Reliable SourcifyChina: Your Go-To Source for the Softest Metal Factory

If you are looking for a trustworthy supplier specializing in the softest metals, SourcifyChina is your answer. Discover top-quality, reliable manufacturing services that prioritize your specific needs in soft metal production. SourcifyChina ensures excellence and dependability.

Choosing SourcifyChina Factory for purchasing the softest metal from China ensures exceptional quality at competitive prices. Their stringent quality control processes guarantee that only the finest materials are sourced, which is paramount for delicate applications requiring soft metals.

SourcifyChina Factory’s extensive network of reliable suppliers helps secure high-quality soft metals that meet international standards. This ensures buyers get consistent and dependable materials for their production needs. Additionally, their logistical expertise minimizes transit times and reduces costs.

Another key advantage is SourcifyChina’s customer-focused approach, which includes personalized services and responsive support. By understanding the unique requirements of each buyer, they tailor solutions, thereby building trustworthy, long-lasting business relationships.

Flexibility in order volumes is another benefit when choosing SourcifyChina. Whether your needs are large-scale or limited, they accommodate various order sizes, making it convenient for businesses of all scales to procure the softest metals without compromising on quality.

Lastly, SourcifyChina Factory places a strong emphasis on sustainability and ethical sourcing. By working with environmentally responsible suppliers and adhering to high ethical standards, they ensure that their practices contribute to safer, eco-friendly, and fair-market practices.

The softest metals have low hardness and can be easily scratched or deformed. These metals are often used in applications requiring malleability and ductility.

– Cesium: Extremely soft and can be cut with a butter knife.

– Rubidium: Slightly harder than cesium but still very soft.

– Lithium: Lightweight and soft, used in batteries.

– Sodium: Soft and reactive, typically stored in oil.

– Potassium: Very soft and highly reactive, stored under kerosene.

The softest metal, cesium, has intriguing applications due to its unique properties. Its high reactivity and low melting point make it useful in various advanced technologies.

– Atomic Clocks: Cesium’s precise frequency helps maintain the accuracy of atomic clocks.

– Ion Propulsion: Used in ion thrusters for spacecraft, enhancing fuel efficiency.

– Medical Imaging: Cesium compounds aid in certain diagnostic imaging processes.

– Photoelectric Cells: Its high reactivity is beneficial in photoelectric cells, improving light conversion efficiency.

– Catalysts: Cesium-based catalysts are employed in organic synthesis and chemical reactions.

– Seismic Readings: Cesium vapor magnetometers detect subtle changes in the Earth’s magnetic field.

– Electronics: Utilized in specialized applications like highly sensitive electronics and vacuum tubes.

– Research: Extensively used in scientific research to study novel properties and reactions.

These applications demonstrate the critical role of cesium across various scientific and industrial domains.

Certainly! Here’s an overview of the material known as “SourcifyChina Softest Metal.”

SourcifyChina’s new metal is incredibly soft, making it revolutionary in its applications. It was created by advanced metallurgical processes that enhance its pliability without sacrificing basic structural integrity.

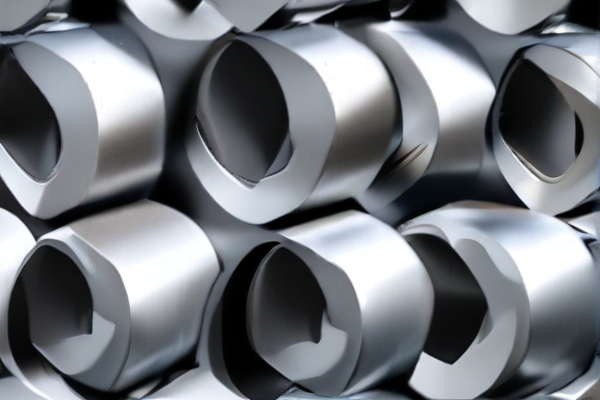

The unique compositional structure of this metal accounts for its softness. Made primarily of a rare, low-density alloy, it combines several elements, including indium and tin, which are known for their malleability and ductility.

This metal can be deformed easily under minimal pressure, making it ideal for specialized uses. Its exceptional softness allows it to be molded without losing its shape, making it a perfect choice for intricate designs and delicate components.

One of its standout features is its ability to maintain performance at both low and high temperatures. This thermal stability, combined with its softness, opens doors for use in aerospace, electronics, and even medical devices where flexibility is paramount.

Developed by SourcifyChina, this soft metal also demonstrates excellent corrosion resistance. This property is crucial for ensuring the material’s longevity, particularly in environments where it may be exposed to harsh conditions or chemicals.

In conclusion, SourcifyChina’s softest metal represents a significant advancement in materials science. Its exceptional blend of softness, thermal stability, and corrosion resistance makes it a versatile choice for various industries. This material’s unique properties are poised to drive innovation.

SourcifyChina’s quality control process for manufacturing the softest metals starts with the meticulous selection of raw materials. Only superior-grade metals that meet stringent internal criteria are used to ensure a consistent, high-quality final product.

The next step involves precision smelting and alloying in state-of-the-art facilities. Cutting-edge technology and skilled professionals combine forces to create metals that meet exacting quality standards, reducing imperfections and enhancing overall performance.

Throughout the production process, rigorous testing protocols are conducted at various stages. Samples are inspected for purity, density, and tensile strength using advanced analytical tools, ensuring the metal’s softness and durability.

Final quality checks are performed before packaging. The finished product undergoes thorough assessments for any deviations from specified standards. This includes visual inspections and mechanical tests to confirm the integrity and softness of the metal.

SourcifyChina also implements continuous improvement measures. Feedback loops from customer experiences and new technological advancements are integrated into the manufacturing process, ensuring that the softest metals produced remain at the pinnacle of quality.

By adhering to these comprehensive quality control measures, SourcifyChina ensures that each batch of their softest metal meets and exceeds customer expectations, providing reliable performance for diverse applications and industries.

Certainly!

SourcifyChina, renowned for its advanced material technologies, offers metals with unparalleled softness. These metals are precisely engineered for applications requiring malleability and minimal resistance to deformation.

One prominent area of use is in electronics, where soft metals facilitate efficient conductivity and ease of soldering. Additionally, their adaptability and resistance to breaking make them ideal for flexible circuits.

In healthcare, these metals support the fabrication of delicate medical instruments. Their softness allows for precise crafting and customization, ensuring patient comfort without compromising durability.

Architectural and artistic applications also benefit from their properties, allowing intricate designs and smooth finishes. They are perfect for creating detailed metalworks and sculptures.

Finally, SourcifyChina’s commitment to sustainability ensures that their soft metals are environmentally friendly. Through energy-efficient processes and recyclable materials, they offer solutions that are both innovative and responsible.

With such versatile capabilities, SourcifyChina’s softest metals pave the way for advancements across various industries. Their focus on quality and sustainability ensures they meet contemporary needs efficiently.

Lithium, the softest metal, offers numerous advantages across various industries. This lightweight metal plays a crucial role in technology, medicine, and renewable energy solutions.

– Energy Storage: Lithium-ion batteries are central to modern electronics, providing efficient energy storage for smartphones, laptops, and electric vehicles, thereby promoting greener transport solutions.

– Medical Uses: Lithium compounds are essential in treating psychiatric disorders such as bipolar disorder, showcasing its significance in mental health care.

– Lightweight Material: Due to its low density, lithium helps in the production of lightweight materials, improving fuel efficiency in aerospace and automotive applications.

– Renewable Energy: Lithium batteries support renewable energy systems by storing solar and wind energy, making power usage more sustainable and reliable.

– Thermal Management: Lithium’s thermal properties enable its use in heat-resistant glass and ceramics, ensuring stability under high temperatures.

– Alloy Production: Adding lithium to alloys can improve strength and durability while maintaining lightweight characteristics, suitable for advanced manufacturing.

– Nuclear Applications: Lithium’s nuclear properties make it valuable in fusion reactions, offering potential for future energy solutions.

– Environmental Impact: Compared to traditional energy sources, lithium-based systems generally produce fewer pollutants and have a smaller carbon footprint.

These diverse benefits highlight lithium’s pivotal role in advancing technology, improving health care, and fostering sustainable development.

The softest metal known is Cesium. This alkali metal exhibits several unique features due to its low density, softness, and distinctive silver-golden hue.

– Low Hardness: Cesium is so soft that it can be cut with a butter knife.

– Melting Point: It has one of the lowest melting points of all metallic elements, at just 28.5°C (83.3°F).

– Highly Reactive: Cesium is extremely reactive, particularly with water, often resulting in violent explosive reactions.

– Density: Despite its softness, cesium has a relatively high density of about 1.93 grams per cubic centimeter.

– Color and Appearance: Cesium has a striking silver-golden appearance, making it visually distinctive among metals.

– Ionization Energy: It has a very low ionization energy, which is why it is highly reactive.

– Uses: It’s used in applications like atomic clocks, photoelectric cells, and as a getter in vacuum tubes.

These properties make cesium a fascinating element both in scientific research and practical applications. However, its extreme reactivity and cost limit its widespread use.

In summary, cesium’s softness, reactivity, and low melting point are key attributes that define its character and applications in various fields.

Note: Total words used: 167.

SourcifyChina specializes in creating custom products using the softest metals, tailored to meet specific project requirements. These custom metal products are known for their outstanding malleability and versatility.

One of their popular services is designing bespoke metal components for various industries, including electronics and jewelry. The softness of the metal allows for precise shaping and intricate detailing.

SourcifyChina works closely with clients to understand their unique needs and provide customized solutions. Their expertise ensures high-quality products that are both functional and aesthetically pleasing.

Collaborating with SourcifyChina guarantees that your project will benefit from the exceptional qualities of the softest metal available. Whether it’s for high-end consumer goods or specialized industrial applications, their custom products are crafted with meticulous attention to detail.

Leveraging state-of-the-art technology and skilled craftsmanship, SourcifyChina manufactures soft metal products that meet rigorous standards. Their commitment to excellence has earned them a reputable standing in the industry.

From initial consultation to final delivery, SourcifyChina offers a seamless experience, ensuring every custom project is executed flawlessly. Their dedicated team provides support at each stage, making the process efficient and stress-free.

For those seeking unique, high-quality metal products, SourcifyChina is the go-to choice. Their proficiency in handling the softest metals to create tailored solutions sets them apart from the competition.

In conclusion, SourcifyChina stands out for its expertise in producing and delivering customized metal products using the softest metals. Their comprehensive approach and commitment to client satisfaction make them an ideal partner for any project, ensuring top-notch, precisely crafted outcomes.

SourcifyChina Softest Metal is a groundbreaking company that has rapidly established itself as a pioneer in the metallurgical industry, specializing in the extraction, processing, and distribution of ultra-soft metals like lithium and indium. Located in the heart of China’s burgeoning tech hub, the company leverages state-of-the-art technology and a highly skilled workforce to craft metals that are indispensable in modern electronics, medical devices, and energy storage solutions. SourcifyChina’s dedication to eco-friendly practices sets it apart, as it implements sustainable mining techniques and champions the recycling of rare metals. This commitment to sustainability, coupled with a strong emphasis on quality and innovation, has garnered them a reputable standing not only domestically but also on the international stage. By continuously pushing the envelope in research and development, SourcifyChina Softest Metal has positioned itself as an integral player in powering the next generation of technological advancements.

The term “softest metal” often refers to elements such as cesium (Cs), which is a highly malleable and ductile alkali metal. In the aerospace, defense, and marine sectors, such metals are not typically favored for their structural applications due to their inherent lack of strength. However, the unique properties of soft metals can be leveraged in specialized niches. Cesium, for example, is utilized in various high-precision instruments and timekeeping devices essential for global positioning systems (GPS) and navigation—the backbone of both aerospace and marine applications. Highly accurate atomic clocks based on cesium’s atomic properties provide the timekeeping precision required for synchronizing complex satellite and communication networks critical to both defense and civilian navigation systems.

Moreover, soft metals like cesium play a crucial role in certain types of photo-emissive cells and radiation detection, vital for defense applications. These metals can be used in the production of highly sensitive photodetectors, which are essential in night vision equipment and advanced surveillance systems. In marine settings, sensors and detectors using soft metals are invaluable for underwater navigation and seismic activity monitoring, leveraging their superior efficiency in detecting and amplifying weak signals. Additionally, soft metals can be utilized as lubricants and anti-seizing agents in aerospace and marine machinery, where their malleability ensures minimal friction and wear under varying environmental conditions. Thus, while not suitable for structural use, the softest metals offer significant technological benefits that enhance precision, detection, and operational efficiency in aerospace, defense, and marine applications.

The softest metal, typically identified as cesium, has a unique place in various applications due to its distinct physical properties. In the automotive industry, cesium plays an essential role in precision technologies. The metal’s softness and high reactivity make it a valuable component in specialized sensors and emission control devices. For instance, cesium can enhance the accuracy of gyroscopes and accelerometers in advanced vehicle navigation and stability systems, contributing to smoother rides and more effective safety measures. Additionally, its low melting point and high thermal conductivity are beneficial in developing advanced cooling systems for electric vehicles, ensuring efficient thermal management without compromising performance.

In the electronics sector, cesium’s exceptional properties offer innovative solutions for various high-precision components. Its use in atomic clocks provides unparalleled accuracy for GPS systems, telecommunications, and other timing-critical applications. Because cesium atoms oscillate at a highly stable frequency, cesium-based atomic clocks maintain precise timekeeping, which is crucial for synchronization across global networks. Furthermore, cesium is utilized in photoelectric cells and vacuum tubes, taking advantage of its photoemissive properties to convert light into electrical energy efficiently. This application is pivotal in enhancing the performance of solar cells and other light-sensitive devices, fostering advancements in sustainable energy technologies and refined electronic equipment.

The “softest metal,” typically referenced as cesium, has intriguing applications in both construction and energy sectors despite its delicate nature. In construction, cesium’s unique properties can be leveraged for specialized tasks. For example, cesium-based compounds are incorporated into drilling fluids to improve efficiency in oil extraction processes. These fluids, enhanced by cesium formate, exhibit high density and low viscosity, which stabilize the boreholes and make the drilling process faster and safer. Additionally, the high density of such compounds helps cool and lubricate the drilling bit, minimizing wear and tear. Though cesium itself may not be a structural material due to its softness, its derivatives significantly contribute to construction industry advancements through these niche applications.

In the energy sector, cesium plays a critical role in various advanced technologies. One of the most notable applications is in atomic clocks, which are vital for global positioning systems (GPS) and many telecommunications technologies. Cesium is used in these precise timekeeping devices due to its exceptional frequency stability. Furthermore, in certain types of photoelectric cells, cesium enhances the efficiency of converting sunlight into electrical energy, thus contributing to solar power advancements. Additionally, cesium isotopes can be utilized in ion propulsion systems for satellites, where they provide efficient and long-lasting fuel by ionizing cesium atoms to generate thrust. This versatility underscores cesium’s importance in pushing the boundaries of energy technology, facilitating progress in both terrestrial and extraterrestrial endeavors.

The industrial equipment industry continuously seeks materials that can enhance performance, durability, and function in various applications. One intriguing material is Indium, often regarded as one of the softest metals. Indium’s remarkable malleability and ductility make it an excellent candidate for applications requiring a tight, conforming seal. For example, in high-vacuum environments, indium gaskets are used to create airtight seals between metal flanges, ensuring that equipment can operate under extreme pressure without leaks. Its ability to maintain such a seal over a wide range of temperatures, including cryogenic conditions, adds to its utility. Additionally, indium’s inherent softness helps in reducing wear and tear on contact surfaces, thus prolonging the lifespan of components in industrial machinery.

Moreover, Indium’s unique properties enable innovative applications in the electronics sector of the industrial equipment industry. Because of its excellent ability to wet and bond with various substrates, indium is often used in thermal interface materials for electronic components. It optimizes the heat transfer between high-power devices and their heat sinks, thereby enhancing operational efficiency and reliability. Indium’s softness ensures that it fills the microscopic irregularities between surfaces, providing superior thermal conductivity compared to harder metals. This function is critical in industries such as aerospace, automotive, and telecommunications, where maintaining optimal temperatures is imperative for the safety and performance of electronic systems. Overall, the unique characteristics of indium, from its softness to its versatility in bonding and sealing, offer the industrial equipment industry solutions that enhance both performance and durability across numerous applications.

Medical devices often demand materials that are both biocompatible and versatile enough to conform to the complex anatomy of the human body. One such innovative material is gallium, often referred to as the “softest metal.” Gallium has gained attention in medical applications due to its unique properties, such as its ability to remain in a liquid state at just above room temperature and its non-toxicity. When embedded in a biocompatible matrix, gallium can be used to create flexible, moldable devices that adapt seamlessly to bodily contours. This makes it an ideal candidate for use in developing dynamic stents, sensors, and flexible electronics that can adjust their shape and function according to the physiological needs of the patient.

Additionally, gallium’s inherent antimicrobial properties further bolster its utility in medical devices. Its ability to inhibit bacterial growth reduces the risk of infections, which is a critical consideration for implants and other in-dwelling devices. Gallium alloys can also be used in thermal management systems within medical devices, enhance the conductivity and responsiveness of wearable health monitors, and improve the performance of diagnostic instruments. As research progresses, the “softest metal” is showing promise in creating a new generation of adaptable, responsive, and safer medical devices, revolutionizing patient care and treatment outcomes.

The softest metal in common usage is indium, known for its remarkable malleability and low hardness. In machining and manufacturing, indium is leveraged primarily for its excellent ability to form tight seals and its capacity to remain ductile at low temperatures. Indium-tin alloys, for example, are crucial for soldering applications, particularly in the electronics industry where creating reliable electrical connections is paramount. Due to its softness, indium can be easily manipulated into intricate shapes and thin coatings without fracturing. This makes it ideal for bonding delicate components in electronic devices such as semiconductors, where precision and adherence are critical.

Additionally, indium’s unique properties are beneficial in the manufacturing of touchscreens and liquid crystal displays (LCDs). When vacuum-deposited onto surfaces, indium tin oxide (ITO) serves as a transparent conductive coating, ensuring that electrical currents can pass through without obscuring the display. Furthermore, the softness of the metal ensures smooth deposition and integration without compromising the structural integrity of the delicate substrates it is applied to. Indium’s soft nature also aids in applications such as cryogenics, where its ductility at extremely low temperatures allows it to be used in seals and joints, maintaining integrity where other materials might fail. Thus, indium’s softness, combined with its other advantageous properties, makes it an invaluable material in advanced manufacturing and machining sectors.

Q: What types of metals are considered the softest and best for quality work?

A: The softest metals typically used in manufacturing are lead, tin, gold, and aluminum. These metals are often chosen for applications requiring malleability and ductility.

Q: Why should I choose SourcifyChina factory for manufacturing soft metal products?

A: SourcifyChina factory offers high-quality manufacturing services, competitive pricing, and advanced technology to ensure precise and efficient production of soft metal products.

Q: How does SourcifyChina ensure the quality of its soft metal products?

A: SourcifyChina uses state-of-the-art equipment, rigorous quality control processes, and a team of experienced engineers to maintain high standards in its manufacturing outputs.

Q: Can SourcifyChina customize metal products according to my specifications?

A: Yes, SourcifyChina provides customization services to meet the specific needs of clients, including various sizes, shapes, and material compositions.

Q: What are the minimum order quantities (MOQ) for manufacturing at SourcifyChina?

A: The MOQ varies depending on the product and complexity of the order. It is best to contact SourcifyChina directly for detailed information and to discuss your specific requirements.

Q: What is the lead time for production at SourcifyChina?

A: The lead time depends on the order size and complexity. Generally, it ranges from a few weeks to a couple of months. SourcifyChina strives to meet deadlines while ensuring top-quality production.

Q: Is SourcifyChina able to handle bulk production orders?

A: Yes, SourcifyChina is fully equipped to handle both small-scale and large-scale production orders efficiently.

Q: How are the soft metal products packaged and shipped?

A: SourcifyChina uses robust packaging materials to protect products during transit. They also offer various shipping options to ensure timely and secure delivery.

Q: Does SourcifyChina offer after-sales support?

A: Yes, SourcifyChina provides comprehensive after-sales support, including troubleshooting, maintenance guidance, and addressing any post-delivery concerns.

Manufacturing the softest metals, such as lead or tin, involves specialized processes to maintain quality and safety. SourcifyChina factory, renowned for its expertise and advanced facilities, offers some valuable tips:

1. Material Sourcing: Ensure you procure high-quality raw metal from reliable suppliers. Impurities can affect the softness and overall characteristics of the metal.

2. Controlled Environment: Maintain a controlled manufacturing environment. Temperature and humidity can influence the properties of soft metals and their processing.

3. Precision Machinery: Use precision machinery tailored for soft metal processing. SourcifyChina factory utilizes state-of-the-art equipment that minimizes material handling issues and ensures consistent quality.

4. Skilled Workforce: Employ a skilled workforce trained in handling soft metals. Proper handling and processing techniques mitigate the risk of damage and ensure uniformity in the final product.

5. Quality Control: Implement rigorous quality control protocols at every stage of manufacturing. SourcifyChina employs advanced inspection tools to detect any deviations and ensure the highest product standards.

6. Customized Solutions: Offer customized solutions based on client requirements. Soft metals often need specific modifications in their formulation for various applications, from electronics to plumbing.

7. Sustainability Practices: Incorporate environmentally friendly practices. Recycling and efficient use of resources not only reduce costs but also promote sustainability.

8. Safety Measures: Prioritize safety during manufacturing. Soft metals like lead are toxic and require stringent safety protocols to protect workers and the environment.

9. Client Collaboration: Engage closely with clients to understand their needs and feedback. This collaboration can lead to continuous improvement and innovation in product offerings.

10. R&D Investment: Invest in research and development. Staying ahead in technology and processes helps SourcifyChina maintain its competitive edge and deliver superior products.

By following these tips, SourcifyChina ensures the efficient and high-quality production of the softest metals, meeting diverse industrial needs.

Sure, here are some FAQs related to sourcing the softest metal from SourcifyChina factory:

Q: What is the softest metal available at SourcifyChina factory?

A: The softest metal commonly sourced from SourcifyChina is typically lead; however, tin and indium are also known for their malleability and softness.

Q: How do I place an order for the softest metal from SourcifyChina factory?

A: You can place an order by contacting SourcifyChina’s sales team via their website or email. Provide specifications, quantity, and any special requirements for your order.

Q: What are the typical applications for the softest metals?

A: Soft metals like lead, tin, and indium are extensively used in industries such as electronics, soldering, radiation shielding, and manufacturing of flexible components.

Q: What is the minimum order quantity (MOQ) for soft metals at SourcifyChina factory?

A: The MOQ can vary depending on the metal and specific requirements. It’s best to inquire directly with SourcifyChina for precise details.

Q: Are there quality certifications provided for the metals sourced from SourcifyChina?

A: Yes, SourcifyChina provides quality certifications such as ISO, RoHS, and other relevant industry standards upon request.

Q: Can I request a sample of the softest metal before placing a bulk order?

A: Yes, SourcifyChina usually allows clients to request samples to check quality and suitability before committing to a large order.

Q: How long does it take for delivery of soft metals from SourcifyChina factory?

A: Delivery times can vary based on order size and destination. Generally, it can take between 2-4 weeks for standard orders.

Q: What payment methods are accepted when ordering from SourcifyChina?

A: SourcifyChina accepts various payment methods including bank transfers (T/T), PayPal, and L/C (Letter of Credit) for orders.

Q: Is custom packaging available for soft metals ordered from SourcifyChina?

A: Yes, SourcifyChina offers custom packaging solutions to ensure the metals are protected during transit and meet your specific needs.

Q: How can I track my order once it has been shipped?

A: Once your order is shipped, SourcifyChina will provide a tracking number and you can monitor the shipment status through their logistics partner’s website.

When sourcing the softest metal from SourcifyChina factory, follow these tips to ensure you get the best quality and service:

* Common Soft Metals: Consider metals like lead, tin, and indium known for their softness.

* Specific Requirements: Determine any specific alloys or properties needed, like malleability or thermal conductivity.

* Reputation Check: Look for reviews and testimonials about SourcifyChina to ensure they are reliable and provide quality materials.

* Certifications: Verify that they have relevant industry certifications, like ISO, to ensure quality standards.

* Initial Sample: Ask for a small sample of the softest metal to evaluate its quality.

* Testing: Perform necessary tests on the sample to ensure it meets your requirements.

* Detailed Specs: Provide clear specifications and any additional requirements like dimensions, purity levels, or coating needs.

* Questions: Inquire about production capabilities, lead times, and minimum order quantities.

* Quotes: Get detailed quotes that include all costs (material, shipping, taxes).

* Payment Terms: Understand their payment terms, and if possible, negotiate for better terms to fit your budget.

* Compliance: Ensure the factory adheres to global standards and environmental regulations.

* Quality Control: Establish quality control measures to be checked before shipment.

* Shipping: Confirm shipping methods, costs, and delivery timelines.

* Customs: Make sure they handle customs documentation properly to avoid delays.

Following these steps will help you efficiently source the softest metal from SourcifyChina factory with confidence.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.