on. SourcifyChina has access to a variety of materials; selecting the right material can affect durability, cost, and production speed.

5. Quality Control: Establish stringent quality control processes, including pre-production samples, in-process inspections, and final quality checks. SourcifyChina’s in-house QC team can ensure that your products meet your standards.

6. Lead Time Management: Clearly communicate your lead time requirements and build in buffer periods for unexpected delays. Regular updates and open lines of communication with SourcifyChina ensure smoother timelines.

7. Cost Analysis: Request detailed cost breakdowns. Understanding each cost component, from raw materials to labor, helps in making informed decisions and optimizing the budget.

8. Sustainability Considerations: Discuss sustainable manufacturing options. SourcifyChina offers eco-friendly materials and processes that can reduce the environmental footprint of your products.

9. Supply Chain Visibility: Maintain transparency in your supply chain by tracking orders in real-time. SourcifyChina’s integrated systems can offer valuable insights and updates.

By focusing on these key areas, you can effectively collaborate with SourcifyChina for rapid and group manufacturing, ensuring high-quality output and efficient production cycles.

Sure, here are some frequently asked questions (FAQs) with their answers about sourcing from “Rapid Manufacturing Group” through SourcifyChina Factory:

Q: What is Rapid Manufacturing Group?

A: Rapid Manufacturing Group is a specialized division focusing on quick production turnarounds, offering high-quality prototypes and short-run productions using advanced manufacturing technologies.

Q: How can SourcifyChina help me source from Rapid Manufacturing Group?

A: SourcifyChina serves as a bridge between overseas clients and reliable factories in China, such as Rapid Manufacturing Group. They assist in finding the right factory, handling negotiations, quality control, and ensuring timely deliveries.

Q: What types of products can Rapid Manufacturing Group produce?

A: They specialize in a wide range of products including CNC machined parts, 3D printed parts, injection-molded components, and other customizable manufacturing solutions.

Q: What is the typical lead time for prototyping?

A: Lead times for prototypes generally range from a few days to a couple of weeks, depending on complexity and material availability.

Q: How do I ensure the quality of my products?

A: SourcifyChina provides comprehensive quality control services, including on-site inspections and regular updates throughout the production process to ensure your specifications are met.

Q: What are the minimum order quantities (MOQ) required?

A: MOQ can vary depending on the specific product and material requirements. Rapid Manufacturing Group often offers flexibility in MOQs, especially for prototypes and low-volume runs.

Q: How do I get a quote?

A: To get a quote, you can provide detailed specifications, designs, and quantities to SourcifyChina, who will then coordinate with Rapid Manufacturing Group to give you an accurate estimate.

Q: Can I visit the factory?

A: Yes, you are welcome to visit the factory. SourcifyChina can help arrange factory tours to provide you with a firsthand look at production facilities and processes.

Q: What payment methods are accepted?

A: Common payment methods include wire transfers (T/T), letters of credit (L/C), and sometimes PayPal or credit cards, depending on the agreement.

Q: What if there are issues with my order?

A: SourcifyChina offers support for resolving any issues, including coordinating directly with the factory to address and rectify any problems swiftly.

This concise FAQ should give you a good overview of what to expect when sourcing from Rapid Manufacturing Group through SourcifyChina Factory.

Sourcing a “rapid manufacturing group from SourcifyChina factory” involves several key steps to ensure you find a reliable and efficient partner. Here are some tips to help you in this process:

1. Define Your Requirements: Clearly outline your manufacturing needs, including materials, specifications, quantities, and timelines. Precise details will help you filter and identify the right manufacturers.

2. Research and Shortlist: Utilize SourcifyChina’s platform to search for manufacturers specializing in rapid manufacturing. Create a shortlist based on reviews, ratings, and their manufacturing capabilities.

3. Evaluate Experience: Check if the manufacturers have experience in producing similar products. Years of operation, past projects, and client testimonials can offer insights into their expertise.

4. Request Samples: Before finalizing a manufacturer, request samples of their work. This helps you evaluate the quality and craftsmanship first-hand. Ensure that the sample matches your specifications.

5. Assess Communication: Efficient communication is critical. Assess how promptly and clearly the manufacturers respond to your inquiries. A responsive manufacturer usually translates to better coordination during production.

6. Visit the Factory: If feasible, organize a visit to the factory. This allows you to inspect their facilities, machinery, quality control measures, and working conditions. It also provides an opportunity for face-to-face discussions with the management team.

7. Check Certifications: Verify the manufacturer’s certifications and compliance with industry standards. Certifications (ISO, CE, etc.) often indicate a commitment to quality and reliability.

8. Negotiate Terms: Discuss contract terms, including pricing, payment options, lead times, and minimum order quantities. Ensure these terms align with your business needs and budget.

9. Review Logistics: Consider the logistics of shipping, including costs, timelines, and potential customs issues. Choose a manufacturer who can offer reliable shipping solutions to your location.

10. Build a Relationship: Establish a long-term relationship with your chosen manufacturer. Regular communication and periodic reviews will help maintain standards and accommodate any future needs.

By carefully following these steps, you can secure a proficient and reliable rapid manufacturing partner through SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.