Technology and Applications of sheet metal for shop

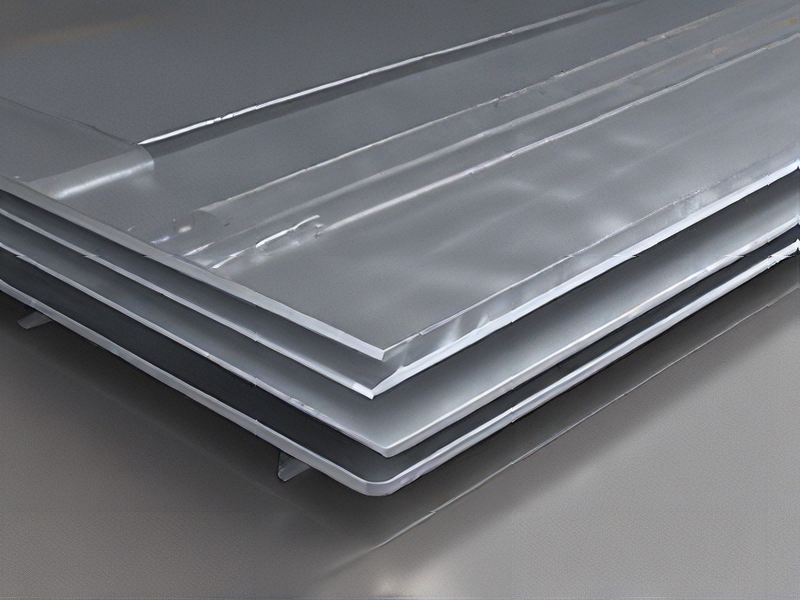

Sheet metal technology is a crucial aspect of modern manufacturing, offering versatility and precision for various applications in a shop environment. This technology involves the processing of metal sheets, typically steel, aluminum, or copper, into different shapes and sizes through cutting, bending, and assembling.

Key Technologies in Sheet Metal Work:

1. Cutting: Methods such as shearing, laser cutting, plasma cutting, and water jet cutting are used to slice sheets into desired shapes with high accuracy.

2. Bending: Press brakes and folding machines bend metal sheets at specific angles, essential for creating components with complex geometries.

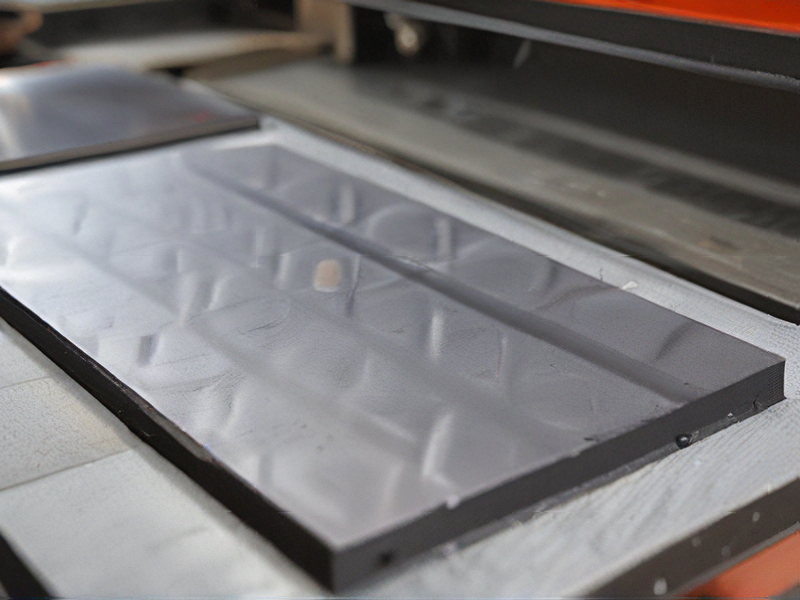

3. Stamping: This process involves using a press to form metal sheets into specific shapes through dies and molds, allowing for mass production of parts.

4. Punching: CNC punch presses create holes or cutouts in metal sheets, which is critical for parts requiring precise perforations.

5. Joining: Techniques like welding, riveting, and adhesive bonding are employed to assemble metal components into final products.

Applications of Sheet Metal:

1. Automotive Industry: Sheet metal forms car bodies, chassis, and other structural components due to its strength and lightweight properties.

2. Aerospace: Used in constructing aircraft skins, wings, and fuselage components, where precision and durability are paramount.

3. Construction: Essential for roofing, gutters, and facades, providing both structural integrity and aesthetic appeal.

4. Electronics: Enclosures, cabinets, and chassis for electronic devices are often made from sheet metal for its shielding and structural benefits.

5. HVAC: Ducts and housings for heating, ventilation, and air conditioning systems are typically fabricated from sheet metal due to its formability and durability.

Benefits:

– Cost-Effective: Efficient for both small and large-scale production.

– Durability: Offers excellent strength and resistance to wear and tear.

– Precision: Advanced machinery ensures high accuracy, reducing waste and improving quality.

Sheet metal technology is integral to modern manufacturing, providing the necessary tools and techniques to create durable, precise, and versatile components across various industries.

Quality Testing Methods for sheet metal for shop and how to control quality

Quality testing methods for sheet metal in a shop typically include:

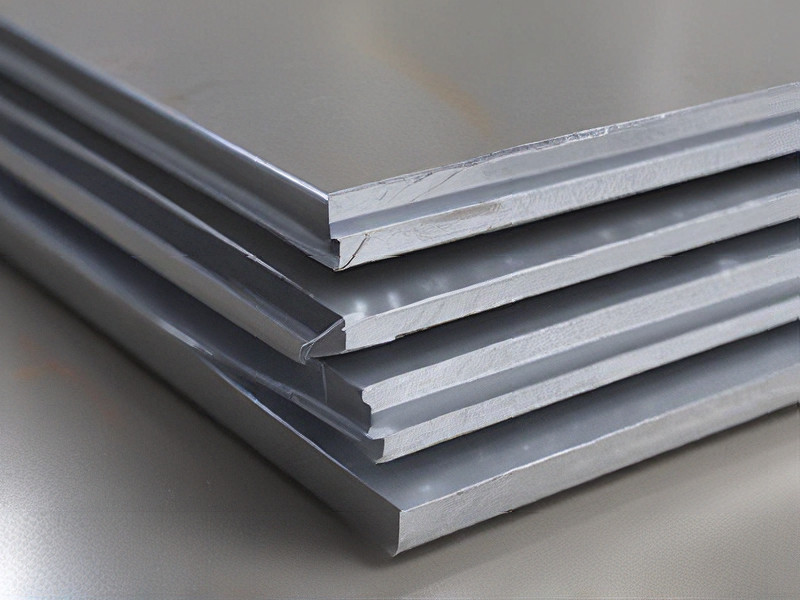

1. Dimensional Inspection: Using calipers, micrometers, or coordinate measuring machines (CMM) to verify dimensions such as thickness, width, and length.

2. Visual Inspection: Examining surfaces for defects like scratches, dents, or surface irregularities that may affect quality.

3. Surface Roughness Measurement: Using profilometers to measure the roughness of the metal surface, ensuring it meets specifications.

4. Tensile Testing: Evaluating the mechanical strength of the metal by subjecting samples to tension until failure, determining its tensile strength and elongation properties.

5. Bend Testing: Checking the metal’s ductility and resistance to cracking by bending test pieces to specified angles.

6. Hardness Testing: Measuring the metal’s hardness using methods like Rockwell or Brinell scales to ensure it meets required hardness levels.

To control quality:

– Establish Standards: Define clear quality standards and specifications for sheet metal products.

– Training: Train personnel in inspection methods and quality control procedures.

– Process Control: Monitor and control production processes to minimize variability and ensure consistency.

– Supplier Quality Assurance: Ensure suppliers meet quality standards for incoming materials.

– Document Control: Maintain documentation of inspections, tests, and quality checks.

– Continuous Improvement: Implement feedback mechanisms and regular audits to identify areas for improvement.

By employing these methods and controls, shops can ensure sheet metal products meet desired quality standards, reducing defects and improving customer satisfaction.

Tips for Procurement and Considerations when Purchasing from sheet metal for shop

When purchasing sheet metal for your shop, consider the following tips and factors:

1. Material Type and Grade: Determine the specific type of sheet metal (e.g., aluminum, stainless steel, galvanized steel) based on your project requirements for strength, corrosion resistance, and appearance.

2. Thickness: Select the appropriate gauge or thickness of sheet metal based on the structural needs of your application. Thicker gauges offer more durability but may be heavier and more expensive.

3. Size and Dimensions: Specify the dimensions and sizes of the sheets required. Consider standard sheet sizes to minimize waste and cost.

4. Surface Finish: Decide on the surface finish (e.g., polished, brushed, matte) that meets your aesthetic and functional needs.

5. Supplier Reliability: Choose a reputable supplier known for quality materials and reliable delivery times. Check reviews and testimonials from other customers.

6. Cost Considerations: Compare prices from multiple suppliers to ensure competitive pricing without compromising quality.

7. Lead Times: Confirm lead times to ensure the supplier can meet your project timelines.

8. Customer Support: Evaluate the supplier’s customer service and support capabilities, especially for handling inquiries, returns, and exchanges.

9. Quality Standards: Verify that the sheet metal meets industry standards and certifications relevant to your application (e.g., ASTM standards for construction).

10. Packaging and Shipping: Consider how the sheet metal will be packaged to prevent damage during transit and whether shipping costs are included in the quote.

By considering these factors, you can make informed decisions when procuring sheet metal for your shop, ensuring that it meets your project requirements effectively and efficiently.

FAQs on Sourcing and Manufacturing from sheet metal for shop in China

FAQs on Sourcing and Manufacturing from Sheet Metal for a Shop in China

1. Why should I consider China for sheet metal sourcing?

China offers competitive pricing, advanced manufacturing technology, and a vast network of suppliers, making it a cost-effective option for sheet metal sourcing.

2. What types of sheet metal materials are available?

Common materials include stainless steel, aluminum, copper, and carbon steel. Each material has unique properties suitable for different applications.

3. How do I find reliable suppliers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Verify supplier credentials through site visits, third-party audits, and requesting references.

4. What is the typical lead time for sheet metal products?

Lead times vary based on order complexity and volume but generally range from 4 to 8 weeks, including production and shipping.

5. How can I ensure the quality of the products?

Implement quality control measures such as:

– Requesting samples before mass production.

– Conducting factory audits.

– Using third-party inspection services like SGS or TÜV.

6. What are the common manufacturing processes for sheet metal?

Processes include cutting (laser, plasma, waterjet), bending, stamping, welding, and finishing (painting, powder coating, anodizing).

7. Are there minimum order quantities (MOQs)?

Yes, most suppliers have MOQs, which can range from a few pieces to several hundred, depending on the complexity and customization of the product.

8. How is pricing determined?

Pricing depends on material type, thickness, complexity of the design, volume, and any additional processing or finishing required.

9. What are the shipping options?

Common shipping methods are by sea (cost-effective for large volumes) and air (faster but more expensive). Ensure your supplier handles proper packaging to prevent damage during transit.

10. What are the payment terms?

Typical terms include a deposit (30-50%) before production and the balance upon completion. Payment methods often used are wire transfers, letters of credit, or through secure platforms like PayPal.

By understanding these aspects, you can make informed decisions when sourcing sheet metal products from China, ensuring quality and cost-efficiency for your shop.