“Reliable SourcifyChina Factory for High-Quality SS Sheet Metal Fabrication – Precision, Durability, and Custom Solutions”

Explore top-tier stainless steel (SS) sheet metal fabrication services with unmatched reliability. SourcifyChina Factory delivers precision-crafted, durable products tailored to meet your specific needs.

Choosing “SourcifyChina” Factory for sourcing SS sheet metal fabrication offers unmatched expertise and quality. With years of experience, we assure high-precision fabrications to meet diverse industrial needs exceeding client expectations.

Our factory utilizes advanced technologies and stringent quality controls to produce superior stainless steel fabrications. A dedicated team ensures that each piece meets international standards, guaranteeing dependability.

Competitive pricing combined with uncompromised quality makes “SourcifyChina” a cost-efficient choice for buyers. We leverage innovative manufacturing processes to reduce waste and optimize resource use for economical production.

Timely delivery is crucial, and “SourcifyChina” excels in adhering to tight schedules. We use a streamlined logistics network to ensure prompt shipment, reducing downtime and maintaining project momentum.

Customer satisfaction is our priority. Our comprehensive support system offers personalized services, from initial consultation to after-sales service, ensuring smoother transactions and higher satisfaction levels.

In summary, “SourcifyChina” Factory is the ideal partner for stainless steel sheet metal fabrication. We offer unparalleled quality, competitive pricing, and exceptional customer service, ensuring that your procurement needs are seamlessly met.

Stainless steel (SS) sheet metal fabrication involves transforming flat sheets of stainless steel into various shapes and sizes for multiple applications. It includes various processes such as cutting, bending, and welding.

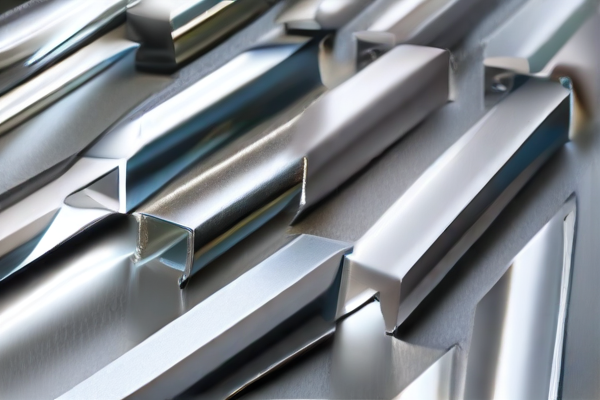

Key Types and Options:

– Cutting

– Laser Cutting: Precision cutting using laser beams.

– Waterjet Cutting: High-pressure water for clean cuts.

– Plasma Cutting: Uses plasma torch for thicker materials.

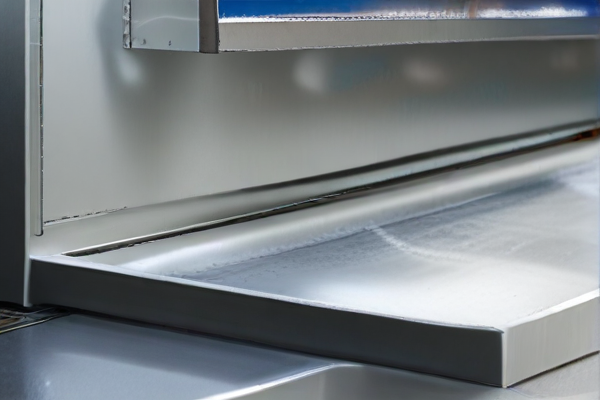

– Bending

– Press Brake Bending: Utilizes a press brake to form shapes.

– Roll Bending: Creates cylindrical shapes and curves.

– Welding

– TIG Welding: Produces high-quality, precise welds.

– MIG Welding: Faster and suitable for thicker materials.

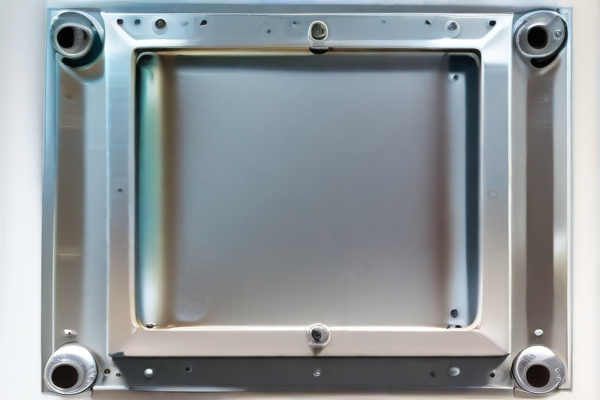

– Forming

– Deep Drawing: Produces complex, deep shapes.

– Stamping: High-speed process for mass production.

– Finishing

– Grinding: Smooths out rough edges.

– Polishing: Achieves a shiny, reflective surface.

– Brushing: Creates a uniform grain finish.

– Joining

– Riveting: Mechanical fastening method.

– Fastening: Using bolts and screws.

Each of these options provides varying levels of precision, strength, and finish, tailored to specific project requirements.

Stainless steel (SS) sheet metal fabrication is a versatile process used in multiple industries due to its durability, corrosion resistance, and aesthetic appeal. It’s crucial in manufacturing custom components and structures.

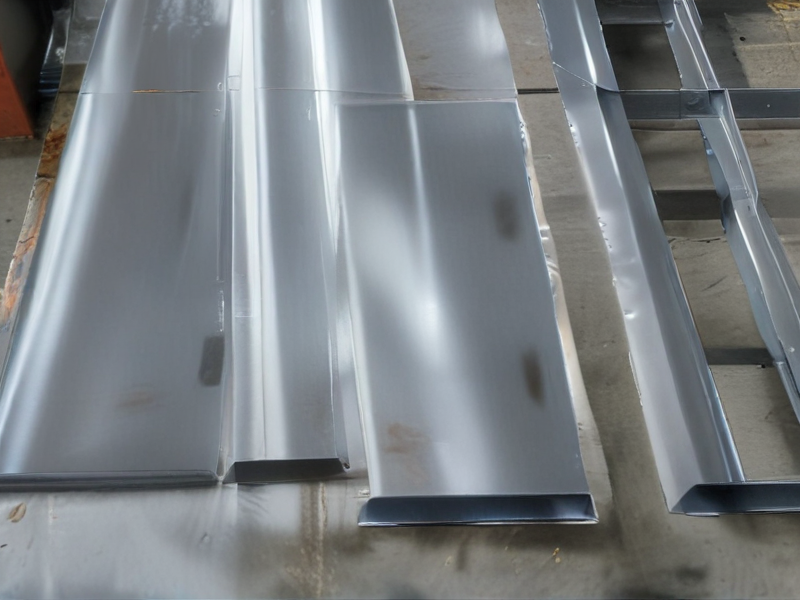

– Automotive Industry:

– Exhaust systems

– Body panels

– Fuel tanks

– Architectural Elements:

– Handrails and railings

– Cladding and facades

– Drainage systems

– Food and Beverage:

– Processing equipment

– Storage and transport containers

– Kitchen appliances

– Medical Field:

– Surgical instruments

– Hospital equipment

– Laboratory furniture

– Aerospace:

– Aircraft components

– Structural elements

– Engine parts

– Energy Sector:

– Heat exchangers

– Boilers and pressure vessels

– Renewable energy components

– Consumer Goods:

– Electronic casings

– Home appliances

– Sporting equipment

– Marine Industry:

– Boat fittings

– Marine hardware

– Offshore platforms

SS sheet metal fabrication enables the creation of both functional and decorative elements, supporting diverse applications from high-tech industries to everyday consumer products.

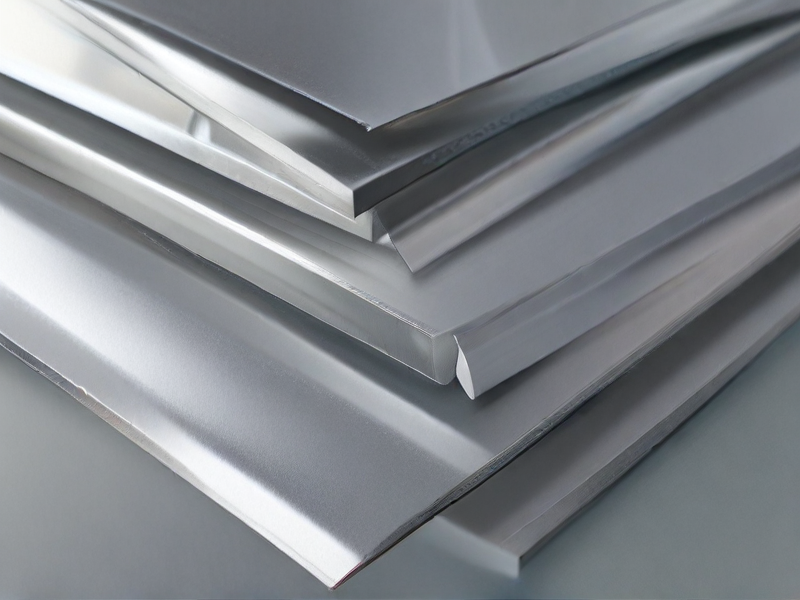

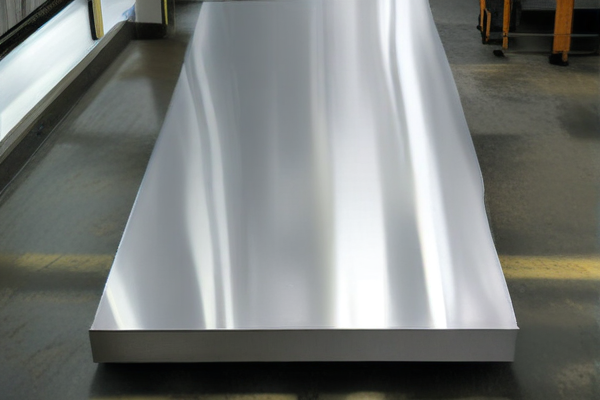

SourcifyChina is renowned for its exceptional SS sheet metal fabrication services. The material used in these applications primarily includes high-grade stainless steel, which is known for its durability, corrosion resistance, and aesthetic appeal.

Stainless steel is highly versatile, making it ideal for a wide range of industries, from automotive to construction. SS sheet metal fabrication involves cutting, bending, and assembling processes that ensure precise and customized outputs tailored to specific needs.

Advanced technology and skilled craftsmanship are integral to achieving the high-quality results that SourcifyChina is known for. Laser cutting, CNC bending, and welding are some of the techniques employed to ensure superior accuracy and finish.

Environmental sustainability is also a key focus. Stainless steel is 100% recyclable, thereby reducing waste and promoting eco-friendly practices in manufacturing. This aligns with the growing emphasis on sustainability in contemporary industry practices.

Customer satisfaction is paramount at SourcifyChina. The emphasis on quality control and timely delivery ensures that clients receive products that meet or exceed their expectations. By combining robust material with state-of-the-art fabrication techniques, SourcifyChina is a leader in the SS sheet metal fabrication industry.

SourcifyChina’s SS sheet metal fabrication emphasizes strict quality control from start to finish. This begins with carefully selecting high-quality raw materials obtained from reliable suppliers to ensure durability and performance.

Advanced technologies are employed in cutting and shaping processes, including laser cutting and CNC machining. Regular machine calibration and maintenance ensure precision and minimize deviations in the final products.

Inspection steps are integrated at various stages of fabrication. Skilled technicians perform visual inspections, dimensional accuracy checks, and mechanical testing to verify that components meet specific standards and tolerances.

Quality control extends to surface treatments like polishing or coating. These treatments are applied under controlled conditions to enhance corrosion resistance and aesthetic appeal, adhering to the specified quality requirements.

Final assembly and packaging also undergo scrutiny. Each component is carefully assembled, and the final product is inspected for defects or inconsistencies before packaging. Proper labeling and documentation accompany each order to guarantee traceability and compliance.

Feedback from clients and periodic audits further refine the quality control protocols at SourcifyChina. Their commitment to continuous improvement helps them maintain high standards and meet the evolving needs of their customers, ensuring satisfaction and reliability in every project.

SourcifyChina offers state-of-the-art SS (stainless steel) sheet metal fabrication services, renowned for their precision and innovation. Specializing in various grades of stainless steel, the company employs advanced machinery to ensure high-quality outputs tailored to meet diverse industrial requirements.

The fabrication capabilities include cutting, bending, welding, and finishing, ensuring a comprehensive approach to all projects. Their cutting-edge techniques are designed for high accuracy and repeatability, making them ideal for both large-scale productions and custom orders.

Utilizing CNC machines and laser cutting technologies, SourcifyChina can handle complex designs and intricate patterns with utmost precision. These technologies not only enhance efficiency but also reduce material waste, ensuring cost-effectiveness.

In addition to standard fabrications, SourcifyChina provides bespoke solutions, collaborating closely with clients for prototypes and specialized orders. This flexibility ensures that specific design requirements and functional needs are met effortlessly.

Furthermore, SourcifyChina’s commitment to quality is evidenced by rigorous inspection protocols. Each product undergoes thorough checks for dimensional accuracy, surface finish, and structural integrity, ensuring that clients receive only the best.

Their team of skilled engineers and technicians bring years of expertise to the table, continually pushing the boundaries of what is possible in SS sheet metal fabrication. Continuous training ensures they remain at the forefront of industry advancements.

SourcifyChina also places a strong emphasis on sustainability. By incorporating environmentally-friendly practices into their operations, they minimize waste and reduce their carbon footprint, aligning with global sustainability goals.

Overall, SourcifyChina stands as a reliable partner in SS sheet metal fabrication, merging top-tier technology, skilled craftsmanship, and a client-centric approach. Their capabilities ensure that each project, whether big or small, is executed with unparalleled precision and quality.

Benefits of SS Sheet Metal Fabrication

Stainless steel (SS) sheet metal fabrication offers numerous advantages, enhancing durability, efficiency, and aesthetics across various applications.

– Durability: Stainless steel offers exceptional resistance to corrosion, rust, and wear, ensuring long-lasting performance.

– Strength: Despite its lightweight nature, SS is incredibly strong, making it suitable for high-stress applications.

– Hygienic: Its non-porous surface resists bacterial growth, ideal for medical and food processing environments.

– Aesthetic Appeal: Provides a sleek, modern look, widely used in architecture and consumer products.

– Versatility: Can be easily shaped, cut, and welded, making it adaptable for diverse project requirements.

– Environmentally Friendly: 100% recyclable, reducing carbon footprint.

Stainless steel (SS) sheet metal fabrication is renowned for its durability and versatility, making it a preferred choice across various industries.

– Corrosion Resistance: SS sheet metal resists rust and corrosion, ideal for environments exposed to moisture and chemicals.

– Strength and Durability: Offers high strength-to-weight ratio, ensuring robustness for both structural and aesthetic applications.

– Heat Resistance: Maintains strength and structural integrity even at high temperatures.

– Aesthetic Appeal: Provides a sleek, modern look which is highly desirable in consumer goods and architecture.

– Flexibility in Design: Easily fabricated into complex shapes, allowing for innovation in design and engineering.

– Hygienic Properties: Non-porous surface helps in maintaining cleanliness, crucial for medical and food industries.

– Recyclability: SS is 100% recyclable, reducing environmental impact.

– Variety of Finishes: Available in brushed, mirrored, and other finishes to meet specific aesthetic and functional requirements.

– Low Maintenance: Requires minimal maintenance due to its durability and resistance to tarnish.

– Resistance to Impact: Able to withstand physical impacts without significant deformation.

Stainless steel sheet metal fabrication is a vital process, combining advanced technology and skilled craftsmanship to meet high demands and stringent specifications across numerous applications.

SourcifyChina, a well-known name in the industry, excels in SS sheet metal fabrication, delivering high-quality custom products tailored to client specifications. Their expertise covers a broad range of industries.

By utilizing advanced machinery and state-of-the-art technology, SourcifyChina ensures precision in every cut and fold, meeting the stringent requirements of their customers. This guarantees reliable and durable end products.

Their skilled team of engineers and technicians are adept at transforming raw metal into intricate, bespoke designs. Whether it’s for industrial applications or decorative elements, their craftsmanship is unparalleled.

SourcifyChina offers end-to-end solutions from concept to completion, guiding clients through each phase of development. This ensures seamless communication and a smooth execution process.

Moreover, their commitment to quality and customer satisfaction is evident in their rigorous testing and quality control measures, ensuring that every product exceeds industry standards before delivery.

Focused on innovation and efficiency, SourcifyChina continually invests in research and development to stay ahead of market trends. This enables them to offer cutting-edge solutions in SS sheet metal fabrication.

For custom products and projects, clients can trust SourcifyChina to deliver impeccable results on time and within budget. Their dedication to excellence makes them a preferred choice for high-quality, custom metal solutions.

SourcifyChina is a prominent player in the realm of SS (stainless steel) sheet metal fabrication, combining cutting-edge technology with traditional craftsmanship to deliver high-quality, precision-engineered metal components. The company is renowned for its comprehensive suite of services, including laser cutting, bending, welding, and finishing, all tailored to meet the specific needs of diverse industries such as automotive, aerospace, electronics, and construction. SourcifyChina leverages state-of-the-art equipment and adheres to stringent quality control measures to ensure each project meets the highest standards of excellence. With a focus on innovation and customer satisfaction, the company collaborates closely with clients to provide customized solutions that enhance efficiency and reduce costs. Its seasoned team of engineers and fabricators bring a wealth of expertise to the table, ensuring that each project is executed with precision, punctuality, and professionalism. In a rapidly evolving market, SourcifyChina stands out as a reliable partner, committed to advancing the capabilities of sheet metal fabrication through continuous improvement and technological advancement.

Stainless steel (SS) sheet metal fabrication is crucial in the aerospace, defense, and marine industries due to its exceptional properties such as corrosion resistance, high strength-to-weight ratio, and excellent durability. In aerospace applications, SS sheet metal is utilized extensively in the construction of aircraft components, including fuselage skins, wing structures, and engine parts, because of its ability to withstand extreme temperatures and environmental conditions. The precision and reliability of fabricated SS parts ensure the safety and performance of aircraft, meeting stringent industry standards and regulatory requirements. Advanced fabrication techniques, such as laser cutting, welding, and CNC machining, are employed to create complex and lightweight designs that enhance the overall efficiency and fuel economy of aerospace vehicles.

In defense applications, SS sheet metal fabrication is pivotal for producing a wide range of essential components, from armored vehicle panels to weapon system housings and military-grade enclosures. The inherent toughness and impact resistance of stainless steel make it ideal for protective applications, providing reliable defense against ballistic threats and harsh operational environments. Similarly, in the marine industry, SS sheet metal is indispensable for constructing ship hulls, structural components, and various marine hardware, owing to its superior resistance to seawater corrosion and biofouling. Fabricated SS parts offer longevity and reduced maintenance costs, critical for naval vessels and commercial ships that operate in challenging maritime conditions. Overall, SS sheet metal fabrication enhances the performance, safety, and longevity of aerospace, defense, and marine assets, making it a vital manufacturing process across these sectors.

SS (stainless steel) sheet metal fabrication plays a pivotal role in the automotive industry, ensuring durability, strength, and resistance to corrosion. The fabrication process typically involves cutting, bending, and assembling stainless steel sheets to create various automotive components, such as exhaust systems, body panels, and structural supports. Stainless steel’s ability to withstand extreme temperatures and harsh environmental conditions makes it ideal for exhaust systems which are exposed to high heat and corrosive gases. Additionally, the lightweight nature of some stainless steel grades contributes to reducing the overall weight of vehicles, thereby enhancing fuel efficiency and performance. The precise and customizable nature of SS sheet metal fabrication also allows for intricate designs and complex components, catering to the sophisticated demands of modern automotive engineering.

In the electronics sector, SS sheet metal fabrication is essential for creating enclosures, brackets, and chassis that house and protect sensitive electronic components. The fabrication process ensures that these components remain secure, cool, and shielded from electromagnetic interference (EMI). Stainless steel’s non-magnetic properties and excellent conductivity are particularly beneficial in creating grounding and shielding parts that mitigate EMI, ensuring the proper functioning of electronic devices. Moreover, the aesthetic appeal of stainless steel, combined with its resistance to oxidation and staining, makes it a popular choice for consumer electronics like smartphones, laptops, and home appliances. The precise fabrication techniques allow for the creation of sleek, minimalist designs that are not only functional but also visually appealing, meeting the demands of tech-savvy consumers who prioritize both performance and style.

Stainless steel (SS) sheet metal fabrication plays a pivotal role in the construction industry, where the demand for durable, versatile, and aesthetically pleasing materials is paramount. SS sheet metal is celebrated for its strength and resistance to corrosion, making it an ideal choice for constructing building facades, roofing systems, and structural components that must endure harsh environmental conditions. Furthermore, its malleability allows for intricate architectural designs and custom-built structures, enhancing both functionality and visual appeal. The metal’s reflective surface can also reduce heat absorption, contributing to energy efficiency in buildings. Additionally, the ease of maintenance and longevity of stainless steel ensure cost-effectiveness over the building’s lifecycle, making it a sustainable option that aligns with modern construction standards.

In the realm of energy applications, SS sheet metal fabrication is indispensable, especially in the burgeoning fields of renewable energy and power generation. Stainless steel’s high thermal and chemical resistance makes it an ideal material for fabricating components of solar panels, wind turbines, and other renewable energy systems. In solar energy systems, for example, the reflective properties and robustness of fabricated SS components significantly enhance the efficiency and longevity of photovoltaic cells and solar thermal collectors. In the oil and gas industry, stainless steel’s ability to withstand high-pressure and corrosive environments ensures the safe and efficient operation of refineries and pipelines. Moreover, its recyclability supports the industry’s shift towards more sustainable practices, underscoring stainless steel’s role in promoting both technological advancement and environmental stewardship.

Stainless steel (SS) sheet metal fabrication plays a critical role in the industrial equipment industry, providing versatile and durable solutions for various applications. Its inherent properties, such as resistance to corrosion, heat, and environmental stress, make it an ideal choice for manufacturing robust components and machinery. From the construction of sanitary equipment and food processing machinery to chemical storage tanks and industrial workbenches, SS sheet metal fabrication meets stringent hygiene and safety standards. Moreover, stainless steel’s aesthetic appeal and ease of maintenance enhance its suitability for equipment exposed to harsh industrial environments, ensuring longevity and reliability.

In addition to durability, SS sheet metal fabrication offers significant advantages in terms of precision and customization. Advanced fabrication techniques like CNC machining, laser cutting, and TIG welding allow for the production of intricate and highly specific parts with unparalleled accuracy. This precision is crucial for industries that rely on tight tolerances and complex assemblies, such as aerospace, automotive, and electronics manufacturing. The ability to fabricate custom-made components tailored to specific industrial applications not only optimizes performance but also streamlines production processes, reducing lead times and costs. Thus, the integration of stainless steel sheet metal fabrication in industrial equipment underscores its indispensability in advancing manufacturing efficiency and technological innovation.

Stainless steel (SS) sheet metal fabrication plays a crucial role in the medical devices industry, primarily due to its exceptional properties of corrosion resistance, durability, and biocompatibility. Medical devices such as surgical instruments, diagnostic equipment, and hospital furniture depend heavily on the precision and reliability of SS sheet metal components. The fabrication process involves cutting, bending, and assembling the stainless steel to meet the stringent standards required in medical settings. Techniques such as laser cutting, CNC machining, and TIG welding ensure that the components have high precision and smooth finishes, essential for aseptic environments to minimize the risk of infection and ensure patient safety.

Moreover, the adaptability of SS sheet metal allows for the creation of custom designs tailored to meet specific medical requirements. This capability is particularly important for developing prosthetics, implants, and customized surgical tools that need to match patient-specific anatomical features. Advanced fabrication methods enable the production of highly intricate and complex shapes without compromising the mechanical strength or integrity of the material. Additionally, stainless steel’s ease of sterilization and maintenance ensures longevity and reusability, making it a cost-effective choice for both disposable and reusable medical devices. Overall, SS sheet metal fabrication is indispensable in advancing medical technology and improving patient outcomes through the creation of high-quality, reliable medical devices.

SS sheet metal fabrication, encompassing the machining and manufacturing of stainless steel, is paramount in various industrial applications due to its robustness and resistance to corrosion. Machining of stainless steel (SS) sheet metal involves precise cutting, bending, welding, and assembling, which ensures that the metal retains its inherent properties while conforming to exact design specifications. Techniques such as laser cutting and CNC (Computer Numerical Control) machining have revolutionized the field, providing exceptional accuracy and efficiency. The ability to consistently produce intricate and precise components has made SS sheet metal fabrication indispensable in aerospace, automotive, and medical device manufacturing, where stringent tolerances and high-quality standards are mandatory.

Manufacturing applications of SS sheet metal fabrication span an array of industries, each benefiting from the versatility and durability of stainless steel. In construction, stainless steel is used for exterior cladding, roofing, and structural components, thanks to its strength and aesthetic appeal. In the food processing and pharmaceutical industries, the non-reactive nature of SS makes it ideal for fabricating equipment and storage containers, ensuring hygiene and safety. Additionally, stainless steel’s resistance to oxidation and staining bolsters its use in marine applications, where exposure to harsh environments is common. The adaptability of SS sheet metal to various forms such as perforated, expanded, or corrugated sheets further extends its utility, cementing its role as a fundamental material in modern machining and manufacturing.

Sure, here’s a concise FAQ for manufacturing “SS sheet metal fabrication quality work from SourcifyChina factory”:

1. What is SS sheet metal fabrication?

SS sheet metal fabrication involves shaping and manipulating stainless steel sheets to create various components and structures through processes such as cutting, bending, welding, and assembling.

2. What types of stainless steel do you work with?

SourcifyChina factory primarily works with various grades of stainless steel, including 304, 316, and 430, tailored to meet different industrial and commercial needs.

3. What quality standards do you adhere to?

Our factory adheres to international quality standards such as ISO 9001 for quality management. We also ensure all products meet relevant ASTM and AISI standards.

4. Can you handle custom fabrication requests?

Yes, we specialize in custom SS sheet metal fabrication and can accommodate specific requirements, including bespoke designs and complex specifications.

5. What are the typical applications for your fabricated SS sheet metal products?

Our SS sheet metal products are used in a wide range of industries, including automotive, construction, medical, food processing, and electronics, among others.

6. What is the lead time for a typical order?

Lead times vary depending on the complexity and volume of the order. Generally, standard projects take between 2 to 6 weeks from confirmation to delivery.

7. Do you offer finishing services for SS sheet metal products?

Yes, we offer various finishing services including polishing, brushing, powder coating, and anodizing to enhance the appearance and durability of the final product.

8. How do you ensure the precision and accuracy of your products?

We utilize advanced CNC machines, laser cutting technology, and rigorous quality control processes to ensure high precision and accuracy in our SS sheet metal fabrication.

9. What is the minimum order quantity (MOQ)?

The MOQ depends on the specific project, but we are flexible and willing to discuss low-volume orders to meet customer needs.

10. How can I get a quote for my project?

You can request a quote by contacting us via our website or email. Please provide detailed specifications, including dimensions, material grade, quantity, and any special requirements. Our team will respond promptly with a tailored quote.

This FAQ provides a quick overview of key aspects regarding SS sheet metal fabrication quality work at SourcifyChina factory.

When it comes to specializing in SS (stainless steel) sheet metal fabrication, having access to the right partner, like SourcifyChina Factory, is crucial. Here are some essential tips to ensure a successful collaboration and high-quality outcomes:

1. Experienced Vendor Selection: Ensure the factory has extensive experience in SS sheet metal fabrication. SourcifyChina Factory boasts a proven track record which is vital for avoiding common pitfalls.

2. Material Quality: Verify that the factory uses high-grade stainless steel. This ensures durability and resistance to corrosion, which are critical properties of stainless steel applications.

3. Advanced Machinery: The factory should be equipped with cutting-edge machinery including CNC machines, laser cutters, and press brakes. SourcifyChina Factory stays updated with the latest technology to deliver precise and consistent results.

4. Custom Capabilities: Look for custom fabrication capabilities. This includes unique designs, complex part formations, and specialized finishes. SourcifyChina Factory offers customized solutions to meet specific project requirements.

5. Quality Control: A robust quality control system is essential. Ensure this includes thorough inspections and adherence to international standards. SourcifyChina Factory’s quality assurance processes ensure exceptional product standards.

6. Cost Efficiency: While quality should not be compromised, competitive pricing is also crucial. SourcifyChina Factory balances cost and quality, providing value for money.

7. Lead Times: Confirm the factory can meet your timelines. Efficient project management and realistic lead times are areas where SourcifyChina Factory excels, minimizing delays.

8. Communication: Seamless communication is key to resolving any issues quickly. Establish clear points of contact with the factory’s team.

9. After-Sales Service: Ensure there is comprehensive support post-production. SourcifyChina Factory offers excellent after-sales services, addressing any concerns promptly.

Collaboration with SourcifyChina Factory, known for its expertise in SS sheet metal fabrication, ensures high-quality production, efficiency, and satisfaction.

#### 1. What types of SS sheet metal fabrication do you offer?

SourcifyChina specializes in a wide range of SS (stainless steel) sheet metal fabrication services, including cutting, bending, welding, punching, and finishing. We cater to various industries such as automotive, construction, electronics, and household appliances.

#### 2. What grades of stainless steel do you work with?

We commonly work with grades 304 and 316 stainless steel, but we can accommodate other grades upon request to meet specific project requirements.

#### 3. What is your minimum order quantity (MOQ)?

Our minimum order quantity varies depending on the complexity and scope of the project. Generally, the MOQ starts at 50 units. Please contact us for specific details.

#### 4. Can you provide samples before placing a bulk order?

Yes, we offer samples to ensure the product meets your specifications. Sample costs and shipping will be discussed during the initial consultation.

#### 5. What is the lead time for an average project?

Lead times vary based on the project’s complexity and volume. Typically, it ranges from 2 to 6 weeks once the design and specifications are finalized.

#### 6. How do you ensure the quality of your SS sheet metal fabrication?

SourcifyChina adheres to strict quality control standards, including ISO 9001 certification. We utilize advanced machinery and conduct rigorous inspections at various production stages to ensure top-notch quality.

#### 7. Do you offer design and engineering support?

Yes, we provide comprehensive design and engineering support. Our experienced team can assist with product design, prototyping, and any necessary adjustments to optimize fabrication.

#### 8. What are the payment terms?

We offer flexible payment terms, typically requiring a deposit before production commences and the balance upon completion. Specific terms will be discussed during the negotiation phase.

#### 9. Can you handle custom fabrication projects?

Absolutely. SourcifyChina excels in custom SS sheet metal fabrication tailored to meet your unique specifications. We work closely with clients to ensure all custom requirements are met.

#### 10. How do you handle logistics and shipping?

We provide comprehensive logistics services, including packaging, customs clearance, and shipping. We work with reliable shipping partners to ensure timely and secure delivery.

Sourcing stainless steel (SS) sheet metal fabrication from a reliable manufacturer like SourcifyChina requires a strategic approach to ensure quality, cost-effectiveness, and timeliness. Here are some tips:

1. Define Requirements Clearly: Detail your specifications including material grade, thickness, dimensions, tolerances, and finishing requirements. This clarity helps in getting accurate quotes and avoiding misunderstandings.

2. Research Capabilities: Ensure SourcifyChina has the technical capabilities and equipment for your specific fabrication needs, such as laser cutting, bending, welding, and finishing services.

3. Request Samples: Ask for sample products to evaluate the quality of workmanship and material before placing a larger order.

4. Check Certifications: Verify that SourcifyChina holds relevant industry certifications like ISO 9001, ensuring adherence to quality management standards.

5. Evaluate Communication: Effective communication is essential. Assess the manufacturer’s responsiveness and clarity in addressing your queries and concerns.

6. Understand Lead Times: Confirm production and shipping timelines to ensure they align with your project schedule. It’s crucial to factor in potential delays and plan accordingly.

7. Negotiate Terms: Discuss pricing, minimum order quantities (MOQs), payment terms, and warranty policies upfront to avoid surprises later.

8. Quality Assurance: Implement quality control measures such as pre-shipment inspections or third-party audits to ensure the products meet your standards.

9. Logistics and Shipping: Clarify responsibilities for shipping, customs, and duties. Choose a reliable logistics partner to ensure timely delivery.

10. Build a Relationship: Establish a strong working relationship with SourcifyChina to ensure smooth ongoing transactions and potential bulk discounts in the future.

By following these tips, you can effectively source high-quality SS sheet metal fabrication from SourcifyChina, ensuring your project’s success.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.