Choosing SourcifyChina Factory for purchasing sheet metal cutting lasers offers several advantages. First, sourcing directly from China provides cost-effectiveness, leveraging the low production costs and vast manufacturing expertise available in the region, ensuring competitive pricing without compromising on quality.

SourcifyChina Factory boasts state-of-the-art technology in laser cutting, ensuring precision and efficiency in every project. Their advanced machinery is capable of fulfilling stringent industrial requirements, guaranteeing products that meet international standards.

Additionally, SourcifyChina Factory places a high emphasis on quality control and compliance. Rigorous testing at every production stage assures buyers that their laser cutting machines are reliable, durable, and capable of high-performance.

Customer satisfaction is a priority for SourcifyChina Factory, providing personalized service and attentive after-sales support. Their professional team is dedicated to helping buyers with installation, maintenance, and any technical queries, ensuring seamless operation.

In conclusion, SourcifyChina Factory combines cost-effectiveness, advanced technology, rigorous quality control, and exceptional customer service, making them a trusted partner for buyers seeking reliable sheet metal cutting lasers from China.

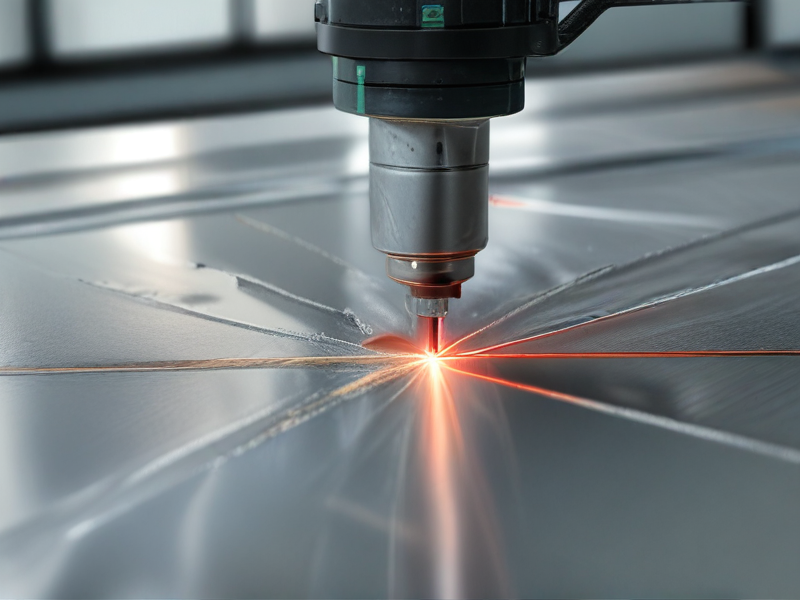

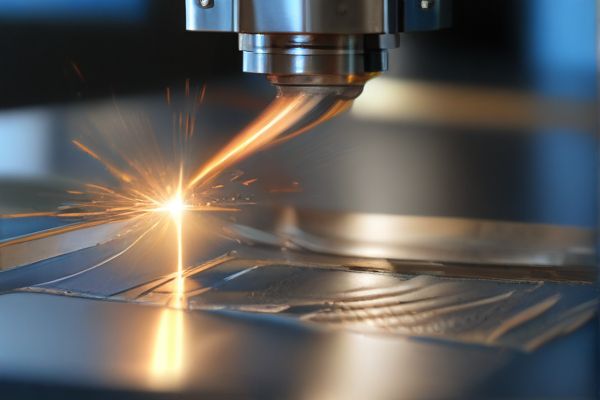

Sheet metal cutting with lasers offers precision, speed, and versatility, making it a preferred method in various industries. Different types and options cater to diverse requirements, ensuring that fabrication processes are efficient and cost-effective.

Types of Laser Cutting for Sheet Metal:

– Fiber Lasers: Known for their high efficiency and precision, fiber lasers are ideal for cutting reflective materials like aluminum and copper.

– CO2 Lasers: Suitable for cutting non-metallic materials and thick metal sheets, CO2 lasers are versatile but have higher maintenance costs.

– Nd:YAG Lasers: Used for tasks requiring high-energy pulses, such as engraving and deep welding, Nd:YAG lasers are less common for standard sheet metal cutting.

Options in Laser Cutting Technology:

– Continuous Wave vs. Pulsed Lasers:

– Continuous Wave: Provides a steady and uninterrupted beam, suitable for smooth and continuous cuts.

– Pulsed Lasers: Emit laser in short bursts, ideal for intricate designs and minimal heat-affected zones.

– Cutting Techniques:

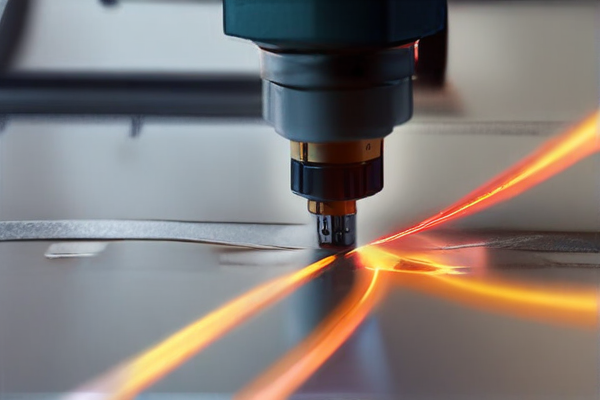

– Fusion Cutting: Uses a combination of laser energy and high-pressure gas to remove molten material.

– Flame Cutting: Utilizes oxygen to react with the metal, creating an exothermic reaction that aids cutting.

– Sublimation Cutting: Vaporizes the material directly, reducing the need for finishing processes.

Considerations for Choosing a Laser Cutter:

– Material Type and Thickness: Different lasers excel in cutting various materials and thicknesses.

– Precision and Speed Requirements: Depending on the complexity and scale of the project, some lasers offer better precision and faster cutting speeds.

– Operational Costs: Maintenance and energy consumption can vary widely between laser types.

– Software and Automation: Advanced software integration and automation capabilities can enhance efficiency and reduce human error.

In summary, understanding the types and options for sheet metal cutting lasers ensures you select the best technology for your fabrication needs, balancing precision, efficiency, and cost.

Sheet metal cutting lasers are essential in various industries for precision cutting, intricate designs, and quick turnarounds with minimal waste. They’re widely used due to their accuracy, speed, and efficiency.

– Aerospace Industry: Fabricates complex, high-precision components for aircraft.

– Automotive Manufacturing: Produces intricate parts for vehicles, improving efficiency and consistency.

– Electronics: Cuts fine, precise components for devices and circuit boards.

– Construction: Creates customized architectural elements and structural supports.

– Medical Equipment: Manufactures accurate, delicate parts required for medical devices.

– Furniture Production: Designs and cuts detailed metal parts for modern furniture.

– Signage and Advertising: Forms intricate and creative metal signs and advertising fixtures.

– Jewelry Making: Engraves and cuts metal with precision for unique jewelry designs.

– HVAC Systems: Produces components for heating, ventilation, and air conditioning systems.

– Agricultural Machinery: Creates durable, precise parts for farming equipment.

Sheet metal cutting lasers transform production processes, offering high customization, exceptional quality, and efficient resource usage across diverse applications.

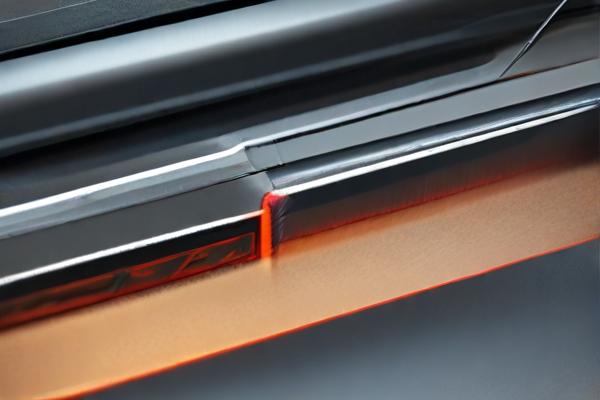

“SourcifyChina sheet metal cutting lasers” use high-quality lasers to ensure precision and efficiency. These machines can handle various metals, such as stainless steel and aluminum, allowing for versatile applications. Their advanced laser technology ensures clean cuts with minimal waste.

The construction of these laser cutters emphasizes durability and reliability. Made with robust materials and state-of-the-art components, the lasers are designed to withstand prolonged usage without compromising performance. This durability ensures long-term cost-effectiveness for industrial applications.

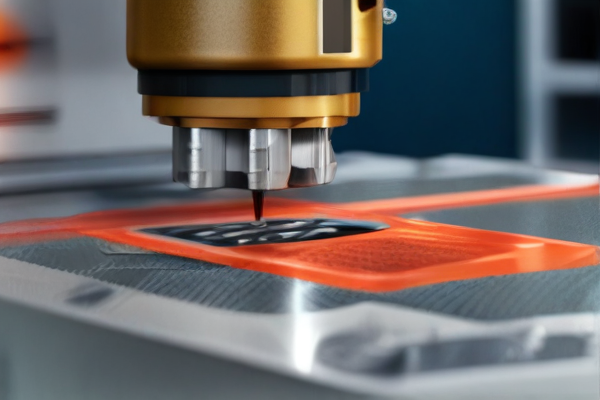

Ease of use is another critical feature. Intuitive interfaces and user-friendly software reduce the need for extensive training, making it accessible for operators of varying skill levels. This usability factor ensures smooth integration into existing workflows.

Safety is paramount in the design. Robust safety mechanisms, including emergency stop functions and protective covers, are standard. These features protect operators and meet industry safety standards, ensuring a secure working environment.

“SourcifyChina sheet metal cutting lasers” are also eco-friendly. They consume less power compared to traditional cutting methods, contributing to energy savings and reducing carbon footprints. This aspect aligns with modern sustainability goals, making them a responsible choice for businesses.

In conclusion, the “SourcifyChina sheet metal cutting lasers” offer a combination of precision, durability, ease of use, safety, and eco-friendliness. These features make them an excellent investment for industries requiring high-quality metal cutting solutions. By incorporating advanced technology and prioritizing user safety, these laser cutters provide a comprehensive solution for various metalworking needs.

SourcifyChina’s sheet metal cutting laser quality control process begins with the meticulous selection of raw materials. Only materials that meet stringent quality standards are used, ensuring the foundation of a high-quality product.

Next, advanced laser cutting machines are calibrated to precise specifications. Regular maintenance and calibration checks guarantee that the laser cuts are accurate and consistent, minimizing errors and waste.

In-process inspections are carried out by skilled technicians using sophisticated measurement tools. These inspections identify and rectify any deviations from design specifications early in the manufacturing process, ensuring high-quality output.

Finished products undergo rigorous quality testing, including dimensional checks and stress testing. This ensures that each product meets client and industry standards before being approved for shipment.

Finally, a comprehensive documentation process records each step of manufacturing and quality control. This transparency not only ensures traceability but also fosters continuous improvement in SourcifyChina’s manufacturing processes, aligning with their commitment to delivering top-tier products.

SourcifyChina’s sheet metal cutting lasers offer unparalleled precision in manufacturing. These state-of-the-art lasers feature highly focused beams, ensuring clean and accurate cuts. This technology eliminates the need for secondary finishing processes and drastically reduces material wastage.

Efficiency is another key capability of SourcifyChina’s laser cutting systems. The high-speed operations enable quicker project turnover without sacrificing the quality of cuts. Automated loading and unloading systems further streamline production, minimizing downtime and increasing overall throughput.

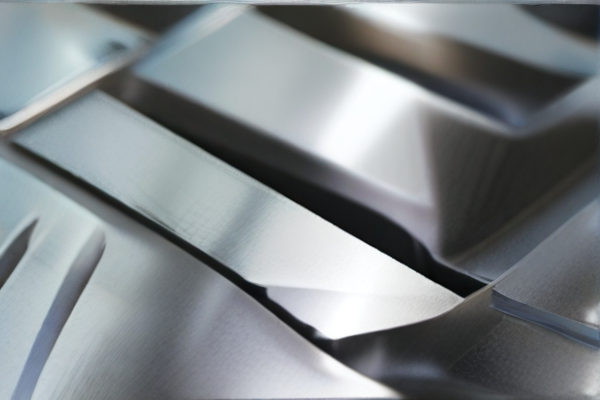

Versatility defines SourcifyChina’s machines. Capable of working with various metals, including stainless steel, aluminum, and brass, these lasers accommodate a wide range of industrial applications. The adaptive technology also allows for intricate designs, expanding creative possibilities for engineers and designers.

Advanced software integration ensures seamless operations. SourcifyChina’s laser systems can easily connect with CAD/CAM software for direct, real-time adjustments. This feature supports customized solutions and enhances communication between design and manufacturing departments, resulting in more efficient workflows.

Additionally, SourcifyChina prioritizes safety and user experience. Their laser cutting machines come equipped with robust safety features like automatic shutoff and protective barriers. User-friendly interfaces make the operation straightforward, reducing the learning curve for new operators, thereby improving productivity.

Lastly, SourcifyChina’s laser systems are energy-efficient and environmentally friendly. With minimal power consumption and reduced emissions, these machines align with sustainable manufacturing practices. This makes them an excellent investment for companies looking to reduce their carbon footprint while maintaining high performance.

In conclusion, SourcifyChina’s sheet metal cutting lasers are a blend of precision, efficiency, versatility, and advanced integration. They offer a complete solution for modern manufacturing needs, emphasizing safety and sustainability. These capabilities make SourcifyChina a top choice for businesses focused on quality and innovation in sheet metal processing.

Laser cutting of sheet metal offers precise, efficient, and versatile solutions for various industrial applications. It has revolutionized manufacturing processes with its numerous benefits.

– High Precision and Accuracy: Laser cutting delivers exceptionally precise cuts with minimal tolerances, ensuring high-quality outcomes.

– Speed and Efficiency: The process is faster than traditional cutting methods, increasing productivity and reducing lead times.

– Versatility: Capable of cutting complex shapes and various materials, including stainless steel, aluminum, and titanium.

– Reduced Waste: The precision of laser cutting minimizes material waste, leading to cost savings.

– Minimal Distortion: The heat-affected zone is small, resulting in less distortion and better structural integrity.

– Automation Capability: Laser cutting machines can be easily automated, allowing for continuous operation and integration into smart manufacturing systems.

– Clean Edges and Finishes: The cuts produced are clean and smooth, often eliminating the need for additional finishing processes.

– Reduced Tool Wear: Unlike mechanical cutting methods, laser cutting tools do not wear out, leading to lower maintenance costs.

– Safety: Laser cutting reduces the risk of accidents, as it is a non-contact process, ensuring a safer working environment.

Overall, laser cutting enhances the efficiency and quality of metal fabrication, making it a preferred choice in modern manufacturing.

Sheet metal cutting lasers are advanced tools that offer precision, speed, and efficiency in manufacturing processes. These lasers are essential for producing high-quality metal components with minimal waste and increased productivity.

– Precision and Accuracy: Laser cutting ensures high precision and accuracy, enabling intricate designs and detailed cuts.

– Speed: Modern lasers can cut through sheet metal rapidly, improving production times.

– Versatility: They are capable of cutting various metals, including steel, aluminum, and brass.

– Automation: Integration with CNC systems allows for automated operations and reduces human error.

– Quality: Laser cutting provides clean edges and smooth finishes, minimizing the need for additional processing.

– Complex shapes: Capable of cutting complex and intricate shapes with ease.

– Energy Efficiency: Many lasers are designed to be energy-efficient, lowering operation costs.

– Minimal Waste: Precision cutting minimizes material wastage, leading to cost savings.

– Thickness Range: Suitable for cutting both thin and thick sheet metals.

– Non-contact Process: As it doesn’t touch the material, there’s less mechanical deformation.

– Reduce Tool Wear: As no physical tool contacts the material, there is no tool wear.

– Safety: Modern laser cutting machines come with advanced safety features to protect workers.

These features make sheet metal cutting lasers a preferred choice in various industries, including automotive, aerospace, and fabrication, enhancing both quality and productivity.

SourcifyChina specializes in custom sheet metal cutting laser solutions, offering precision and efficiency in creating high-quality metal components. Utilizing advanced laser technology, they cater to diverse industries, ensuring each piece meets rigorous standards.

Their laser cutting services are ideal for intricate designs and complex shapes, enabling customers to realize ambitious projects. From automotive to aerospace, SourcifyChina adapts to specific sector needs, delivering bespoke products that enhance performance and functionality.

In addition to cutting, they provide value-added services such as bending, welding, and finishing. This comprehensive approach ensures that each project is not only accurate but also ready for immediate integration into larger assemblies.

SourcifyChina emphasizes customer satisfaction through clear communication and timely delivery. Their experienced team collaborates with clients from concept to completion, guaranteeing that the final products align perfectly with initial specifications and project goals.

Environmental sustainability is a priority, with SourcifyChina utilizing eco-friendly processes and materials. This commitment not only supports the planet but also aligns with the growing demand for green manufacturing solutions.

Their state-of-the-art facilities are equipped with the latest laser cutting technology, ensuring high precision and consistency. By continually investing in technological advancements, SourcifyChina stays at the forefront of the industry, offering innovative solutions to complex challenges.

With a focus on innovation, quality, and customer-oriented service, SourcifyChina is a trusted partner for projects requiring custom sheet metal cutting. Their expertise and dedication make them a go-to choice for clients seeking reliable, high-quality manufacturing solutions.

SourcifyChina is an industry leader in precision sheet metal cutting and laser cutting services, renowned for its cutting-edge technology and unparalleled craftsmanship. Specializing in advanced laser cutting techniques, the company offers a comprehensive range of services catering to various industries, from automotive to aerospace and consumer electronics to medical devices. Leveraging state-of-the-art machinery and a team of experienced professionals, SourcifyChina ensures high precision, excellent efficiency, and minimal material wastage in its operations. The company stands out for its commitment to quality and customer satisfaction, constantly investing in the latest technologies and adhering to stringent quality control measures. By providing customized solutions and quick turnaround times, SourcifyChina has carved a niche for itself in the highly competitive metal fabrication market, earning the trust and loyalty of clients both locally and internationally. Through its dedication to innovation and excellence, SourcifyChina continues to set new benchmarks in the realm of sheet metal cutting and laser cutting services.

The application of sheet metal cutting lasers in the aerospace, defense, and marine industries is a game-changer, offering unprecedented levels of precision and efficiency. In aerospace, where the need for lightweight yet strong components is paramount, laser cutting allows manufacturers to produce complex geometries and intricate designs with a high degree of accuracy. This precision reduces material wastage and ensures that parts fit perfectly within the tight tolerances required for modern aircraft. Additionally, the speed of laser cutting improves production timelines, which is critical for meeting stringent delivery schedules. Components such as brackets, panels, and intricate body parts for both commercial and military aircraft are now more reliably produced thanks to advancements in laser technology.

In the defense and marine sectors, the benefits of laser cutting extend to the creation of specialized parts and equipment that demand durability and exacting standards. For defense applications, laser-cut metals are used in the manufacture of armored vehicles, weaponry, and even land and sea-based defense systems. These applications benefit from the ability of laser cutting to work with a variety of metals, including those that are incredibly strong and resistant to harsh conditions. In marine applications, the laser’s precision is vital for creating components that withstand corrosive sea environments while fitting seamlessly into ship structures. This includes everything from hull reinforcements to specialized tubing systems. Overall, laser cutting technology fosters innovation and enhances the reliability of components critical to these high-stakes industries.

In the automotive industry, sheet metal cutting lasers play a crucial role in manufacturing and assembly processes. These high-precision tools are employed to cut complex shapes and designs in car bodies, chassis, and other components with remarkable accuracy and speed. The use of laser cutting reduces material wastage and allows for greater flexibility in design changes, which is essential in an industry driven by rapid innovation and customization. Additionally, laser cutting enhances the strength and performance of automotive parts by ensuring clean edges and precise cuts, which contribute to better fitting and welding of components. This precision also aids in reducing the overall weight of vehicles, leading to improved fuel efficiency and lower emissions.

In the electronics industry, sheet metal cutting lasers are indispensable for producing enclosures, chassis, and intricate components for various devices. The ability to achieve fine, precise cuts makes laser cutting ideal for creating the small, detailed parts required in electronics manufacturing. This is particularly important for producing heat sinks, housings, and brackets used in devices like smartphones, laptops, and servers. Laser cutting ensures that these components meet tight tolerances and high-quality standards necessary for the reliable performance of electronic products. Furthermore, the non-contact nature of laser cutting minimizes the risk of damage to delicate electronic parts, maintaining the integrity of the components throughout the manufacturing process. This technology supports the industry’s drive towards miniaturization and higher performance in electronic devices.

Sheet metal cutting lasers have revolutionized the construction industry by significantly enhancing precision and efficiency. In large-scale construction projects, these high-powered lasers are utilized for cutting and shaping metal sheets into specific components essential for building structures. The ability of laser cutters to produce intricate designs and achieve high levels of accuracy can save considerable time and reduce the need for extensive manual labor. This precision also minimizes material waste, thus lowering costs and conserving resources. Additionally, laser cutting can handle various types of metals such as steel, aluminum, and copper, making it versatile for diverse construction applications including frameworks, roofing, and decorative architectural elements.

In the energy sector, sheet metal cutting lasers are equally transformative, especially in the manufacturing of renewable energy technologies. For instance, solar panels and wind turbines require finely cut metal parts for their structure and functioning. Laser cutting meets these demands by providing clean, precise cuts that ensure optimal performance and durability of energy equipment. Furthermore, the precision of laser cutting enhances the development of advanced energy storage systems like batteries and fuel cells, which often require intricate and compact metal components. The high adaptability and efficiency of laser cutting make it integral not only in the production of energy systems but also in the maintenance and upgrading of existing infrastructure, contributing significantly to the advancement of sustainable energy solutions.

The industrial equipment industry has increasingly adopted sheet metal cutting lasers due to their precision, speed, and versatility. Laser cutting technology uses a concentrated beam of light to cut through various types of metals such as steel, aluminum, and titanium with unparalleled accuracy. This technology allows manufacturing processes to achieve intricate designs and complex geometries that were previously difficult or impossible to achieve with traditional cutting methods. The high precision of laser cutting minimizes material wastage and reduces the need for secondary finishing processes, thereby enhancing overall productivity. In industries like automotive, aerospace, and construction, where high precision and quality are paramount, laser cutting has become an indispensable tool for producing lightweight and durable components.

Moreover, sheet metal cutting lasers offer significant operational efficiencies. Automated laser cutting systems can run continuously with minimal human intervention, significantly boosting throughput and reliability while reducing labor costs. These systems are often integrated into computer numerical control (CNC) machines, allowing for rapid prototyping and mass production of customized parts with consistent quality. The technology’s non-contact nature ensures that there is minimal wear and tear on the equipment, leading to lower maintenance costs and longer machine lifespan. Additionally, laser cutting is environmentally friendly; it produces fewer pollutants compared to mechanical cutting methods and can cut metals without the need for harmful cutting fluids. Given these advantages, the adoption of sheet metal cutting lasers in the industrial equipment sector continues to grow, driving innovation and efficiency across multiple industries.

The application of sheet metal cutting lasers in the field of medical devices has revolutionized the production of various intricate and precision-engineered components. This technology enables the creation of complex geometries and micrometer-level precision, essential for medical devices such as surgical instruments, stents, and implantable devices. The precise nature of laser cutting ensures minimal thermal distortion, reduced material waste, and seamless edges, which are critical for the production of components that need to meet stringent medical standards. Such precision also facilitates rapid prototyping and customizations, allowing manufacturers to adapt swiftly to changing design requirements and reducing the time-to-market for innovative medical solutions.

Furthermore, laser cutting of sheet metal is highly beneficial for maintaining biocompatibility and hygiene standards essential for medical applications. By using specific laser parameters, manufacturers can ensure that the materials retain their inherent properties, such as corrosion resistance and structural integrity, which are vital for medical devices exposed to bodily fluids and sterilization processes. The ability to cut a variety of metals, including stainless steel, titanium, and specialized alloys, further expands the range of applications. Laser cutting systems operate with high efficiency and repeatability, which is crucial for producing large volumes of consistent, high-quality medical components. Overall, the integration of sheet metal cutting lasers into the manufacturing of medical devices not only enhances the quality and reliability of the end products but also contributes to the advancement of medical technology and patient care.

Sheet metal cutting lasers are pivotal in machining and manufacturing due to their precision and versatility. These lasers employ focused beams of light to slice through metal sheets with high accuracy, enabling intricate designs and complex geometries that traditional methods struggle to achieve. The technology ensures minimal material waste and reduces the need for secondary finishing processes, as laser cuts are typically clean and precise. This efficiency not only enhances production speed but also lowers operational costs, making it an attractive option for industries such as automotive, aerospace, and electronics where exacting standards are essential.

In manufacturing applications, sheet metal cutting lasers facilitate rapid prototyping and mass production. Their programmable nature allows for easy adjustments and adaptations to design changes, fostering innovation and flexibility in product development. The ability to cut various metals, including stainless steel, aluminum, and titanium, broadens their applicability across different sectors. Moreover, the integration of computer numerical control (CNC) systems with laser cutters further automates the process, ensuring consistent quality and reducing manual labor. This technological synergy enhances overall productivity, making sheet metal cutting lasers indispensable in modern manufacturing environments.

Sure! Here is a list of frequently asked questions (FAQ) with answers regarding manufacturing “sheet metal cutting laser quality work” from SourcifyChina factory, all within 300 words:

Q1: What materials can the laser cutting process at SourcifyChina handle?

A1: SourcifyChina can process a variety of materials including stainless steel, carbon steel, aluminum alloys, and galvanized sheet metals, ensuring precision and high-quality cuts.

Q2: What is the maximum thickness SourcifyChina’s laser cutting equipment can handle?

A2: SourcifyChina’s laser cutting equipment can handle sheet metals with a maximum thickness of 25mm for carbon steel, 20mm for stainless steel, and 15mm for aluminum.

Q3: What are the tolerances for the laser cutting process at SourcifyChina?

A3: Our laser cutting services typically achieve tolerances of ±0.1mm, ensuring premium quality and precision for intricate designs and industrial applications.

Q4: What industries does SourcifyChina typically serve with its laser cutting services?

A4: SourcifyChina serves various industries such as automotive, aerospace, construction, electronics, and custom metal fabrication, providing tailored solutions to meet specific project requirements.

Q5: What is the lead time for laser cutting orders at SourcifyChina?

A5: The lead time for laser cutting orders usually ranges from 3 to 10 business days, depending on the complexity and quantity of the order. We prioritize efficiency without compromising on quality.

Q6: Can SourcifyChina provide design assistance or customized solutions?

A6: Yes, SourcifyChina offers design consultation and customized solutions. We work closely with clients to meet their specifications, whether it’s for prototyping or mass production.

Q7: How does SourcifyChina ensure the quality of their laser cutting work?

A7: SourcifyChina ensures quality through rigorous inspection processes, state-of-the-art equipment, and skilled technicians. We are committed to delivering superior precision and consistency in every project.

Q8: Are there options for secondary processes like bending or welding after laser cutting?

A8: Yes, SourcifyChina provides additional services including bending, welding, and surface treatment to meet comprehensive fabrication needs.

Q9: How can I get a quote for a laser cutting project from SourcifyChina?

When considering sheet metal cutting via laser manufacturing from SourcifyChina factory, it’s essential to optimize your processes and product quality. Here are some tips:

1. Material Selection: Choose high-quality metals compatible with laser cutting, such as stainless steel, aluminum, and carbon steel. SourcifyChina can provide material specs to match your needs.

2. Precision: Leverage SourcifyChina’s advanced laser cutting technology for high precision and minimal tolerances. This ensures intricate designs and tight-fitting components.

3. Design for Manufacturing (DFM): Engage with SourcifyChina’s engineering team early in the design process. They can offer valuable insights to enhance manufacturability, reduce waste, and minimize costs.

4. Laser Power and Speed: Align your requirements with the appropriate laser power and cutting speed. SourcifyChina’s experts can recommend settings that balance cutting efficiency with edge quality.

5. Batch Production: For large orders, SourcifyChina offers batch production capabilities, maintaining consistency and optimizing costs. Discuss scalability needs upfront to streamline production.

6. Tolerance Accuracy: Confirm achievable tolerances with SourcifyChina to ensure your components meet necessary specifications without requiring additional post-processing.

7. Cost Optimization: SourcifyChina can assist in optimizing costs through material utilization and reducing cutting time. Consider bulk ordering to take advantage of economies of scale.

8. Quality Control: Ensure rigorous quality checks are in place. SourcifyChina employs advanced QC procedures, including dimensional inspection and surface finish checking.

9. Communication Channels: Establish clear communication channels. Prompt and clear communication helps address any concerns quickly and ensures alignment throughout the project.

10. Lead Times: Understand their lead times and factor this into your production schedule. Early planning helps avoid potential delays.

By following these tips, you can effectively utilize SourcifyChina’s laser cutting services for sheet metal, ensuring high-quality outputs and efficient manufacturing processes.

1. What types of sheet metal can the cutting laser handle?

The laser cutting machines at SourcifyChina factory can handle a variety of sheet metals, including stainless steel, carbon steel, aluminum, brass, and copper. The factory provides precise cuts for different material thicknesses to suit your project needs.

2. What thicknesses of sheet metal can be cut?

SourcifyChina’s laser cutting equipment can cut sheet metals ranging from 0.5 mm to 25 mm in thickness. The exact thickness limit depends on the type of metal and the laser technology used.

3. What is the maximum sheet size that can be processed?

The maximum sheet size that the factory can accommodate is typically 3000 mm x 1500 mm. For specific dimensions and custom sizes, it’s best to consult with their technical team for detailed capabilities.

4. How precise are the laser cuts?

The laser cutting machines at SourcifyChina factory offer high precision with tolerances typically within ±0.1 mm. This ensures that parts meet stringent quality and specification standards.

5. Can SourcifyChina handle custom designs and bulk orders?

Yes, SourcifyChina specializes in both custom designs and bulk orders. They offer CAD/CAM support and can handle high volume production runs to meet your specific project requirements.

6. What is the typical lead time for an order?

The lead time can vary based on order size and complexity, but generally, it’s between 7 to 15 working days. For urgent projects, you may request expedited processing depending on current production loads.

7. How do I get a quote for my project?

To get a quote, you can provide your design files, material specifications, and quantity requirements directly to SourcifyChina. They will review your details and provide a competitive quote typically within 24 to 48 hours.

8. Are there quality control measures in place?

Yes, SourcifyChina has stringent quality control measures including material inspection, laser calibration, and post-cutting checks to ensure each product meets your requirements.

9. What payment methods are accepted?

SourcifyChina accepts various payment methods, including bank transfers (T/T), PayPal, and letters of credit (L/C). It’s best to confirm with their sales team for the most convenient options.

10. Do they provide after-sales service and support?

Sourcing sheet metal cutting lasers from SourcifyChina factory involves several key steps to ensure you get a reliable and high-quality product. Here are some tips to guide you through the process:

1. Research the Supplier: Start by researching SourcifyChina factory’s reputation. Look for reviews, ratings, and any feedback from previous customers. Websites like Alibaba, Global Sources, and Made-in-China can provide valuable insights.

2. Verify Certifications: Ensure that the factory has the necessary certifications for manufacturing and exporting laser cutting machines. This includes ISO certification and any relevant industry-specific certifications.

3. Product Specifications: Clearly define the specifications you need for the sheet metal cutting lasers. This includes power, cutting thickness, accuracy, and any additional features. Communicate these requirements to the factory.

4. Request Samples: Before placing a large order, request a sample unit. This allows you to evaluate the quality, performance, and adherence to specifications.

5. Factory Visit: If possible, visit the factory in person. This gives you a firsthand look at their production capabilities, quality control processes, and working conditions.

6. Quality Assurance: Discuss the factory’s quality assurance procedures. Ensure they have robust testing and inspection processes in place for their products.

7. Negotiation: Negotiate terms such as pricing, payment conditions, and delivery schedules. Make sure all agreements are documented in a contract.

8. Logistics and Shipping: Clarify the logistics and shipping arrangements. Confirm the Incoterms (e.g., FOB, CIF) and ensure the factory can handle the shipping requirements to your location.

9. After-Sales Support: Ensure the factory offers reliable after-sales support, including warranty, maintenance, and repair services.

10. Communication: Maintain clear and consistent communication with the factory. Use video calls, emails, and instant messaging apps to stay in touch and address any concerns promptly.

By following these tips, you can effectively source high-quality sheet metal cutting lasers from SourcifyChina factory, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.