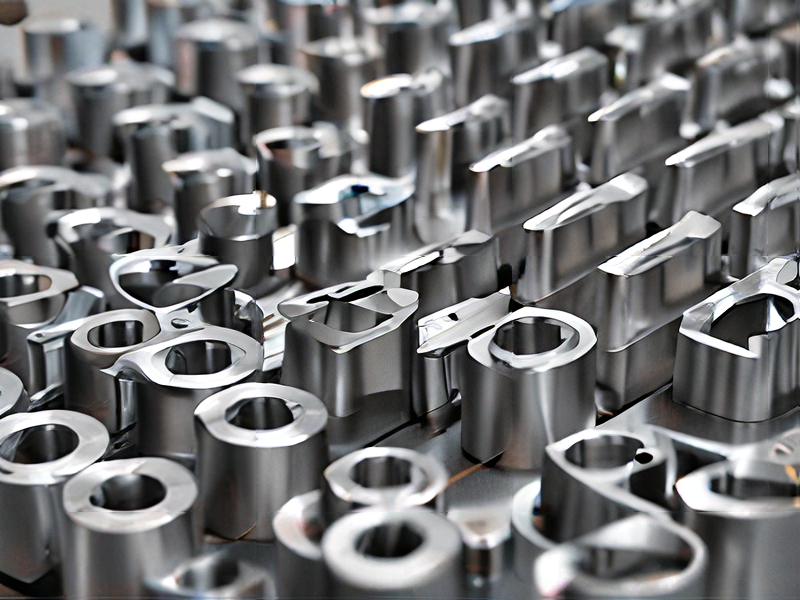

Technology and Applications of soft machining

Soft machining encompasses various technologies aimed at shaping or modifying materials without causing substantial deformation or damage. One prominent technique is Electrical Discharge Machining (EDM), where controlled electrical discharges erode material from a workpiece. EDM is crucial for intricate geometries, hard metals, and heat-sensitive materials like titanium alloys and ceramics, where conventional machining methods are impractical.

Another method is Ultrasonic Machining (USM), employing high-frequency vibrations combined with abrasive slurry to remove material from brittle substances like glass and ceramics. This non-thermal process ensures minimal heat generation, preserving material integrity.

Chemical Machining (CHM) involves selective material dissolution using chemicals. It’s advantageous for complex shapes and delicate components in aerospace and electronics. Photochemical Machining (PCM) is a subset utilizing photoresist masks and chemical etchants to create precise patterns in metal sheets, used extensively in electronics manufacturing.

Soft machining finds applications across diverse industries. For example, in aerospace, EDM produces turbine blades with complex cooling channels. In electronics, PCM crafts intricate circuit board patterns. Medical implants benefit from USM’s precision in shaping biocompatible materials. Overall, soft machining technologies continue to evolve, enabling manufacturing advancements in sectors requiring intricate, heat-sensitive, or brittle materials.

Quality Testing Methods for soft machining and how to control quality

Quality testing in soft machining involves several methods to ensure the precision and accuracy of the machining process. These methods can be broadly categorized into dimensional inspection, surface inspection, and material property verification.

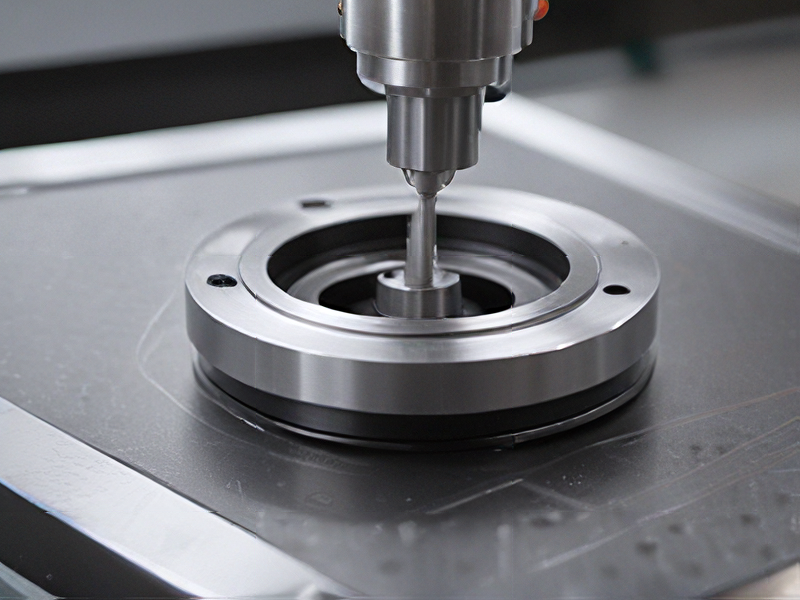

Dimensional Inspection

1. Coordinate Measuring Machine (CMM): A CMM uses a probe to measure the coordinates of points on a part’s surface, providing precise measurements of dimensions, shapes, and positions.

2. Laser Scanning: This non-contact method captures the shape of an object using laser light to generate a 3D model for comparison against design specifications.

Surface Inspection

1. Visual Inspection: Using magnifying lenses or microscopes, inspectors can detect surface defects such as scratches, cracks, or uneven finishes.

2. Surface Roughness Measurement: Instruments like profilometers measure the surface texture to ensure it meets specified roughness criteria.

Material Property Verification

1. Hardness Testing: This involves measuring the resistance of the material to deformation, often using tools like Rockwell or Vickers hardness testers.

2. Microstructural Analysis: Techniques like optical microscopy or scanning electron microscopy (SEM) examine the material’s microstructure to detect inconsistencies or defects.

Quality Control Methods

1. Statistical Process Control (SPC): By collecting data from the machining process and using control charts, SPC helps monitor and control the process, identifying trends that could indicate deviations from quality standards.

2. In-Process Monitoring: Sensors and monitoring systems can detect issues in real-time, allowing immediate adjustments to the machining process.

3. Regular Calibration: Ensuring all measuring and inspection tools are regularly calibrated maintains accuracy and reliability.

4. Training and Certification: Regular training for operators on quality standards and proper use of inspection equipment ensures consistent quality control.

By integrating these methods, manufacturers can effectively control and ensure the quality of soft machined parts, reducing defects and improving overall product reliability.

Tips for Procurement and Considerations when Purchasing from soft machining

When procuring from soft machining suppliers, several key considerations can optimize the purchasing process:

1. Quality Standards: Ensure suppliers adhere to industry standards like ISO 9001 for quality management systems. Request samples or visit facilities to assess their machining capabilities and quality control measures.

2. Technical Expertise: Evaluate suppliers based on their experience and technical competence in soft machining processes such as milling, turning, or grinding. Look for certifications or specialized knowledge relevant to your specific needs.

3. Capacity and Scalability: Assess the supplier’s capacity to handle your current and future volume requirements. Consider their ability to scale production to meet fluctuations in demand without compromising on quality or lead times.

4. Material Sourcing and Traceability: Verify the origin and quality of raw materials used in soft machining. Suppliers should offer traceability and ensure materials meet regulatory and performance requirements.

5. Cost and Pricing: Compare pricing structures, including unit costs, setup fees, and volume discounts. Consider total cost of ownership, including transportation, inventory management, and potential rework costs.

6. Lead Times and Flexibility: Evaluate lead times for production and delivery. Suppliers should demonstrate flexibility in accommodating urgent orders or changes in specifications.

7. Supplier Reliability and Reputation: Research supplier reputation through references, online reviews, or industry networks. Reliable communication and transparency are crucial for long-term partnerships.

8. Sustainability and Compliance: Assess suppliers’ commitment to sustainability practices and compliance with environmental regulations. This may include waste management, energy efficiency, and ethical sourcing practices.

9. Contractual Terms and Conditions: Review contracts thoroughly, outlining delivery schedules, quality expectations, payment terms, and dispute resolution procedures.

10. Communication and Support: Establish clear lines of communication and expectations regarding technical support, order tracking, and post-delivery service.

By prioritizing these considerations, procurement teams can mitigate risks, optimize costs, and establish productive partnerships with soft machining suppliers.

FAQs on Sourcing and Manufacturing from soft machining in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from soft machining in China:

1. What is soft machining?

Soft machining refers to the process of manufacturing parts using techniques like milling, turning, drilling, and grinding, typically before the final hardening process.

2. Why choose China for soft machining?

China offers cost-effective manufacturing solutions due to lower labor and production costs, along with a well-established infrastructure for soft machining.

3. How do I find a reliable soft machining supplier in China?

Research online platforms, attend trade shows, or use sourcing agents to identify reputable manufacturers. Verify their certifications, capabilities, and customer reviews.

4. What are the common challenges when sourcing soft machining from China?

Challenges may include language barriers, quality control issues, intellectual property protection, and logistical complexities such as shipping and customs.

5. How can I ensure quality when outsourcing soft machining to China?

Implement stringent supplier qualification processes, conduct regular inspections, request samples and prototypes, and maintain clear communication regarding quality standards and expectations.

6. What are the typical lead times for soft machining projects in China?

Lead times vary depending on project complexity, volume, and supplier capabilities. Generally, they range from a few weeks to several months.

7. What are the payment terms usually used when sourcing from China?

Common payment terms include 30% deposit upfront and 70% upon completion or shipment, but terms can vary based on the supplier’s policies and negotiation.

8. How do I protect my intellectual property when outsourcing to China?

Utilize non-disclosure agreements (NDAs), patents, trademarks, and work with reputable suppliers with strong intellectual property protection policies.

Navigating soft machining sourcing from China involves thorough research, clear communication, and diligent quality assurance to ensure successful partnerships and high-quality products.