Choosing SourcifyChina for sheet metal design purchases from China ensures access to top-quality manufacturing. Their state-of-the-art facilities adhere to international standards, providing consistent and reliable output. With advanced technology and skilled labor, they guarantee precision and excellence in every product.

SourcifyChina boasts extensive experience in handling diverse buyer requirements. Customization is at the core of their operations, allowing for tailored solutions to meet unique client specifications. This flexibility ensures every project is executed perfectly and punctually.

Pricing is another compelling reason to opt for SourcifyChina. By leveraging local resources and economies of scale, they offer competitive rates without compromising on quality. Their transparent pricing structure ensures no hidden costs, saving buyers both time and money.

Customer satisfaction is a top priority at SourcifyChina. Their dedicated support team provides continuous assistance throughout the purchasing process, addressing any concerns promptly. This commitment to service excellence results in a seamless, worry-free experience for buyers.

By choosing SourcifyChina, you partner with a reliable, innovative, and customer-focused manufacturer capable of delivering high-quality sheet metal designs. Their comprehensive approach to manufacturing, coupled with competitive pricing and exceptional support, makes them the ideal choice for your purchasing needs in China.

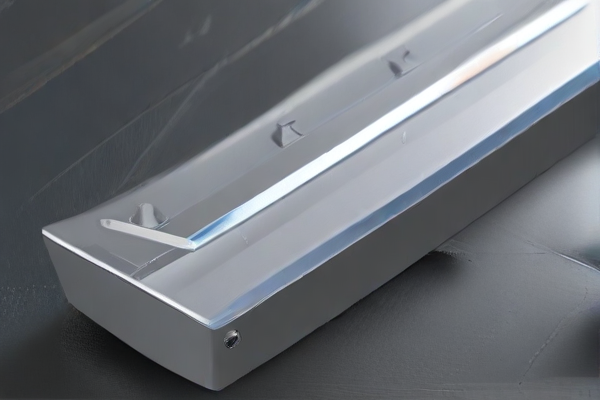

Sheet metal design involves creating components or structures using thin metal sheets. It incorporates techniques like bending, cutting, and forming. The design optimizes material usage while ensuring strength and functionality.

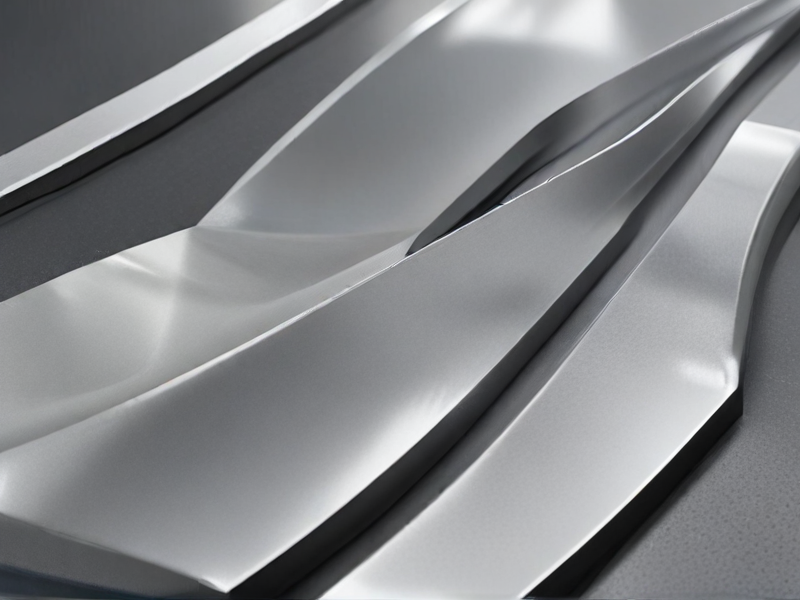

– Bending: Modifying angles of the metal at specified locations to create shapes.

– Cutting: Removing material using shearing, laser cutting, plasma cutting, or water jet cutting.

– Forming: Deforming metal sheets without cutting, e.g., stamping, embossing, or deep drawing.

– Joining: Combining different sheet metal parts using welding, riveting, or adhesives.

– Material Selection: Choosing appropriate metals such as aluminum, stainless steel, or copper based on the application.

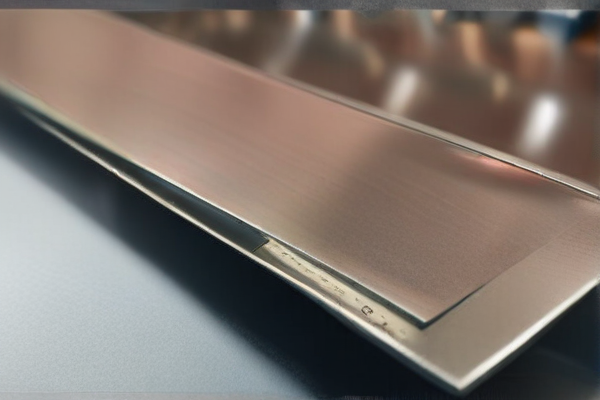

– Surface Finishing: Improving aesthetics and resistance to corrosion through processes like powder coating, anodizing, or galvanizing.

– CAD Software: Utilizing Computer-Aided Design tools like SolidWorks, AutoCAD, or CATIA for precise modeling.

– Simulation: Performing stress analysis and thermal analysis to predict the behavior of the design.

– Prototyping: Creating a prototype using rapid prototyping methods to validate design before full-scale production.

– Manufacturing Constraints: Considering limitations of manufacturing processes to ensure feasibility and cost-effectiveness.

– Design for Manufacturability: Ensuring the design can be easily and efficiently produced.

– Tooling: Designing custom tools and dies specific to the sheet metal design to aid production.

– Assembly: Planning the assembly process, including the sequence of operations to join parts.

– Tolerance and Fit: Specifying acceptable variations to ensure parts fit together properly.

– Cost Analysis: Evaluating costs involved in material, manufacturing, and finishing to budget efficiently.

– Compliance: Ensuring the design meets industry standards and regulations.

This summary encapsulates the multifaceted nature of sheet metal design and the various considerations and techniques involved.

Sheetmetal design finds extensive applications in various industries due to its versatility, precision, and efficiency in creating durable and functional components. This design discipline is integral to manufacturing processes.

– Automotive Industry: Production of car bodies, chassis, and intricate engine parts.

– Aerospace Sector: Fabrication of aircraft components like fuselages and wing structures.

– Consumer Electronics: Crafting durable enclosures and structural frames for gadgets.

– Construction: Manufacturing of HVAC systems, roofing panels, and structural supports.

– Medical Equipment: Creation of surgical instruments and diagnostic machine casings.

– Agricultural Machinery: Development of resilient frames and functional components for farming equipment.

– Marine Applications: Building boat hulls and structural components for ships.

– Defense Industry: Production of armor plates, vehicle exteriors, and weapon components.

– Renewable Energy: Crafting frames and supports for solar panels and wind turbines.

– Furniture Manufacturing: Designing robust and aesthetically pleasing metal furniture.

– Home Appliances: Production of durable outer shells and components for appliances.

– Rail Transport: Construction of train carriages and rail infrastructure components.

– Industrial Machinery: Fabrication of machine parts and protective casings.

– HVAC Systems: Manufacturing ductwork, vents, and enclosures for heating and cooling systems.

– Signage: Creation of durable metal signs and advertisement structures.

– Custom Projects: Tailored designs for specific client needs in various sectors.

Each application leverages sheetmetal design for its flexibility, strength, and cost-effectiveness, essential for creating reliable and high-quality products across different fields.

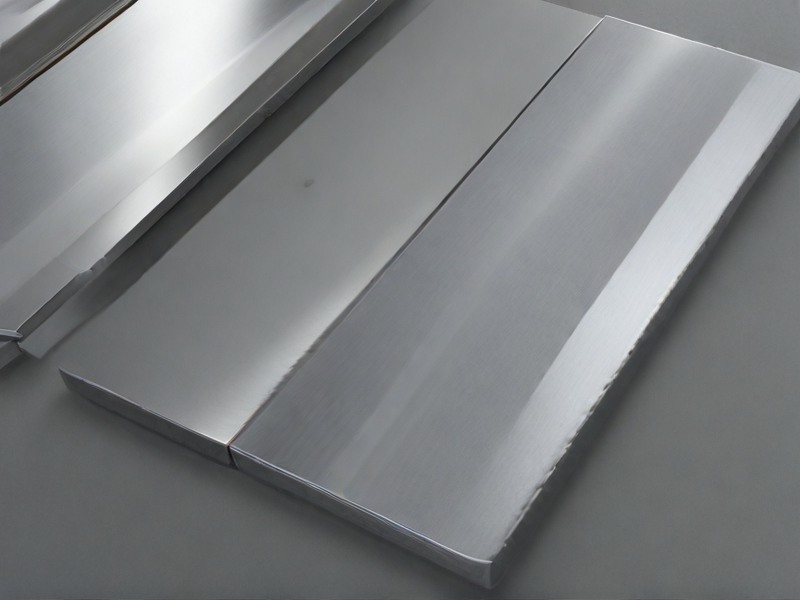

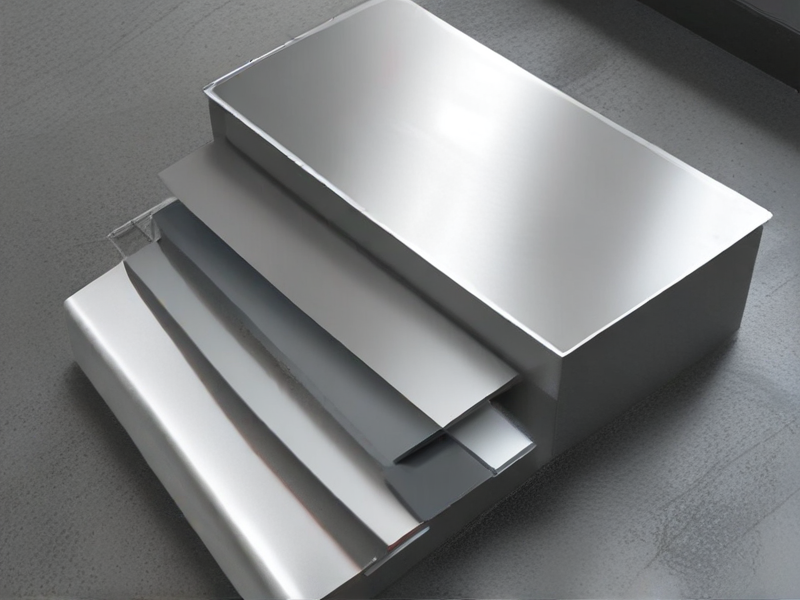

SourcifyChina specializes in sheet metal design, offering a range of materials tailored for diverse industrial applications. They use high-quality stainless steel, known for its corrosion resistance and durability, making it ideal for both indoor and outdoor applications.

Aluminum is another material frequently used in their designs, valued for its lightweight properties and excellent strength-to-weight ratio. This makes it especially suitable for transport and aerospace industries where weight is a critical factor.

For budget-conscious projects, SourcifyChina also provides mild steel. Though less resistant to corrosion than stainless steel, mild steel is highly versatile and cost-effective, suitable for numerous applications like construction and automotive manufacturing.

Additionally, they offer galvanized steel, which undergoes a hot-dip galvanization process to improve its resistance to rust and corrosion. This makes it a preferred choice for outdoor fabrications, such as roofing and fencing.

Their advanced fabrication techniques, combined with a deep understanding of material properties, ensure that every project meets precise specifications and high-quality standards. With SourcifyChina, you get both material excellence and impeccable design expertise.

SourcifyChina excels in sheet metal design, ensuring top-notch quality control throughout the manufacturing process. Every project begins with meticulous planning and design, utilizing advanced CAD software to create precise blueprints. These detailed designs lay the foundation for a flawless manufacturing process, reducing the risk of errors.

Raw material inspection is a crucial step, where materials are tested for compliance with international standards. Only premium-quality metals are approved for production, ensuring the final products are durable and reliable. This thorough vetting process minimizes defects and enhances the overall quality of the output.

Throughout the manufacturing process, SourcifyChina employs state-of-the-art machinery and technologies to maintain consistent precision and accuracy. Automated systems work in tandem with skilled technicians to monitor and adjust the process as needed. Real-time data collection enables quick responses to any anomalies, ensuring the production line operates smoothly.

Regular quality audits are conducted at various stages of production to catch any issues early. Comprehensive tests, including stress tests and dimensional inspections, ensure that each component meets the stringent quality criteria. These rigorous assessments guarantee that the final product is built to last and performs to the highest standards.

A final inspection is carried out before the products are shipped to clients. This last quality check ensures that all items are free from defects and meet customer specifications. SourcifyChina’s commitment to quality control in sheet metal design culminates in delivering reliable, high-quality products that exceed client expectations. This rigorous approach to quality ensures that SourcifyChina remains a trusted partner in the manufacturing industry.

SourcifyChina excels in sheet metal design with a comprehensive suite of services tailored to meet diverse industry standards. Their capabilities range from precision cutting and forming to advanced welding and finishing techniques. This ensures high-quality, durable, and cost-efficient solutions for a wide range of applications.

Utilizing state-of-the-art machinery and software, SourcifyChina delivers intricate and accurate designs. Their expertise guarantees that every project meets stringent quality guidelines while adhering to tight timelines. Whether it’s prototyping or large-scale production, the firm’s technical prowess is apparent in their thorough attention to detail.

Moreover, SourcifyChina places a strong emphasis on innovation and continuous improvement. By integrating the latest technologies and fostering a culture of collaboration, they consistently push the boundaries of what’s possible in sheet metal design. This commitment to staying ahead of industry trends ensures that they deliver cutting-edge solutions to their clients.

Dedicated customer support is at the forefront of their service offering. They work closely with clients to understand specific requirements, offering consultation and ongoing support throughout the project lifecycle. This approach ensures that the final product not only meets but exceeds customer expectations.

In conclusion, SourcifyChina’s exceptional capabilities in sheet metal design make them a leader in the industry. They combine technical proficiency, state-of-the-art technology, and dedicated customer service to deliver unparalleled results. Whether you need a prototype or full-scale production, SourcifyChina is equipped to handle all your sheet metal design needs.

Sheet metal design offers various substantial benefits, enhancing efficiency, cost-effectiveness, and overall quality in manufacturing processes. It is a crucial aspect for industries that emphasize durable and precise components.

Key benefits include:

– Cost Efficiency: Sheet metal is often more affordable than other materials and requires less labor-intensive manufacturing processes.

– Durability: Offers excellent resistance to corrosion, weathering, and wear, which extends the lifecycle of products.

– Flexibility in Design: Easily formed into various shapes and sizes to meet specific requirements or unique designs.

– Scalability: Ideal for both small-scale and large-scale production runs, offering consistency.

– Weight Efficiency: Despite its durability, sheet metal components can be made lightweight, improving overall efficiency.

– Recyclability: Environmentally friendly as it can be recycled without losing its properties.

– Ease of Fabrication: Techniques like cutting, bending, and welding are straightforward and widely understood, allowing for quick turnaround times.

– High Strength-to-Weight Ratio: Provides robust support without adding excessive weight, crucial in industries like automotive and aerospace.

– Low Maintenance: Requires minimal upkeep, reducing long-term operational costs.

– Precision and Accuracy: Modern technologies like CNC machining enhance precision in producing components, ensuring high-quality results.

In conclusion, sheet metal design significantly contributes to the efficiency and effectiveness of manufacturing, providing a versatile and durable solution suitable for various applications across numerous industries.

Sheet metal design is crucial in various industries due to its versatility, cost-effectiveness, and ease of manufacturing. It encompasses a range of technical considerations to ensure functional and durable components.

– Material Selection: Choosing the right material—aluminum, stainless steel, etc.—based on factors like strength, corrosion resistance, and weight.

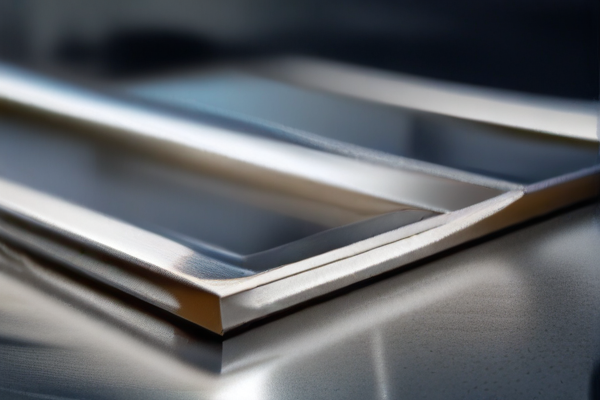

– Thickness: Determining the appropriate gauge to balance strength and flexibility.

– Bend Radius: Ensuring bends aren’t too sharp to avoid material cracking, typically at least the material’s thickness.

– Relief Cuts: Implementing relief cuts to minimize stress during bending and forming.

– Hole Sizes: Ensuring holes are neither too large to compromise strength nor too small to increase manufacturing difficulty.

– Tolerances: Defining acceptable variances in dimensions for precision fitting.

– Fastening Methods: Using techniques like riveting, welding, or bolting to join parts securely.

– Tabs and Slots: Designing for ease of assembly and structural integrity.

– Edge Conditioning: Smoothing and rounding edges to prevent injuries and improve aesthetics.

– Surface Treatments: Applying coatings or finishes for corrosion resistance and aesthetic purposes.

– Forming Methods: Using techniques like stamping, bending, and hydroforming for efficient production.

– Cutting Methods: Employing laser cutting, punching, or shearing for precise shapes.

– Cost Considerations: Balancing design complexity with manufacturing cost efficiency.

– Draft Angles: Including draft angles in designs for ease of ejection from molds or dies in mass production.

By paying attention to these features, designers can create effective and manufacturable sheet metal products suitable for a wide range of applications.

SourcifyChina excels in the art of sheet metal design, offering unparalleled custom products tailored to meet diverse industrial needs. Their expertise encompasses cutting-edge techniques and premium materials, ensuring high-quality, durable products for various applications.

Custom sheet metal projects by SourcifyChina are a blend of precision engineering and innovative design. Whether it’s prototyping, short-run manufacturing, or large-scale production, they adhere to stringent quality standards to deliver outstanding results.

The company utilizes advanced tools like CNC machining and laser cutting, enabling seamless fabrication capabilities. They stay ahead of industry trends by investing in technology and training, ensuring state-of-the-art solutions.

SourcifyChina’s design team collaborates closely with clients to understand their specific requirements. This collaborative approach facilitates the creation of custom solutions that perfectly align with clients’ objectives and operational needs.

From concept to completion, SourcifyChina manages every facet of the project lifecycle. Their comprehensive project management ensures timelines are met, budgets are adhered to, and quality is never compromised.

Their portfolio spans across automotive, aerospace, electronics, and consumer products, showcasing a diverse range of successful projects. Their adaptability and customization capabilities make them a preferred partner in sheet metal design.

SourcifyChina also offers post-production services, including finishing, assembly, and testing. These integrated services provide a one-stop solution, enhancing the overall efficiency and reducing project turnaround times.

In conclusion, SourcifyChina stands out as a leader in custom sheet metal design, combining technological prowess with a customer-centric approach. Their commitment to quality and innovation makes them an ideal choice for businesses seeking reliable and custom-engineered sheet metal solutions.

SourcifyChina Sheetmetal Design is a premier engineering and manufacturing firm specializing in the design, prototyping, and production of high-precision sheet metal components. Based in China, the company leverages advanced technology and industry expertise to meet the diverse needs of a global clientele. With a commitment to innovation and quality, SourcifyChina offers tailored solutions ranging from complex geometries to simple, high-volume parts. Their state-of-the-art facilities are equipped with cutting-edge CNC machinery, laser cutting, and bending equipment, enabling them to deliver products that meet stringent international standards. The firm prides itself on its skilled engineering team that collaborates closely with clients to transform concepts into flawless, manufacturable components. Dedicated to sustainability and efficiency, SourcifyChina also implements environmentally-friendly practices throughout its production processes. Through meticulous attention to detail and unwavering customer service, SourcifyChina Sheetmetal Design has established itself as a trusted partner for businesses seeking reliable, high-quality sheet metal solutions.

Sheetmetal design plays a crucial role in the aerospace, defense, and marine industries, given its superior strength-to-weight ratio, cost-effectiveness, and versatility. In aerospace applications, sheetmetal components are essential for constructing the aircraft’s skin, wings, and fuselage, providing not only structural integrity but also aerodynamic efficiency. The precision engineering involved in crafting these components ensures that the aircraft can withstand extreme pressures and temperatures, optimizing performance and safety. Furthermore, advanced techniques such as CNC machining and hydroforming allow for the production of highly intricate and lightweight parts, contributing to overall fuel efficiency and reducing operational costs.

In defense and marine applications, sheetmetal design is integral to the construction of vehicles and vessels that require robust and durable solutions. Military vehicles and naval ships utilize sheetmetal for armor plating, framework, and internal components. The high-strength materials used in sheet metalwork, such as aluminum alloys and high-tensile steels, are essential for protecting personnel and equipment from hostile environments and ballistic impacts. Additionally, the adaptability of sheetmetal allows for rapid prototyping and iterative design adjustments, which are critical in defense applications where evolving threats necessitate swift advancements. In the marine industry, corrosion-resistant sheetmetal components are fundamental for hulls, superstructures, and other vital parts, ensuring longevity and reliability in harsh oceanic conditions. Overall, the implementation of sophisticated sheetmetal design techniques across these sectors underscores their importance in meeting stringent performance and safety standards.

Sheetmetal design plays a crucial role in the automotive industry by enhancing the structural integrity and aesthetic appeal of vehicles. Its application extends to various components, including body panels, chassis, and interior elements. Through advanced techniques like stamping, bending, and laser cutting, manufacturers can create lightweight yet durable parts that contribute to fuel efficiency and overall vehicle performance. Precision in sheetmetal design also enables the incorporation of complex geometries and features, improving aerodynamics and crashworthiness. Additionally, sheetmetal components are often designed for ease of assembly and cost-effective mass production, ensuring that quality and efficiency are maintained throughout the manufacturing process.

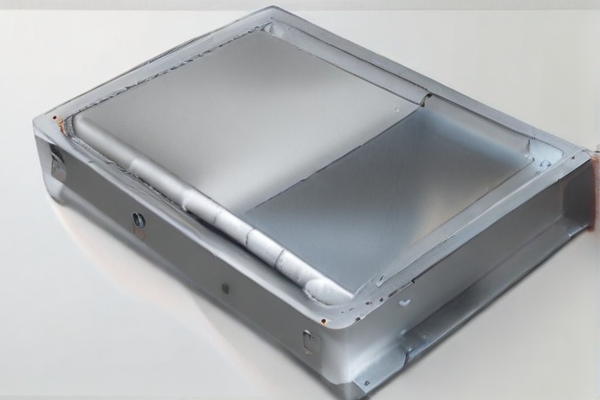

In the electronics industry, sheetmetal design is pivotal in creating enclosures, brackets, and structural frames for a myriad of devices such as computers, servers, and consumer electronics. Metals like aluminum and steel are commonly used for their excellent thermal management properties, providing both heat dissipation and electromagnetic interference (EMI) shielding. The precision offered by modern sheetmetal design techniques facilitates the integration of intricate features like cutouts, fastener holes, and ventilation slots, which are essential for functional and ergonomic product designs. Furthermore, the adaptability of sheetmetal design allows for rapid prototyping and quick turnarounds in production, catering to the fast-paced innovation cycle of the electronics sector. This synergy between design flexibility and material robustness is essential for developing reliable and high-performance electronic products.

Sheetmetal design plays a pivotal role in the construction industry, contributing significantly to the structural integrity and functional aesthetics of buildings. Architects and engineers employ sheetmetal in designing various components such as roofing, siding, gutters, and ductwork. Its malleability allows for precise customization, ensuring that these elements seamlessly integrate with the overall architectural blueprint while also providing durability and resistance to weather conditions. Advanced techniques like CNC (Computer Numerical Control) machining and laser cutting further enhance the precision and efficiency of constructing these components. Moreover, innovations in sheetmetal design facilitate faster project timelines and cost savings due to the ease of fabrication and installation.

In the realm of energy, sheetmetal design is indispensable in manufacturing equipment and systems for energy generation and conservation. Heat exchangers, a critical component in power plants and HVAC systems, rely heavily on the conductive properties of metals to efficiently transfer heat. Sheetmetal’s adaptability allows for the creation of intricate designs that maximize surface area and enhance energy efficiency. Additionally, wind turbines and solar panels are often constructed using precisely engineered sheetmetal parts, contributing to the robustness and efficiency of renewable energy technologies. The lightweight yet strong nature of sheetmetal ensures that these energy systems can withstand environmental stresses while maintaining optimal performance. As energy demands grow, advancements in sheetmetal design continue to contribute to more sustainable and efficient solutions.

The industrial equipment industry heavily relies on sheetmetal design due to its versatility, durability, and cost-effectiveness. Sheetmetal is used in the fabrication of various components and assemblies, often forming the backbone of machinery housings, structural frames, and enclosures. Advanced design software allows engineers to create intricate shapes and structures that streamline manufacturing processes and reduce material waste. By optimizing the thickness, bend radii, and joint configurations, designers can enhance the mechanical properties of the components, ensuring they withstand operational stresses and environmental conditions. The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) facilitates precise, automated cutting and forming processes, resulting in higher efficiency and consistency in mass production.

Additionally, sheetmetal design contributes significantly to the modularity and maintainability of industrial equipment. The ability to design interlocking panels and easily removable covers simplifies assembly, disassembly, and access for maintenance, repairs, and upgrades. This modular approach not only reduces downtime but also allows for the customization of equipment to meet specific industry needs. With advancements in materials and coating technologies, sheetmetal components can be made resistant to corrosion, abrasion, and extreme temperatures, further extending their lifespan. As automation and robotics become more prevalent in manufacturing, the importance of optimized sheetmetal design continues to grow, driving innovations that improve the overall performance and efficiency of industrial equipment.

Sheetmetal design plays a crucial role in the medical devices sector by facilitating the creation of durable, hygienic, and precisely engineered components. Medical devices often demand strict compliance with safety and regulatory standards, and sheetmetal responds effectively to these requirements. For instance, the casing and housing of various diagnostic and surgical equipment, such as MRI machines, X-ray units, and surgical robots, are typically crafted from high-quality sheetmetal. This material can be bent, cut, and shaped to exact specifications, allowing engineers to design components that meet stringent medical standards while also ensuring durability and ease of sterilization. Additionally, sheetmetal’s resistance to corrosion and wear makes it ideal for use in environments where hygiene and reliability are paramount.

Moreover, the adaptability of sheetmetal design enhances the innovation of medical devices. The precision in sheetmetal fabrication enables the production of custom-designed enclosures and frameworks that can incorporate complex shapes, cutouts, and mounting points for electronic components and sensors. This flexibility is particularly beneficial in the development of advanced machinery like patient monitoring systems and automated medication dispensers. Furthermore, the use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies in sheetmetal allows for rapid prototyping and iteration, significantly speeding up the development cycle for new medical devices. By leveraging sheetmetal design, manufacturers can achieve a balance between structural integrity, functional versatility, and compliance with health regulations, thereby advancing the medical field through reliable, innovative technologies.

Sheet metal design holds a pivotal role in both machining and manufacturing applications, serving as a backbone for various industries such as automotive, aerospace, and consumer electronics. In the context of machining, sheet metal design involves the careful planning and preparation of flat metal sheets, which are subsequently subjected to processes such as cutting, bending, and forming. Advanced machining techniques like laser cutting, water jet cutting, and CNC machining enable the precise shaping of metal sheets to meet exact specifications. These machining processes are essential for producing intricate parts with high dimensional accuracy and smooth finishes, making them indispensable for complex assemblies and demanding applications.

On the manufacturing side, sheet metal design facilitates mass production through efficient and cost-effective methods. Techniques such as stamping, pressing, and roll forming allow for the rapid and consistent production of parts from sheet metal. Additionally, the use of computer-aided design (CAD) software streamlines the design process, enabling engineers to create highly detailed and optimized sheet metal components. This ensures that material usage is minimized while maintaining strength and functionality. The versatile nature of sheet metal also allows for the integration of various finishing processes, such as powder coating and anodizing, to enhance both the aesthetic appeal and durability of the final product. As a result, sheet metal design remains a cornerstone in contemporary manufacturing, driving innovation and efficiency across multiple sectors.

What is SourcifyChina’s expertise in sheet metal design and manufacturing?

SourcifyChina specializes in high-quality sheet metal design and manufacturing, offering services from prototyping to mass production. Our factory is equipped with advanced technology to ensure precision, efficiency, and durability in every project.

What types of sheet metal products does SourcifyChina manufacture?

We manufacture a wide range of sheet metal products, including enclosures, brackets, panels, and custom components tailored to various industries such as automotive, electronics, and aerospace.

How does SourcifyChina ensure the quality of its sheet metal products?

Quality is ensured through rigorous inspection processes, adherence to international standards, and the use of cutting-edge machinery. We implement quality control checks at every production stage, from material selection to final product inspection.

Can SourcifyChina assist with custom sheet metal design?

Yes, our experienced engineering team can assist with custom designs to meet specific project requirements. We offer design consultations, CAD modeling, and prototyping services to ensure your design is optimized for manufacturing.

What materials does SourcifyChina work with for sheet metal fabrication?

We work with a variety of materials including aluminum, steel, stainless steel, and other alloys. Our team can help you choose the best material for your project’s needs and budget.

What is the typical lead time for a sheet metal project?

Lead times vary depending on the project’s complexity and volume. However, we strive to deliver prototypes within 2-4 weeks and larger production runs within 6-8 weeks.

Does SourcifyChina provide finishing services for sheet metal products?

Yes, we offer a range of finishing services including powder coating, anodizing, plating, and painting to enhance the appearance and durability of your sheet metal products.

How does SourcifyChina handle large volume orders?

We have scalable production capabilities and an efficient workflow to handle large volume orders while maintaining high quality and on-time delivery. Our supply chain management ensures all materials and components are sourced effectively.

Is SourcifyChina environmentally responsible in its manufacturing process?

Absolutely. We are committed to environmentally responsible manufacturing practices, including waste reduction, recycling, and energy-efficient processes. Our factory complies with environmental regulations and standards to minimize our ecological footprint.

How can I get a quote for my sheet metal project with SourcifyChina?

When considering sheet metal design manufacturing through SourcifyChina factory, it’s crucial to optimize design and communication for efficiency, cost-effectiveness, and quality. Here are some actionable tips:

1. Material Selection:

– Choose appropriate materials considering strength, weight, and cost. Common options are stainless steel, aluminum, and galvanized steel.

– Consult with SourcifyChina to understand material availability and cost implications.

2. Design for Manufacturability (DFM):

– Simplify designs to minimize complexity and reduce manufacturing costs.

– Ensure tolerances are realistic. Tight tolerances increase costs and complexity.

– Consider bending allowances and radii to avoid cracking or unwanted deformation.

3. Prototyping and Testing:

– Develop prototypes to validate design and functionality before full-scale production.

– Use initial prototypes to test assembly processes and fit.

4. Cost Optimization:

– Design parts to reduce waste and optimize sheet usage.

– Consider standard sheet sizes to minimize cutting and material waste.

5. Communication and Documentation:

– Provide clear, detailed drawings with proper dimensions, tolerances, and material specifications.

– Use 3D models to aid clearer communication and avoid misunderstandings.

6. Surface Finishing:

– Decide on surface finish early in the design process (e.g., powder coating, anodizing) to ensure aesthetic and functional quality.

– Discuss finishing processes with SourcifyChina to match their capabilities with your requirements.

7. Lead Time and Logistics:

– Plan for lead times, including production and shipping.

– Establish clear communication channels for progress updates and potential delays.

8. Quality Control:

– Implement stringent quality control measures to ensure product conformance.

– Request regular quality reports and consider third-party inspections if necessary.

By focusing on these key aspects, you can enhance the efficiency, quality, and cost-effectiveness of your sheet metal design manufacturing with SourcifyChina factory.

Sure, here are some frequently asked questions (FAQ) with answers concerning sourcing sheetmetal design from SourcifyChina factory:

1. What is SourcifyChina?

SourcifyChina is a comprehensive manufacturing and sourcing company based in China that specializes in various product categories, including sheetmetal design and production. They offer end-to-end supply chain solutions for diverse industries.

2. What kinds of sheetmetal designs can SourcifyChina handle?

SourcifyChina can handle a variety of sheetmetal designs, ranging from simple brackets and enclosures to complex assemblies and custom designs. Their capabilities include cutting, bending, welding, stamping, and surface treatment.

3. How do I submit my sheetmetal design requirements?

You can submit your sheetmetal design requirements by contacting SourcifyChina through their website or email. Typically, you will need to provide detailed drawings, technical specifications, and any other critical information relevant to your design.

4. What file formats are accepted for design submissions?

SourcifyChina accepts various file formats, including CAD files (such as .dwg, .dxf, .step), PDFs, and other commonly used engineering drawing formats. It’s best to confirm the preferred format with their team.

5. How long does it take to get a quotation?

The time to receive a quotation may vary depending on the complexity of the design and the volume of your order. However, SourcifyChina typically provides quotations within 48 to 72 hours after receiving the complete design specifications.

6. What are the payment terms and methods?

SourcifyChina offers flexible payment terms, which may include down payments, milestone payments, or full payment upon order completion. Accepted payment methods usually include wire transfers, PayPal, and Letters of Credit (L/C).

7. Are there any quality assurance measures in place?

Yes, SourcifyChina has stringent quality assurance processes that include in-process inspections, final quality checks, material certifications, and adherence to international quality standards like ISO.

8. Can SourcifyChina handle large volume orders?

Absolutely, SourcifyChina is equipped to handle both small and large volume orders. Their scalable operations enable them to manage production runs ranging from prototypes to mass production.

9. What is the typical lead time for production?

Sourcing sheet metal design from a factory like SourcifyChina can be streamlined with careful planning and the right approach. Here are some tips to ensure a smooth process:

1. Define Specifications Clearly:

Detail all requirements, including dimensions, materials, tolerances, finishes, and any special treatments. A comprehensive design document helps avoid misunderstandings.

2. Select the Right Supplier:

Research SourcifyChina’s capabilities, quality standards, and previous projects. Ensure they have experience with sheet metal design to meet your specific needs.

3. Request Samples:

Ask for prototypes or samples to evaluate the factory’s workmanship and adherence to specifications before committing to large orders.

4. Quality Assurance:

Establish quality control measures. Define inspection criteria and agree on methods for identifying and handling defects.

5. Communication:

Maintain clear and regular communication. Use tools like email, video calls, and project management software to keep all parties updated on progress and address any issues promptly.

6. Explore Costing:

Get a detailed quote, including material, labor, tooling, and shipping costs. Compare with other suppliers to ensure competitive pricing without compromising quality.

7. Logistics and Lead Time:

Discuss and agree on lead time for production and shipping. Factor in potential delays, customs processing, and handling.

8. Contract and Terms:

Draft a comprehensive contract covering all aspects – pricing, delivery schedule, quality standards, payment terms, and consequences for non-compliance.

9. Frequent Visits/Audits:

If feasible, visit the factory periodically or hire third-party inspectors to audit and ensure standards are consistently met.

10. Scalable Relationship:

Build a long-term relationship for scalable orders. This offers better negotiation power and priority for future projects.

By following these steps, you can effectively source sheet metal design services from SourcifyChina, ensuring quality, cost-efficiency, and timely delivery.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.