Technology and Applications of sheet steel fabricators

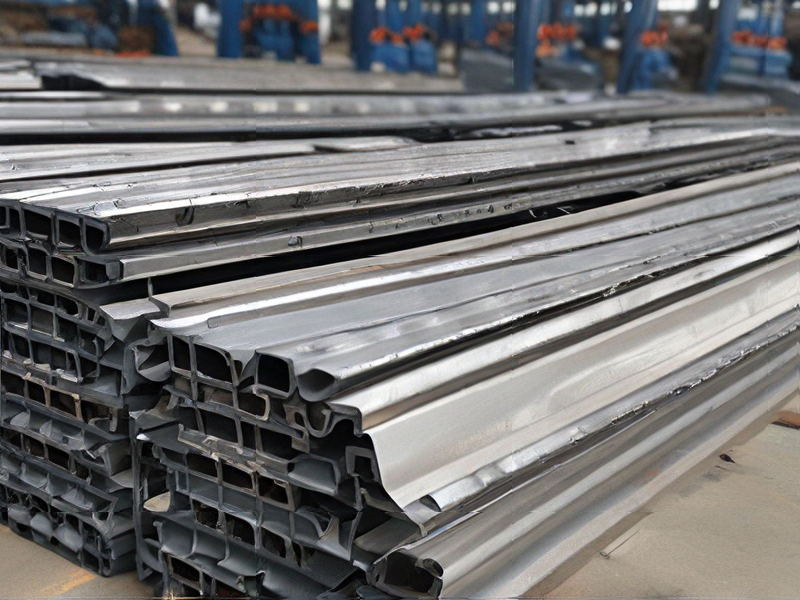

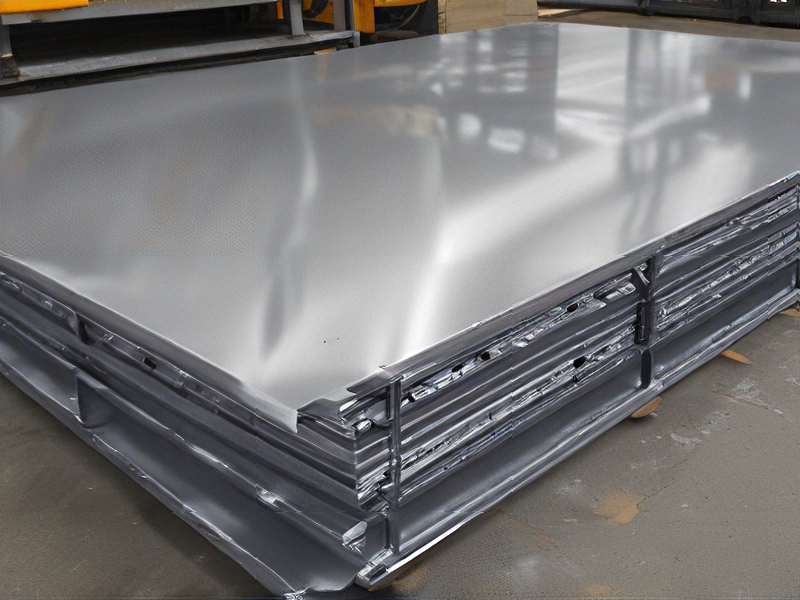

Sheet steel fabricators specialize in the manipulation and transformation of flat steel sheets into a wide range of products used across various industries. Utilizing advanced technologies, these fabricators perform processes such as cutting, bending, welding, and assembling to create components for automotive, construction, aerospace, and consumer goods sectors.

Key technologies include:

1. Laser Cutting: Utilizes high-powered lasers to cut precise shapes and patterns from steel sheets. This method offers exceptional accuracy and can handle complex designs.

2. CNC Machining: Computer Numerical Control (CNC) machines automate the cutting, drilling, and shaping processes, ensuring high precision and repeatability.

3. Press Braking: This technique bends sheet metal into desired angles and shapes. It is essential for forming parts with complex geometries.

4. Welding: Various welding techniques, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), are used to join steel sheets, providing strong and durable bonds.

5. Punching: CNC punching machines create holes and indents in metal sheets, often used for creating mounting points or ventilation openings.

Applications of sheet steel fabricators span numerous industries:

1. Automotive: Fabricated steel parts are crucial in vehicle bodies, chassis, and engine components, providing strength and durability.

2. Construction: Steel sheets are used in building frameworks, roofing, and cladding due to their structural integrity and resistance to environmental factors.

3. Aerospace: Lightweight yet strong steel components are essential in aircraft construction, ensuring safety and performance.

4. Consumer Goods: Household appliances, electronics, and furniture often incorporate fabricated steel parts for their robustness and longevity.

5. Industrial Equipment: Machines and tools in manufacturing plants rely on steel components fabricated for precision and reliability.

The integration of advanced fabrication technologies allows for high efficiency, reduced waste, and the ability to produce intricate designs, meeting the diverse needs of modern industries.

Quality Testing Methods for sheet steel fabricators and how to control quality

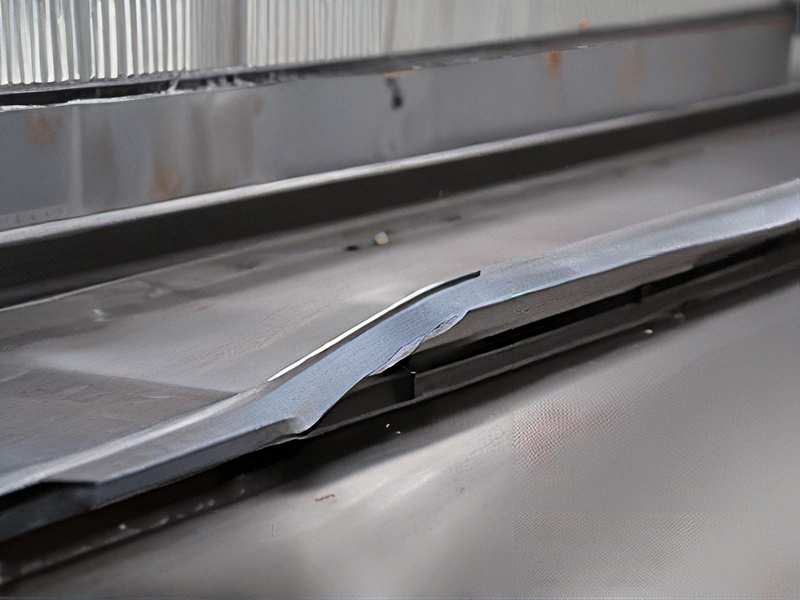

Quality testing for sheet steel fabricators involves several methods to ensure the material meets specified standards and performs reliably in its intended application. Key methods include:

1. Visual Inspection:

– Surface Defects: Checking for scratches, dents, rust, and other surface imperfections.

– Dimensional Accuracy: Verifying measurements to ensure compliance with specifications.

2. Mechanical Testing:

– Tensile Test: Measuring the steel’s strength and ductility.

– Hardness Test: Determining the material’s resistance to deformation.

– Bend Test: Assessing the flexibility and elasticity by bending the steel.

3. Non-Destructive Testing (NDT):

– Ultrasonic Testing: Using high-frequency sound waves to detect internal defects.

– Radiographic Testing: X-rays or gamma rays to inspect internal structures.

– Magnetic Particle Inspection: Identifying surface and slightly subsurface discontinuities.

4. Chemical Analysis:

– Spectroscopy: Determining the chemical composition to ensure proper alloying elements are present.

Quality Control Measures

1. Standard Operating Procedures (SOPs):

– Developing and adhering to detailed SOPs for each stage of fabrication to maintain consistency.

2. Regular Calibration of Equipment:

– Ensuring all testing and manufacturing equipment are regularly calibrated for accurate measurements.

3. Training and Certification:

– Providing regular training for personnel on the latest quality standards and testing techniques.

4. Documentation and Traceability:

– Keeping detailed records of material certifications, test results, and inspections to trace any issues back to their source.

5. Statistical Process Control (SPC):

– Using statistical methods to monitor and control the production process, identifying trends and preventing defects.

6. Continuous Improvement:

– Implementing feedback loops and regularly reviewing processes to identify and rectify inefficiencies.

By employing these testing methods and quality control measures, sheet steel fabricators can ensure high-quality production, meeting industry standards and customer requirements.

Tips for Procurement and Considerations when Purchasing from sheet steel fabricators

When procuring from sheet steel fabricators, careful planning and consideration can ensure you receive quality products while maintaining cost efficiency. Here are some key tips:

1. Define Requirements Clearly: Specify material type, thickness, dimensions, and any special treatments or finishes. Include tolerance levels and quality standards to avoid discrepancies.

2. Supplier Evaluation: Assess fabricators based on their experience, reputation, and certifications (like ISO 9001). Review their portfolio and client testimonials to gauge their reliability and quality.

3. Quality Assurance: Confirm the fabricator’s quality control processes. Ensure they conduct inspections and tests (such as tensile strength, hardness, and corrosion resistance) to meet your specifications.

4. Lead Times and Capacity: Discuss lead times upfront to align with your project timeline. Verify the fabricator’s production capacity to ensure they can handle your order volume without delays.

5. Cost Factors: Obtain detailed quotes including material costs, labor, tooling, and transportation. Compare multiple suppliers but avoid compromising quality for a lower price.

6. Sustainability: Consider fabricators that use sustainable practices and materials. This can reduce environmental impact and potentially qualify for green certifications or incentives.

7. Logistics and Delivery: Plan logistics carefully, including shipping methods and packaging. Ensure the fabricator has reliable delivery mechanisms to prevent damage during transit.

8. Communication: Maintain clear and continuous communication with the fabricator. Regular updates and open channels can prevent misunderstandings and address issues promptly.

9. Contracts and Agreements: Draft detailed contracts outlining terms, conditions, timelines, and penalties for non-compliance. Ensure both parties understand and agree to the terms.

10. After-Sales Support: Check for after-sales services such as installation support, maintenance, and warranty terms. A fabricator offering robust after-sales support can be more valuable in the long run.

By following these guidelines, you can secure high-quality sheet steel products, ensure smooth procurement processes, and foster a reliable relationship with your fabricator.

FAQs on Sourcing and Manufacturing from sheet steel fabricators in China

FAQs on Sourcing and Manufacturing from Sheet Steel Fabricators in China

#### 1. Why source sheet steel fabricators from China?

China offers competitive pricing, a wide range of manufacturers, advanced technology, and substantial production capacity. Many fabricators adhere to international quality standards.

#### 2. How to find reliable sheet steel fabricators in China?

Utilize platforms like Alibaba, Global Sources, and Made-in-China. Verify credentials through reviews, audits, and certifications like ISO.

#### 3. What should be considered when selecting a fabricator?

Consider factors such as experience, production capacity, quality control processes, communication skills, and compliance with international standards.

#### 4. How to ensure the quality of sheet steel products?

Request samples, conduct factory audits, and implement third-party inspections. Establish clear specifications and quality standards in the contract.

#### 5. What are the common challenges in sourcing from China?

Challenges include communication barriers, cultural differences, shipping delays, and quality control issues. Mitigate these with clear contracts and regular inspections.

#### 6. What are the standard payment terms?

Common terms include a 30% deposit before production and 70% balance before shipment. Letter of Credit (LC) is also widely used for larger orders.

#### 7. How to handle logistics and shipping?

Work with experienced freight forwarders. Understand Incoterms (FOB, CIF, DDP) to manage costs and responsibilities effectively.

#### 8. What legal considerations are there?

Ensure the contract is detailed and covers all aspects, including quality standards, delivery schedules, payment terms, and dispute resolution mechanisms.

#### 9. How can intellectual property be protected?

Use Non-Disclosure Agreements (NDAs) and consider registering your intellectual property in China. Choose reputable manufacturers with a track record of respecting IP.

#### 10. How to maintain long-term relationships with Chinese suppliers?

Foster good communication, visit factories when possible, provide constructive feedback, and ensure timely payments to build trust and reliability.