Choosing SourcifyChina Factory for purchasing sheet metal duct fabrication offers unparalleled quality and competitive pricing. Their state-of-the-art manufacturing facilities ensure precision and durability, making them a reliable partner for global buyers.

SourcifyChina Factory specializes in custom sheet metal fabrication, tailored to meet specific project requirements. Their experienced engineering team works closely with clients to deliver solutions that perfectly match their needs.

Moreover, SourcifyChina Factory maintains rigorous quality control standards, ensuring each product adheres to international specifications. Their commitment to excellence minimizes the risk of defects and rework, saving time and costs for buyers.

With extensive experience in exporting to various markets, SourcifyChina Factory understands the logistics and regulatory nuances of international trade. They provide comprehensive shipping and documentation services, facilitating smooth and timely deliveries.

Customer service at SourcifyChina Factory is top-notch, offering responsive and efficient communication throughout the purchasing process. Buyers receive regular updates and support, ensuring transparency and satisfaction from order placement to delivery.

In conclusion, SourcifyChina Factory stands out as a premier choice for sheet metal duct fabrication due to their quality, customization capabilities, stringent quality control, international trade expertise, and exceptional customer service. Partnering with them ensures a seamless and cost-effective procurement process, tailored to meet high industry standards.

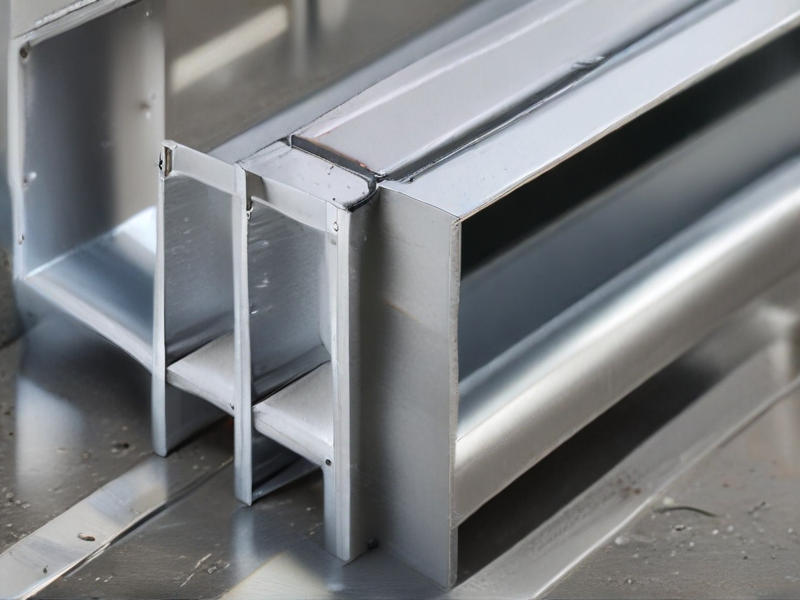

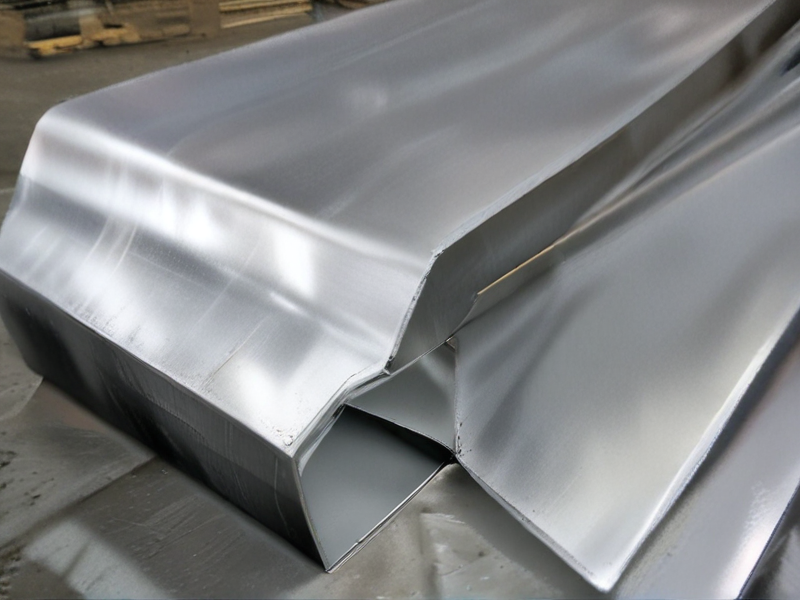

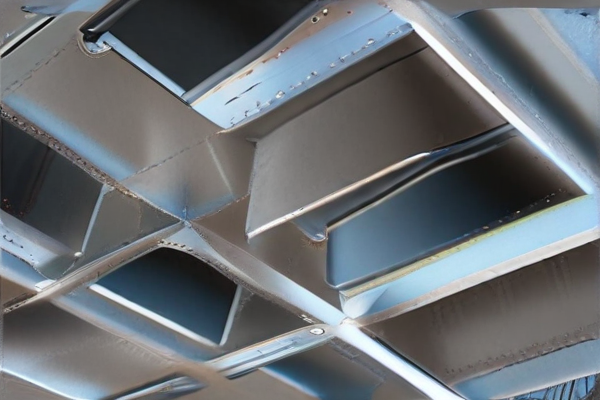

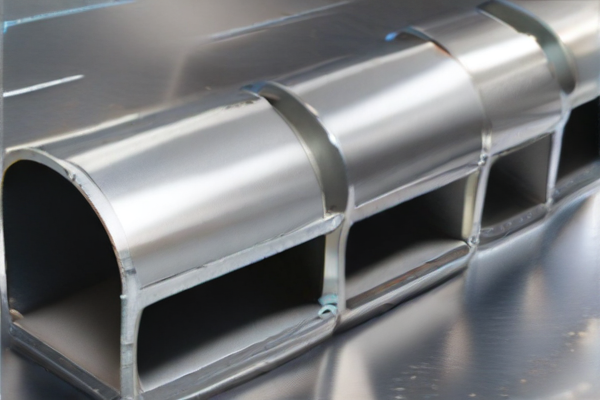

Sheet metal duct fabrication involves creating ducts for HVAC systems, ensuring efficient airflow. Various materials and methods cater to different needs, enhancing durability, insulation, and installation efficiency.

– Galvanized Steel: Common, corrosion-resistant, durable.

– Aluminum: Lightweight, rust-resistant, easy to handle.

– Stainless Steel: High strength, corrosion-resistant, used in high-demand environments.

– Copper: Antimicrobial, high durability, often used in specialized applications.

– Fabric Ducts: Flexible, easy to install, suitable for large spaces.

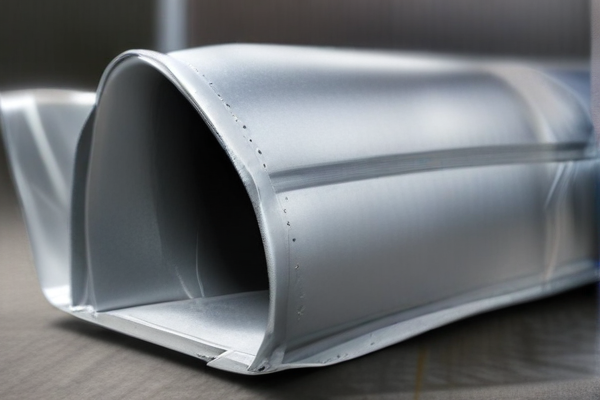

– Spiral Ducts: Aesthetic appeal, efficient airflow, often used in exposed installations.

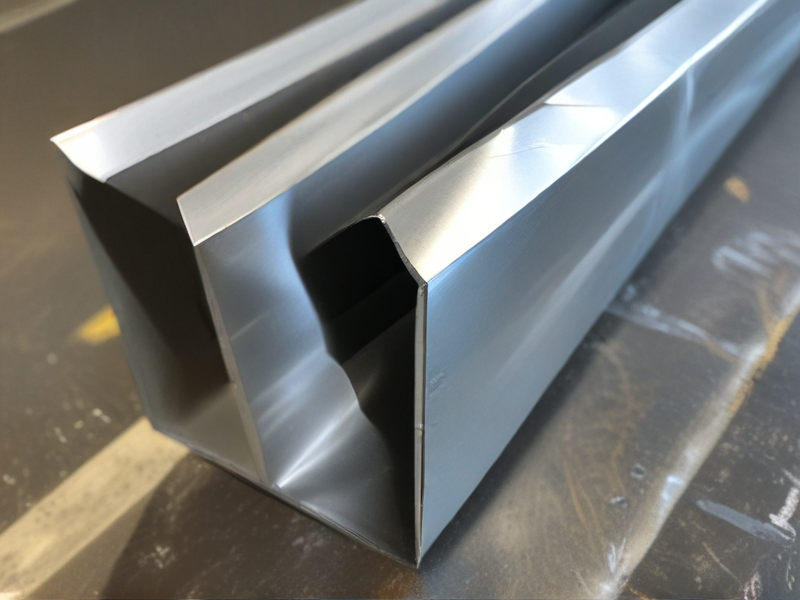

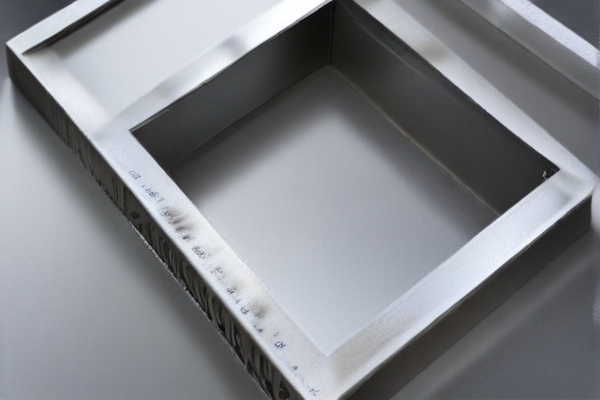

– Rectangular Ducts: Space-efficient, customizable, commonly used in commercial buildings.

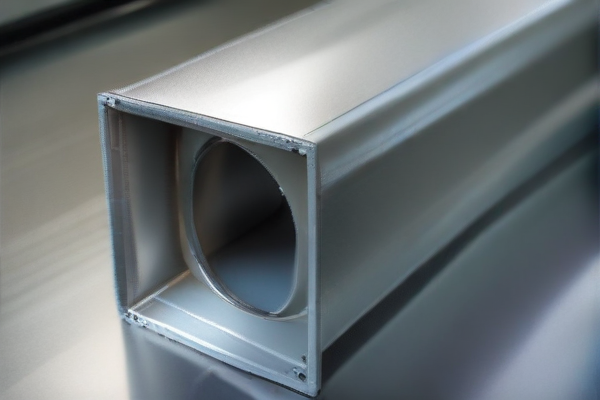

– Round Ducts: Optimal airflow, reduced leakage, easy to clean.

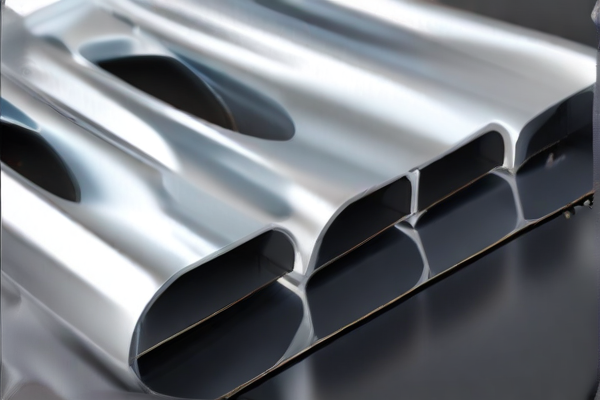

– Double-Wall Ducts: Improved insulation, reduced noise, used in temperature-sensitive environments.

– Flexible Ducts: Easy to install in tight spaces, cost-effective, ideal for residential use.

– Custom Fabrication: Tailored solutions for unique architectural or functional requirements.

– Automated Fabrication: Precision and speed, reduced labor costs, consistent quality.

– Hand Fabrication: Skilled craftsmanship, custom modifications, detailed work.

– Plasma Cutting: Precision cuts, efficient, used for intricate designs.

– Laser Cutting: High precision, minimal material waste, suitable for detailed patterns.

– Water Jet Cutting: Versatile, no heat distortion, suitable for various materials.

– Welding: Strong joints, durability, used in high-strength applications.

– Seamless Welding: Aesthetic finish, no leaks, used in visible ductwork.

– Flanging: Strong connections, ease of assembly, used in modular systems.

– Lockforming: Secure, efficient jointing method, used for long duct runs.

These options and methods in sheet metal duct fabrication address various HVAC requirements, ensuring functionality and efficiency in different settings.

Sheet metal duct fabrication is essential in HVAC systems, providing efficient air distribution in residential, commercial, and industrial buildings. Custom-fabricated ducts ensure optimal airflow and energy efficiency.

Applications:

– Residential HVAC systems

– Commercial HVAC systems

– Industrial ventilation

– Air filtration systems

– Exhaust systems

– Custom ductwork for unique architectural designs

– Dust and fume extraction systems

– Kitchen ventilation

– Laboratory ventilation systems

– Data center cooling

– Cleanroom environments

– Marine ventilation systems

– Hospital air systems

– Underground parking ventilation

– Green building projects

Sheet metal duct fabrication is a versatile and vital aspect of modern construction, catering to diverse ventilation needs across various sectors.

SourcifyChina sheet metal duct fabrication uses high-quality materials to ensure durability and efficiency in HVAC systems. The materials include galvanized steel, stainless steel, and aluminum, chosen for their resistance to corrosion and ability to withstand various environmental conditions.

Galvanized steel is popular for its protective zinc coating, which prevents rust and extends the ductwork’s lifespan. It’s an economical choice for many industrial and commercial applications, ensuring long-term reliability.

Stainless steel is known for its exceptional strength and resistance to both heat and corrosion. This makes it ideal for demanding environments where hygiene and durability are paramount, such as in hospitals and laboratories.

Aluminum is lightweight yet strong, offering excellent corrosion resistance and thermal conductivity. It’s often used in areas where weight is a critical factor, such as in aerospace and marine applications.

Overall, SourcifyChina’s selection of materials for sheet metal duct fabrication guarantees high performance, longevity, and compliance with industry standards. This commitment to quality ensures that their duct systems meet the specific needs of various sectors, providing robust and efficient air distribution solutions.

SourcifyChina’s sheet metal duct fabrication quality control process ensures top-notch product standards. It starts with meticulous selection of raw materials, emphasizing durability and compliance with industry specifications.

The manufacturing phase incorporates precision engineering and advanced machinery to maintain exact dimensions and consistency. Each piece undergoes rigorous inspections at various stages to detect defects early.

Advanced software tools are used for design verification, ensuring all specifications are met before production begins. This reduces errors and enhances overall efficiency.

Finally, finished products are subjected to comprehensive testing, including stress tests and performance evaluations, to ensure they meet all required safety and functionality standards.

SourcifyChina excels in sheet metal duct fabrication, offering precision-engineered solutions for various industrial and commercial applications. Their capabilities include cutting-edge CNC machinery, ensuring high-quality and accurate ductwork production.

The company specializes in custom duct fabrication, providing tailored designs to meet specific project requirements. This flexibility allows them to cater to diverse needs, from HVAC systems to complex ventilation setups.

Advanced materials and state-of-the-art technology enable SourcifyChina to produce durable and efficient duct systems. Their expertise in handling different metals, including stainless steel and aluminum, ensures optimal performance and longevity.

SourcifyChina’s skilled workforce is adept at delivering intricate ductwork with minimal tolerances. Their commitment to quality control guarantees products that meet stringent industry standards and client specifications.

In addition to manufacturing, SourcifyChina offers comprehensive services including design consultation, prototyping, and installation support. This end-to-end approach ensures seamless project execution and customer satisfaction.

Their efficient production processes and robust supply chain management enable quick turnaround times and competitive pricing. SourcifyChina’s focus on innovation and continuous improvement keeps them at the forefront of the sheet metal duct fabrication industry.

By leveraging advanced software for design and simulation, SourcifyChina enhances the precision and efficiency of their fabrication processes. This integration of technology ensures optimal airflow performance and energy efficiency in the final products.

SourcifyChina’s dedication to sustainability is evident in their use of eco-friendly materials and processes. They aim to reduce environmental impact while maintaining high standards of quality and performance.

With a strong reputation for reliability and excellence, SourcifyChina is a trusted partner for businesses seeking top-tier sheet metal duct fabrication solutions. Their comprehensive capabilities and customer-centric approach make them a leader in the industry.

Sheet metal duct fabrication offers numerous advantages for HVAC systems, ensuring efficiency and longevity in both residential and commercial buildings. Here are some key benefits:

– Customization: Fabricated ducts can be tailored to fit any specific design requirements, ensuring a perfect fit for unique building layouts.

– Durability: Sheet metal is known for its long-lasting nature, resistant to corrosion and physical damage, leading to fewer replacements and repairs.

– Energy Efficiency: Properly fabricated sheet metal ducts minimize air leakage, enhancing the overall efficiency of HVAC systems and reducing energy costs.

– Enhanced Air Quality: Metal ducts are less likely to harbor mold and bacteria compared to other materials, promoting better indoor air quality.

– Fire Resistance: Sheet metal ducts offer superior fire resistance, contributing to safer building environments.

– Cost-Effectiveness: Despite the initial higher cost, the long-term savings in maintenance and energy efficiency make sheet metal ducts a cost-effective choice.

– Ease of Maintenance: The smooth surfaces of sheet metal ducts make them easier to clean and maintain, further contributing to their longevity and performance.

– Versatility: Suitable for both new installations and retrofits, sheet metal duct fabrication can adapt to various HVAC system requirements.

Sheet metal duct fabrication involves the creation of ductwork systems essential for HVAC (heating, ventilation, and air conditioning). These ducts are designed to channel air efficiently within buildings.

– Material: Utilizes galvanized steel, stainless steel, or aluminum for longevity and resistance to corrosion.

– Customization: Can be tailored to meet specific project requirements, including size, shape, and design.

– Efficiency: Engineered for optimal airflow, reducing energy consumption and operational costs.

– Durability: Built for long-term use, capable of withstanding varied environmental conditions.

– Seamless Integration: Designed for easy integration with existing HVAC systems, ensuring minimal disruption.

– Precision: Fabrication often employs advanced machinery for precise cutting, bending, and forming.

– Insulation: Options for internal or external insulation to enhance thermal performance and noise reduction.

– Standards Compliance: Manufactured to meet industry standards and codes, ensuring safety and reliability.

– Ease of Installation: Lightweight and modular components simplify installation and maintenance.

– Adaptability: Suitable for residential, commercial, and industrial applications, offering flexibility in use.

– Aesthetic Options: Can be painted or coated to fit the visual and functional demands of the space.

SourcifyChina specializes in custom sheet metal duct fabrication, offering precision and high-quality products tailored to specific requirements. Their expertise ensures each duct system meets exact specifications, providing optimal performance and efficiency in various applications.

Using advanced technology and skilled craftsmanship, SourcifyChina manufactures ductwork that fits seamlessly into complex HVAC systems. Their custom solutions cater to diverse industries, including residential, commercial, and industrial sectors, ensuring durability and reliability.

SourcifyChina’s project management team works closely with clients from design to installation, ensuring timely delivery and adherence to project timelines. Their comprehensive approach guarantees satisfaction and successful implementation of all projects.

By prioritizing quality and customer service, SourcifyChina has established itself as a trusted partner in sheet metal duct fabrication. Their commitment to excellence drives continuous innovation and improvement in their product offerings.

SourcifyChina is a premier company specializing in sheet metal duct fabrication, renowned for its precision engineering and high-quality products. Based in China, the company leverages advanced manufacturing techniques and state-of-the-art technology to produce custom ductwork solutions tailored to a diverse range of industrial and commercial applications. SourcifyChina’s expertise encompasses the entire fabrication process, from initial design and prototyping to final production and quality assurance. The company’s commitment to excellence is reflected in its stringent adherence to industry standards and its ability to deliver reliable, durable, and efficient duct systems. With a strong focus on customer satisfaction, SourcifyChina offers competitive pricing and timely delivery, ensuring that clients receive the best value for their investment. Whether for HVAC systems, industrial ventilation, or specialized projects, SourcifyChina stands out as a trusted partner in the sheet metal duct fabrication industry.

Sheet metal duct fabrication plays a crucial role in the aerospace, defense, and marine industries, providing essential solutions for ventilation, air conditioning, and exhaust systems. In aerospace, the precise fabrication of sheet metal ducts ensures optimal airflow management within aircraft, contributing to efficient engine performance and cabin comfort. These ducts must withstand high temperatures and pressures, necessitating advanced materials and fabrication techniques to ensure durability and reliability. Similarly, in the defense sector, sheet metal ducts are integral to the functionality of military vehicles and installations, where they facilitate effective cooling and heating systems. The ability to customize ductwork to fit complex geometries and stringent specifications is critical, ensuring that defense equipment operates under extreme conditions without compromising performance or safety.

In marine applications, sheet metal duct fabrication is essential for maintaining the environmental control systems aboard ships and submarines. These ducts are designed to handle corrosive sea environments and the dynamic conditions encountered at sea. Efficient ventilation systems are vital for controlling humidity, removing contaminants, and ensuring air quality in confined marine spaces. The robust construction of these ducts supports the longevity and reliability of marine vessels, contributing to the safety and comfort of crew members. Across these industries, advancements in fabrication technology, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enhance the precision and efficiency of sheet metal duct production, meeting the high standards required for aerospace, defense, and marine applications.

Sheet metal duct fabrication plays a vital role in the automotive industry, particularly in the design and manufacturing of vehicle components. Sheet metal ducts are used to create various parts, such as exhaust systems, air intake systems, and heat shields, all of which are crucial for the vehicle’s performance and safety. The precision and durability of fabricated sheet metal ducts ensure that they can withstand the high temperatures and pressures experienced during vehicle operation. Additionally, advancements in fabrication techniques, such as laser cutting and CNC machining, have enhanced the ability to produce complex shapes and designs with high accuracy, contributing to improved aerodynamics and overall efficiency of modern vehicles.

In the electronics industry, sheet metal duct fabrication is essential for creating enclosures and casings that protect sensitive electronic components from environmental factors and electromagnetic interference. These ducts are commonly used in the production of server racks, computer chassis, and other electronic housing applications. The fabrication process allows for the customization of designs to meet specific requirements, such as ventilation and cooling, which are critical for maintaining the optimal performance of electronic devices. Moreover, the use of high-quality materials and precise fabrication techniques ensures that the enclosures provide robust protection and longevity, helping to extend the lifespan of the electronic equipment housed within.

In the construction industry, sheet metal duct fabrication is crucial for creating efficient HVAC systems, ensuring proper ventilation, heating, and cooling within buildings. This process involves cutting, bending, and assembling sheet metal to form ducts that distribute air throughout residential, commercial, and industrial structures. The precision in fabricating these ducts is vital, as it affects the overall air flow efficiency and energy consumption of HVAC systems. Advanced techniques, including computer-aided design (CAD) and automated machinery, enhance the accuracy and speed of production, leading to better quality control and reduced labor costs. Properly fabricated sheet metal ducts help maintain indoor air quality and contribute to the building’s structural integrity by supporting optimal environmental conditions.

In the energy sector, sheet metal duct fabrication plays a significant role in ensuring energy efficiency and sustainability. High-quality ductwork minimizes air leakage, which directly impacts the energy performance of heating and cooling systems. Well-sealed and insulated ducts prevent energy loss, thereby reducing the operational costs and environmental footprint of buildings. Additionally, custom-fabricated ducts can be designed to accommodate renewable energy systems, such as solar-powered HVAC units, further promoting green energy solutions. By integrating advanced materials and fabrication methods, the industry can produce ducts that support the efficient use of energy resources, ultimately contributing to the broader goals of energy conservation and environmental protection.

Sheet metal duct fabrication plays a pivotal role in the industrial equipment sector, particularly in HVAC (Heating, Ventilation, and Air Conditioning) systems. This process involves the precise cutting, shaping, and assembling of sheet metal to create ducts that transport air throughout industrial facilities. The fabrication of these ducts is crucial for maintaining optimal air quality, temperature control, and efficient ventilation in large manufacturing plants, warehouses, and other industrial environments. Advanced fabrication techniques, including computer-aided design (CAD) and automated cutting technologies, ensure high accuracy and consistency, which are essential for the complex layouts and stringent performance requirements of industrial HVAC systems. The durability and adaptability of sheet metal make it an ideal material for withstanding the demanding conditions typically found in industrial settings.

Moreover, the customization capabilities of sheet metal duct fabrication support the unique and varied needs of different industries. For instance, in sectors such as pharmaceuticals, food processing, and electronics manufacturing, where specific environmental conditions are critical, custom-fabricated ducts can be designed to meet precise specifications, ensuring compliance with industry standards and regulations. The use of galvanized or stainless steel in these applications enhances corrosion resistance and longevity, reducing maintenance costs and downtime. Furthermore, innovations in fabrication, such as laser cutting and robotic welding, have significantly improved the efficiency and speed of production, allowing for quicker turnaround times and greater flexibility in responding to changes in industrial demands. Overall, sheet metal duct fabrication is an indispensable aspect of the industrial equipment industry, providing essential infrastructure for effective climate control and operational efficiency.

Sheet metal duct fabrication, traditionally known for its applications in HVAC systems, has found its niche in the medical device industry due to its versatility, durability, and precision. In medical settings, maintaining sterile, controlled environments is crucial, and sheet metal ducts play a pivotal role in ensuring efficient air filtration and ventilation within critical spaces like operating rooms and laboratories. The superior strength and malleability of sheet metal allow for the creation of custom ductwork that fits the unique spatial requirements of medical facilities, providing a seamless and hygienic solution. With advanced fabrication techniques, manufacturers can produce ducts with precise tolerances and complex geometries, contributing to improved air quality and infection control.

Beyond air management, sheet metal fabrication extends to the creation of enclosures and protective casings for a myriad of medical devices and machinery. These enclosures are critical in protecting sensitive medical equipment from contaminants and mechanical damage, ensuring their functionality and longevity. The ability to fabricate sheet metal with exact specifications allows for the integration of essential features like access panels, mounting brackets, and cable management systems, tailored to the needs of specific medical devices. Additionally, the material’s resistance to corrosion and ease of sterilization make it an ideal choice for environments that demand high standards of cleanliness and reliability. Collectively, the application of sheet metal duct fabrication in the medical device industry not only enhances the performance of critical systems but also elevates the overall safety and efficiency of healthcare delivery.

Sheet metal duct fabrication plays a crucial role in modern machining and manufacturing, especially within the HVAC (Heating, Ventilation, and Air Conditioning) industry. This process involves the cutting, forming, and assembly of metal sheets into ducts that facilitate the efficient flow of air in residential, commercial, and industrial settings. Precision is key in sheet metal duct fabrication; advanced techniques like CNC (Computer Numerical Control) machining and laser cutting are employed to ensure accuracy and uniformity. These methods enable the creation of ducts with complex shapes and tight tolerances, meeting specific design requirements and standards. Additionally, innovations in material handling and automation enhance the production speed and reduce labor costs, making the process more efficient and cost-effective.

Manufacturing applications of sheet metal duct fabrication extend beyond HVAC systems. The automotive, aerospace, and construction industries also utilize these processes to create components that require robust yet lightweight metal structures. In automotive manufacturing, for example, custom-fabricated ducts are used for air intake systems and exhausts, while in aerospace, precision-formed ducts contribute to the intricate air and fluid management systems of aircraft. The versatility of sheet metal duct fabrication allows for the production of both standard and bespoke components, catering to a wide range of specifications and functional needs. As technology advances, the integration of digital design tools and robotic systems continues to revolutionize the field, pushing the boundaries of what can be achieved with sheet metal in various industrial applications.

Q: What materials are used in your sheet metal duct fabrication?

A: SourcifyChina factory uses high-quality galvanized steel, stainless steel, and aluminum for sheet metal duct fabrication, ensuring durability and corrosion resistance.

Q: How do you ensure the quality of your sheet metal ducts?

A: We adhere to strict quality control processes, including regular inspections, precision cutting, and welding, as well as compliance with international standards like ISO 9001.

Q: Can you customize ductwork to specific dimensions and designs?

A: Yes, we offer custom fabrication services to meet the unique requirements of each project, including various shapes, sizes, and design specifications.

Q: What is the typical lead time for an order?

A: Lead times vary depending on order size and complexity, but typically range from 2 to 4 weeks. Expedited services are available upon request.

Q: Do you provide insulation and coating options for the ducts?

A: Yes, we offer a range of insulation and coating options to enhance thermal efficiency and protection against environmental factors.

Q: How do you handle large volume orders?

A: SourcifyChina factory is equipped with advanced machinery and skilled workforce to efficiently manage and fulfill large volume orders without compromising quality.

Q: What are the shipping options available?

A: We provide flexible shipping options, including sea, air, and express delivery, depending on the urgency and destination of the order.

Q: Can I get a sample before placing a large order?

A: Yes, we can provide samples for evaluation to ensure the product meets your requirements before proceeding with a larger order.

Q: What kind of after-sales support do you offer?

A: We offer comprehensive after-sales support, including technical assistance, troubleshooting, and warranty services to ensure customer satisfaction.

Q: How do I place an order with SourcifyChina factory?

A: Orders can be placed through our website, email, or by contacting our sales team directly for personalized assistance and consultation.

Sheet metal duct fabrication is a crucial process in HVAC systems, ensuring efficient air flow and temperature control within buildings. SourcifyChina factory offers some tips to optimize this manufacturing process:

1. Material Selection: Opt for high-quality galvanized steel or aluminum for durability and cost-effectiveness. These materials withstand corrosion and ensure longevity.

2. Precision Cutting: Use advanced CNC machines for cutting sheet metal. This improves accuracy, reducing waste and ensuring components fit together seamlessly.

3. Bending Techniques: Employ precision bending equipment to create sharp, precise angles. Proper bending minimizes airflow resistance within the ducts.

4. Seam Welding: Utilize techniques like TIG or MIG welding for stronger, leak-proof seams. This reinforces the duct structure and prevents air leaks.

5. Quality Control: Implement rigorous inspection protocols. Check for dimensions, weld integrity, and material defects to maintain high standards.

6. Custom Fabrication: Offer customizable options to meet specific client requirements, enhancing customer satisfaction and expanding your market reach.

7. Coating & Finishing: Apply protective coatings to prevent corrosion and enhance the duct’s lifespan. Powder coating is a popular choice for its durability.

8. Automation: Integrate automation technology to streamline production. Automated assembly lines reduce labor costs and improve consistency.

9. Supply Chain Management: Partner with reliable suppliers for raw materials and components. Efficient supply chain management ensures timely production and delivery.

10. Sustainability Practices: Implement eco-friendly practices such as recycling scrap metal and using energy-efficient machinery. Sustainability is increasingly important to clients and regulatory bodies.

Incorporating these tips into your sheet metal duct fabrication process can enhance product quality, operational efficiency, and customer satisfaction. SourcifyChina factory stands out by leveraging advanced technology and precision engineering to deliver superior HVAC solutions.

What types of sheet metal ducts can SourcifyChina fabricate?

SourcifyChina specializes in fabricating a variety of sheet metal ducts, including round, rectangular, and oval ducts. They can accommodate custom designs to meet specific project requirements.

What materials does SourcifyChina use for duct fabrication?

SourcifyChina uses high-quality materials such as galvanized steel, stainless steel, and aluminum to ensure durability and performance. They select materials based on the application and environmental conditions.

What is the typical lead time for an order?

The lead time for sheet metal duct fabrication varies depending on the order size and complexity. Typically, it ranges from 2 to 6 weeks. SourcifyChina provides an estimated timeline during the quotation process.

Can SourcifyChina handle custom design requirements?

Yes, SourcifyChina offers custom fabrication services to meet specific design requirements. Customers can provide detailed drawings or collaborate with their engineering team to develop custom solutions.

What quality control measures does SourcifyChina implement?

SourcifyChina follows strict quality control protocols, including material inspection, dimensional checks, and performance testing. They adhere to international standards to ensure the highest quality products.

Does SourcifyChina offer prototyping services?

Yes, SourcifyChina provides prototyping services to help customers validate designs before full-scale production. This ensures that all specifications are met and any necessary adjustments can be made.

How can I request a quote from SourcifyChina?

To request a quote, you can visit SourcifyChina’s website and fill out the inquiry form, or contact their sales team directly via email or phone. Be sure to provide detailed specifications and drawings for accurate pricing.

What are the shipping options available?

SourcifyChina offers various shipping options including air freight, sea freight, and express courier services. They work with reputable logistics partners to ensure timely and safe delivery of products.

Does SourcifyChina provide after-sales support?

Yes, SourcifyChina offers comprehensive after-sales support, including installation guidance, troubleshooting, and maintenance advice. Their customer service team is available to assist with any post-purchase inquiries.

Sourcing sheet metal duct fabrication from SourcifyChina factory involves a strategic approach to ensure quality, cost-efficiency, and timely delivery. Here are some essential tips:

1. Research and Verification: Begin by thoroughly researching SourcifyChina’s reputation. Look for reviews, ratings, and testimonials from previous clients. Verify the factory’s certifications and quality standards, such as ISO certifications.

2. Clear Specifications: Provide detailed specifications of the sheet metal ducts you need. This includes material type, thickness, dimensions, and any special requirements. Clear specifications help avoid misunderstandings and ensure you get exactly what you need.

3. Request Samples: Before committing to a large order, request samples. Evaluating samples allows you to assess the quality and workmanship of the products.

4. Cost Analysis: Get a detailed quote from SourcifyChina, including material costs, labor, shipping, and any additional fees. Compare this with quotes from other suppliers to ensure competitive pricing.

5. Quality Control: Establish clear quality control processes. This could include regular inspections, third-party audits, and requiring the factory to adhere to specific quality standards.

6. Lead Time and Delivery: Confirm the lead time and delivery schedule. Ensure that the factory can meet your timeline requirements and that shipping logistics are clear and efficient.

7. Communication: Maintain clear and consistent communication. Use clear, concise language to avoid misunderstandings. Regular updates on production status are essential.

8. Contracts and Agreements: Draft a comprehensive contract outlining all terms and conditions, including payment terms, delivery schedules, quality standards, and penalties for non-compliance.

9. Cultural Sensitivity: Be mindful of cultural differences and practices in China. Building a respectful and understanding relationship can facilitate smoother transactions.

10. Sustainability and Compliance: Ensure the factory adheres to environmental and labor regulations. This is crucial for ethical sourcing and long-term sustainability.

By following these steps, you can effectively source sheet metal duct fabrication from SourcifyChina, ensuring high-quality products and a reliable supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.